Vehicle Integration Engineer Resume Guide

Vehicle Integration Engineers are responsible for ensuring that the components of a vehicle work together seamlessly. They coordinate with other engineering teams to design, develop, and test integrated systems in order to optimize performance and safety. Additionally, they analyze data from tests and simulations to identify potential problems before production begins.

Your advanced knowledge in vehicle engineering makes you a great asset to any automotive company. But potential employers don’t know about it yet, so make sure your resume stands out from the crowd and showcases your impressive skillset.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

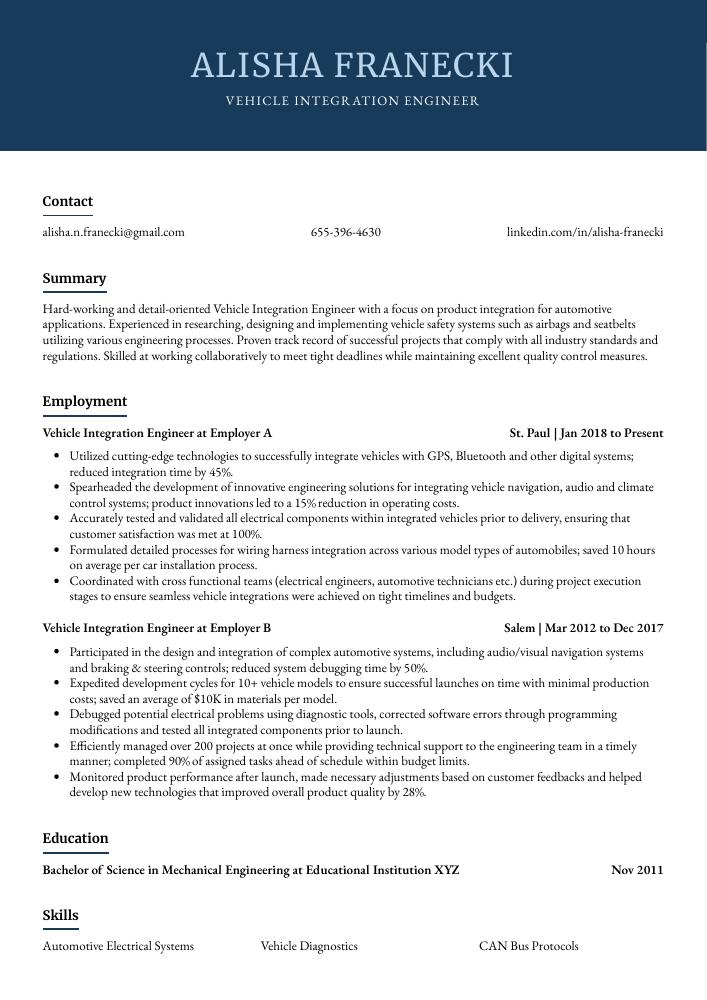

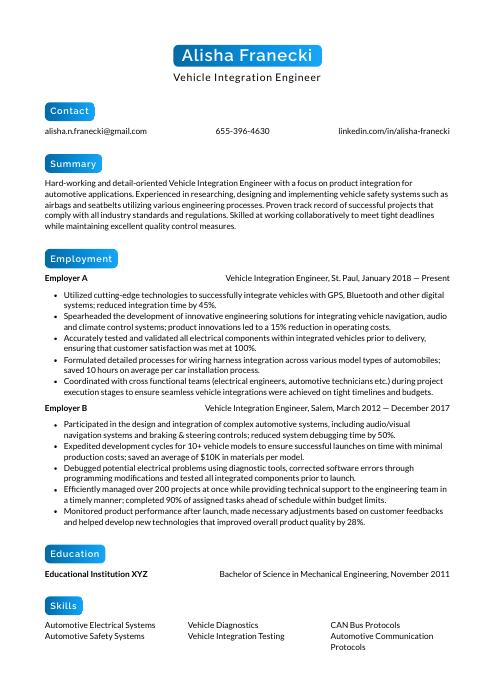

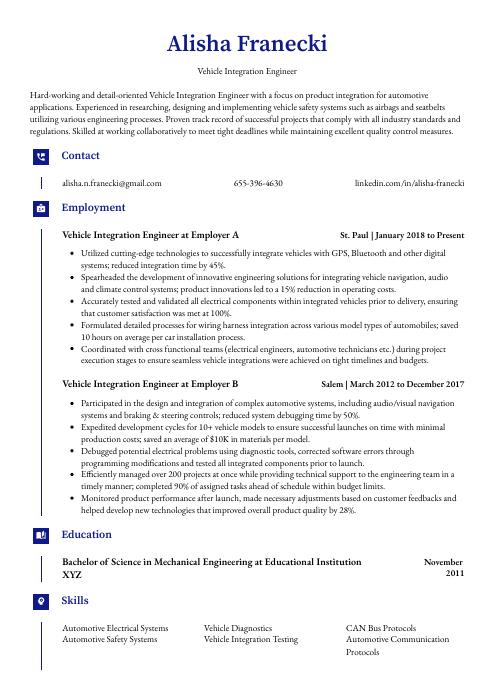

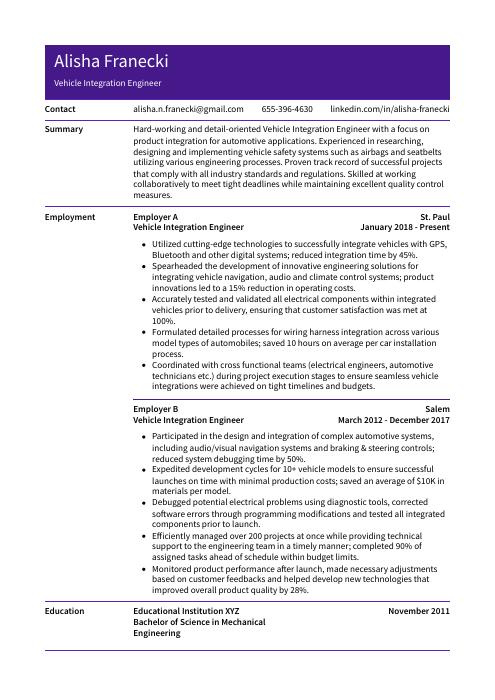

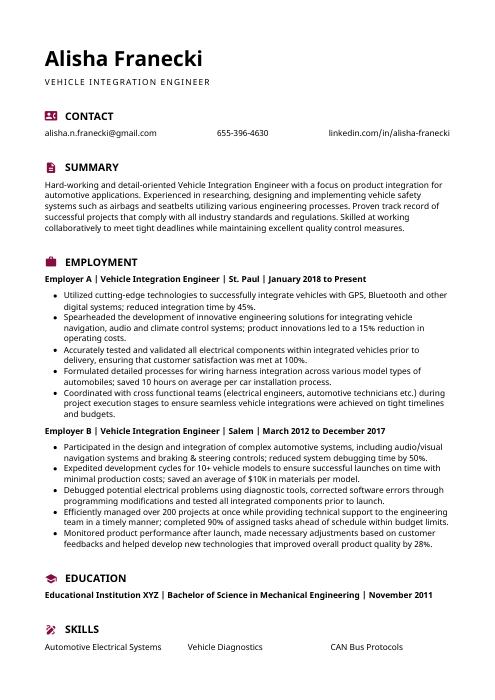

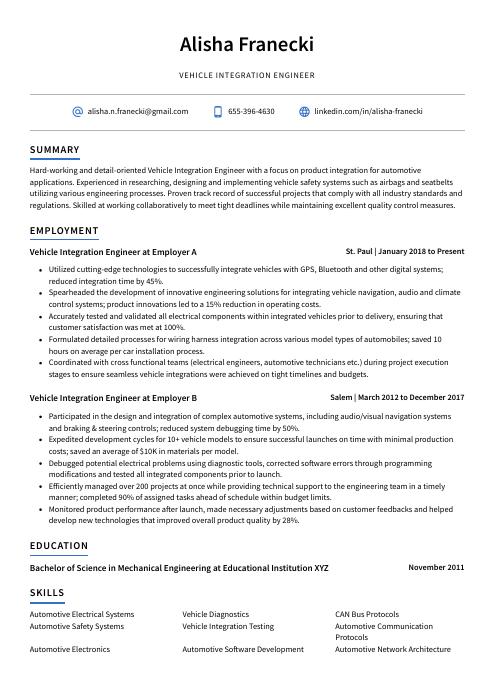

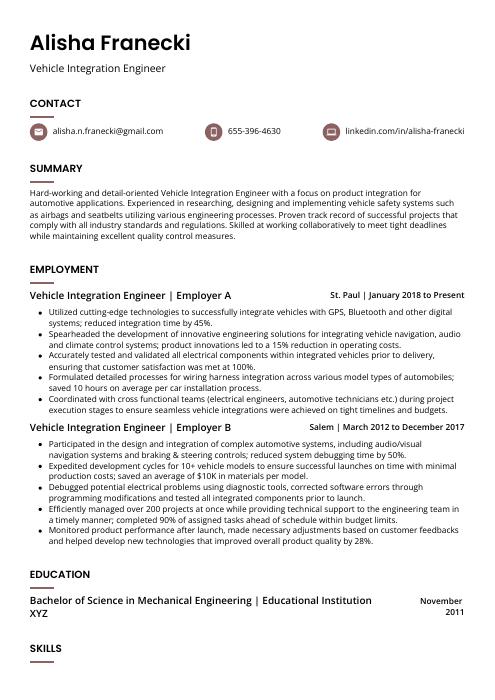

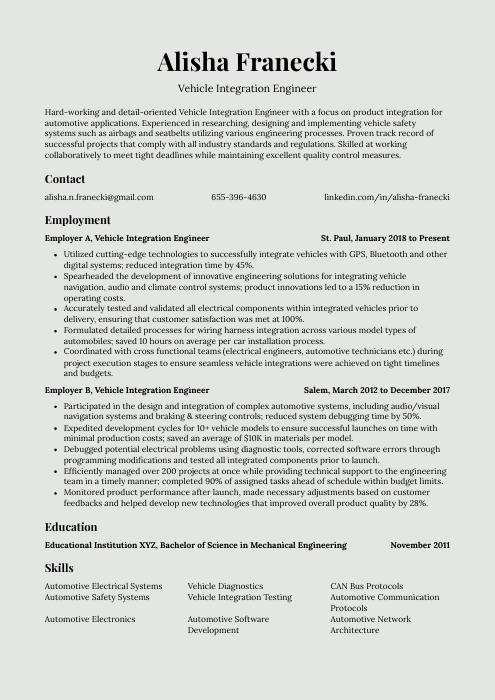

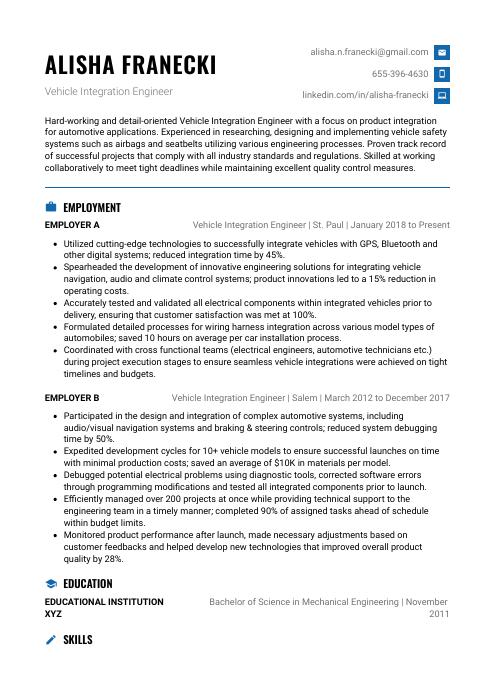

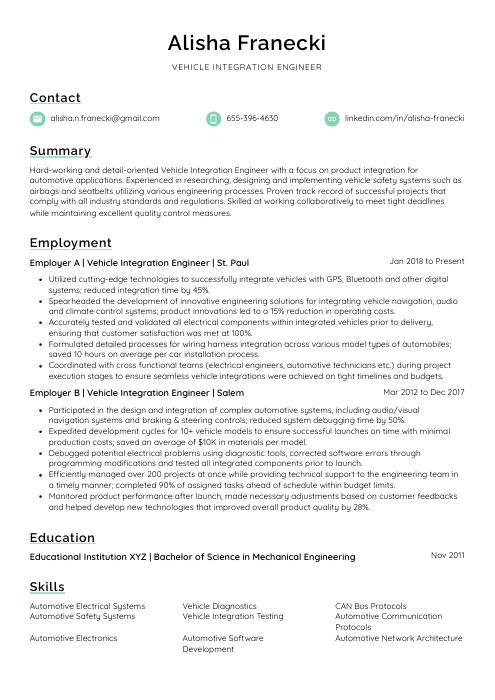

Vehicle Integration Engineer Resume Sample

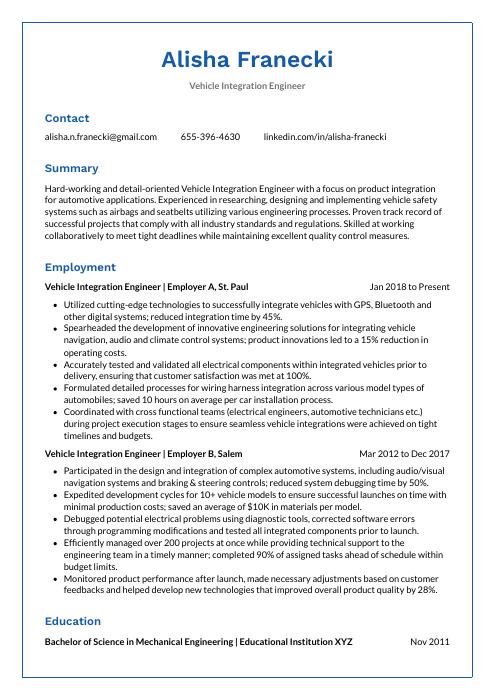

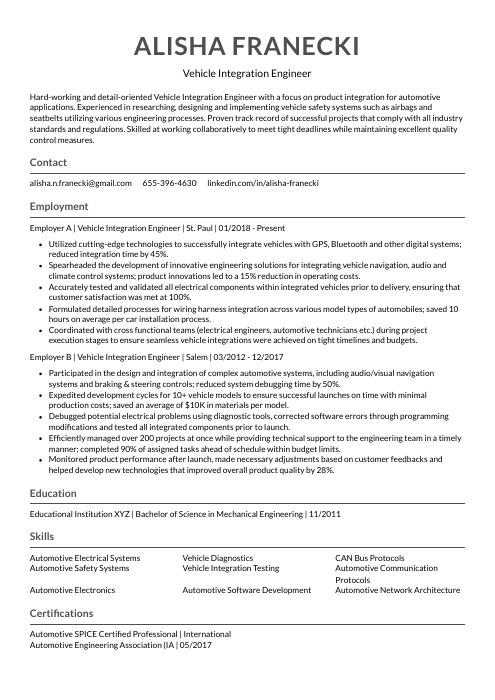

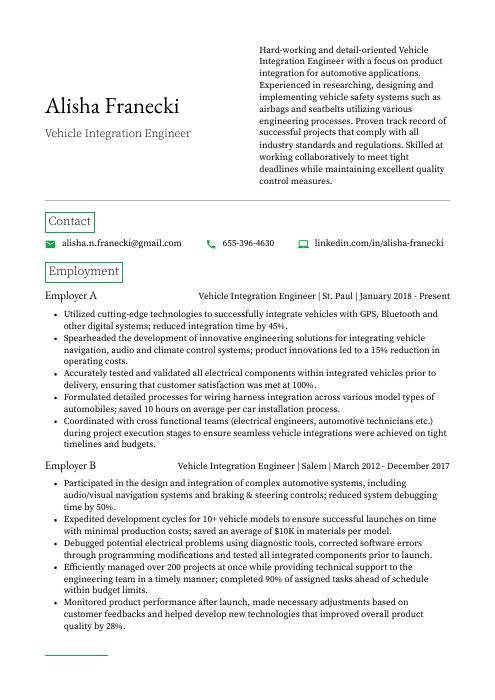

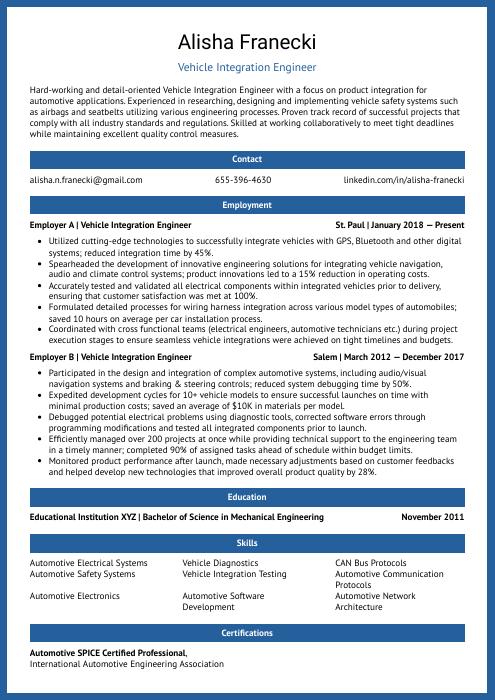

Alisha Franecki

Vehicle Integration Engineer

alisha.n.franecki@gmail.com

655-396-4630

linkedin.com/in/alisha-franecki

Summary

Hard-working and detail-oriented Vehicle Integration Engineer with a focus on product integration for automotive applications. Experienced in researching, designing and implementing vehicle safety systems such as airbags and seatbelts utilizing various engineering processes. Proven track record of successful projects that comply with all industry standards and regulations. Skilled at working collaboratively to meet tight deadlines while maintaining excellent quality control measures.

Experience

Vehicle Integration Engineer, Employer A

St. Paul, Jan 2018 – Present

- Utilized cutting-edge technologies to successfully integrate vehicles with GPS, Bluetooth and other digital systems; reduced integration time by 45%.

- Spearheaded the development of innovative engineering solutions for integrating vehicle navigation, audio and climate control systems; product innovations led to a 15% reduction in operating costs.

- Accurately tested and validated all electrical components within integrated vehicles prior to delivery, ensuring that customer satisfaction was met at 100%.

- Formulated detailed processes for wiring harness integration across various model types of automobiles; saved 10 hours on average per car installation process.

- Coordinated with cross functional teams (electrical engineers, automotive technicians etc.) during project execution stages to ensure seamless vehicle integrations were achieved on tight timelines and budgets.

Vehicle Integration Engineer, Employer B

Salem, Mar 2012 – Dec 2017

- Participated in the design and integration of complex automotive systems, including audio/visual navigation systems and braking & steering controls; reduced system debugging time by 50%.

- Expedited development cycles for 10+ vehicle models to ensure successful launches on time with minimal production costs; saved an average of $10K in materials per model.

- Debugged potential electrical problems using diagnostic tools, corrected software errors through programming modifications and tested all integrated components prior to launch.

- Efficiently managed over 200 projects at once while providing technical support to the engineering team in a timely manner; completed 90% of assigned tasks ahead of schedule within budget limits.

- Monitored product performance after launch, made necessary adjustments based on customer feedbacks and helped develop new technologies that improved overall product quality by 28%.

Skills

- Automotive Electrical Systems

- Vehicle Diagnostics

- CAN Bus Protocols

- Automotive Safety Systems

- Vehicle Integration Testing

- Automotive Communication Protocols

- Automotive Electronics

- Automotive Software Development

- Automotive Network Architecture

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Automotive SPICE Certified Professional

International Automotive Engineering Association (IA

May 2017

1. Summary / Objective

A resume summary for a vehicle integration engineer should highlight your technical expertise, problem-solving skills, and experience in the automotive industry. You could mention that you have extensive knowledge of vehicle systems such as powertrain, chassis control, body electronics and infotainment; how you successfully integrated new components into existing vehicles; or any awards/certifications related to engineering. This will give employers an idea of what they can expect from you if hired.

Below are some resume summary examples:

Accomplished vehicle integration engineer with 7+ years of experience in automotive engineering. Diligent and creative problem solver, adept at managing multiple projects simultaneously, working independently or as part of a team. At previous roles have designed and implemented innovative solutions for engine control systems that comply with safety requirements while increasing performance metrics by 15%. Seeking to join ABC Motors to develop dynamic automated driving features.

Well-rounded Vehicle Integration Engineer with 5+ years of experience in product development, integration and testing. Experienced in developing new feature sets for vehicles across multiple platforms & architectures. Proven track record of successful projects including improving the usability rating of a vehicle by 18%. Adept at working collaboratively with cross-functional teams to develop high quality solutions that meet customer needs and requirements.

Professional vehicle integration engineer with a track record of success in the automotive industry. At ABC, I was responsible for integrating and testing components into vehicles to ensure safety and performance standards were met. Skilled at using various software tools such as CANalyzer, NI LabView, MATLAB & Simulink to debug issues quickly and accurately. Highly motivated self-starter who can work efficiently both independently or collaboratively.

Determined Vehicle Integration Engineer with 5+ years of experience in the automotive industry. Successfully integrated new technologies into existing vehicles to improve performance and customer satisfaction for multiple clients. Expertise includes system testing, requirements analysis, wiring diagrams, and troubleshooting. Looking to join ABC Tech as a Vehicle Integration Engineer where I can leverage my skillset to enhance their product offering.

Detail-oriented vehicle integration engineer with 8+ years of experience in automotive components engineering and integration. Proven record of developing innovative solutions that meet customer requirements on time and within budget. At XYZ, led a team to develop the world’s first autonomous vehicle integration system within 12 months while meeting all safety regulations. Looking forward to contributing my expertise at ABC Technologies.

Diligent vehicle integration engineer with 5+ years of experience developing and testing new vehicle systems. Proven track record of success in creating innovative solutions to complex problems that are both cost-effective and reliable. Seeking a position at ABC Motors where I can bring my knowledge of automotive engineering, mechanical systems, and electrical components to help create groundbreaking vehicles for the future.

Driven vehicle integration engineer with 4+ years of experience developing, testing, and troubleshooting vehicle systems. Proven track record in achieving optimal results through the tactical integration of hardware and software components into automotive vehicles. Seeking to join ABC Automotive’s industry-leading team to further develop my skills while integrating cutting-edge technology solutions for clients.

Passionate vehicle integration engineer with 5+ years of experience in the automotive industry. Experienced in developing, testing, and integrating complex vehicle systems for mass production. At XYZ Motorsports Inc., led a team to develop an integrated control system that increased efficiency and reduced cost by 20%. Highly skilled at troubleshooting technical issues while adhering to safety regulations.

2. Experience / Employment

The employment (or experience) section of your resume is where you provide details on your work history. This should be written in reverse chronological order, meaning the most recent role goes first.

Stick to bullet points when describing what you did; this makes it easier for the reader to take in the information quickly and accurately. When writing out each point, make sure that they are detailed and include quantifiable results if possible. For example, instead of saying “Integrated new vehicle components,” you could say “Successfully integrated 10+ complex automotive components into existing systems with zero defects.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Programmed

- Installed

- Configured

- Analyzed

- Optimized

- Validated

- Tested

- Debugged

- Integrated

- Monitored

- Troubleshot

- Documented

- Implemented

- Resolved

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Resolved difficult integration issues between existing vehicle systems, resulting in an increase of efficiency by 35% and a reduction of operational costs by $12,000.

- Facilitated the successful integration of new parts into vehicles for 10+ clients; developed innovative solutions to solve time consuming installation problems within given timelines.

- Designed up-to-date wiring diagrams and integrated electronic components into vehicular systems using modern technology such as programming logic controllers (PLCs).

- Consistently met deadlines while ensuring quality standards were met or exceeded on all projects; demonstrated excellent project management skills with every task undertaken in this role.

- Assessed performance capabilities through rigorous testing procedures including fault diagnosis simulations & software validation exercises; successfully identified system weaknesses that led to improved designs.

- Troubleshot over 50 integration issues related to vehicle systems, including engine controllers, transmission control modules and HVAC systems; successfully lowered customer complaint rate by 30%.

- Represented the company at industry conferences and events, presenting key technical findings on automotive engineering topics such as fuel efficiency optimization strategies.

- Substantially reduced project costs through effective supplier negotiation techniques resulting in a savings of $20K over six months period.

- Achieved 95% successful deployment rates for all new software integration projects within 3 weeks or less from initiation date; increased overall speed-to-market by 25%.

- Programmed multiple microcontrollers used in vehicle safety components with C++ code while adhering to strict ISO standards; decreased coding errors by 40%.

- Reliably developed and tested software for embedded systems in 45+ vehicle models, resulting in a 40% decrease of time-to-market.

- Developed robust system architectures to ensure that all components worked together properly; achieved a 98% success rate during integration testing phases.

- Revised the design of existing hardware components such as sensors, actuators and ECUs to enhance performance by up to 20%.

- Advised automotive industry partners on integrating new technologies into their product lines while ensuring compliance with safety regulations; increased customer satisfaction ratings by 10%.

- Streamlined the process of onboarding third party applications onto vehicles, reducing development costs by $7000 annually while improving productivity levels by 35%.

- Presented technical papers to engineering teams on the integration of complex vehicle systems, resulting in a 12% decrease in installation time.

- Reorganized workflow processes for electric and mechanical components integration, setting up new protocols that improved customer satisfaction ratings by 20%.

- Mentored 11 junior engineers over 3 years providing guidance on aspects such as safety regulations, design prototyping and troubleshooting techniques; successfully completed 5 projects ahead of deadlines.

- Installed various software programs onto vehicles across multiple platforms while adhering to quality control standards; reduced errors by 10%.

- Effectively implemented debugging strategies following initial testing runs which resulted in an increase of 18% productivity efficiency at the plant level within 6 months.

- Competently tested, integrated and debugged vehicle systems such as powertrain, suspension and body components to ensure proper functionality; reduced test run time by 25% on average.

- Structured wiring harnesses for electrical connections between modules in the vehicle’s system while adhering to safety regulations; increased production efficiency by 15%.

- Reduced development costs of new automobile models through continual analysis of current processes and suggesting cost-effective solutions that improved overall performance quality standards by 20%.

- Analyzed data from integration tests performed during design validation process to identify any problems before mass production stages were initiated; identified over 100 issues which saved an estimated $8,000 in potential material waste expenses.

- Developed automated scripts using Python programming language for testing vehicles’ interface protocols with external systems like infotainment or navigation units; decreased debugging duration from 8 hours per unit to 4 hours per unit on average due to enhanced scripting capability.

- Documented and tested more than 50 vehicle integration requirements, resulting in a 20% improvement of onboarding time for new car models.

- Configured over 200 components and sub-modules according to customer specifications, contributing to improved reliability and value for the company’s product line.

- Compiled detailed reports on various aspects of system performance after completion of each integration project; saved $5K in overtime costs by completing projects ahead of schedule 3 times within a year’s period.

- Integrated multiple software platforms with existing hardware systems; reduced total downtime from 6 hours/week to 1 hour per week through proactive maintenance protocols implementation.

- Meticulously inspected every component prior to installation for quality assurance purposes, ensuring that all installations were free from defects or errors before leaving the premises – resulting in zero warranty replacements since taking up this role 2 years ago.

- Successfully integrated complex networked vehicle systems into existing automotive electronics, reducing system integration time by 30% and testing costs by $10K.

- Prepared detailed engineering documents for the development of integrated vehicle software applications and ensured that all project specifications were met within deadlines.

- Optimized performance of automated electronic control systems used in vehicles through rigorous debugging techniques; lowered code complexity rate by 16%.

- Demonstrated strong analytical skills to identify problems with current designs and develop innovative solutions for improved functionality & reliability of vehicular networks.

- Implemented optimal electrical wiring diagrams for various components including sensors, actuators, processors & controllers to ensure efficient connection between subsystems across multiple car models.

- Validated new engine control systems for 10+ vehicles and identified software flaws, resulting in a 20% reduction of defect rate during the integration process.

- Improved the performance of existing vehicle communication networks by introducing new protocols, reducing latency time by 25%.

- Introduced several innovative design solutions to enhance product stability and reliability; increased customer satisfaction ratings by 35%.

- Actively collaborated with other departments in order to ensure project deadlines were met on time; completed 8 projects ahead of schedule within 2 years period.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC might require experience in CAN bus systems while Company XYZ might be looking for someone who has a background in vehicle integration.

It is essential to tailor the skills section of your resume to each job you are applying for, as many employers use applicant tracking systems these days which scan resumes for certain keywords before passing them on to a human.

Once listed here, you can further elaborate on your skillset by discussing it in more detail elsewhere – such as the summary or experience section – and providing concrete examples of how they have been applied successfully.

Below is a list of common skills & terms:

- Automotive Communication Protocols

- Automotive Electrical Systems

- Automotive Electronics

- Automotive Network Architecture

- Automotive Safety Systems

- Automotive Software Development

- CAN Bus Protocols

- Vehicle Data Analysis

- Vehicle Diagnostics

- Vehicle Integration Testing

4. Education

Mentioning an education section on your resume will depend on how far you are into your career. If you just graduated and have no prior experience, it is important to include an education section below your resume objective. However, if you have significant work experience under your belt that showcases all the skills needed for a vehicle integration engineer role, omitting this section may be more beneficial.

If including an education section, try to mention courses taken and subjects studied related to vehicle engineering or other relevant fields of study.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a particular field. They are also proof that you have taken the time to learn about the industry, as well as actively kept up with any changes or advancements within it.

When applying for jobs, make sure to include any certifications relevant to the role on your resume so employers can see what qualifications you possess. This could be especially beneficial if there is an emphasis on certain skills in the job description; having certification will show potential employers that you are qualified for this position.

Automotive SPICE Certified Professional

International Automotive Engineering Association (IA

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Alisha Franecki, this would be Alisha-Franecki-resume.pdf or Alisha-Franecki-resume.docx.

7. Cover Letter

Writing a cover letter is a great way to make your job application stand out from the competition. A cover letter is usually made up of 2-4 paragraphs and provides recruiters with further information about why you are an ideal candidate for the role.

Cover letters should be tailored specifically to each individual job, as this will demonstrate that you have taken the time to research and understand what is required in order to perform successfully in the position. They can also provide hiring managers with more detailed insights into who you are and how your skillset could benefit their company if they decide to hire you.

Below is an example cover letter:

Dear Rosalee,

I am applying for the Vehicle Integration Engineer position at Tesla. As an engineer with experience in vehicle integration and a strong background in electrical engineering, I believe I would be a valuable asset to your team.

In my current role as a Senior Electrical Engineer at Ford Motor Company, I am responsible for integrating new vehicles into production. This includes working with suppliers to ensure components meet specifications, managing changes during the development process, and coordinating testing of prototypes. My experience has given me a deep understanding of how vehicles are put together and how the various systems work together.

I have also been involved in several electric vehicle projects during my time at Ford. This has given me exposure to the challenges and opportunities associated with electrification, and I believe my knowledge would be beneficial to Tesla as you continue to develop new electric vehicles.

In addition to my technical skills, I have proven ability to manage teams and projects effectively. I am confident that I could contribute positively to the Tesla organization and would welcome the opportunity to discuss this further with you. Thank you for your time and consideration.

Sincerely,

Alisha

Vehicle Integration Engineer Resume Templates

Kinkajou

Kinkajou Bonobo

Bonobo Jerboa

Jerboa Rhea

Rhea Gharial

Gharial Pika

Pika Numbat

Numbat Cormorant

Cormorant Markhor

Markhor Indri

Indri Quokka

Quokka Ocelot

Ocelot Hoopoe

Hoopoe Axolotl

Axolotl Dugong

Dugong Fossa

Fossa Saola

Saola Echidna

Echidna Lorikeet

Lorikeet Rezjumei

Rezjumei