Supply Chain Engineer Resume Guide

Supply chain engineers are responsible for designing, implementing and managing the overall supply chain strategy. They analyze the current processes in order to identify areas of improvement and cost savings, develop new strategies based on customer needs, create process flow diagrams and ensure that all stakeholders understand their roles within the system.

Your expertise in supply chain management and engineering would prove invaluable to any organization. However, employers need an introduction to you first; your resume must be up-to-date and demonstrate why they should hire you.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

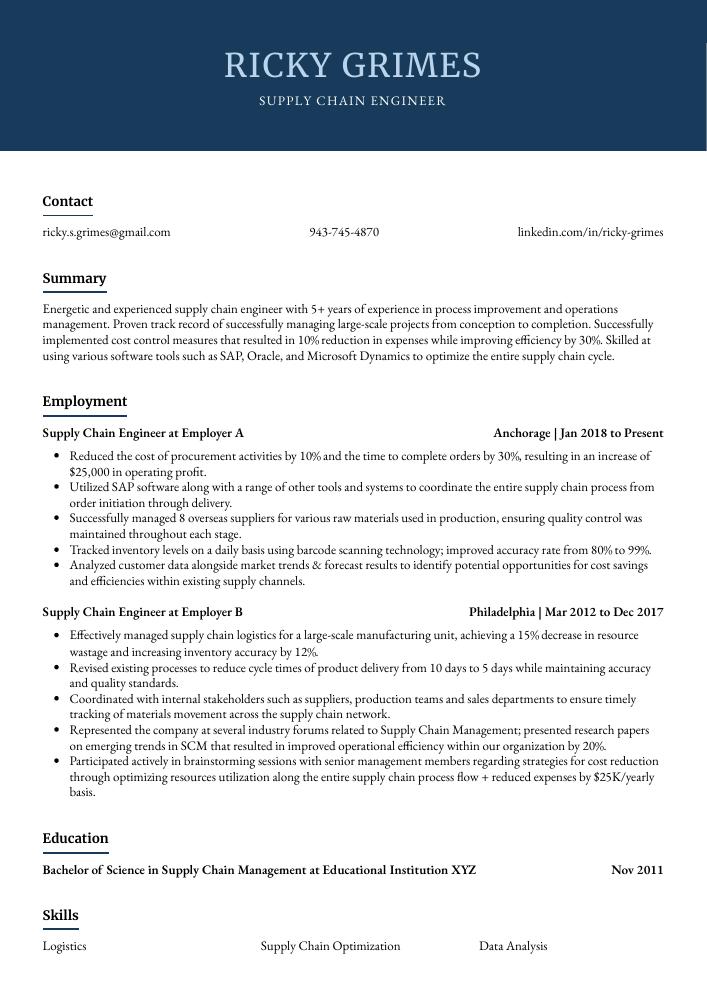

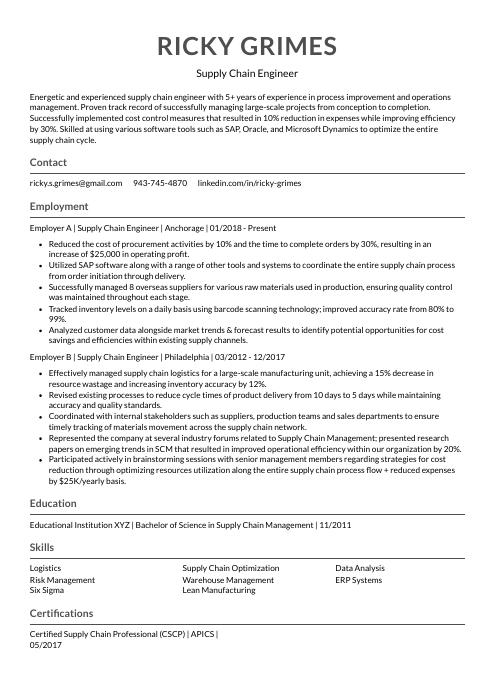

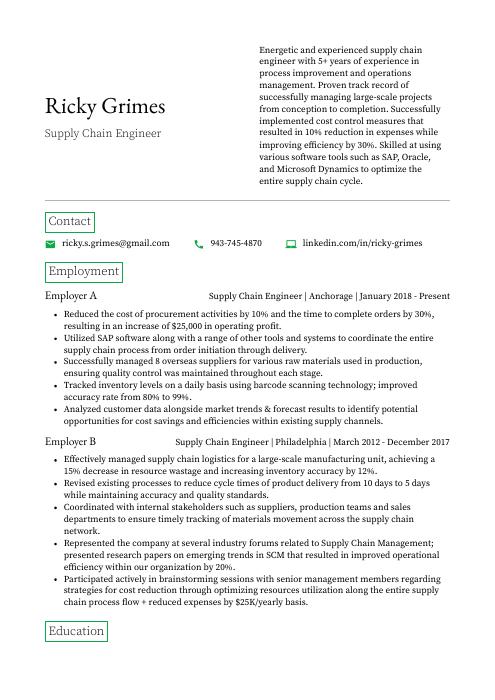

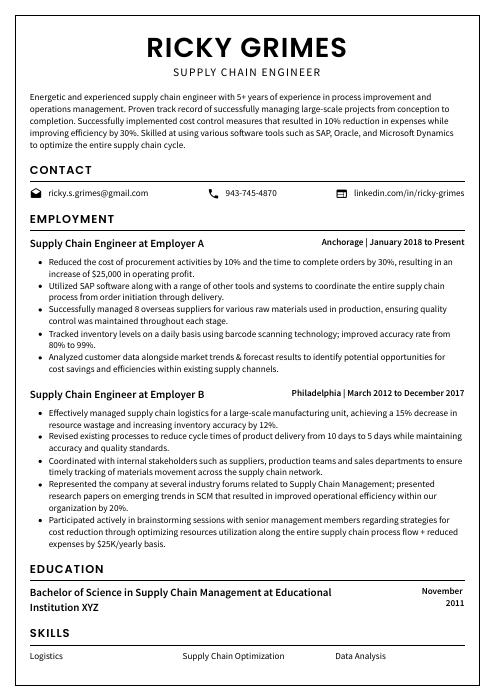

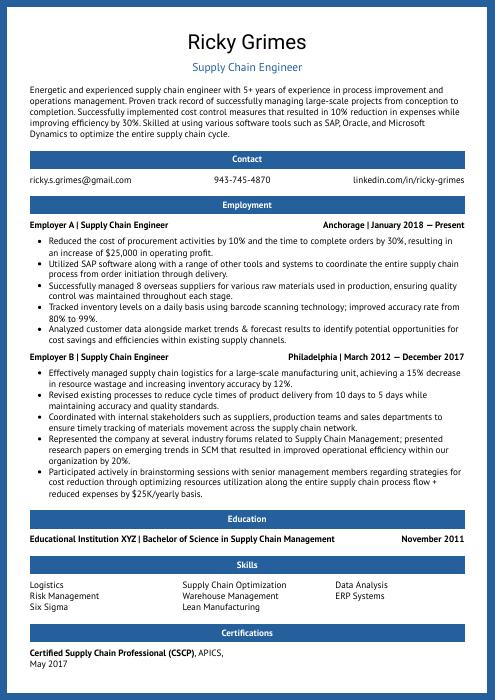

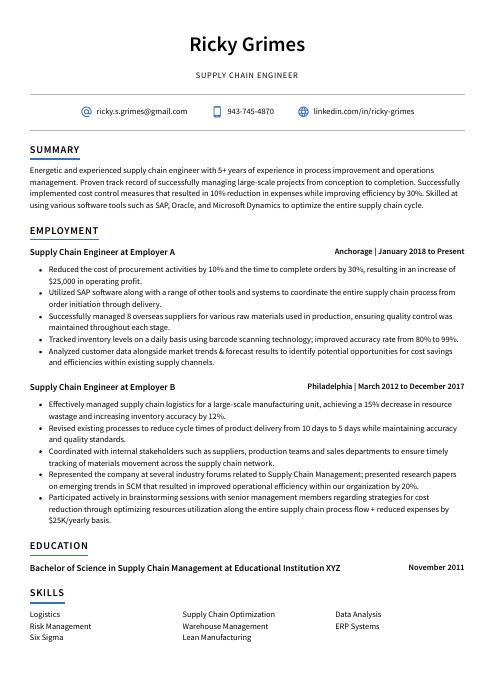

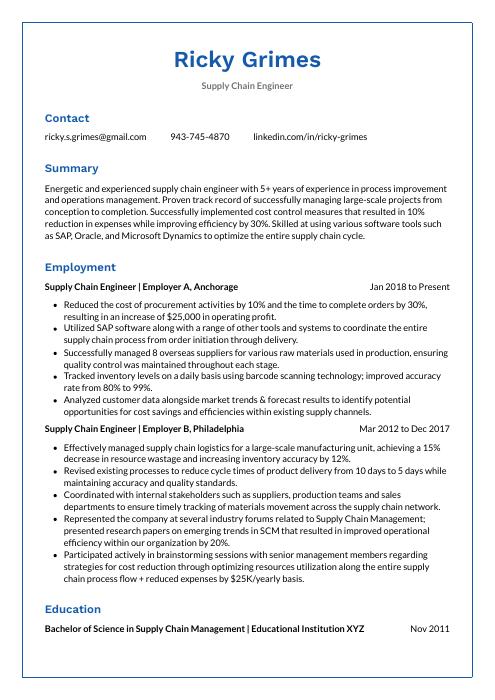

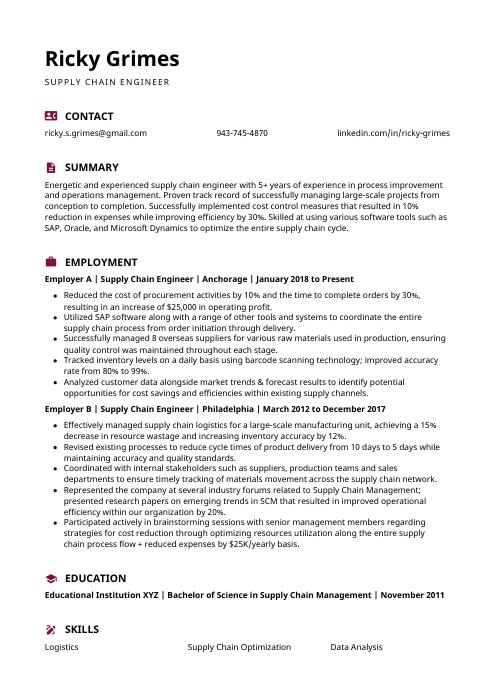

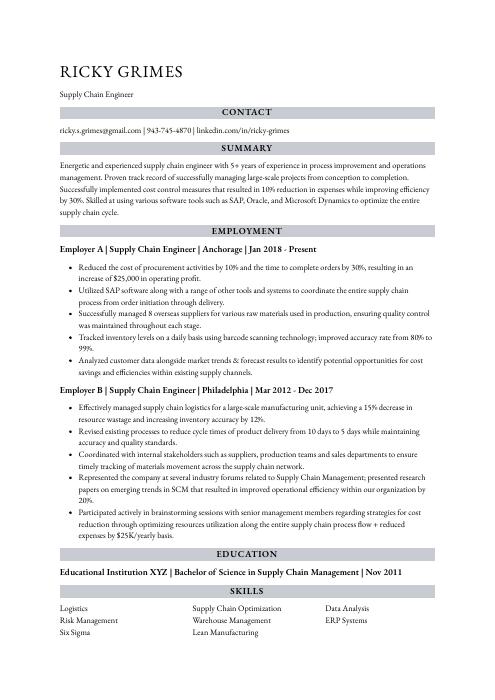

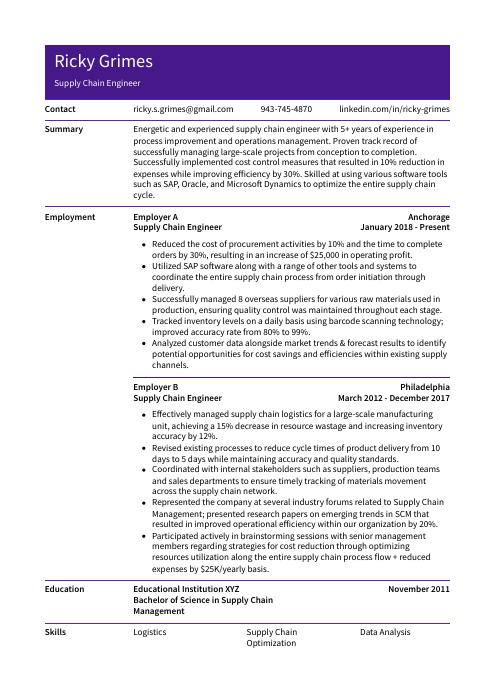

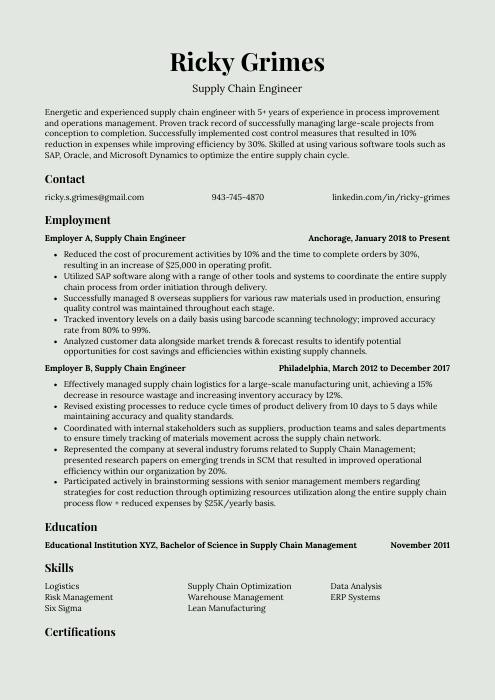

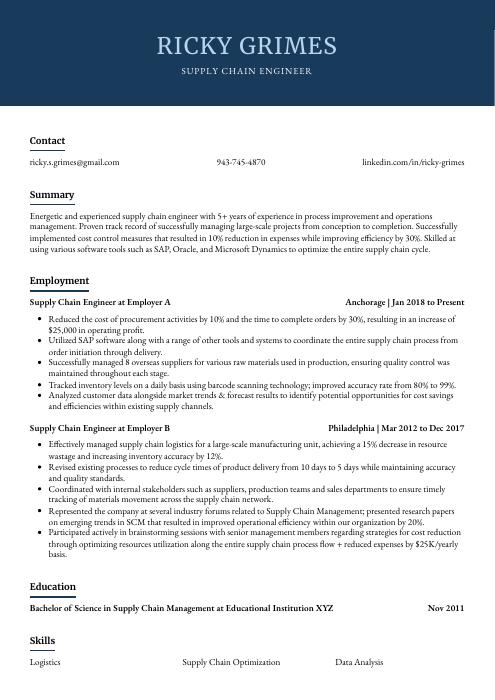

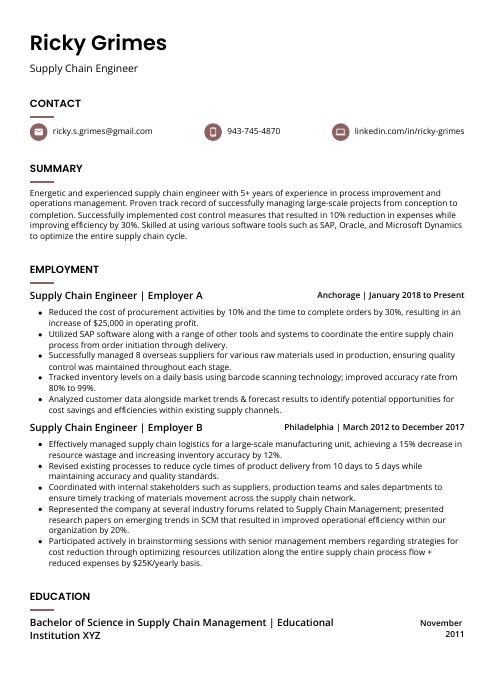

Supply Chain Engineer Resume Sample

Ricky Grimes

Supply Chain Engineer

ricky.s.grimes@gmail.com

943-745-4870

linkedin.com/in/ricky-grimes

Summary

Energetic and experienced supply chain engineer with 5+ years of experience in process improvement and operations management. Proven track record of successfully managing large-scale projects from conception to completion. Successfully implemented cost control measures that resulted in 10% reduction in expenses while improving efficiency by 30%. Skilled at using various software tools such as SAP, Oracle, and Microsoft Dynamics to optimize the entire supply chain cycle.

Experience

Supply Chain Engineer, Employer A

Anchorage, Jan 2018 – Present

- Reduced the cost of procurement activities by 10% and the time to complete orders by 30%, resulting in an increase of $25,000 in operating profit.

- Utilized SAP software along with a range of other tools and systems to coordinate the entire supply chain process from order initiation through delivery.

- Successfully managed 8 overseas suppliers for various raw materials used in production, ensuring quality control was maintained throughout each stage.

- Tracked inventory levels on a daily basis using barcode scanning technology; improved accuracy rate from 80% to 99%.

- Analyzed customer data alongside market trends & forecast results to identify potential opportunities for cost savings and efficiencies within existing supply channels.

Supply Chain Engineer, Employer B

Philadelphia, Mar 2012 – Dec 2017

- Effectively managed supply chain logistics for a large-scale manufacturing unit, achieving a 15% decrease in resource wastage and increasing inventory accuracy by 12%.

- Revised existing processes to reduce cycle times of product delivery from 10 days to 5 days while maintaining accuracy and quality standards.

- Coordinated with internal stakeholders such as suppliers, production teams and sales departments to ensure timely tracking of materials movement across the supply chain network.

- Represented the company at several industry forums related to Supply Chain Management; presented research papers on emerging trends in SCM that resulted in improved operational efficiency within our organization by 20%.

- Participated actively in brainstorming sessions with senior management members regarding strategies for cost reduction through optimizing resources utilization along the entire supply chain process flow + reduced expenses by $25K/yearly basis.

Skills

- Logistics

- Supply Chain Optimization

- Data Analysis

- Risk Management

- Warehouse Management

- ERP Systems

- Six Sigma

- Lean Manufacturing

Education

Bachelor of Science in Supply Chain Management

Educational Institution XYZ

Nov 2011

Certifications

Certified Supply Chain Professional (CSCP)

APICS

May 2017

1. Summary / Objective

The summary or objective at the top of your resume is like a movie trailer – it provides the hiring manager with essential bits of information and, if written correctly, should compel them to read on. In this section you can highlight your experience in supply chain engineering and how you have improved processes for companies in the past. You could also mention any certifications or awards that demonstrate your expertise in this field as well as any special projects or initiatives you’ve been involved with.

Below are some resume summary examples:

Well-rounded supply chain engineer with 6 years of experience in manufacturing and logistics. Seeking to join ABC Company to utilize expertise in developing efficient supply chains, driving cost savings, and enhancing customer service levels. At XYZ, achieved a 20% reduction in inventory costs while improving order fulfillment accuracy by 45%. Proven ability to create innovative solutions that maximize efficiency within the organization’s operations.

Detail-oriented and results-driven Supply Chain Engineer with 5+ years of experience in optimizing supply chain processes, reducing costs and improving efficiency. Proven track record of successfully identifying cost savings opportunities across multiple projects while managing complex global procurement networks. Skilled at developing customized solutions to eliminate bottlenecks and leveraging advanced data analytics tools for decision making.

Professional supply chain engineer with 10 years of experience in inventory management, process optimization, and demand/supply planning. Skilled at developing and implementing end-to-end supply chain strategies to drive cost savings while improving customer service levels. At XYZ company achieved a 20% reduction in inventory costs while maintaining optimal stock levels 95% of the time. Experienced user of ERP systems (SAP & Oracle).

Determined supply chain engineer with 7+ years of experience in designing and implementing supply chains for large-scale industries. At XYZ, improved efficiency by 25% through a process improvement initiative that included introducing lean principles to the warehouse operations. Looking to join ABC Corp as its next Supply Chain Engineer and bring my problem-solving skillset to bear on their complex logistical challenges.

Diligent and experienced supply chain engineer with 7+ years of experience in logistics and operations management. Highly effective at streamlining processes to reduce costs and increase efficiency, resulting in a 10% reduction in transportation expenses for Company X during 2020. Seeking to join ABC Tech as their next Supply Chain Engineer to develop smarter solutions and drive the company’s growth.

Enthusiastic supply chain engineer with 3+ years of experience in the manufacturing industry. Skilled at developing and implementing innovative solutions to optimize supply chain operations from end-to-end. Adept at leading cross-functional projects and reducing costs by 20%. At XYZ, designed a new inventory tracking system that reduced stockouts by 25%, resulting in cost savings of $30K/month.

Amicable and organized supply chain engineer with 5+ years of experience leading the successful design, implementation, and optimization of global logistics systems. At XYZ Industries, crafted a cost-effective system that reduced transportation expenses by 25%. Committed to bringing this expertise to ABC Corporation’s mission to increase customer satisfaction through streamlined processes.

Proficient supply chain engineer with 7+ years of experience in global supply chain management. Expertise in data analysis, inventory control, and logistics optimization. Proven track record of reducing costs by 11% through process improvements and streamlining operations at Company X. Looking to leverage these skills to optimize the efficiency of ABC Supply Chain’s processes and systems.

2. Experience / Employment

Next comes the work history section, which should be written in reverse chronological order. This means your most recent role is listed at the top.

Stick to bullet points when providing details on what you did, as this allows the reader to quickly digest the information. You want to include quantifiable results and explain how they were achieved; for example, instead of saying “Reduced inventory costs,” you could say, “Implemented a new supply chain management system that resulted in an 8% reduction in inventory costs.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Managed

- Optimized

- Monitored

- Forecasted

- Scheduled

- Analyzed

- Implemented

- Streamlined

- Resolved

- Negotiated

- Collaborated

- Shipped

- Tracked

- Coordinated

- Automated

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Structured

- Utilized

Below are some example bullet points:

- Resolved numerous supply chain issues, resulting in a 7% reduction of inventory costs and an 8-week turnaround time for new orders.

- Forecasted demand with 97% accuracy and tracked over 100 metric KPIs to identify risks within the organization’s global supply chain network; implemented strategies that improved order lead times by 20%.

- Negotiated and managed contracts with third party suppliers to ensure competitive pricing, on-time delivery of goods, quality assurance standards, as well as secure long term relationships.

- Competently designed & executed automated processes such as Warehouse Management Systems (WMS) which optimized warehouse operations efficiency by 40%.

- Facilitated continuous improvement initiatives throughout the entire supply chain process; generated cost savings totaling $1 million annually due to successful implementations of Lean Manufacturing principles & practices.

- Optimized the supply chain process, reducing order processing time by 25% and inventory costs by $20K.

- Improved distribution accuracy up to 99%, eliminating customer complaints due to mis-shipments or wrong orders.

- Collaborated with stakeholders in production planning, forecasting and scheduling of shipments; achieved on-time delivery rate of 90%.

- Spearheaded the development of an automated ordering system that enabled faster tracking & tracing along with reduced paperwork errors from 4% to 0%.

- Meticulously identified areas for improvement within the supply chain network which resulted in a 10% decrease in overall shipping times and costs per shipment cycle.

- Reorganized supply chain processes to create cost savings of $55,000 annually and improved delivery times by 20%.

- Compiled data from suppliers around the globe to identify inefficiencies and develop strategies for streamlining operations; reduced supply chain costs by over 10% within 6 months.

- Advised senior management on best practices related to inventory control, order fulfillment and logistics optimization while adhering strictly to industry standards & regulations.

- Structured innovative processes that enabled better tracking of shipments across borders, resulting in an impressive 30% decrease in delays due to customs clearance issues.

- Independently managed all aspects of supply chain planning including forecasting demand, ordering materials/products and monitoring stock levels; decreased out-of-stock rates by 25%.

- Streamlined order processing systems to reduce inventory levels and improve supply chain accuracy by 15%.

- Shipped over 1,000 orders per day on time with a 99% success rate, significantly increasing customer satisfaction scores.

- Accurately forecasted demand for seasonal products, resulting in an increase of $25K in revenue within the last 6 months.

- Introduced innovative technologies such as RFID tracking and automated warehouse solutions to optimize existing processes; decreased delivery times from 4 days to 3 days across all locations worldwide.

- Implemented changes that improved operational efficiency by 35%, saving $20K annually in labor costs while reducing stockouts by 25%.

- Reliably managed a multi-million dollar supply chain network, optimizing the capital expenditure budget by 15%.

- Achieved cost savings of over $250K annually through strategic sourcing and supplier negotiations; improved product availability for customers worldwide.

- Presented innovative solutions to streamline distribution processes and reduce inventory levels in 5 warehouses across 3 continents; resulting in an 8% reduction of outbound shipping costs.

- Automated order fulfillment system with customized software, increasing delivery accuracy from 72% to 90%.

- Scheduled daily operations for warehouse staff using advanced scheduling algorithms that decreased turnaround time by 30 minutes per shipment on average.

- Prepared and implemented supply chain optimization designs for 10+ projects, reducing inventory and costs by 25%.

- Managed the logistical flow of raw materials and finished goods across 8 warehouses; increased delivery accuracy to 95%.

- Efficiently developed automated processes using cutting-edge software tools such as Warehouse Management Systems (WMS), resulting in a 20% decrease in administrative workloads.

- Monitored warehouse operations on an ongoing basis, identifying cost saving opportunities through improved process flows that saved up to $10K annually.

- Demonstrated expertise in analyzing data from customer order histories, forecasting demand & developing strategies to improve product availability while maintaining desired levels of stock control with minimal inventory investment overhead.

- Actively managed and improved an inventory of over 10,000 items; reduced supply chain costs by 28% while expediting the delivery process.

- Mentored a team of 5 junior supply chain engineers in best practices for optimizing logistics operations; increased efficiency levels by 15%.

- Expedited production processes at 3 manufacturing facilities across 2 states, resulting in $1 million+ cost savings annually due to decreased delays and wastage.

- Formulated strategies for streamlining complex import/export procedures based on data-driven insights from market trends & customer feedback; achieved an 85% accuracy rate in forecasting product demand with minimal errors or discrepancies reported.

- Developed innovative solutions to automate key warehouse management tasks, enabling personnel to complete orders up to 50% faster than before and reducing labor hours by 500+.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might require a candidate to have expertise in supply chain management software, while another might be looking for someone with experience of inventory optimization.

It is important to tailor the skills section of your resume accordingly because many employers use applicant tracking systems that scan resumes for certain keywords before passing them on to human recruiters.

In addition, you should also provide detailed examples and explanations elsewhere in your resume – such as the summary or work experience sections – about how you utilized those particular skills during past roles.

Below is a list of common skills & terms:

- Data Analysis

- ERP Systems

- Lean Manufacturing

- Logistics

- Risk Management

- Six Sigma

- Supply Chain Optimization

- Warehouse Management

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it is a good idea to mention your education below the objective statement. However, if you have significant work experience that should be showcased above all else, omitting an education section may be best.

If including an education section is necessary for the supply chain engineer role you are applying for, make sure to highlight relevant courses and subjects studied related to this field of expertise.

Bachelor of Science in Supply Chain Management

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a certain field. They can be especially useful for those who are looking to break into an industry or switch careers, as they provide evidence of the skills you have acquired.

Including certifications on your resume is important because it shows employers that you have taken the initiative to stay up-to-date with current trends and technologies related to the job position you’re applying for. This will help give them confidence in hiring you over other applicants without certification credentials.

Certified Supply Chain Professional (CSCP)

APICS

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Ricky Grimes, this would be Ricky-Grimes-resume.pdf or Ricky-Grimes-resume.docx.

7. Cover Letter

Cover letters are essential documents for job applications and can help you stand out from the competition. They usually consist of 2 to 4 paragraphs that are separate from your resume, allowing you to provide an introduction as well as highlight why you’re a great fit for the role.

Writing a cover letter is not always required but it’s highly recommended if you want to make sure your application stands out from others. It gives recruiters more insight into who you are and what makes you different than other applicants – something that cannot be achieved with just a resume alone.

Below is an example cover letter:

Dear Robb,

I am writing to apply for the Supply Chain Engineer position at XYZ Corporation. With my experience in supply chain management and engineering, as well as my knowledge of lean manufacturing principles, I am confident that I can contribute to the success of your organization.

In my current role as Supply Chain Manager at ABC Company, I oversee all aspects of supply chain operations, from procurement and inventory management to transportation and logistics. I have successfully implemented lean manufacturing principles throughout our facility, which has resulted in increased efficiency and productivity. In addition, I have developed strong relationships with suppliers and customers alike, which has helped us maintain a high level of customer satisfaction.

I am knowledgeable in a variety of software applications related to supply chain management, including SAP R/3 and Microsoft Dynamics AX. In addition, I have a solid understanding of statistical analysis methods such as Six Sigma and Kanban. My analytical skills are further evidenced by the fact that I have authored several papers on topics related to supply chain management that have been published in industry-leading journals.

I am excited about the opportunity to bring my experience and knowledge to XYZ Corporation. I believe that I can be an asset to your team and look forward to contributing to your company’s success. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions or would like additional information about my qualifications.

Sincerely,

Ricky

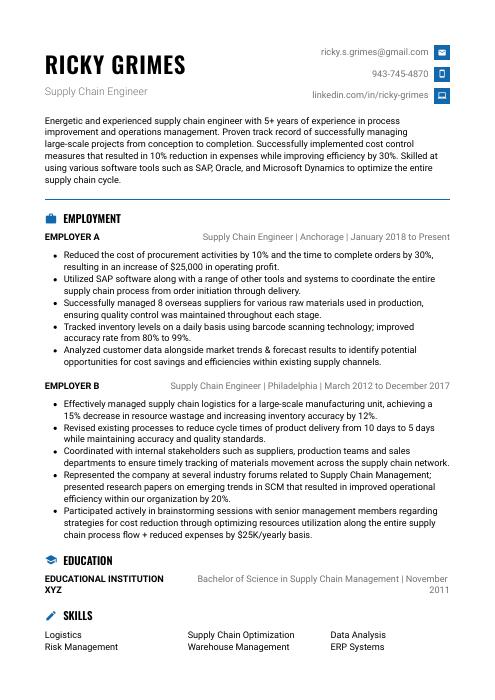

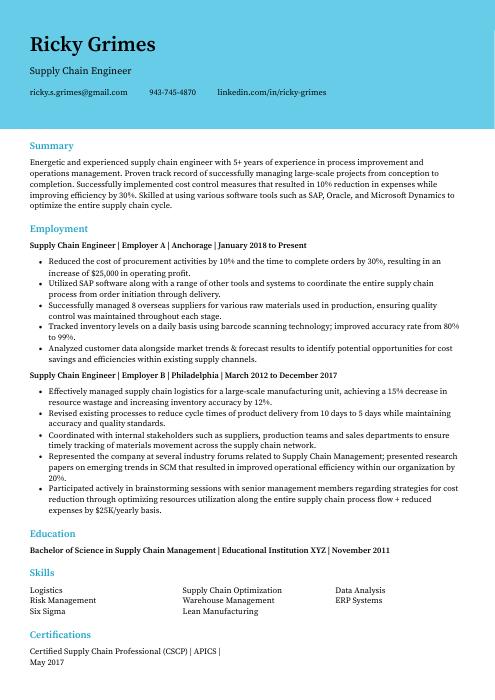

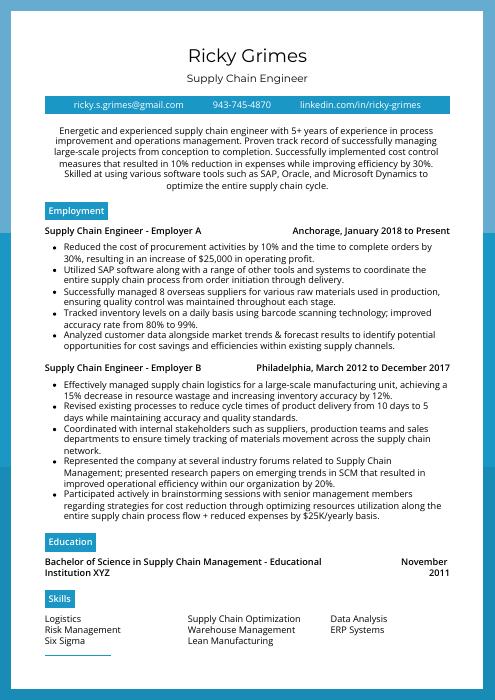

Supply Chain Engineer Resume Templates

Indri

Indri Jerboa

Jerboa Kinkajou

Kinkajou Quokka

Quokka Echidna

Echidna Dugong

Dugong Rhea

Rhea Cormorant

Cormorant Ocelot

Ocelot Axolotl

Axolotl Markhor

Markhor Hoopoe

Hoopoe Numbat

Numbat Pika

Pika Saola

Saola Bonobo

Bonobo Fossa

Fossa Gharial

Gharial Lorikeet

Lorikeet Rezjumei

Rezjumei