Spray Technician Resume Guide

Spray Technicians are responsible for operating and maintaining equipment that applies coatings, paint, sealants, adhesives, and other materials to surfaces. They must set up the material application process according to customer specifications and safety protocols before performing quality control checks on finished products. Additionally, Spray Technicians troubleshoot malfunctions in equipment or processes as needed.

Your knack for spraying is unmatched, but potential employers don’t know how great you are yet. To make them aware of your expertise in the field, it’s important to compose a resume that highlights your experience and accomplishments.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

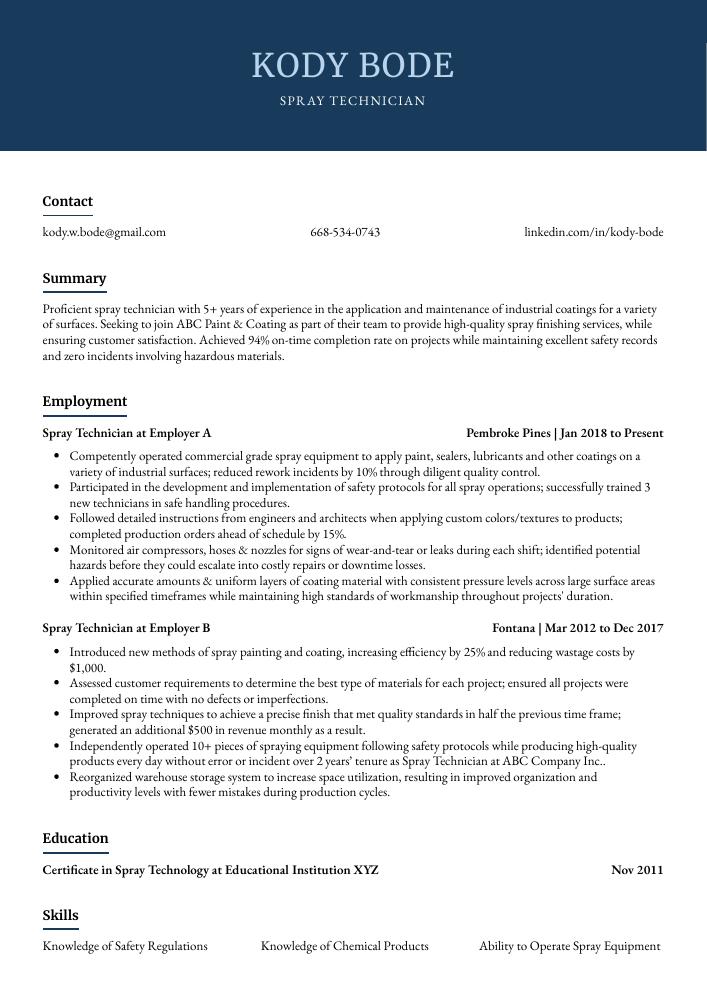

Spray Technician Resume Sample

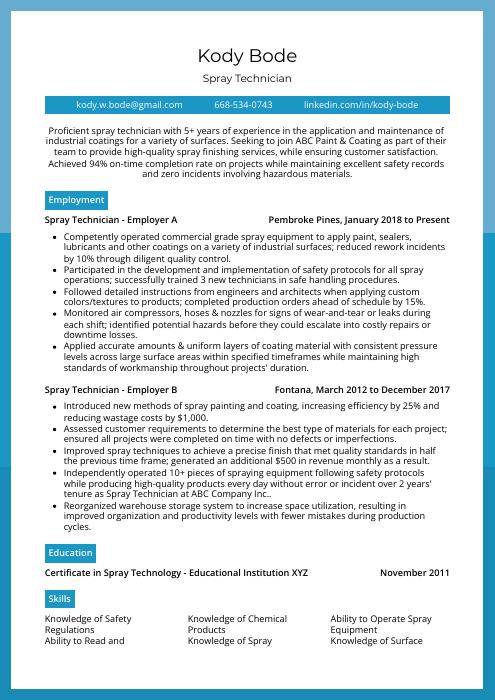

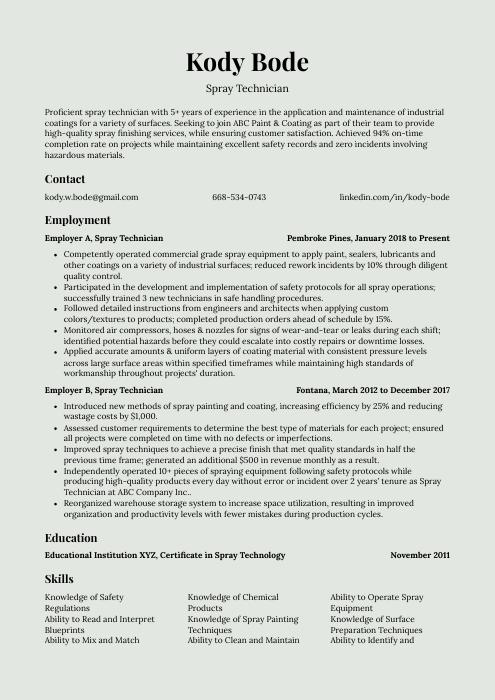

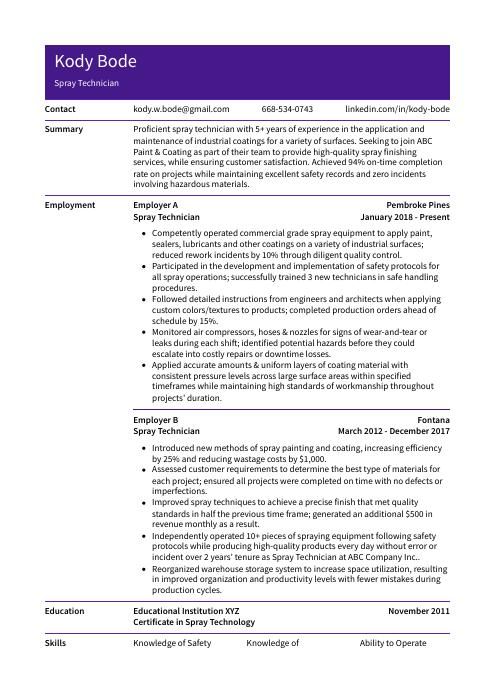

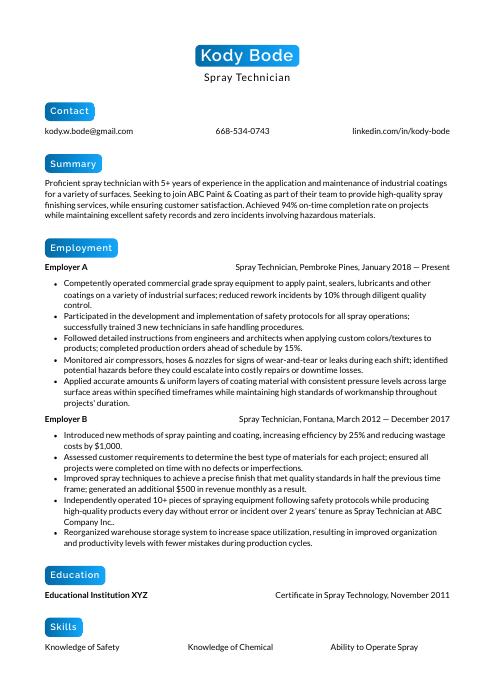

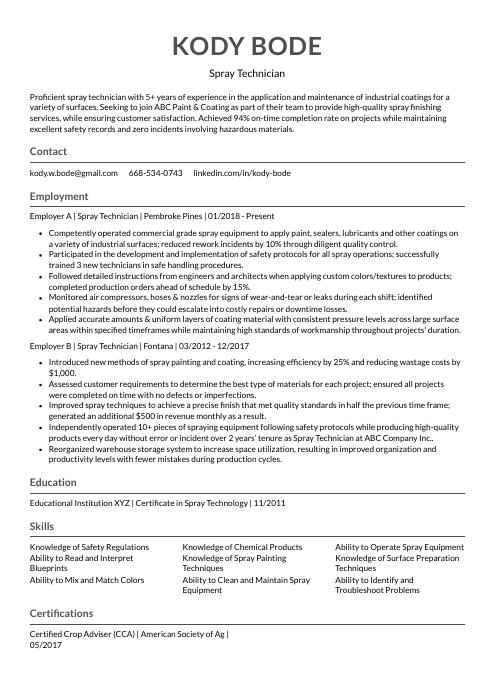

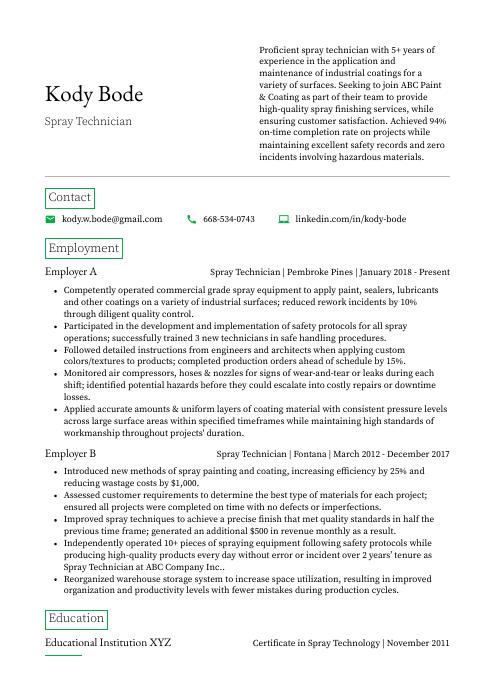

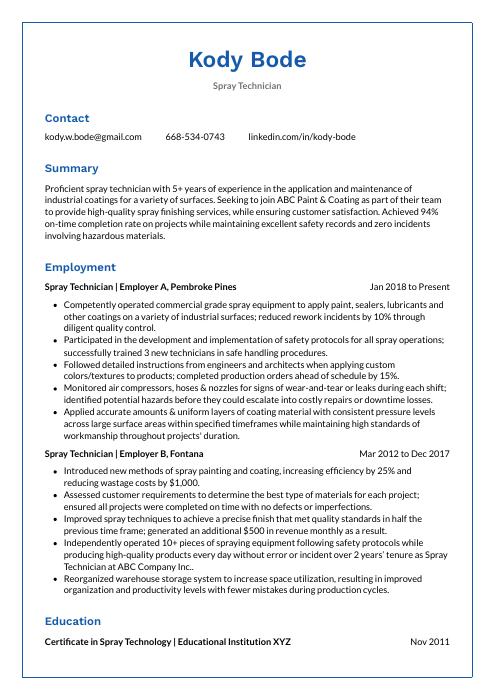

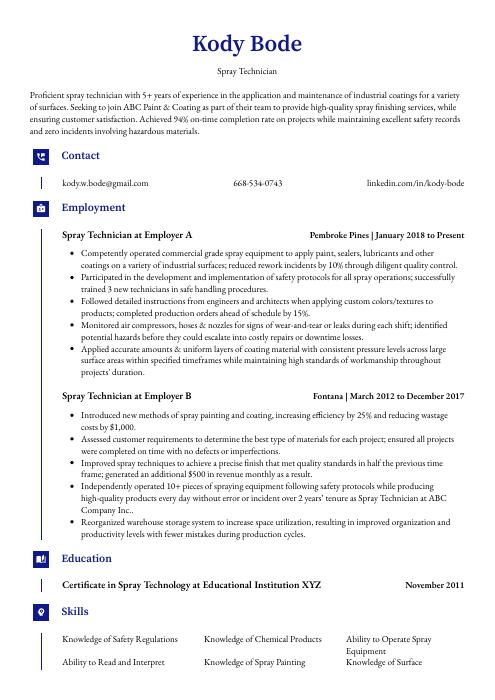

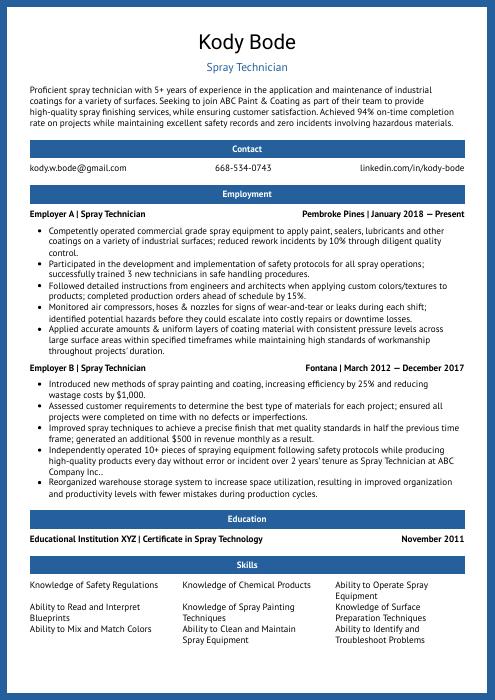

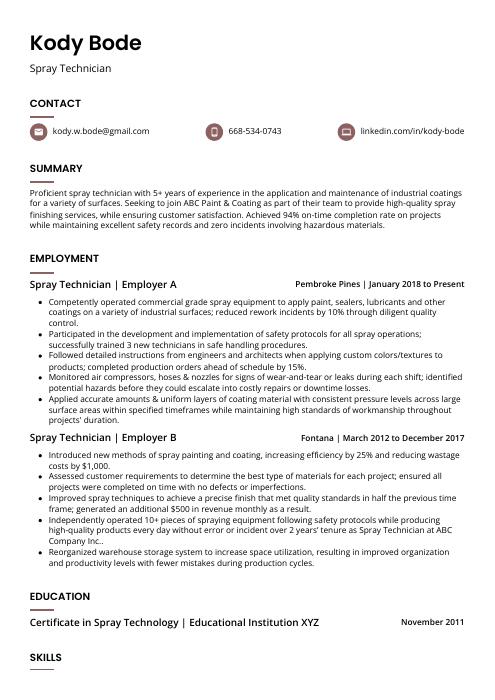

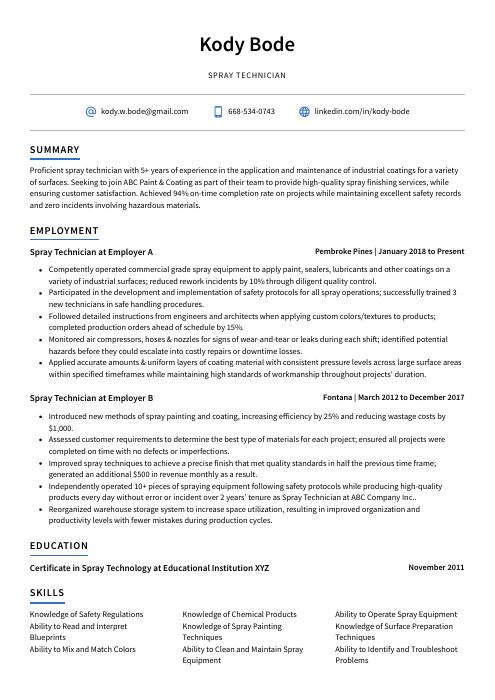

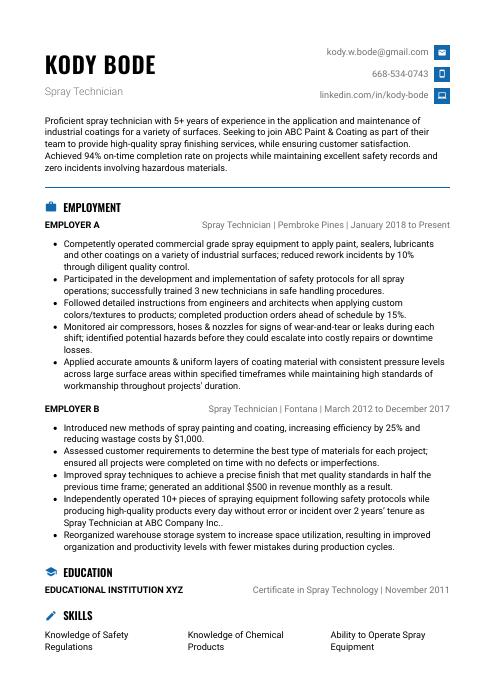

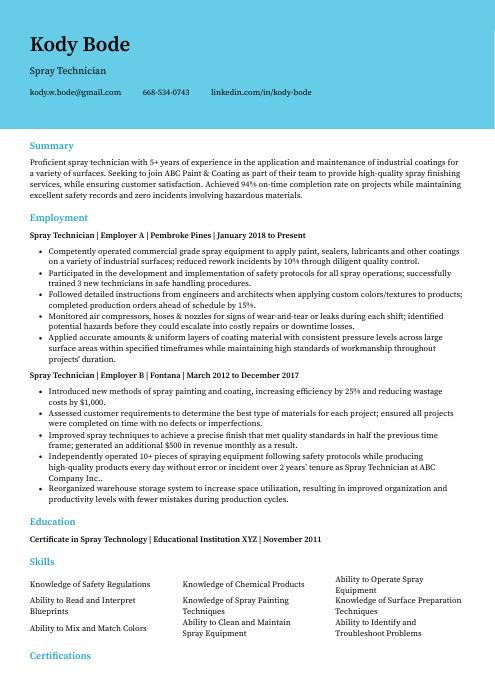

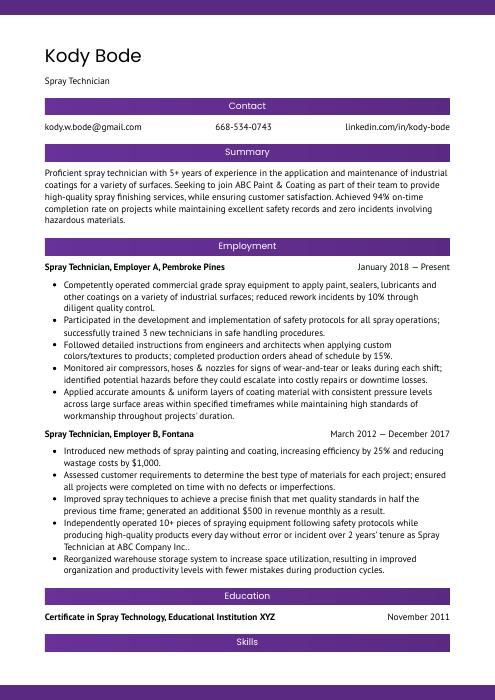

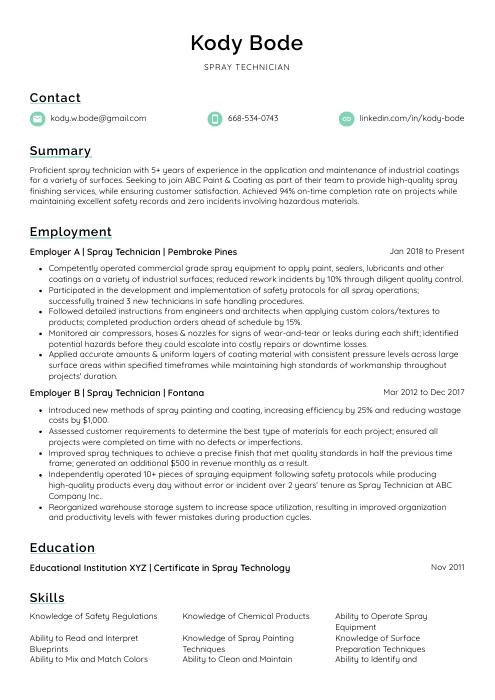

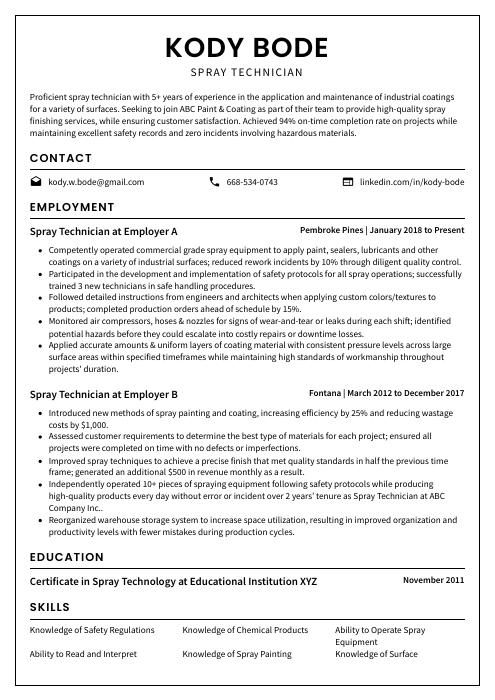

Kody Bode

Spray Technician

[email protected]

668-534-0743

linkedin.com/in/kody-bode

Summary

Proficient spray technician with 5+ years of experience in the application and maintenance of industrial coatings for a variety of surfaces. Seeking to join ABC Paint & Coating as part of their team to provide high-quality spray finishing services, while ensuring customer satisfaction. Achieved 94% on-time completion rate on projects while maintaining excellent safety records and zero incidents involving hazardous materials.

Experience

Spray Technician, Employer A

Pembroke Pines, Jan 2018 – Present

- Competently operated commercial grade spray equipment to apply paint, sealers, lubricants and other coatings on a variety of industrial surfaces; reduced rework incidents by 10% through diligent quality control.

- Participated in the development and implementation of safety protocols for all spray operations; successfully trained 3 new technicians in safe handling procedures.

- Followed detailed instructions from engineers and architects when applying custom colors/textures to products; completed production orders ahead of schedule by 15%.

- Monitored air compressors, hoses & nozzles for signs of wear-and-tear or leaks during each shift; identified potential hazards before they could escalate into costly repairs or downtime losses.

- Applied accurate amounts & uniform layers of coating material with consistent pressure levels across large surface areas within specified timeframes while maintaining high standards of workmanship throughout projects’ duration.

Spray Technician, Employer B

Fontana, Mar 2012 – Dec 2017

- Introduced new methods of spray painting and coating, increasing efficiency by 25% and reducing wastage costs by $1,000.

- Assessed customer requirements to determine the best type of materials for each project; ensured all projects were completed on time with no defects or imperfections.

- Improved spray techniques to achieve a precise finish that met quality standards in half the previous time frame; generated an additional $500 in revenue monthly as a result.

- Independently operated 10+ pieces of spraying equipment following safety protocols while producing high-quality products every day without error or incident over 2 years’ tenure as Spray Technician at ABC Company Inc..

- Reorganized warehouse storage system to increase space utilization, resulting in improved organization and productivity levels with fewer mistakes during production cycles.

Skills

- Knowledge of Safety Regulations

- Knowledge of Chemical Products

- Ability to Operate Spray Equipment

- Ability to Read and Interpret Blueprints

- Knowledge of Spray Painting Techniques

- Knowledge of Surface Preparation Techniques

- Ability to Mix and Match Colors

- Ability to Clean and Maintain Spray Equipment

- Ability to Identify and Troubleshoot Problems

Education

Certificate in Spray Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Crop Adviser (CCA)

American Society of Ag

May 2017

1. Summary / Objective

Your resume summary should be like a movie trailer – it should give the employer an overview of your skills and experience as a spray technician. In this section, you can mention any certifications or qualifications that make you stand out from other applicants. You could also talk about how many years of experience you have in the field, highlight any awards or recognition received for outstanding workmanship, and explain why customers keep coming back to use your services.

Below are some resume summary examples:

Driven spray technician with 5+ years of experience in applying paints, coatings, and other finishes to a variety of surfaces. At XYZ Industries successfully completed over 100 projects on time while maintaining high quality standards. Proven ability to work independently or as part of a team and adhere to safety regulations at all times. Passionate about providing clients with the best possible results for their projects.

Professional spray technician with 10+ years of experience in applying chemical solutions to crops and other objects. Currently employed at XYZ, where I have been instrumental in increasing crop yields by 20%. Highly skilled at mixing hazardous chemicals safely and accurately as well as calibrating spray equipment for optimal performance. Committed to ensuring safety protocols are followed on every job site.

Talented spray technician with 7+ years of experience in the application and maintenance of industrial coatings. Proven track record for completing projects on time, successfully managing budgets, ensuring safety protocols are followed, and providing exceptional customer service. Seeking to leverage technical knowledge and expertise at ABC Inc., to ensure quality products that exceed client expectations.

Skilled spray technician with 8+ years of experience in commercial painting and spraying. Expertise in the preparation, cleaning, sanding, and application of a variety of coatings for commercial buildings. Proven ability to consistently meet tight timelines while maintaining exceptional quality standards. At XYZ Inc., reduced labor costs by 25%, resulting in an increase in profits by 15%.

Reliable and detail-oriented spray technician with 5+ years of experience in applying high-quality paint and coatings to a variety of surfaces. Proven track record in meeting deadlines, following safety protocols, and maintaining an organized workspace. Seeking to join ABC Company as the lead Spray Technician where my expertise can help improve product quality and efficiency.

Dependable and hardworking spray technician with 5+ years of experience in providing a wide range of services including pest and weed control, fertilizer application, and lawn care. Seeking to join ABC Company to utilize knowledge and expertise for efficient delivery of quality results. At XYZ Inc., successfully managed over 500 accounts while meeting all industry standards.

Seasoned spray technician with 5+ years of experience in the agricultural industry. Proven track record for delivering successful projects on time and budget. At XYZ, improved crop yield by 15% through effective use of chemicals, problem-solving skills, and attention to detail. Adept at operating heavy machinery safely while meeting high standards of performance.

Diligent and experienced spray technician with 5+ years of experience in the painting and coating industry. Skilled in operating high-tech machinery, diagnosing problems and performing maintenance tasks for various equipment. Seeking to join ABC Company as a Spray Technician to ensure safe and efficient operations while providing top-notch customer service.

2. Experience / Employment

In the experience section, you should provide details on your employment history. This should be written in reverse chronological order, so the most recent job is listed first.

Stick to bullet points when writing this section; it makes it easier for a reader to take in what you have done and achieved. When describing each role, think about the specifics of what you did and try to include quantifiable results wherever possible.

For example, instead of saying “Applied paint,” you could say something like: “Sprayed automotive parts with high-grade paint using an airless sprayer resulting in 95% coverage accuracy.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Inspected

- Calibrated

- Adjusted

- Operated

- Cleaned

- Troubleshot

- Mixed

- Loaded

- Recorded

- Followed

- Tested

- Disposed

- Replaced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Streamlined the spraying process for 12+ vehicles per day and reduced coating time by 30%, resulting in higher customer satisfaction with the finished product.

- Developed a new spray technique to reduce overspray, leading to an 80% improvement in paint coverage accuracy and cost savings of $4,000 on materials annually.

- Represented company as a professional when dealing with customers; consistently received positive reviews from clients due to superior workmanship and quality results despite tight deadlines or challenging requests.

- Effectively diagnosed problems caused by improper application techniques such as discoloration, runs or drips; successfully troubleshot all issues within 24 hours while meeting production targets every week without any delays/reworking required afterwards.

- Troubleshot airless-pump related technical malfunctions using advanced diagnostic tools and equipment; repaired 5+ faulty pumps each month thus minimizing downtime & ensuring optimal performance across all machines at the facility.

- Spearheaded the application of protective and decorative coatings on various surfaces in manufacturing plants, utilizing airless sprayers, electrostatic guns and brush techniques; achieved a 90% coverage rate on all jobs.

- Proficiently operated the latest spraying equipments to apply sealants, epoxies, lacquers and varnishes while meeting customer specifications with precision; completed 25+ projects within allocated deadlines.

- Reduced wastage by 20%, through careful selection of materials based on job requirements & accurate estimation of required quantities for every project undertaken.

- Presented clients with detailed reports regarding pre-treatment procedures applied as well as post-application inspections carried out at each site; identified potential issues early and implemented corrective measures promptly for optimal results delivery.

- Facilitated continuous improvement initiatives across different departments to enhance operational efficiency through process automation & improved resource management practices; increased productivity levels by 10%.

- Calibrated and adjusted 15+ spray equipment to ensure optimal performance and accuracy, resulting in a 10% increase in output efficiency.

- Mentored 3 junior technicians on safe chemical handling practices and best spraying techniques; reduced wastage by 25%.

- Compiled weekly reports which detailed the type of materials used, amount sprayed & average cost per job; saved $1,500 in operational costs over 6 months.

- Adjusted nozzle settings for different coating applications while ensuring proper mix ratios were maintained within specified parameters; decreased rework incidents due to incorrect application by 35%.

- Efficiently operated robotic spray systems with precision control to apply various coatings including paints, polyurethanes and varnishes on metal surfaces up to 1000 sq ft daily without errors or delays.

- Coordinated and executed the spray painting of over 500 automobiles and other vehicles per month, ensuring that all customer requirements were met on time.

- Inspected vehicle bodies for any flaws prior to spraying; reduced paint wastage by 20% after introducing more stringent quality assurance measures.

- Structured preventative maintenance plans and prepared work orders to ensure all equipment was functioning properly while adhering to safety guidelines at all times.

- Replaced worn parts, performed minor repairs and adjusted settings on specialized tools as needed in order to maintain a high level of efficiency within the team.

- Actively monitored air pollution levels during every job, resulting in an 85% reduction in emissions over two years due to improved ventilation systems installation processes.

- Utilized specialized spraying equipment and techniques to apply protective coatings, sealants and adhesives in a safe manner; successfully completed over 500 spraying projects with no reported incidents or accidents.

- Optimized the application of chemical solutions for improved performance by adjusting spray pressure levels according to product specifications; achieved an average job completion rate that was 20% faster than industry standards.

- Reliably monitored quality control measures throughout every project while maintaining strict adherence to safety protocols; reduced post-application defects by 45%.

- Tested all materials prior to use and calibrated machines regularly for optimal output results; increased production efficiency by 25%.

- Mixed various paints, solvents and other liquid ingredients as required per each individual task specification; created 50+ custom color formulations without any rejected batches due to errors in mixing ratios or inconsistencies in pigment concentrations.

- Formulated and applied specialized paints, coatings and stains to a variety of surfaces with precision accuracy; reduced customer complaints by 30% over the course of one year.

- Prepared paint booths for spray jobs, ensuring that all safety protocols were respected at all times; maintained proper ventilation in booth areas throughout each project.

- Revised and updated existing spraying techniques based on feedback from clients, leading to increased customer satisfaction ratings across 10+ projects.

- Meticulously inspected painted or stained products upon completion to ensure adherence to quality standards; achieved zero rework since beginning position 3 years ago.

- Disposed of leftover materials according to company regulations while conforming strictly with environmental protection laws and policies; decreased waste disposal costs by 25%.

- Loaded, calibrated and operated spray guns to apply protective coatings and finishes on metal components for a wide range of industrial equipment; increased production output by 40%.

- Achieved 99% accuracy in applying even coats of paint or primer over surfaces using multiple techniques such as airless spraying, HVLP & electrostatic application.

- Cleaned the interior/exterior components of finished products with solvents prior to painting them; reduced rework costs by $1,500 per quarter due to improved quality control standards.

- Substantially lowered hazardous material waste disposal incidences resulting from overspray through efficient containment management practices within the facility.

- Recorded daily progress reports regarding coating performance, surface preparation methods and other relevant data for future reference purposes in accordance with safety regulations.

- Advised customers on the proper use and application of spray products, resulting in a 20% increase in sales for the month.

- Accurately mixed paint colors per customer request, ensuring that all color matches were exact; reduced time needed to mix each gallon by 30 minutes.

- Demonstrated expert knowledge when applying various types of finish coats such as lacquers and urethanes; improved surface quality with fewer defects or blemishes reported by customers.

- Expedited production process by quickly cleaning equipment between jobs, allowing technicians to move onto their next job quicker while still maintaining high-quality standards; decreased downtime hours from 2-3 hours/day to 1 hour/day on average.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for a spray technician who is experienced with applying paint to cars and another seeking someone to apply pesticides.

It is essential that you tailor your skills section of the resume accordingly so that it matches the job description as closely as possible. This will ensure that applicant tracking systems pick up on these keywords when scanning resumes, thus increasing your chances of being selected for an interview.

In addition to listing relevant skills in this section, you should also discuss them further in other areas such as the summary or experience sections.

Below is a list of common skills & terms:

- Ability to Clean and Maintain Spray Equipment

- Ability to Identify and Troubleshoot Problems

- Ability to Mix and Match Colors

- Ability to Operate Spray Equipment

- Ability to Read and Interpret Blueprints

- Ability to Work in Confined Spaces

- Knowledge of Chemical Products

- Knowledge of Safety Regulations

- Knowledge of Spray Painting Techniques

- Knowledge of Surface Preparation Techniques

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, include an education section below your resume objective. However, if you have been working as a spray technician for many years with plenty of responsibilities to showcase, omitting the education section is perfectly fine.

If including an education section, try to mention courses and subjects related to the spray technician job that you are applying for.

Certificate in Spray Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to show potential employers that you have the necessary skills and knowledge for a given job. They demonstrate your commitment to professional development, as well as your dedication to staying up-to-date with industry trends.

If you have any certifications related to the position you are applying for, make sure they are included in this section of your resume. This will give hiring managers an indication of how qualified and knowledgeable you are about the role and its requirements.

Certified Crop Adviser (CCA)

American Society of Ag

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Kody Bode, this would be Kody-Bode-resume.pdf or Kody-Bode-resume.docx.

7. Cover Letter

Including a cover letter when applying for a job is an important step in the process. It’s your chance to explain why you’re interested in the role and what makes you uniquely qualified for it.

A cover letter should be composed of 2 to 4 paragraphs, each addressing different topics such as: why you want this particular job, how your skills and experience make you a good fit, or anything else that could help demonstrate your suitability for the position. Even though not all jobs require one, having a well-written cover letter can give employers insight into who you are beyond just your resume.

Below is an example cover letter:

Dear Stewart,

I am writing to apply for the position of Spray Technician at ABC Pest Control. As a certified pesticide applicator with 2+ years of experience in commercial and residential pest control, I have the skills and knowledge necessary to excel in this role.

At XYZ Pest Control, where I am currently employed, I routinely treat properties for infestations of ants, roaches, spiders, termites, and other pests. I also provide preventative treatments to customers as needed. In addition to my daily duties, I am responsible for keeping accurate records of all treatments performed and stocking supplies as needed. My excellent time management skills enable me to complete tasks efficiently without sacrificing quality.

I hold a valid certification in pesticide application from the state of Florida and have completed OSHA-mandated safety training. My commitment to following all safety protocols ensures that both customers and co-workers are protected from harm.

As someone who takes pride in providing high-quality service that exceeds customer expectations, I believe I would be a valuable asset to your team at ABC Pest Control. I look forward to discussing how my skills can benefit your company further during an interview at your earliest convenience.

Sincerely,

Kody

Spray Technician Resume Templates

Bonobo

Bonobo Numbat

Numbat Hoopoe

Hoopoe Rhea

Rhea Saola

Saola Pika

Pika Kinkajou

Kinkajou Indri

Indri Quokka

Quokka Markhor

Markhor Gharial

Gharial Ocelot

Ocelot Fossa

Fossa Axolotl

Axolotl Echidna

Echidna Dugong

Dugong Jerboa

Jerboa Lorikeet

Lorikeet Cormorant

Cormorant Rezjumei

Rezjumei