Welding Foreman Resume Guide

Welding Foremen are responsible for overseeing the activities of a welding team. They ensure that safety regulations and quality standards are met, supervise welders on the job, provide technical assistance when needed, and inspect finished products to guarantee accuracy.

You have the experience and leadership skills that would make you an ideal welding foreman. But potential employers don’t know who you are yet, so to introduce yourself, it’s important to write a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

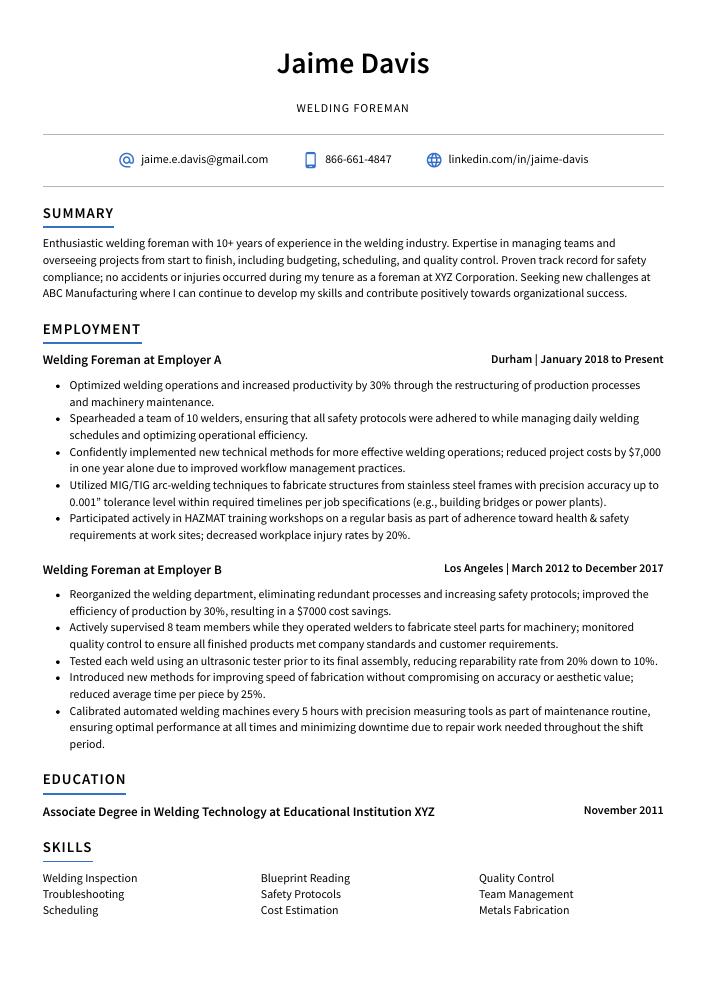

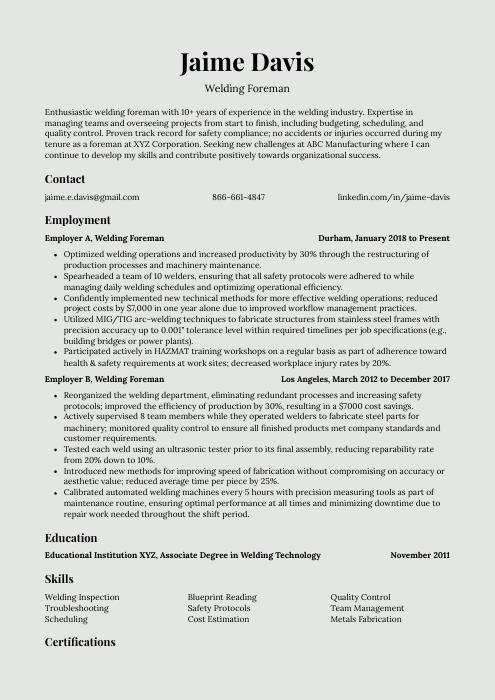

Welding Foreman Resume Sample

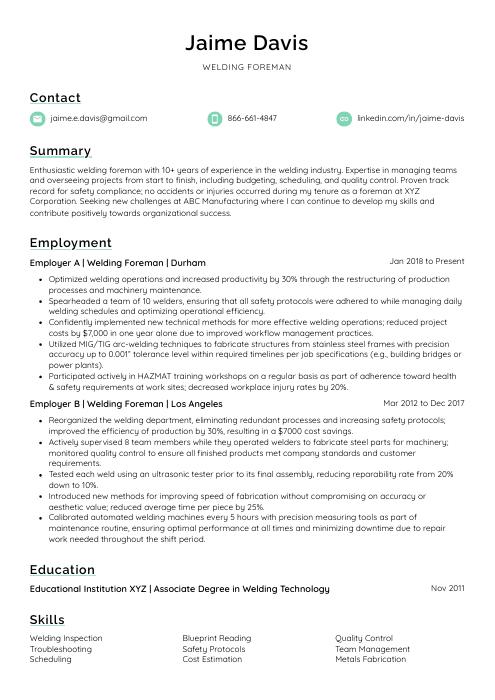

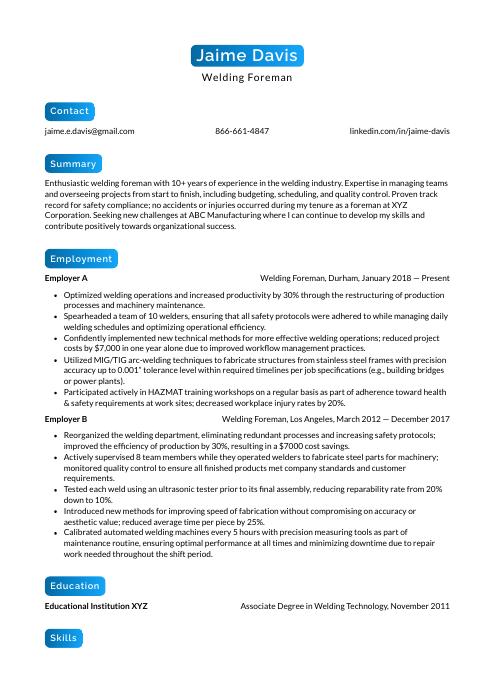

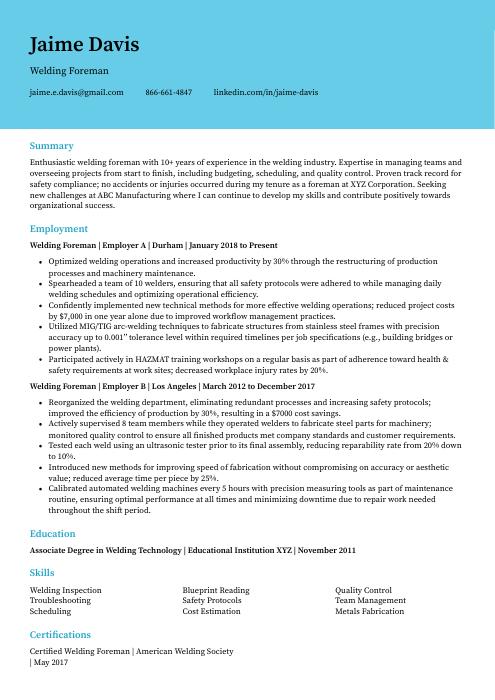

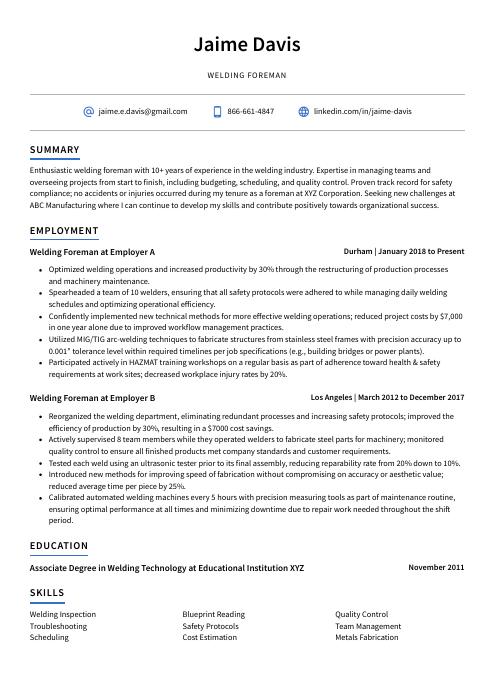

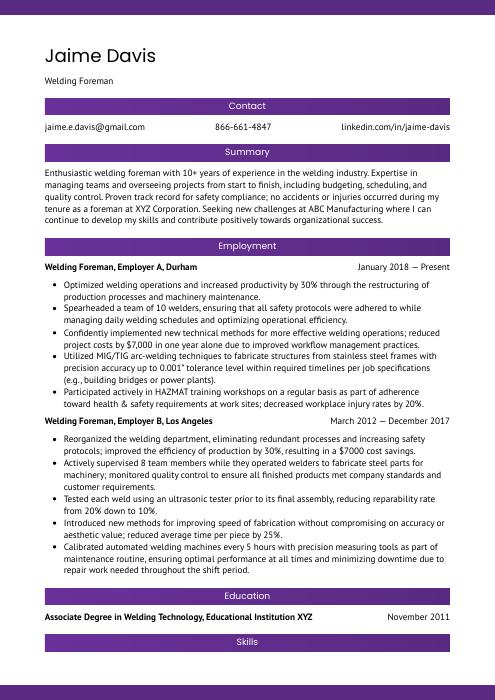

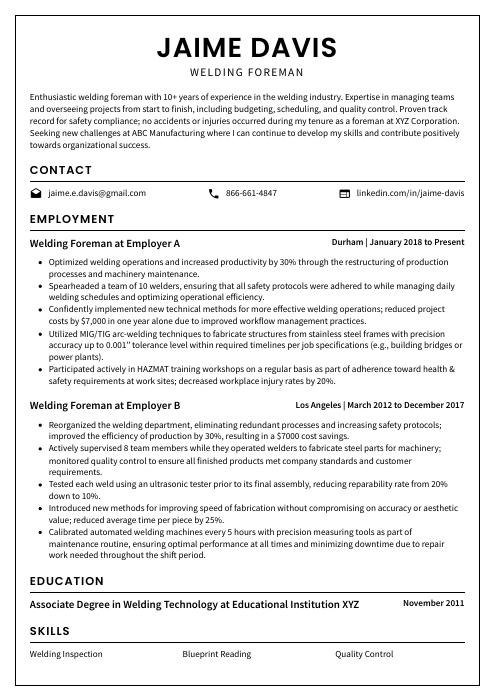

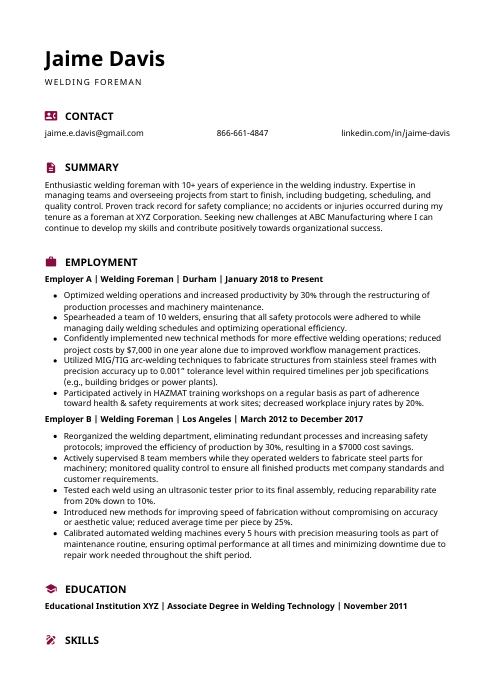

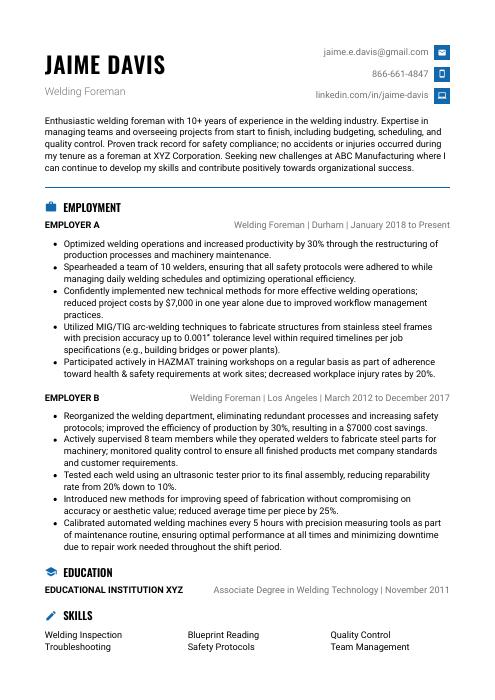

Jaime Davis

Welding Foreman

[email protected]

866-661-4847

linkedin.com/in/jaime-davis

Summary

Enthusiastic welding foreman with 10+ years of experience in the welding industry. Expertise in managing teams and overseeing projects from start to finish, including budgeting, scheduling, and quality control. Proven track record for safety compliance; no accidents or injuries occurred during my tenure as a foreman at XYZ Corporation. Seeking new challenges at ABC Manufacturing where I can continue to develop my skills and contribute positively towards organizational success.

Experience

Welding Foreman, Employer A

Durham, Jan 2018 – Present

- Optimized welding operations and increased productivity by 30% through the restructuring of production processes and machinery maintenance.

- Spearheaded a team of 10 welders, ensuring that all safety protocols were adhered to while managing daily welding schedules and optimizing operational efficiency.

- Confidently implemented new technical methods for more effective welding operations; reduced project costs by $7,000 in one year alone due to improved workflow management practices.

- Utilized MIG/TIG arc-welding techniques to fabricate structures from stainless steel frames with precision accuracy up to 0.001” tolerance level within required timelines per job specifications (e.g., building bridges or power plants).

- Participated actively in HAZMAT training workshops on a regular basis as part of adherence toward health & safety requirements at work sites; decreased workplace injury rates by 20%.

Welding Foreman, Employer B

Los Angeles, Mar 2012 – Dec 2017

- Reorganized the welding department, eliminating redundant processes and increasing safety protocols; improved the efficiency of production by 30%, resulting in a $7000 cost savings.

- Actively supervised 8 team members while they operated welders to fabricate steel parts for machinery; monitored quality control to ensure all finished products met company standards and customer requirements.

- Tested each weld using an ultrasonic tester prior to its final assembly, reducing reparability rate from 20% down to 10%.

- Introduced new methods for improving speed of fabrication without compromising on accuracy or aesthetic value; reduced average time per piece by 25%.

- Calibrated automated welding machines every 5 hours with precision measuring tools as part of maintenance routine, ensuring optimal performance at all times and minimizing downtime due to repair work needed throughout the shift period.

Skills

- Welding Inspection

- Blueprint Reading

- Quality Control

- Troubleshooting

- Safety Protocols

- Team Management

- Scheduling

- Cost Estimation

- Metals Fabrication

Education

Associate Degree in Welding Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Welding Foreman

American Welding Society

May 2017

1. Summary / Objective

A resume summary/objective for a welding foreman should highlight your experience in the field, as well as any certifications or awards you have earned. Include information about how many years of experience you have and what types of projects you are most familiar with. You can also mention your ability to lead teams, manage budgets, and adhere to safety protocols. Finally, include an example of how you successfully completed a project on time and within budget.

Below are some resume summary examples:

Accomplished welding foreman with 12+ years of experience in the construction and fabrication industry. Adept at managing large teams, overseeing projects from start to finish, and ensuring quality control measures are met. At XYZ Company, identified an operational bottleneck that led to a 30% increase in production efficiency. Motivated leader looking for a Welding Foreman role at ABC where I can leverage my skillset to drive success and growth within the organization.

Professional welding foreman with 10+ years of experience in the fabrication industry. Experienced in overseeing welding operations and managing a team of welders, including training new employees on safety protocols. Responsible for quality control measures to ensure customer satisfaction and successful project completion within tight deadlines. Looking to join ABC Company as lead welder to bring my extensive knowledge and expertise into their organization.

Reliable welding foreman with a decade of experience in the metal fabrication industry. Experienced in overseeing all welding operations, from budgeting to scheduling and quality assurance. Proven record of improving overall efficiency by 30% at ABC Steel Company, while also reducing labor costs by 15%. Committed to providing safe working conditions for employees and ensuring completion of projects on time and within budget.

Driven and proactive welding foreman with 10+ years of experience overseeing construction projects and supervising teams of welders. Proven track record in developing cohesive teams, establishing production goals and meeting deadlines within budget constraints. Seeking to join ABC Construction as a Welding Foreman where I can leverage my extensive knowledge to ensure the successful completion of all assigned projects.

Seasoned welding foreman with 8+ years of experience in the field. At XYZ, oversaw a team of 15 welders and managed multiple projects at once. Implemented safety measures that reduced accident rate by 20%. Experienced in developing detailed project plans and ensuring compliance to all applicable codes. Highly organized, efficient leader looking for an opportunity to lead the welding department towards success.

Dependable welding foreman with 10+ years of experience in structural steel fabrication, pipeline construction, and welding processes. Highly skilled at managing a team of welders to complete large-scale projects on time and within budget. At XYZ Inc., successfully managed the installation of over 800 tons of structural steel for an oil refinery expansion project without any safety incidents or delays.

Committed welding foreman with 10+ years of experience in leading teams and coordinating projects. Seeking to join ABC Welding as the next welding foreman, where I can use my expertise in fabrication and production processes to increase efficiency and maximize productivity. At XYZ Company, achieved a 20% reduction in project costs by introducing new process improvements.

Hard-working, experienced welding foreman with a successful track record of building and leading high-performance teams. Skilled at creating efficient processes and developing innovative solutions to complex problems. At XYZ, increased productivity by 20%, reduced costs by 15%, and improved quality control standards, resulting in a 30% reduction in customer complaints.

2. Experience / Employment

The employment (or experience) section is where you detail your work history. It should be written in reverse chronological order, meaning the most recent job is listed first.

Stick to bullet points for this section; doing so makes it easier for the reader to take in what you’re saying quickly and easily. When writing each point, make sure that you include details about what was done and any results achieved.

For example, instead of saying “Supervised welding team,” you could say, “Managed a team of 10 welders on an industrial construction project with a budget of $2 million dollars; completed the project 6 weeks ahead of schedule.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Supervised

- Monitored

- Inspected

- Fabricated

- Welded

- Assembled

- Troubleshot

- Calibrated

- Operated

- Aligned

- Adjusted

- Repaired

- Installed

- Tested

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Monitored welding team of 25 in a large-scale manufacturing facility, ensuring that safety protocols were strictly followed and deadlines met.

- Meticulously trained all welding personnel on the proper use of tools and techniques, increasing productivity by 15% over 3 months.

- Expedited production schedule to deliver quality welds within tight timelines; oversaw completion of 250+ complex projects with zero defects or delays reported from clients.

- Assembled specialized equipment for non-standard tasks such as pressure vessel fabrication; reduced tool assembly time per job by 30 minutes on average without compromising accuracy or precision standards.

- Improved inventory management system for stocking supplies like electrodes, shielding gas cylinders & fluxes, leading to an annual cost savings of $6,000+.

- Operated welding equipment to oversee welding operations and ensure welds met industry standards in accordance with American Welding Society (AWS) regulations; improved production speed by 10% while maintaining a high-quality standard.

- Revised existing plans, drafted new plans and developed work instructions for 20+ welding projects per month; reduced overall project costs by 15%.

- Prepared daily reports detailing the progress of assigned tasks, materials used and any issues encountered during each shift; minimized downtime due to unexpected delays or problems on the job site.

- Formulated training programs for junior welder apprentices designed to promote safety awareness and increase proficiency in metal fabrication skills such as TIG/MIG welding, plasma cutting & oxyacetylene gas cutting within 6 months period per apprentice.

- Successfully implemented quality control measures that ensured all products were inspected according to agreed specifications before shipment; decreased customer return rate from 3% to 0%.

- Presented detailed blueprints and instructions to a team of 8 welders, ensuring the accurate alignment of parts in accordance with safety codes; substantially reduced welding errors by 45%.

- Aligned production schedules with customer deadlines while managing an inventory of over 500 tons of raw materials and supplies; completed projects on time without exceeding budget.

- Coordinated activities between multiple departments such as engineering, purchasing, maintenance and quality control to ensure smooth manufacturing processes across all stages.

- Installed specialized equipment for various welding jobs including MIG/TIG arc welders, robotic arms & orbital welders; trained new employees on proper usage & operation techniques within 2 weeks per individual.

- Substantially improved operational efficiency through the implementation of innovative welding strategies that saved $7000 in labor costs last quarter alone.

- Independently managed a team of 8 welders and ensured that all welding activities were conducted in accordance with OSHA safety regulations; reduced workplace injuries by 40%.

- Advised the production department on the best techniques to use for different welding projects and completed 30+ assignments within budget while meeting tight deadlines.

- Troubleshot problems quickly on-site using advanced diagnostic tools, minimizing downtime by 70% compared to previous quarter’s results.

- Achieved total customer satisfaction through successful implementation of innovative approaches such as laser cutting systems for more accurate cuts; received 5 client awards over 2 years as recognition for superior quality workmanship.

- Structured comprehensive training programs involving hands-on practice sessions, theoretical classes & mentorship opportunities to ensure that new staff members could contribute effectively from day 1; increased productivity among junior welders by 25%.

- Demonstrated exceptional expertise in welding and fabrication processes to successfully guide a team of 15 welders for the completion of large-scale construction projects.

- Reduced downtime by 30% through improved troubleshooting techniques, efficient workflows and proactive scheduling measures.

- Compiled comprehensive reports on production timelines, orders completed & materials utilized; regularly monitored progress against budgets to ensure that all targets were met within expected time frames.

- Reliably operated equipment such as plasma cutters, oxyacetylene torches and saws per safety guidelines; ensured proper maintenance was carried out on tools before each shift started in order to reduce malfunctions during use.

- Inspected finished products for quality assurance purposes prior to delivery or shipment; identified any defects or errors promptly thus reducing rework costs by 40%.

- Assessed blueprints, drawings and other technical documents to ensure accuracy of welded structures; reduced welding errors by 12%.

- Facilitated the smooth operation of daily tasks in a team-based environment with 10+ personnel; developed schedules for proper resource allocation and implemented organizational strategies that saved $10,000 in labor costs on average.

- Mentored junior welders to enhance their skillset through hands-on training sessions lasting 4 hours per day; increased productivity levels by 15% within 3 months of implementation.

- Thoroughly inspected all completed projects for adherence to safety regulations and quality standards before being sent offsite; achieved zero customer complaints over last 6 months due to excellence in workmanship & attention to detail.

- Welded structural steel components using MIG/TIG processes as well as flux core arc welding (FCAW) techniques with an overall success rate exceeding 98%.

- Fabricated metal parts and components for a diverse range of construction projects, adjusting welding settings to ensure that all welds met or exceeded industry standards in terms of quality.

- Consistently monitored the performance of 8+ welder operators, providing feedback on their work and ensuring that safety procedures were adhered to at all times; reduced welding errors by 45%.

- Developed comprehensive training materials for new hires in order to familiarize them with safe operating practices and appropriate use of tools & equipment; trained 10 apprentices over 3 months who learned faster than the average trainee.

- Repaired damaged machinery when necessary using cutting-edge welding techniques such as TIG, MIG & ARC processes; completed repairs within budget limits while minimizing downtime by 30%.

- Supervised up to 15 workers daily while coordinating workflow between teams to maximize efficiency and productivity; helped complete 5 large-scale industrial projects ahead of schedule resulting in $25k cost savings per project.

- Competently supervised a team of 12 welders, ensuring all welding operations were executed in accordance with safety standards and industry regulations; implemented new safety protocols that reduced workplace accidents by 15%.

- Streamlined the workflow process to ensure efficiency while minimizing costs; saved $5,000 on supplies and equipment over three months without sacrificing quality of work.

- Represented company at various trade shows and conferences, providing expert insight into modern welding techniques, processes and materials used for superior results within budget requirements.

- Developed comprehensive training plans to help apprentices become certified welders in half the time compared to traditional methods; trained 50+ employees during tenure with no major incidents reported.

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may specialize in welding for the automotive industry and Organization B may specialize in building construction.

Therefore, it is essential to tailor the skills section of your resume to each job that you are applying for; this will help ensure that applicant tracking systems (computer programs used by many employers) recognize your qualifications as a good fit.

In addition to listing key skills here, you should also discuss them further throughout other sections of your resume such as the summary or experience section. This will give recruiters more insight into how competent you are with these particular abilities.

Below is a list of common skills & terms:

- Arc Welding

- Blueprint Reading

- Cost Estimation

- Metals Fabrication

- Quality Control

- Safety Protocols

- Scheduling

- Team Management

- Troubleshooting

- Welding Inspection

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the resume objective. However, if you have significant work experience that speaks for itself, omitting an education section is perfectly acceptable.

If including an education section, try to list courses or subjects related to welding foreman roles such as safety protocols and industrial operations management.

Associate Degree in Welding Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and skills in a particular field. They are also an excellent way of showing potential employers that you have kept up with the latest industry trends and developments.

Including certifications on your resume is beneficial as it shows hiring managers that you are committed to professional development, which can be highly attractive for any employer looking for new talent.

Certified Welding Foreman

American Welding Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Jaime Davis, this would be Jaime-Davis-resume.pdf or Jaime-Davis-resume.docx.

7. Cover Letter

A cover letter is an important part of any job application. It’s a document that provides additional information about your qualifications, experience and professional goals in relation to the role you are applying for.

Cover letters should be concise yet informative and typically consist of 2-4 paragraphs that explain why you’re the best fit for the position. While not always required, they offer recruiters more insight into who you are as an individual and can help make sure your resume stands out from other applicants.

Below is an example cover letter:

Dear Ardella,

I am writing to apply for the Welding Foreman position with ABC Corporation. I have a degree in welding technology from XYZ Trade School and seven years of experience working as a welder. In my current role, I oversee a team of welders and serve as the liaison between the welding department and other departments in the company. I am confident that I can bring my knowledge and experience to your organization and contribute to your bottom line.

In my current role, I am responsible for ensuring that projects are completed on time and within budget. I have developed strong project management skills and an eye for detail that allows me to identify potential problems early on. My team has consistently received high marks for quality workmanship, due in part to my close supervision.

I am also well-versed in safety procedures and have implemented several initiatives to reduce accidents in the workplace. My efforts have resulted in a 30% reduction in accidents over the past year.

I would welcome the opportunity to discuss how I can put my skills to work for your organization. Thank you for your time and consideration, and please do not hesitate to contact me at [phone number] or [email address].

Sincerely,

Jaime

Welding Foreman Resume Templates

Quokka

Quokka Gharial

Gharial Pika

Pika Lorikeet

Lorikeet Kinkajou

Kinkajou Dugong

Dugong Axolotl

Axolotl Jerboa

Jerboa Cormorant

Cormorant Indri

Indri Rhea

Rhea Saola

Saola Fossa

Fossa Markhor

Markhor Ocelot

Ocelot Hoopoe

Hoopoe Echidna

Echidna Numbat

Numbat Bonobo

Bonobo Rezjumei

Rezjumei