Supply Chain Technician Resume Guide

Supply chain technicians are responsible for overseeing the entire supply chain process from ordering materials and goods to delivering them. They work with suppliers, manufacturers, distributors, customers and other stakeholders in order to ensure that products arrive on time and meet customer expectations. Additionally, they monitor inventory levels and coordinate the transportation of goods within the supply chain network.

You have the knowledge and experience to be an invaluable asset to any supply chain team. But employers don’t know who you are yet, so it’s up to you to create a resume that captures their attention. Show them what makes you the best candidate for the job!

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

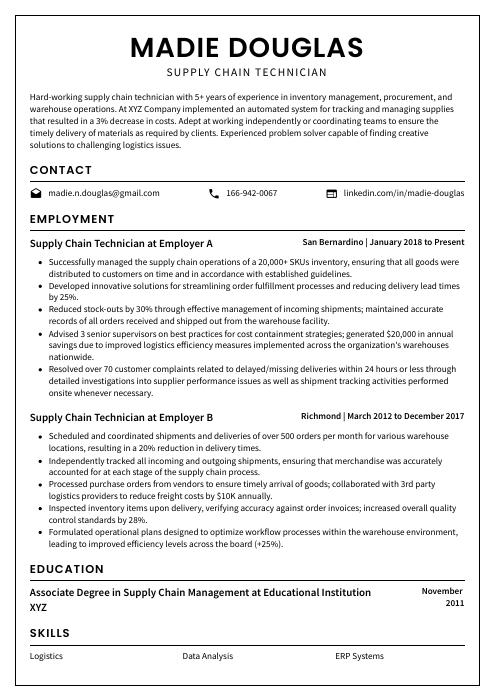

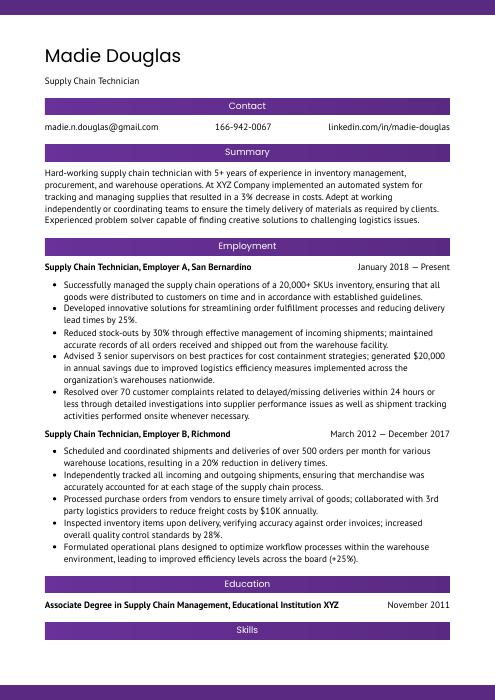

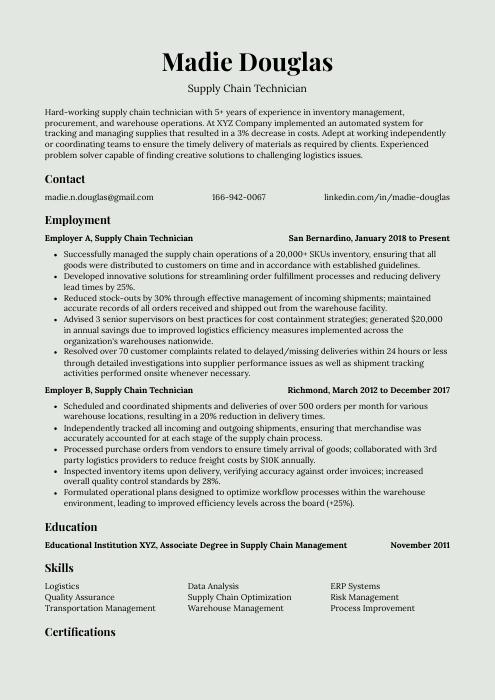

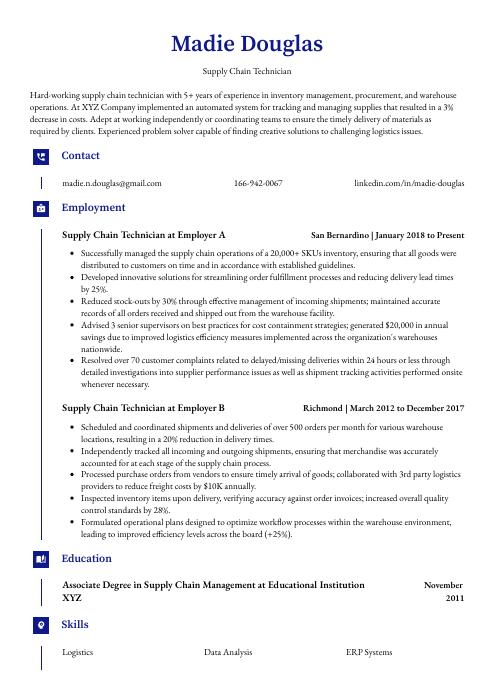

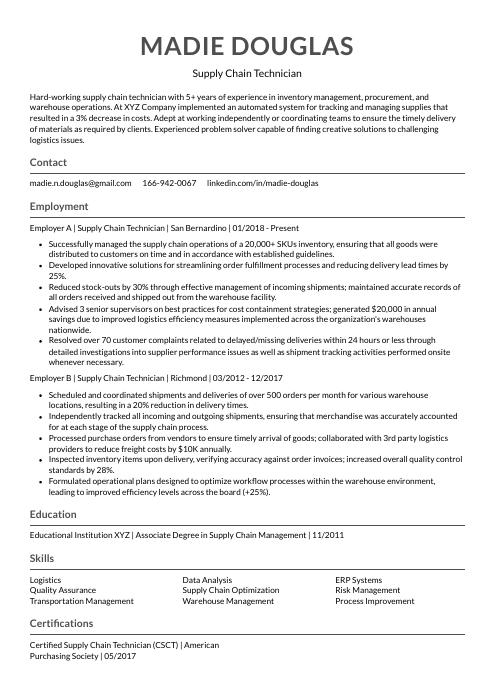

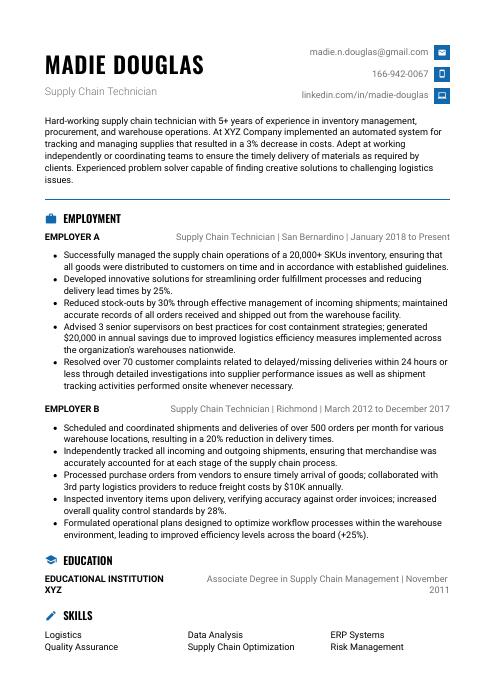

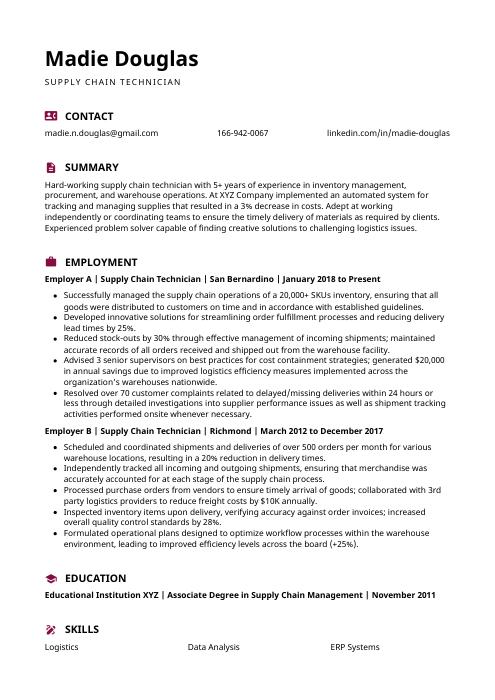

Supply Chain Technician Resume Sample

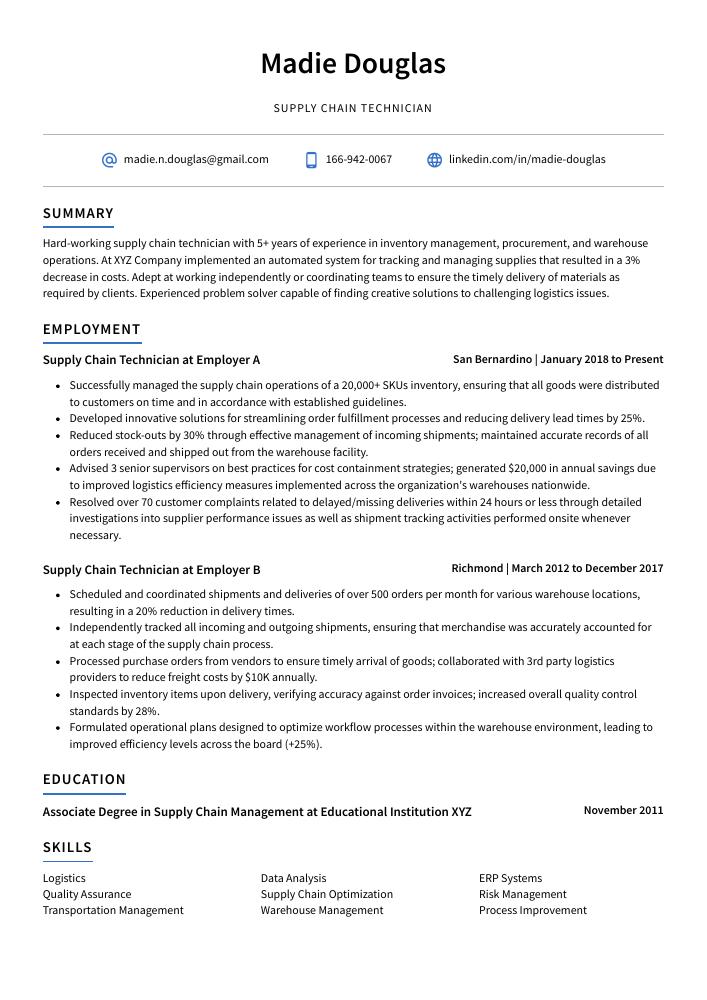

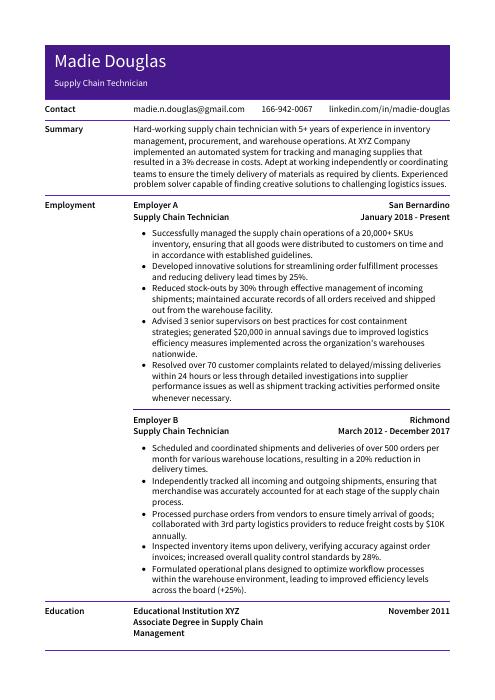

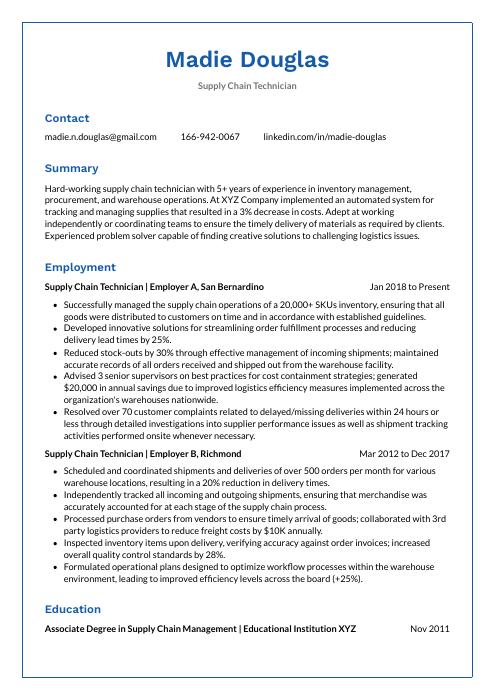

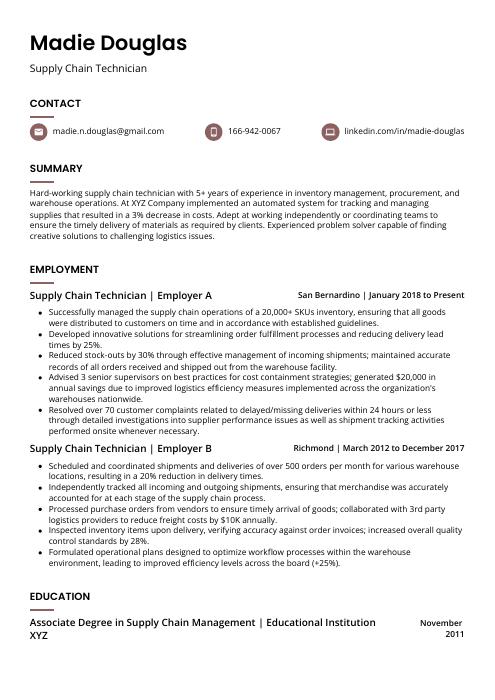

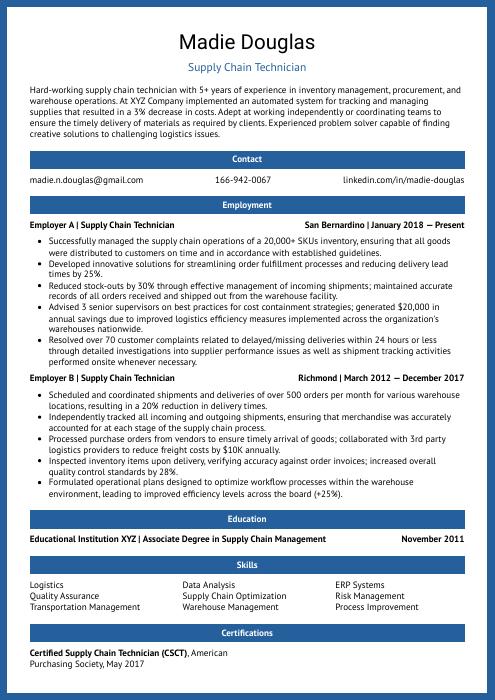

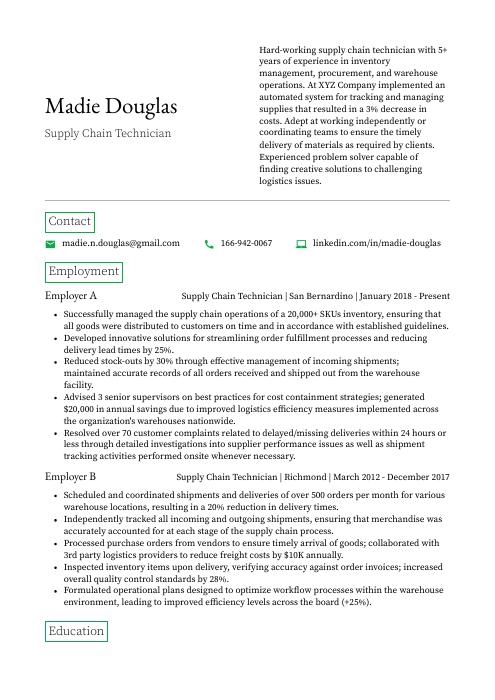

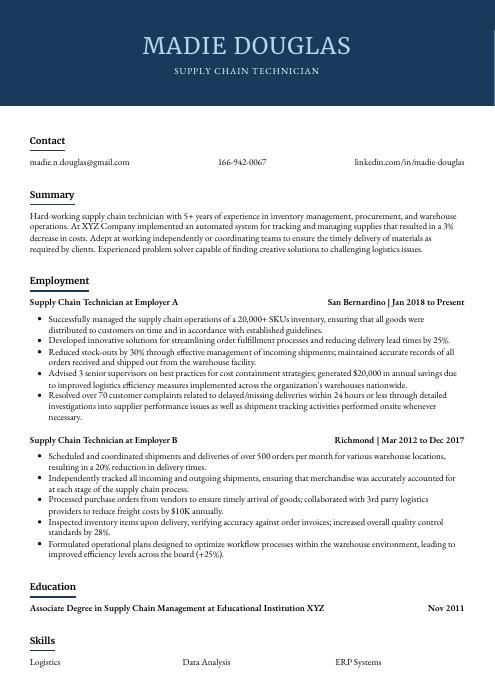

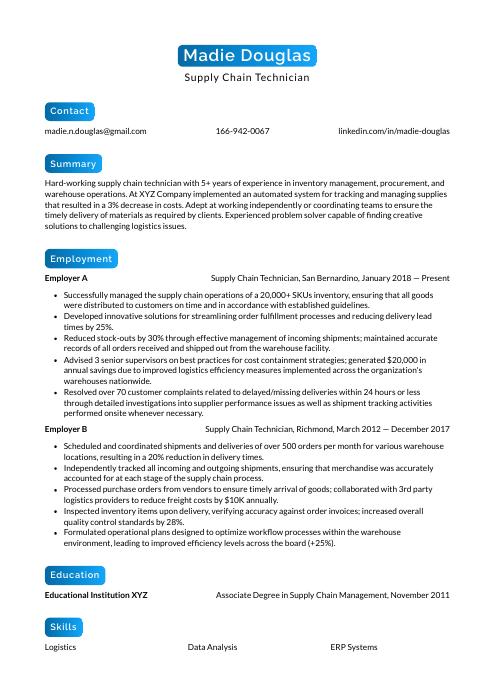

Madie Douglas

Supply Chain Technician

[email protected]

166-942-0067

linkedin.com/in/madie-douglas

Summary

Hard-working supply chain technician with 5+ years of experience in inventory management, procurement, and warehouse operations. At XYZ Company implemented an automated system for tracking and managing supplies that resulted in a 3% decrease in costs. Adept at working independently or coordinating teams to ensure the timely delivery of materials as required by clients. Experienced problem solver capable of finding creative solutions to challenging logistics issues.

Experience

Supply Chain Technician, Employer A

San Bernardino, Jan 2018 – Present

- Successfully managed the supply chain operations of a 20,000+ SKUs inventory, ensuring that all goods were distributed to customers on time and in accordance with established guidelines.

- Developed innovative solutions for streamlining order fulfillment processes and reducing delivery lead times by 25%.

- Reduced stock-outs by 30% through effective management of incoming shipments; maintained accurate records of all orders received and shipped out from the warehouse facility.

- Advised 3 senior supervisors on best practices for cost containment strategies; generated $20,000 in annual savings due to improved logistics efficiency measures implemented across the organization’s warehouses nationwide.

- Resolved over 70 customer complaints related to delayed/missing deliveries within 24 hours or less through detailed investigations into supplier performance issues as well as shipment tracking activities performed onsite whenever necessary.

Supply Chain Technician, Employer B

Richmond, Mar 2012 – Dec 2017

- Scheduled and coordinated shipments and deliveries of over 500 orders per month for various warehouse locations, resulting in a 20% reduction in delivery times.

- Independently tracked all incoming and outgoing shipments, ensuring that merchandise was accurately accounted for at each stage of the supply chain process.

- Processed purchase orders from vendors to ensure timely arrival of goods; collaborated with 3rd party logistics providers to reduce freight costs by $10K annually.

- Inspected inventory items upon delivery, verifying accuracy against order invoices; increased overall quality control standards by 28%.

- Formulated operational plans designed to optimize workflow processes within the warehouse environment, leading to improved efficiency levels across the board (+25%).

Skills

- Logistics

- Data Analysis

- ERP Systems

- Quality Assurance

- Supply Chain Optimization

- Risk Management

- Transportation Management

- Warehouse Management

- Process Improvement

Education

Associate Degree in Supply Chain Management

Educational Institution XYZ

Nov 2011

Certifications

Certified Supply Chain Technician (CSCT)

American Purchasing Society

May 2017

1. Summary / Objective

A resume summary/objective is the first thing a hiring manager will read, so it is important to make sure you write one that grabs their attention. As a supply chain technician, your summary should highlight any experience or certifications you have in logistics and inventory management. You could also mention how many years of experience you have working with various software systems, as well as any special projects or initiatives that resulted from your work.

Below are some resume summary examples:

Proficient supply chain technician with 5+ years of experience in inventory management and logistics. At XYZ, managed warehouse operations for 40+ clients across the US and Canada. Developed effective forecasting models to predict demand and reduce stock-outs by 25%. Innovative problem solver who quickly identifies issues within the supply chain process. Proven track record of getting things done efficiently while maintaining a high level of accuracy.

Seasoned supply chain technician with 8+ years of experience in lean warehouse management and inventory control. Highly skilled at forecasting demand, optimizing stocking levels, and creating efficient processes that ensure accurate deliveries. Achieved a 15% reduction in delivery times for XYZ Company by streamlining the order fulfillment process. Looking to bring this expertise to ABC Supplies as their next supply chain technician.

Diligent and experienced supply chain technician with 5+ years of experience in managing and maintaining supply chains. At XYZ, planned and implemented a new system for inventory tracking that increased accuracy by 20%. Saved an estimated $125,000 annually through cost-effective modifications to the distribution process. Proven ability to use data analysis tools like MS Excel effectively to improve operations and reduce costs.

Professional supply chain technician with 10+ years of experience in operations management and logistics. Seeking to leverage expertise in inventory control, systems optimization, and supply chain analytics for ABC Co. At XYZ Inc., improved efficiency by 20% via streamlined delivery routes and automated tracking system implementation. Received “Top Performer” award for consistently meeting deadlines on time.

Detail-oriented supply chain technician with 5+ years of experience in inventory control and order fulfillment for a diverse range of products. Proven ability to work under pressure, multitask efficiently, manage multiple projects simultaneously and ensure accuracy in every aspect. Seeking to join ABC Company where I can leverage my expertise to drive supply chain operations more effectively.

Committed supply chain technician with 3+ years of experience in inventory management, warehouse operations and logistics. Skilled at optimizing supply chains for efficiency and cost savings. At XYZ Inc., improved order accuracy from 70% to 98%. Developed a new system that reduced shipping costs by 10%. Proven ability to handle high-volume demand while maintaining quality control standards.

Energetic and detail-oriented supply chain technician with 3+ years of experience in streamlining processes to ensure on-time deliveries. Skilled at tracking and managing inventory, analyzing data for emerging trends, and developing strategies to optimize the supply chain process. At XYZ Company, significantly reduced backorders by 20% through effective forecasting techniques.

Enthusiastic supply chain technician with 5+ years of experience in inventory management and supply chain operations. Adept at troubleshooting issues, implementing process improvements, and developing automated workflows to optimize the efficiency of supply chains. Looking to contribute my expertise to ABC Company’s supply chain operations for their global customer base.

2. Experience / Employment

In the experience section, you should list your employment history in reverse chronological order. Stick to bullet points when writing this section; it makes the information easier for readers to digest quickly.

When discussing what you did at each job, provide detail and quantifiable results where applicable. For example, instead of saying “Managed inventory,” you could say something like “Maintained an accurate inventory of over 2,000 items across five warehouses using a custom-built software system that resulted in a 20% reduction in stock discrepancies.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Coordinated

- Optimized

- Scheduled

- Shipped

- Tracked

- Analyzed

- Forecasted

- Managed

- Processed

- Resolved

- Inspected

- Stocked

- Loaded

- Unloaded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Represented the company in various supply chain operations, including inventory management, procurement and product delivery services; increased overall efficiency by 20%.

- Unloaded incoming goods from suppliers to storage facilities while ensuring accuracy of shipment contents with minimal discrepancies (< 5%).

- Utilized data-driven methods to analyze customer demand patterns and optimize order quantity/placement strategies for maximum profitability.

- Effectively coordinated the transportation of finished products between warehouses on a weekly basis; reduced shipping costs by 25% through strategic route planning & scheduling optimization techniques.

- Optimized warehouse organization protocols to ensure safe handling practices were followed during stock loading/unloading activities and achieved zero safety incidents throughout entire tenure as Supply Chain Technician.

- Compiled and maintained accurate inventory records for over 11,000 products across 4 warehouses; reduced stock discrepancies by 35%.

- Analyzed and monitored supply chain performance indicators such as delivery times, order fill rates and backorder levels to ensure efficient operations.

- Reliably handled goods receipt processes from suppliers in timely manner, ensuring that all relevant information was correctly documented before being transferred into the warehouse management system (WMS).

- Facilitated communication between internal departments on a daily basis to optimize scheduling of orders for production lines; successfully processed 600+ orders per week without any delays or errors in shipment data accuracy.

- Loaded shipments onto trucks with forklift equipment while adhering to safety protocols and regulations; ensured that outgoing pallets were properly labeled with product descriptions prior to departure from the facility.

- Tracked and monitored supply chain activities of over 200 suppliers, ensuring that all orders were fulfilled in a timely and cost-efficient manner; reduced delivery time by 30% with improved communication.

- Competently managed inventory levels to reduce stockouts and errors in the warehouse, resulting in a 25% reduction on backorder shipments for the year.

- Reorganized receiving department layout to enable better management of goods flow throughout the warehouse; decreased cycle count discrepancies by 40%.

- Mentored junior staff members on proper supply chain procedures and practices, leading to enhanced cooperation between departments across all shifts within the facility.

- Shipped out 1 million units per month while adhering strictly to safety regulations; increased shipment accuracy rate from 90% up to 98%.

- Spearheaded the optimization of supply chain operations, resulting in a 25% reduction in transportation costs and an increase of 7% efficiency within the organization.

- Introduced new inventory management processes to help ensure accuracy and reduce stockouts; achieved 100% compliance with all vendor orders for 3 consecutive quarters.

- Streamlined delivery times by 10%, reducing lead time from order placement to product arrival at customer sites by 15%.

- Revised existing procedures pertaining to supplier requirements, quality assurance standards and risk mitigation strategies; improved overall reliability of suppliers by 20%.

- Substantially reduced warehouse errors through implementation of automated tracking systems, resulting in a 50% decrease in delayed shipments over 6 months period.

- Coordinated the transport of materials and products between suppliers, warehouses, retail stores and end customers; improved delivery times by 15% while reducing operational costs by $2,000 per month.

- Presented monthly reports to the supply chain team on inventory levels, stock movement trends and order fulfillment statuses; identified potential areas for improvement that led to a 20% increase in customer satisfaction ratings over 6 months.

- Monitored supplier performance metrics such as lead time reliability, defective item percentage and cost savings achieved versus standard process efficiency benchmarks; reduced overall material costs through optimized purchasing practices by 10%.

- Participated in regular safety checks of vehicles used for transportation according to company policy standards; took necessary steps to reduce environmental impact from fuel usage when scheduling deliveries upcountry.

- Accurately maintained records of all incoming/outgoing shipments using warehouse management systems (WMS); enabled quick access to critical information which greatly facilitated decision-making within the organization’s supply chain operations processes.

- Consistently monitored and tracked inventory levels of over 3000+ products, ensuring stock availability was maintained at all times and reducing backorder scenarios by 25%.

- Structured an efficient supply chain process model to increase order accuracy and delivery time; improved overall customer satisfaction rates by 12% in the last quarter.

- Improved warehouse productivity through strategic placement of materials across 6 distribution centers, optimizing shipping costs while maintaining service level agreements with vendors.

- Stocked shelves with merchandise for store displays according to planograms on a daily basis; reduced shelf replenishment time from 2 hours per day to 1 hour 15 minutes within 3 months’ period.

- Assessed logistics systems performance on a regular basis, identified areas for improvement & implemented solutions that resulted in cost savings of $1 million annually within first year as Supply Chain Technician.

- Expedited the procurement of over $250,000 worth of raw materials and supplies for production processes, ensuring timely delivery with no delays.

- Demonstrated excellent organization and problem-solving skills by managing the supply chain operations in a fast-paced environment; spearheaded cost reduction initiatives that saved 20% on freight costs annually.

- Managed inventory levels to maintain optimal stock in all warehouses while avoiding excesses through rigorous data analysis; reduced out-of-stock incidents from 10% to 2%.

- Meticulously tracked purchases, shipments and returns using industry standard software systems such as SAP & Oracle; increased accuracy across entire process by 33%.

- Prepared purchase orders for suppliers according to specifications provided by buyers, following up regularly on order status and resolving any discrepancies quickly before they became issues.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for someone with experience in inventory management and another may require knowledge of logistics.

It is important to tailor the skills section of your resume to each job you are applying for, as many employers use applicant tracking systems these days which scan resumes for certain keywords before passing them on to a human.

In addition, it is beneficial to elaborate further upon the most relevant skillset by discussing it in more detail elsewhere on your resume (such as within the summary or experience sections).

Below is a list of common skills & terms:

- Data Analysis

- ERP Systems

- Logistics

- Process Improvement

- Quality Assurance

- Risk Management

- Supply Chain Optimization

- Transportation Management

- Warehouse Management

4. Education

Mentioning your education on a resume depends largely on how far along you are in your career. If you just graduated and have no prior experience, include an education section below your resume objective. On the other hand, if you have plenty of work experience to showcase, it is perfectly acceptable to omit this section altogether.

If including an education section, try to mention courses or subjects related to the supply chain technician role for which you are applying.

Associate Degree in Supply Chain Management

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise and proficiency in a certain field. They show potential employers that you have taken the time and effort to become certified, which can be an important factor when it comes to getting hired.

When applying for jobs, make sure to include any certifications relevant to the position on your resume. This will give hiring managers more confidence in considering you as a candidate for their open positions.

Certified Supply Chain Technician (CSCT)

American Purchasing Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Madie Douglas, this would be Madie-Douglas-resume.pdf or Madie-Douglas-resume.docx.

7. Cover Letter

Including a cover letter with your job application can be a great way to show potential employers why you’re the perfect candidate for the role. Made up of 2-4 paragraphs, it provides an opportunity for you to provide more detailed information about yourself and highlight key skills that aren’t mentioned in your resume.

Although not always required by recruiters, writing a cover letter is highly recommended as it helps demonstrate your enthusiasm for the position and allows them to get a better idea of who you are as an individual.

Below is an example cover letter:

Dear Haskell,

I am writing to apply for the Supply Chain Technician position at your company. With more than four years of experience working in supply chain and logistics, I have the skills and knowledge needed to be a successful member of your team.

In my current role as a supply chain technician at [company name], I work with a team of five other technicians to manage all aspects of our company’s supply chain, including inventory management, order fulfillment, and shipping. We are responsible for ensuring that all orders are fulfilled on time and that product quality is maintained. In addition to my technical skills, I have excellent communication and interpersonal skills that allow me to effectively work with others.

I am confident that I can be an asset to your team and contribute to the success of your organization. I would welcome the opportunity to discuss my qualifications further with you at your earliest convenience. Thank you for your time and consideration.

Sincerely,

Madie

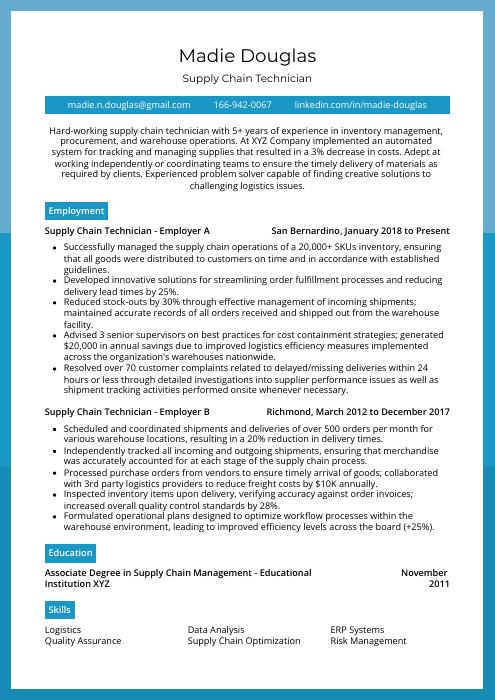

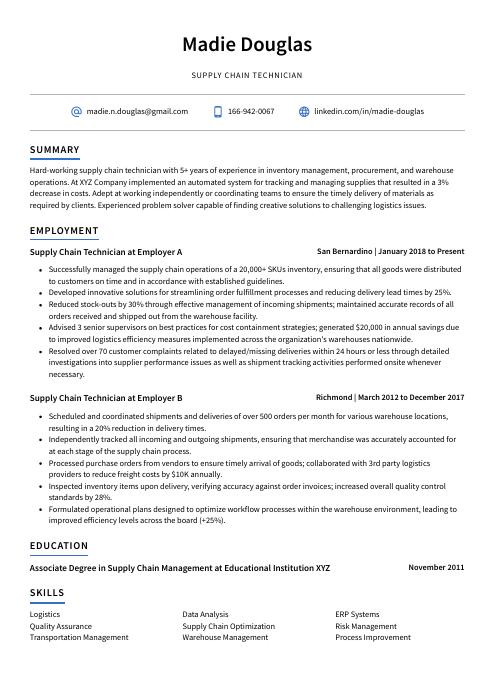

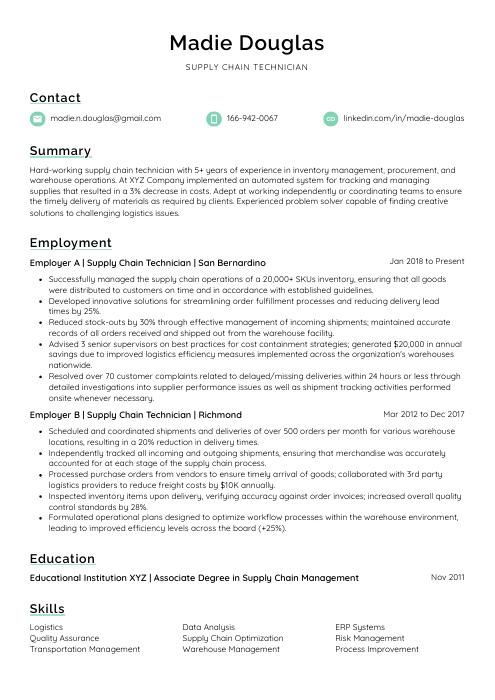

Supply Chain Technician Resume Templates

Pika

Pika Markhor

Markhor Fossa

Fossa Ocelot

Ocelot Quokka

Quokka Bonobo

Bonobo Kinkajou

Kinkajou Cormorant

Cormorant Jerboa

Jerboa Saola

Saola Gharial

Gharial Indri

Indri Echidna

Echidna Dugong

Dugong Numbat

Numbat Hoopoe

Hoopoe Rhea

Rhea Axolotl

Axolotl Lorikeet

Lorikeet Rezjumei

Rezjumei