Tool and Die Maker Resume Guide

Tool and die makers design, construct, maintain, troubleshoot and repair metalworking tools used in the manufacturing of parts or products. They use a variety of metals such as steel, brass and aluminum to create dies that are used to shape metal into desired shapes for mass production.

You have the precision and expertise to make any tool or die with accuracy. But potential employers don’t know about your capabilities, so you must write a resume that proves why you are the best person for the job.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

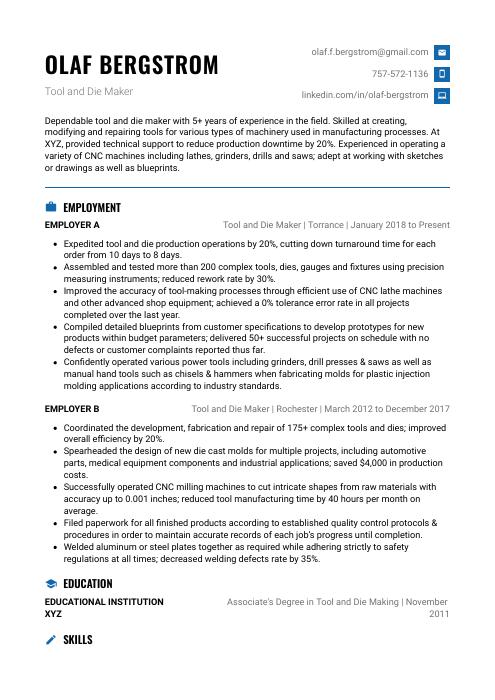

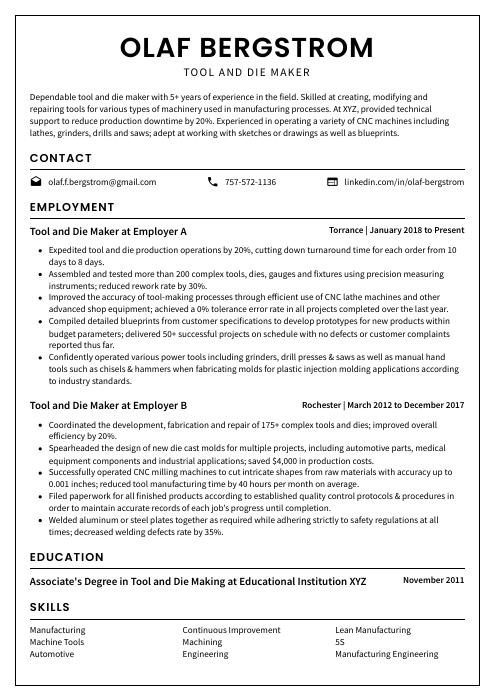

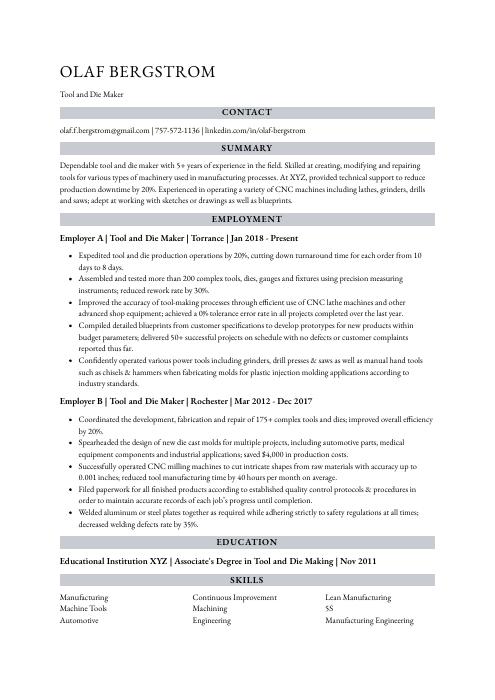

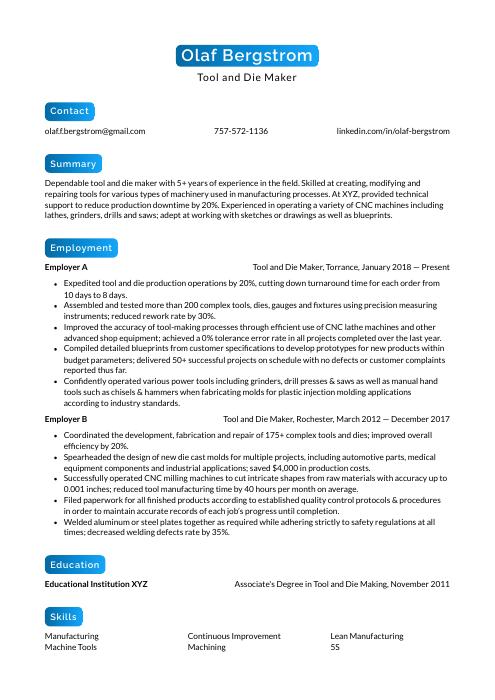

Tool and Die Maker Resume Sample

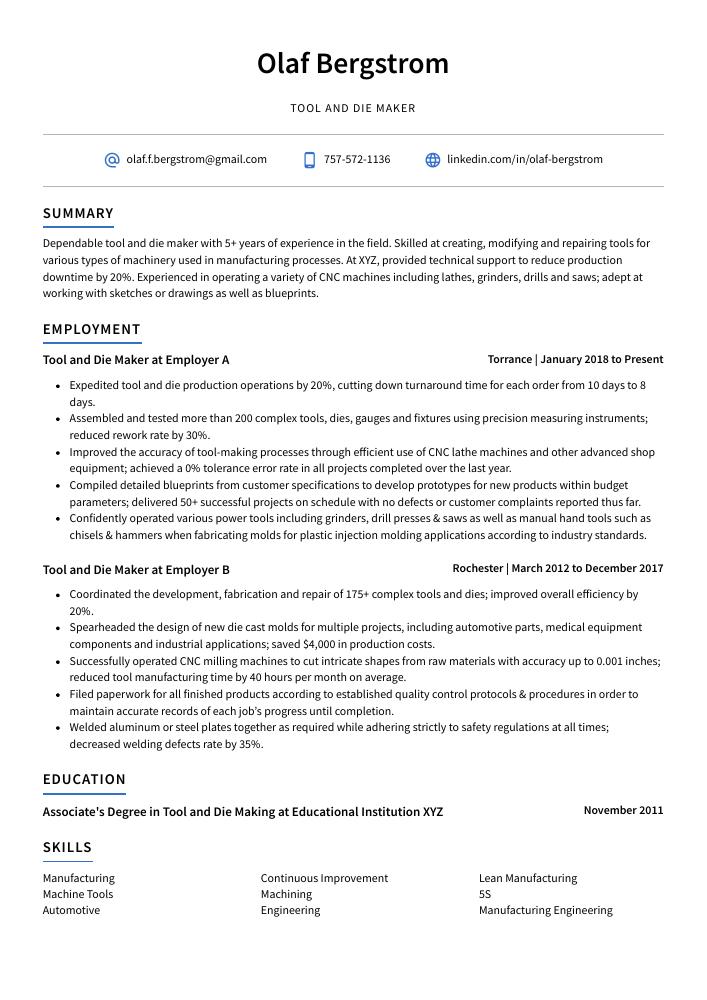

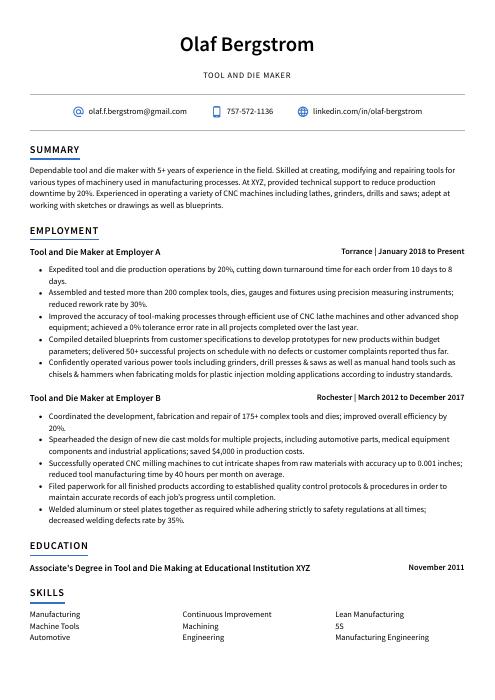

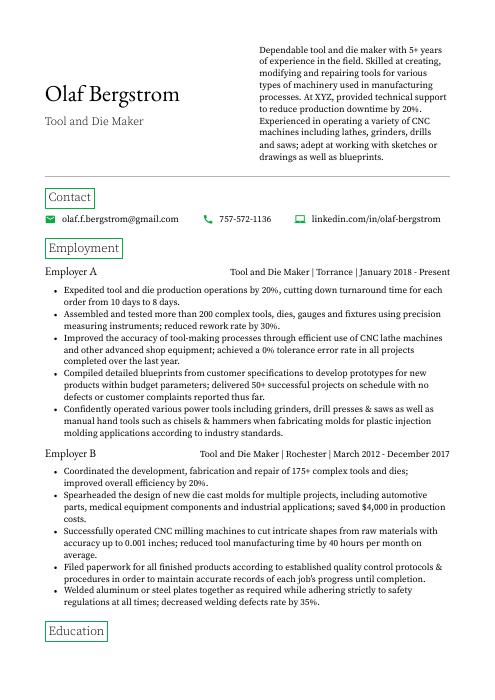

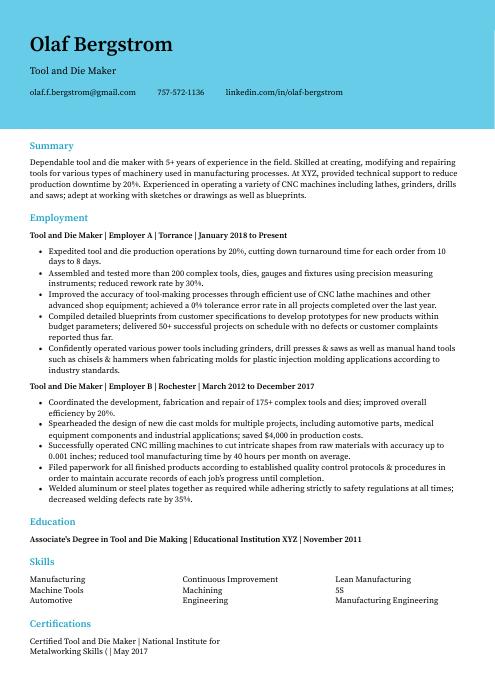

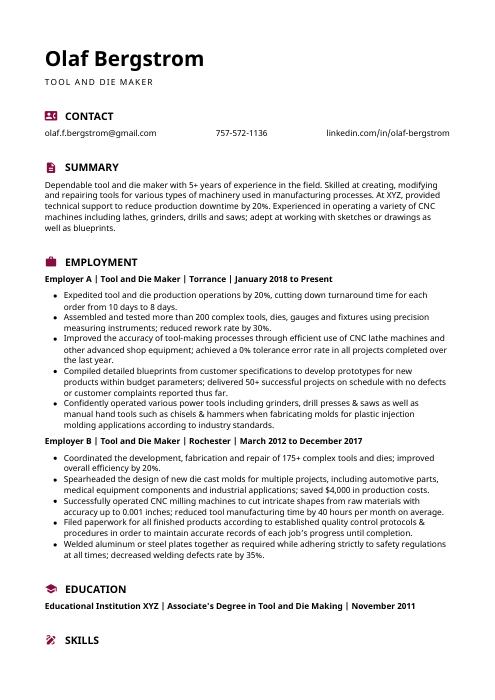

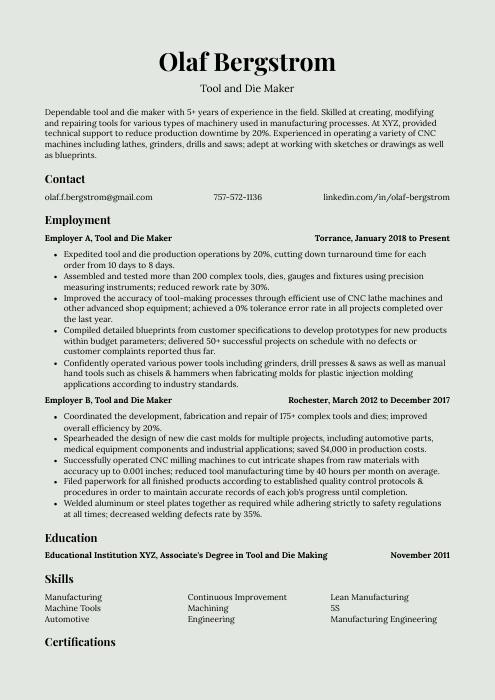

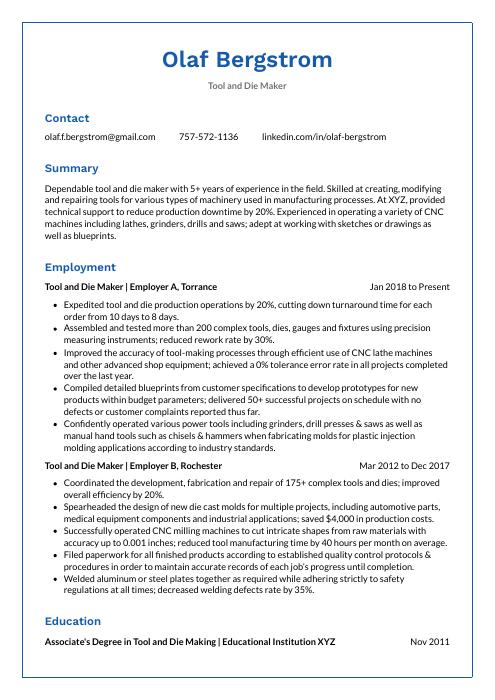

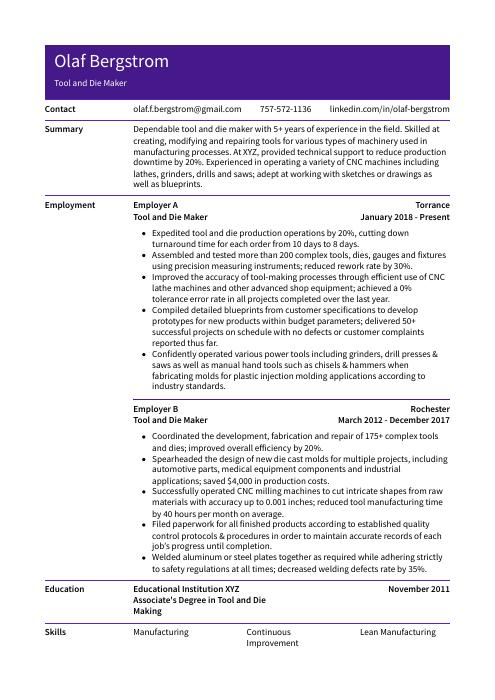

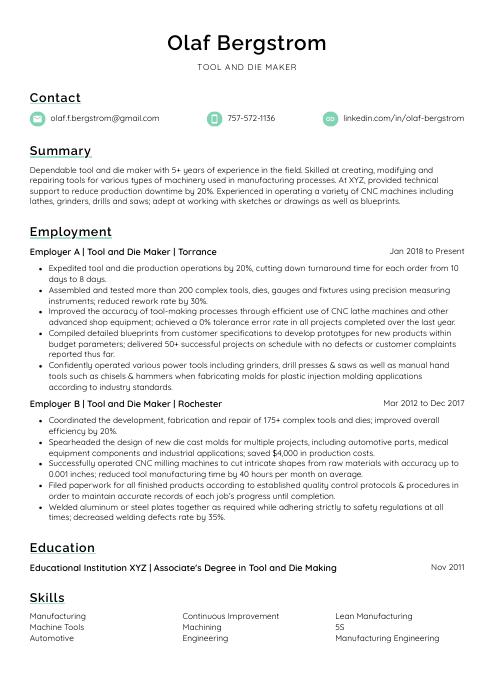

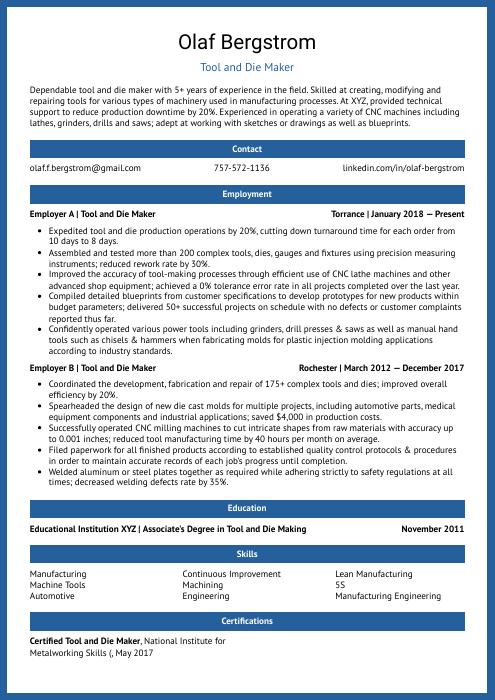

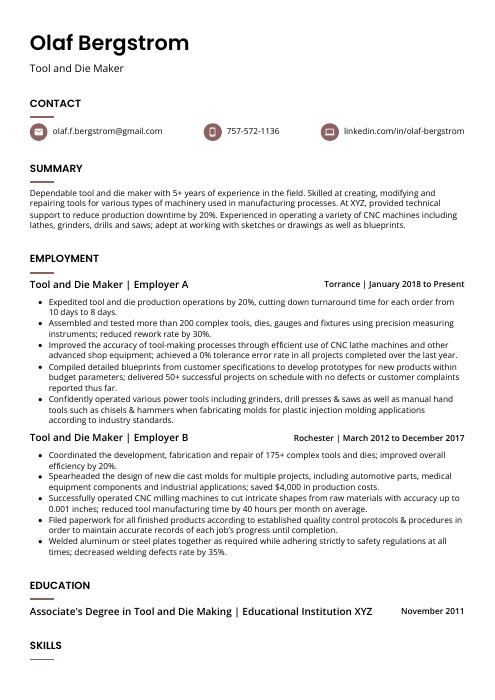

Olaf Bergstrom

Tool and Die Maker

olaf.f.bergstrom@gmail.com

757-572-1136

linkedin.com/in/olaf-bergstrom

Summary

Dependable tool and die maker with 5+ years of experience in the field. Skilled at creating, modifying and repairing tools for various types of machinery used in manufacturing processes. At XYZ, provided technical support to reduce production downtime by 20%. Experienced in operating a variety of CNC machines including lathes, grinders, drills and saws; adept at working with sketches or drawings as well as blueprints.

Experience

Tool and Die Maker, Employer A

Torrance, Jan 2018 – Present

- Expedited tool and die production operations by 20%, cutting down turnaround time for each order from 10 days to 8 days.

- Assembled and tested more than 200 complex tools, dies, gauges and fixtures using precision measuring instruments; reduced rework rate by 30%.

- Improved the accuracy of tool-making processes through efficient use of CNC lathe machines and other advanced shop equipment; achieved a 0% tolerance error rate in all projects completed over the last year.

- Compiled detailed blueprints from customer specifications to develop prototypes for new products within budget parameters; delivered 50+ successful projects on schedule with no defects or customer complaints reported thus far.

- Confidently operated various power tools including grinders, drill presses & saws as well as manual hand tools such as chisels & hammers when fabricating molds for plastic injection molding applications according to industry standards.

Tool and Die Maker, Employer B

Rochester, Mar 2012 – Dec 2017

- Coordinated the development, fabrication and repair of 175+ complex tools and dies; improved overall efficiency by 20%.

- Spearheaded the design of new die cast molds for multiple projects, including automotive parts, medical equipment components and industrial applications; saved $4,000 in production costs.

- Successfully operated CNC milling machines to cut intricate shapes from raw materials with accuracy up to 0.001 inches; reduced tool manufacturing time by 40 hours per month on average.

- Filed paperwork for all finished products according to established quality control protocols & procedures in order to maintain accurate records of each job’s progress until completion.

- Welded aluminum or steel plates together as required while adhering strictly to safety regulations at all times; decreased welding defects rate by 35%.

Skills

- Manufacturing

- Continuous Improvement

- Lean Manufacturing

- Machine Tools

- Machining

- 5S

- Automotive

- Engineering

- Manufacturing Engineering

Education

Associate’s Degree in Tool and Die Making

Educational Institution XYZ

Nov 2011

Certifications

Certified Tool and Die Maker

National Institute for Metalworking Skills (

May 2017

1. Summary / Objective

Your resume summary should be a snapshot of your tool and die making experience. It should give the employer an overview of your skills, qualifications, and accomplishments in this field. For example, you could mention how many years of experience you have as a tool and die maker; any certifications or awards that demonstrate your expertise; the types of tools and machines you are most proficient with; or any unique projects that showcase your problem-solving abilities.

Below are some resume summary examples:

Driven tool and die maker with 5+ years of experience in the manufacturing industry. Skilled at designing, building, and maintaining a variety of tooling systems to produce precision-engineered parts for clients’ specifications. Established track record of successful completion of projects on time and within budget constraints. Dedicated to providing top-notch customer service while meeting all safety requirements.

Determined Tool and Die Maker with 10+ years of experience in the machining industry. Skilled at designing, constructing, maintaining, repairing complex tools and dies used to produce parts or products for automotive manufacturing companies. At XYZ Inc., successfully designed jigs and fixtures that allowed an automatic assembly process to be applied on a production line resulting in cost savings of $27K annually.

Well-rounded tool and die maker with 8+ years of experience in the manufacturing industry. Skilled in operating a variety of machines, including CNC lathes, milling machines, and EDMs. Experienced at designing complex tools for production lines using CAD software such as SolidWorks. Successfully completed 10 projects ahead of schedule while maintaining quality standards to the highest degree possible.

Professional tool and die maker with 10+ years of experience in the automotive industry. Experienced in machining, assembly, troubleshooting and repair of complex tools and dies used for manufacturing process improvement. Skilled at developing innovative solutions to reduce costs while increasing production output. At XYZ Company was instrumental in improving customer satisfaction by 30%.

Detail-oriented and knowledgeable tool and die maker with 11+ years of experience in the manufacturing industry. Skilled in operating a wide range of tools, machines, and equipment to create precision-machined parts for industrial use. Seeking to join ABC Manufacturing as a Tool & Die Maker where I can utilize my knowledge and expertise to ensure quality production results.

Diligent and detail-oriented tool and die maker with 8+ years of experience in the manufacturing industry. Track record of developing, constructing and repairing a wide range of tools to customer specifications while meeting tight deadlines. Passionate about joining ABC Manufacturing where I can utilize my expertise to create innovative solutions for clients’ needs.

Seasoned tool and die maker with 10+ years of experience in designing, fabricating, maintaining, and repairing molds for a variety of industries. Expertise in using CNC machines to produce complex parts with precision accuracy. Aiming to leverage proven problem-solving skills at ABC Manufacturing as the next tool and die maker on their team.

Committed and meticulous tool and die maker with 10+ years of experience creating, modifying, and maintaining molds for a variety of industrial applications. Proven ability to troubleshoot malfunctioning machines and devise solutions quickly. Looking to apply expertise in machining operations at ABC Company as part of their dynamic team.

2. Experience / Employment

In the experience/employment/work history section, you want to provide details on your past roles. This section should be written in reverse chronological order, with the most recent job listed first.

When discussing what you did, use bullet points and include as much detail as possible about the tasks performed and results achieved. For example, instead of saying “Built tools,” say something like “Created custom-designed tools for automotive parts using a CNC milling machine; reduced production time by 25%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Fabricated

- Assembled

- Operated

- Inspected

- Programmed

- Calibrated

- Adjusted

- Troubleshot

- Measured

- Drilled

- Lathed

- Milled

- Shaped

- Filed

- Welded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Revised existing tool and die designs to improve production efficiency, resulting in a 15% reduction of manufacturing costs.

- Efficiently operated various machines such as lathes, milling machines, grinders & EDM’s to produce complex components with high precision.

- Participated in daily quality inspections on finished products and identified defects; successfully reduced defect rate by 20%.

- Calibrated equipment regularly to ensure that all tools met the required specifications for accuracy; improved product performance by 10%.

- Fabricated molds made from different materials such as steel, aluminum or plastics within tight deadlines; completed projects 5 days ahead of schedule on average.

- Consistently maintained and repaired over 50+ precision tools and dies, resulting in a 45% improvement of production efficiency.

- Assessed complex technical drawings to determine the best machining processes for each tooling project; completed 10 projects with high accuracy within specified deadlines.

- Streamlined metal fabrication process by introducing 5 new designs that improved the overall quality of products while reducing material wastage by 25%.

- Troubleshot malfunctions on automated equipment, identified root causes and minimized downtime from 3 hours to 30 minutes per incident on average.

- Presented methods for effectively handling materials at various stages of product development during team meetings; reduced cycle time by 20% as a result.

- Resourcefully operated CNC machines and manual lathes to fabricate tooling components from raw materials, achieving a 95% accuracy rate on all projects.

- Utilized advanced CAD/CAM software to analyze blueprints & drawings of dies and molds for product improvement; singlehandedly lowered production lead times by 15%.

- Milled complex parts with precision using a variety of hand tools such as jig saws, grinders and milling machines in order to create high-quality products that met customer specifications.

- Reorganized the die shop’s inventory system resulting in an increase in productivity by 25%, while significantly reducing work-in-progress errors caused by supply chain mismanagement issues.

- Structured maintenance schedules for machinery equipment used daily within the factory environment; reduced machine downtime incidents due to malfunctions or breakdowns from 10 hours per month to less than 3 hours monthly averagely.

- Thoroughly maintained and adjusted over 30+ tooling machines, ensuring that all tools were operating at peak performance while reducing downtime by 25%.

- Adjusted fixtures and jigs to the exact specifications of blueprints or CAD models; saved 200 man-hours in production time with accurate programming.

- Programmed CNC lathes for mass production runs of complex components according to customer requirements, resulting in a 40% increase in output compared to before.

- Lathed small precision parts from raw materials such as aluminum, brass and steel using manual mills/lathes as needed; reduced errors during machining by 10%.

- Represented the company on trade show floors across the US, showcasing new products developed via metal fabrication techniques & tooling processes for potential clients & buyers.

- Developed more than 250+ precision tool and die components for manufacturing production lines, meeting complex customer specifications with up to +/- 0.005” tolerances.

- Independently designed and programmed CNC machines to produce tools from a wide range of materials; reduced setup time by 40% through innovative CAD/CAM solutions.

- Formulated detailed documentation packages that included process flow diagrams, part drawings and quality control plans; improved efficiency in the manufacturing cycle by 15%.

- Mentored three apprentices on machining fundamentals as well as safety protocols while operating machinery; they achieved full certification within 6 months of training under supervision.

- Introduced new technologies such as EDM wire cutting into the workflow which enabled cost savings due to faster turnaround times – resulting in an $8,000 reduction in annual expenses per machine center.

- Achieved average production rates of 600 parts per hour, surpassing expectations and resulting in a 5% increase in revenue.

- Facilitated the construction of precision tools, dies and molds to exact specifications by using CNC-controlled machines; inspected workpieces for accuracy before releasing them into production.

- Operated manual lathes, drills, grinders and other specialized equipment with expertise to create induction hardened surfaces on metal components as required by customer orders.

- Meticulously monitored tool wear-and-tear during manufacturing process; replaced broken/worn out tools promptly to prevent any delays or product defects from occurring down the line.

- Demonstrated superior problem solving skills when troubleshooting machine issues such as incorrect settings or worn out drill bits; reduced downtime caused due to technical glitches by 25%.

- Actively operated CNC lathes, mills and other advanced tooling machinery to shape metal components according to precise specifications; reduced machining times by 23%.

- Reduced scrap rates significantly through proper setup of tools and machines, as well as rigorous quality control checks throughout the production process.

- Shaped over 1250 precision parts per day from raw materials such as steel, aluminum and brass using hand tools like taps, dies & chisels when necessary in order to meet customer requirements.

- Inspected finished products for conformity with design drawings prior to release for assembly or shipment; identified defects quickly before they caused costly delays/rejections downstream.

- Drilled a variety of holes into metals pieces with great accuracy using manual drilling equipment; increased productivity on this task by 30% compared to traditional methods used previously.

- Optimized the design of die sets for a range of products, resulting in an increase of production output by 20%.

- Measured and inspected the accuracy and quality control standards of tools designed to produce precision parts; reduced scrap rate from 15% to 3%.

- Effectively operated CNC mills, lathes, grinders and other machining equipment during the fabrication process while ensuring adherence to safety protocols.

- Prepared detailed sketches that illustrated tooling specifications such as dimensions, tolerances & material requirements; increased productivity by 10 hours per week on average compared with manual designs.

- Advised machine operators on proper procedure when installing dies into presses or operating their machines during production runs; lowered downtime incidents due to operator error by 25%.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in CNC machining, while the other may be looking for someone with knowledge of welding.

Therefore, it is essential to customize your skills section according to each job that you are applying for as this will help you stand out from the competition and increase your chances of getting hired. It’s also important because many companies use applicant tracking systems which scan resumes for certain keywords before they reach a human recruiter.

In addition to listing relevant skills here, make sure to elaborate on them further in other resume sections such as summary or work experience.

Below is a list of common skills & terms:

- 5S

- APQP

- AutoCAD

- Automotive

- CNC

- CNC Programming

- Continuous Improvement

- Design for Manufacturing

- Engineering

- FMEA

- Fixtures

- GD&T

- Grinding

- ISO

- Injection Molding

- Kaizen

- Lathe

- Lean Manufacturing

- Machine Tools

- Machinery

- Machining

- Manufacturing

- Manufacturing Engineering

- Manufacturing Operations Management

- Metal Fabrication

- Milling

- PPAP

- Process Improvement

- Product Development

- Root Cause Analysis

- SOLIDWORKS

- SPC

- Six Sigma

- Stamping

- Troubleshooting

- Welding

4. Education

Mentioning your education section on your resume will depend largely on how far along you are in your career. If you just graduated and have no prior experience, it is essential to include an education section below your resume objective. However, if you have been working as a tool and die maker for years with plenty of responsibilities to showcase, omitting the education section may be necessary.

If including an education section, try to mention courses or subjects related specifically to the tool and die making job you are applying for.

Associate’s Degree in Tool and Die Making

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field and show potential employers that you are highly qualified for the job. Having certifications on your resume will give hiring managers confidence in your abilities, as they can be sure of the quality of training you have received.

If there is an industry-specific certification or qualification relevant to the position you are applying for, make sure it is included in this section of your resume so that recruiters know about it right away.

Certified Tool and Die Maker

National Institute for Metalworking Skills (

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Olaf Bergstrom, this would be Olaf-Bergstrom-resume.pdf or Olaf-Bergstrom-resume.docx.

7. Cover Letter

Including a cover letter in your job application can be the difference between being considered for a role and not. It’s an opportunity to add personality, explain why you’re the best candidate for the role and showcase your knowledge of the company.

A cover letter is usually made up of 2 to 4 paragraphs that are separate from your resume. This additional information helps recruiters understand more about who you are as an individual and how well suited you’d be in their team.

Below is an example cover letter:

Dear Ashley,

I am interested in the Tool and Die Maker position at your company. I have eight years of experience working as a tool and die maker, and my skills align well with the qualifications listed in your job description. In my current role, I operate CNC machines to create tools, dies, molds, fixtures, and gauges. I also troubleshoot machine issues and perform preventative maintenance on a regular basis.

In addition to my hands-on experience, I have completed coursework in blueprint reading, metallurgy, and quality control procedures. My attention to detail ensures that each tool or die meets specifications before it leaves my workstation. My team members know they can rely on me to produce high-quality products efficiently.

I am confident that I can be an asset to your company as a tool and die maker. If given the opportunity, I will use my skills and knowledge to contribute to your organization’s success. Thank you for your time; I look forward to hearing from you soon about this exciting opportunity!

Sincerely,

Olaf

Tool and Die Maker Resume Templates

Jerboa

Jerboa Gharial

Gharial Rhea

Rhea Echidna

Echidna Cormorant

Cormorant Numbat

Numbat Kinkajou

Kinkajou Axolotl

Axolotl Quokka

Quokka Dugong

Dugong Hoopoe

Hoopoe Saola

Saola Markhor

Markhor Bonobo

Bonobo Indri

Indri Pika

Pika Lorikeet

Lorikeet Ocelot

Ocelot Fossa

Fossa Rezjumei

Rezjumei