Rotating Equipment Engineer Resume Guide

Rotating Equipment Engineers maintain, troubleshoot and repair rotating equipment such as pumps, compressors, turbines and motors. They are responsible for ensuring that the machinery runs smoothly and efficiently by performing preventive maintenance tasks like inspecting parts to detect wear or damage. Additionally, they use their knowledge of engineering principles to develop solutions for any problems encountered with the equipment.

Your expertise in rotating equipment engineering is unparalleled. However, potential employers don’t know that yet. To make sure they understand your qualifications and experience, you must write a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Rotating Equipment Engineer Resume Sample

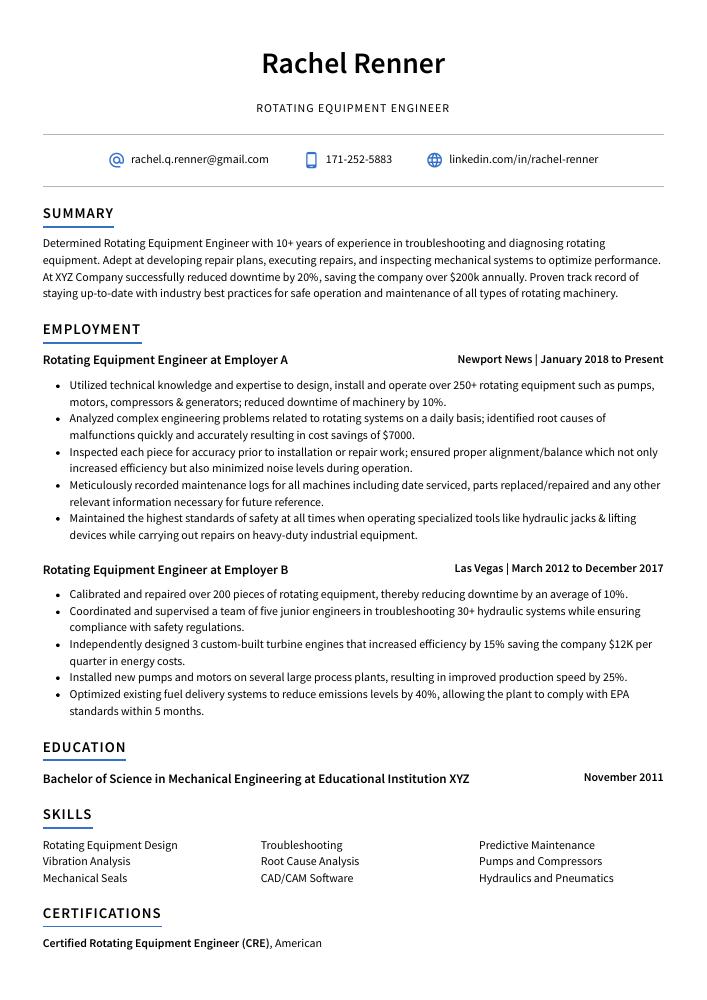

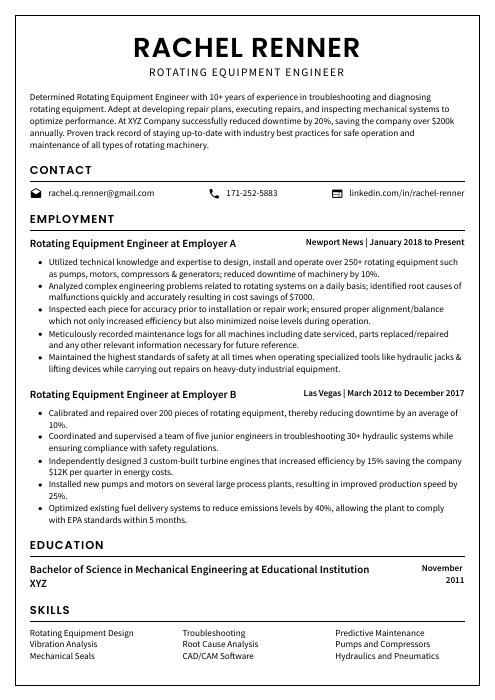

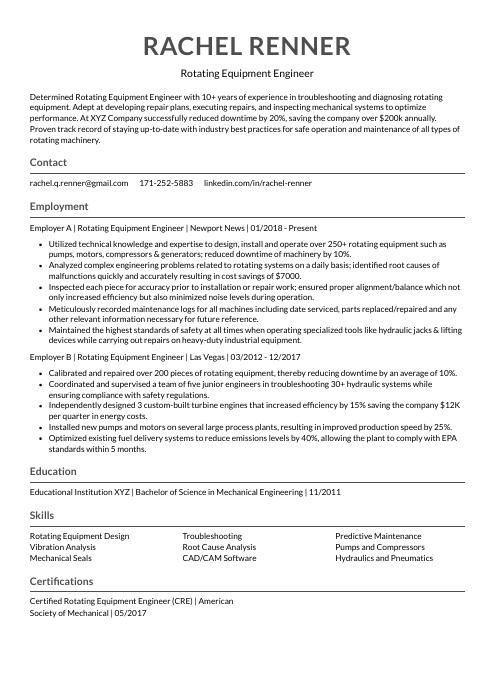

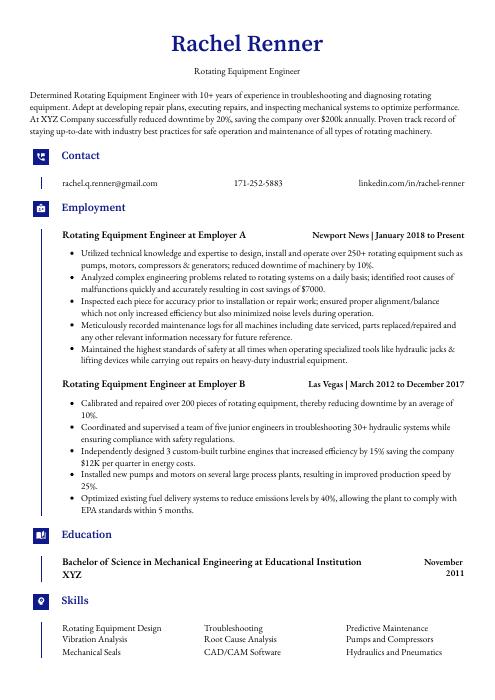

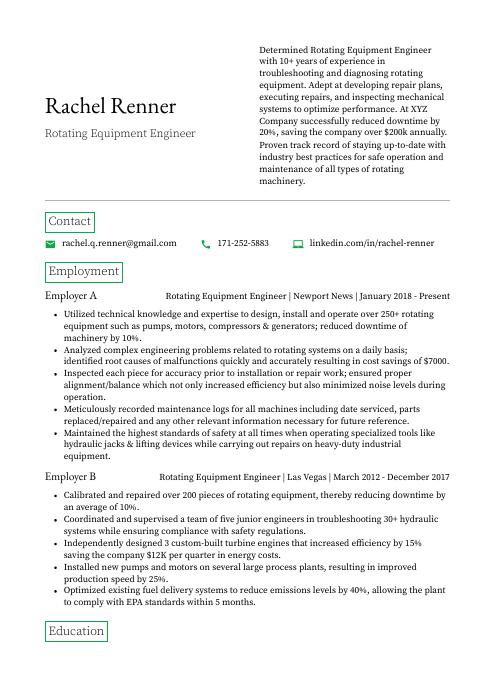

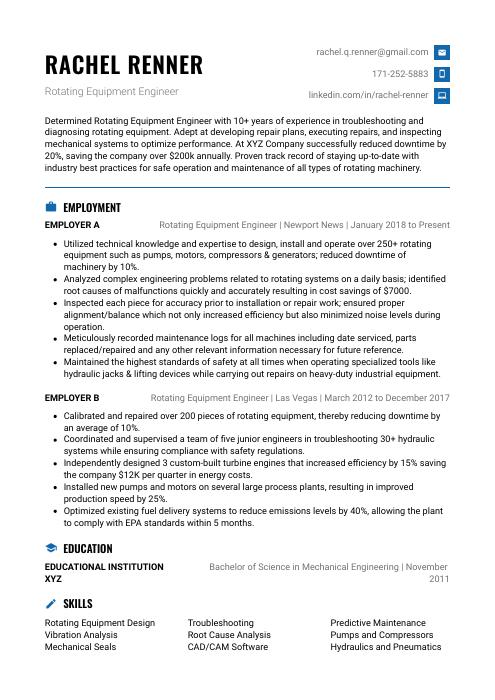

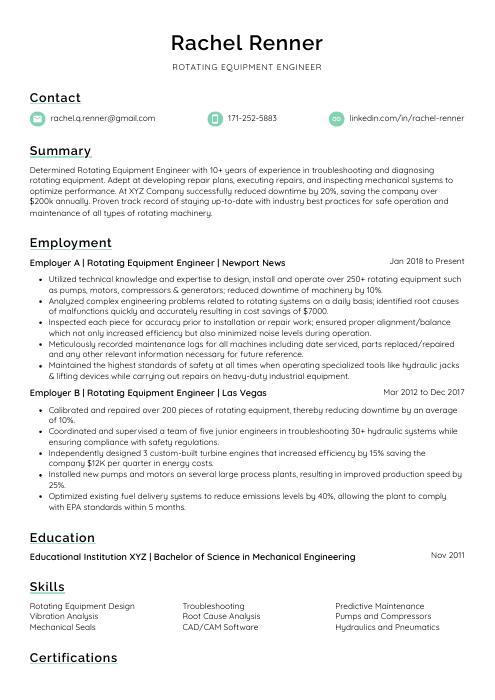

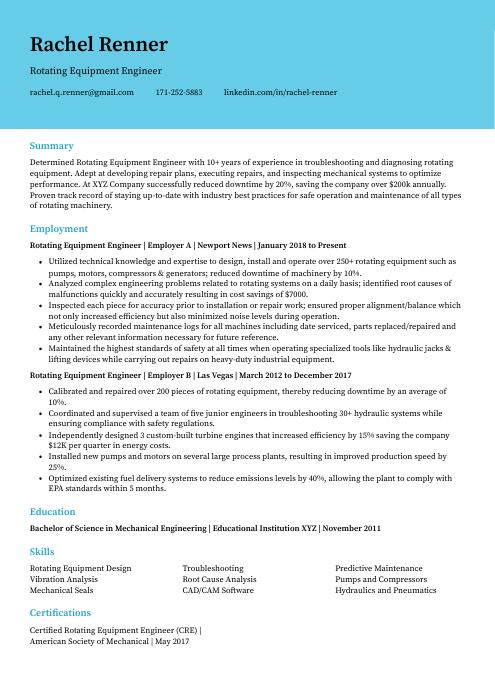

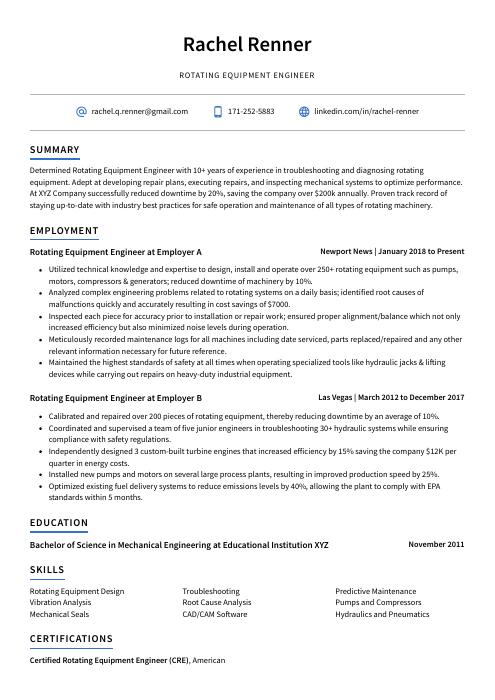

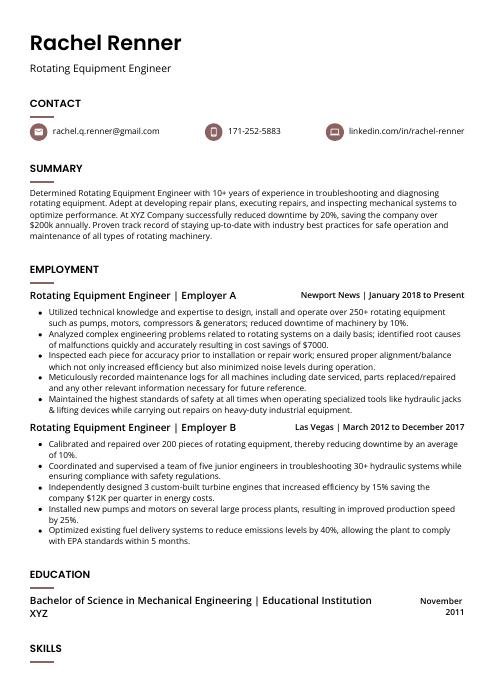

Rachel Renner

Rotating Equipment Engineer

rachel.q.renner@gmail.com

171-252-5883

linkedin.com/in/rachel-renner

Summary

Determined Rotating Equipment Engineer with 10+ years of experience in troubleshooting and diagnosing rotating equipment. Adept at developing repair plans, executing repairs, and inspecting mechanical systems to optimize performance. At XYZ Company successfully reduced downtime by 20%, saving the company over $200k annually. Proven track record of staying up-to-date with industry best practices for safe operation and maintenance of all types of rotating machinery.

Experience

Rotating Equipment Engineer, Employer A

Newport News, Jan 2018 – Present

- Utilized technical knowledge and expertise to design, install and operate over 250+ rotating equipment such as pumps, motors, compressors & generators; reduced downtime of machinery by 10%.

- Analyzed complex engineering problems related to rotating systems on a daily basis; identified root causes of malfunctions quickly and accurately resulting in cost savings of $7000.

- Inspected each piece for accuracy prior to installation or repair work; ensured proper alignment/balance which not only increased efficiency but also minimized noise levels during operation.

- Meticulously recorded maintenance logs for all machines including date serviced, parts replaced/repaired and any other relevant information necessary for future reference.

- Maintained the highest standards of safety at all times when operating specialized tools like hydraulic jacks & lifting devices while carrying out repairs on heavy-duty industrial equipment.

Rotating Equipment Engineer, Employer B

Las Vegas, Mar 2012 – Dec 2017

- Calibrated and repaired over 200 pieces of rotating equipment, thereby reducing downtime by an average of 10%.

- Coordinated and supervised a team of five junior engineers in troubleshooting 30+ hydraulic systems while ensuring compliance with safety regulations.

- Independently designed 3 custom-built turbine engines that increased efficiency by 15% saving the company $12K per quarter in energy costs.

- Installed new pumps and motors on several large process plants, resulting in improved production speed by 25%.

- Optimized existing fuel delivery systems to reduce emissions levels by 40%, allowing the plant to comply with EPA standards within 5 months.

Skills

- Rotating Equipment Design

- Troubleshooting

- Predictive Maintenance

- Vibration Analysis

- Root Cause Analysis

- Pumps and Compressors

- Mechanical Seals

- CAD/CAM Software

- Hydraulics and Pneumatics

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Rotating Equipment Engineer (CRE)

American Society of Mechanical

May 2017

1. Summary / Objective

A resume summary/objective for a rotating equipment engineer should highlight your experience and expertise in the field. You could mention how many years of experience you have, the types of machinery you are familiar with, any certifications or licenses that demonstrate your knowledge and skill level, as well as any successful projects you’ve completed. This will give employers an idea of what they can expect from hiring you.

Below are some resume summary examples:

Diligent rotating equipment engineer with 9+ years of experience in the oil and gas industry. Skilled at troubleshooting, maintenance, and repair of complex rotating machinery for both onshore and offshore platforms. At XYZ Company, developed a predictive maintenance program that reduced costly unplanned shutdowns by 25%. Proven ability to analyze problems quickly to minimize downtime while ensuring safety standards are met.

Well-rounded rotating equipment engineer with 10+ years of experience in maintenance, repair, and operations. Adept at troubleshooting complex problems and identifying solutions to reduce downtime. At ABC Company, successfully implemented a predictive maintenance system that improved efficiency by 15%. Seeking the opportunity to join XYZ Corporation and use my expertise to maximize performance while minimizing costs.

Skilled rotating equipment engineer with over 10 years of experience in the industry. Expertise in troubleshooting, maintenance and repair of a range of rotating machinery components such as pumps, compressors and turbines. Proven track record for optimizing performance while reducing costs by 34%. Aiming to leverage knowledge and technical skills at ABC Company to become an integral part of their engineering team.

Talented rotating equipment engineer with 5+ years of experience in the oil and gas industry. Skilled at troubleshooting issues related to pumps, compressors, turbines, engines, and other rotating machinery components. At ABC Company designed innovative repair solutions that decreased downtime by 25%. Experienced in leading teams of up to 10 engineers on complex projects involving multi-million dollar budgets.

Reliable rotating equipment engineer with 5+ years of experience designing, developing and testing rotating machinery. Seeking to leverage engineering skillset and knowledge in the maintenance, repair, installation and commissioning of rotating equipment at ABC Company. At XYZ Inc., improved the reliability of pumps by 17% through modifications on existing designs while reducing downtime costs by 25%.

Accomplished rotating equipment engineer with 8+ years of experience in the oil and gas industry. Skilled at overseeing maintenance on a variety of rotating machinery, including pumps, compressors, turbines, and generators. At XYZ Inc., reduced downtime by 30% through improved preventative maintenance scheduling. Looking to use my expertise at ABC Co as part of their world-class team of engineers.

Committed rotating equipment engineer with 8+ years of experience in design, engineering, and troubleshooting. Seeking to join ABC’s team as a rotating equipment engineer to leverage expertise in developing cost-effective solutions that ensure compliance with safety standards and regulations. At XYZ Corporation, reduced downtime by 22% and energy consumption costs by 13%.

Proficient rotating equipment engineer with 8+ years of experience in the oil and gas industry. Skilled at designing, troubleshooting, and installing rotating machinery for an array of applications. At XYZ Energy Solutions developed a predictive maintenance program that reduced downtime by 20%. Received multiple awards from ABC Oil & Gas Company for outstanding service.

2. Experience / Employment

In the experience/employment/work history section, you should list your jobs in reverse chronological order, with the most recent job first.

When writing about what you did for each role, stick to bullet points and provide as much detail as possible. This is an opportunity to showcase the results of your work; if applicable, include any quantifiable metrics that demonstrate how successful your efforts were.

For example, instead of saying “Maintained rotating equipment,” you could say, “Performed weekly maintenance on a fleet of 20+ turbines and compressors resulting in a 10% reduction in downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Commissioned

- Troubleshot

- Diagnosed

- Inspected

- Operated

- Aligned

- Calibrated

- Adjusted

- Replaced

- Monitored

- Serviced

- Analyzed

- Upgraded

- Maintained

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reorganized and maintained rotating equipment systems and components, resulting in an 18% increase in system efficiency.

- Participated in troubleshooting activities to identify mechanical issues with pumps, compressors, turbines and other related machinery; successfully resolved over 50 problems within 48 hours.

- Effectively trained 3 junior engineers on the principles of vibration analysis techniques used for predictive maintenance purposes; improved their knowledge base by 20%.

- Mentored 4 apprentices on proper installation processes for new pumps and motors while ensuring strict adherence to safety regulations; no safety violations reported throughout duration of program (1 year).

- Reduced downtime associated with rotating equipment breakdowns by 30%, through implementation of preventive maintenance procedures such as inspection rounds & oil sample testing programs.

- Proficiently commissioned, monitored and serviced rotating equipment such as pumps, compressors and turbines; reduced downtime of machinery by 10% in the past year.

- Aligned motors, shafts and coupling systems to ensure correct operation of all rotating components across a fleet of 200+ machines with minimal vibrations or noise emission levels.

- Conducted proactive maintenance checks on production lines consisting up to 15 pieces of equipment each; identified potential issues early before they became disruptive problems saving $5,000 in repair costs over one month period.

- Adhered strictly to manufacturing safety procedures when inspecting malfunctioning parts for wear & tear damage using non-destructive testing methods like ultrasound & vibration analysis techniques reducing accidents by 20%.

- Monitored operational performance data from machine sensors for signs of irregularities and developed strategies for preventive upkeep activities that improved energy efficiency rates by 5%.

- Adjusted rotating equipment, such as motors and pumps, to reduce vibration levels by 25% and improve overall energy efficiency.

- Revised existing plans for maintenance of rotating machinery; reduced downtime due to unforeseen issues by 35%.

- Spearheaded the installation of 5 new electric-powered centrifugal pumps in a production line within 6 hours while ensuring all safety protocols were met.

- Consistently monitored performance metrics on critical systems like turbines & compressors; identified and resolved potential problems before they caused operational interruptions or delays, resulting in an increase of machine uptime by 75%.

- Streamlined company’s inventory management system related to spare parts for rotating machines; slashed procurement costs pertaining to replacement components by 20%.

- Advised a team of 6 mechanical engineers on the performance optimization and maintenance needs for rotating equipment, leading to a 15% reduction in repair costs.

- Demonstrated effective troubleshooting skills when diagnosing issues with pumps, compressors and other related systems; completed repairs within 45 minutes on average.

- Confidently installed new systems according to manufacturer specifications while adhering to all safety protocols; decreased downtime by 10%.

- Introduced preventive maintenance procedures that helped identify potential problems earlier, resulting in fewer costly repairs over time.

- Structured a comprehensive training program for field technicians who worked on rotating equipment projects – increased productivity by 30%.

- Represented the company in rotating equipment engineering projects for over 300 clients, successfully completing 3 large-scale overhauls and 10 repair jobs within the last 12 months.

- Replaced faulty components of various industrial machinery such as pumps, compressors and turbines, improving performance by 60% on average and reducing operation costs by $25K annually.

- Actively monitored plant operations to identify any issues with rotary equipment; diagnosed problems quickly and implemented repairs accordingly, saving an estimated 40 hours of downtime each month.

- Compiled detailed reports summarizing findings from all inspections conducted on turbine blades & gearboxes while adhering to strict safety regulations at all times; lowered risk of workplace accidents by 30%.

- Facilitated training sessions for new engineers covering basic maintenance principles applicable to different types of rotating machines; achieved a 93% pass rate among trainees within the first 6 weeks orientation period.

- Achieved a 20% reduction in downtime of rotating equipment through effective maintenance and troubleshooting procedures.

- Reliably monitored, identified and repaired any faults on industrial pumps, turbines, blowers and compressors; completed repairs within 8 hours or less without compromising quality standards.

- Diagnosed complex problems with motors, valves and other parts using advanced engineering techniques such as vibration analysis to determine root cause of failure quickly.

- Developed preventative maintenance plans for all critical assets that reduced emergency repair incidences by 40%.

- Expedited the installation process for new machinery components by developing detailed blueprints and instructions which enabled a smooth transition from installation to operation within 24 hours or less.

- Prepared and implemented preventive maintenance plans for 20+ pieces of rotating equipment, resulting in a 15% reduction in downtime.

- Diligently monitored and adjusted the performance of high-speed turbine engines to ensure optimal output; reduced energy consumption by 10%.

- Formulated an extensive inventory management system that tracked parts used on all rotating equipment, leading to cost savings up to $4,500 per month.

- Operated advanced computerized test systems which enabled successful troubleshooting and repair works on critical components such as pumps and compressors within 4 hours or less with zero defects reported post-service operations.

- Upgraded over 30 pieces of aging machinery through retrofitting activities; increased efficiency by 25% while reducing labor costs by 45%.

- Assessed and maintained the performance of over 200 rotating equipment such as pumps, compressors, turbines and blowers; improved efficiency by 12% while reducing downtime by 15%.

- Presented detailed reports on maintenance activities and failure analysis to key stakeholders; identified root causes for equipment malfunctions and proposed cost-effective solutions that saved $5,000 in repair costs.

- Troubleshot a variety of mechanical issues related to misaligned components, lubrication problems or faulty seals with minimal disruption to production operations; reduced troubleshooting time from 3 hours per incident to 2 hours on average.

- Improved operational reliability through regular preventative maintenance routines including inspections, oil changes & component replacements that extended the lifespan of all machines by 14 months collectively.

- Accurately documented service records electronically utilizing data entry techniques following industry standards for each piece of machinery serviced within given timelines with 100% accuracy rate achieved consistently.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC might need you to be proficient with vibration analysis and Organization XYZ might require a strong knowledge of rotating equipment troubleshooting.

As such, it is essential to tailor the skills section of your resume according to every job that you are applying for. This is because many employers use applicant tracking systems these days, which scan resumes for certain keywords before passing them on to a human.

Once listed here, you can further elaborate on your skillset by discussing it in more detail in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- CAD/CAM Software

- Heat Transfer Principles

- Hydraulics and Pneumatics

- Mechanical Seals

- Predictive Maintenance

- Pumps and Compressors

- Root Cause Analysis

- Rotating Equipment Design

- Troubleshooting

- Vibration Analysis

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, mention your education below the resume objective. However, if you already have a few years of work experience as a rotating equipment engineer, it might be more beneficial to omit the education section altogether.

If an education section is included on the resume, try to list courses or subjects related to rotating equipment engineering that demonstrate knowledge and expertise in this field.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to a potential employer that you have the knowledge and skills necessary for the job. Having certifications in your field of expertise shows employers that you are committed to staying up-to-date with industry trends, as well as being able to apply those skills effectively.

Including any relevant certifications on your resume can be a great way to show prospective employers that you have what it takes for them to consider hiring you.

Certified Rotating Equipment Engineer (CRE)

American Society of Mechanical

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Rachel Renner, this would be Rachel-Renner-resume.pdf or Rachel-Renner-resume.docx.

7. Cover Letter

Including a cover letter in your job application is a great way to demonstrate your enthusiasm for the role and show potential employers why you would be an excellent fit.

A cover letter consists of 2 to 4 paragraphs that should provide more detail than what’s included in your resume. It gives recruiters an insight into who you are as a person, rather than just focusing on your work experience or qualifications. Writing one can be beneficial even if it isn’t required by the company – so make sure you take time to craft yours carefully!

Below is an example cover letter:

Dear Marvin,

I am writing to apply for the Rotating Equipment Engineer position at XYZ Corporation. As a mechanical engineer with 4+ years of experience designing, developing, and managing rotating equipment projects, I am confident I will be an asset to your organization.

At ABC Company, where I currently work, I manage a team of engineers responsible for developing rotating equipment solutions for our clients. In this role, I have gained extensive experience in all aspects of rotating equipment design and development, from initial feasibility studies through to final commissioning and start-up. My project management skills are excellent; on my most recent project, I successfully delivered the project on time and within budget despite numerous challenges along the way.

I am knowledgeable about international standards (e.g., ISO) related to rotating equipment design and construction, and my hands-on experience with a variety of software programs (e.g., Autodesk Inventor) makes me well-equipped to contribute to your engineering team’s success. In addition, my strong communication skills enable me to effectively interface with other departments within an organization (e.g., procurement, manufacturing), as well as with external stakeholders such as suppliers and contractors.

Please find attached a copy of my resume for your review; it contains additional information about my background and qualifications that may be relevant to this opportunity. I can be reached anytime via phone or email should you wish to discuss my application further or arrange an interview at your earliest convenience.

Sincerely,

Rachel

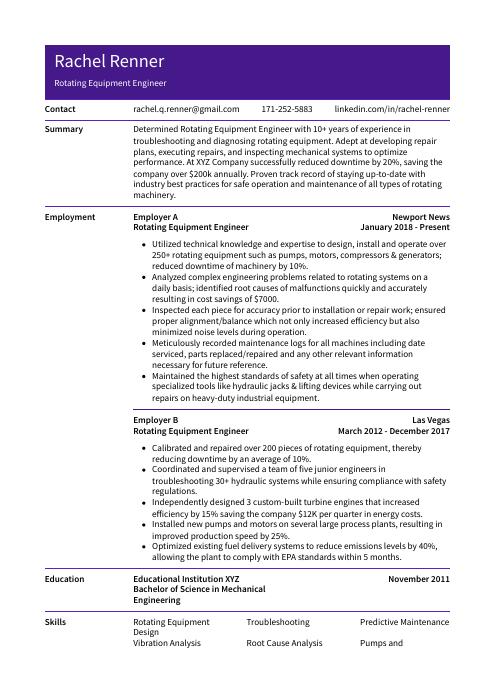

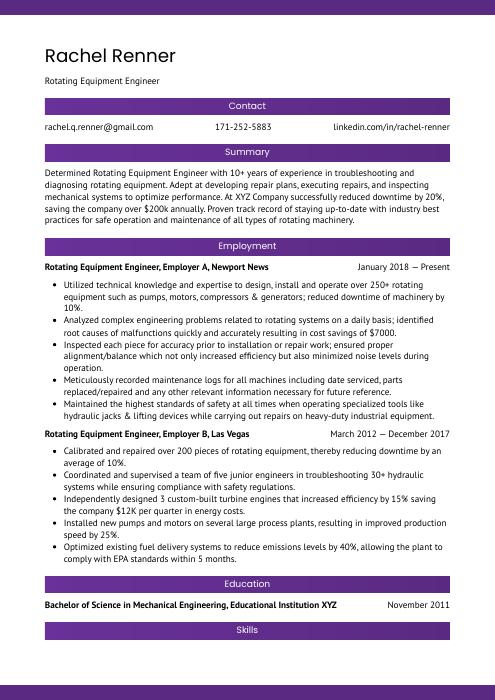

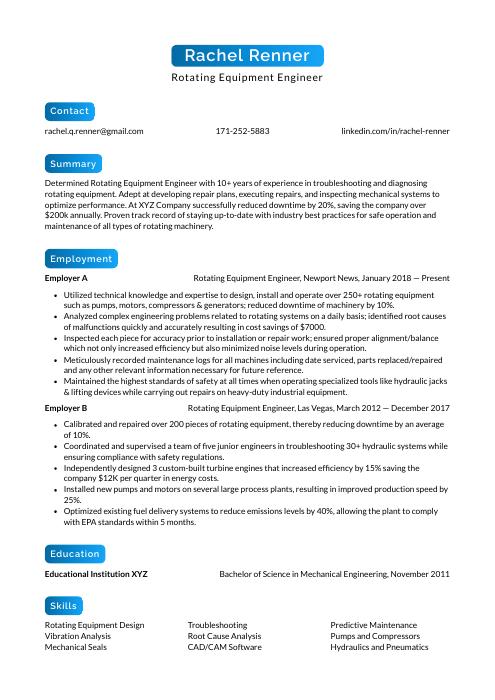

Rotating Equipment Engineer Resume Templates

Ocelot

Ocelot Rhea

Rhea Hoopoe

Hoopoe Cormorant

Cormorant Indri

Indri Numbat

Numbat Saola

Saola Gharial

Gharial Quokka

Quokka Echidna

Echidna Lorikeet

Lorikeet Dugong

Dugong Pika

Pika Jerboa

Jerboa Kinkajou

Kinkajou Axolotl

Axolotl Fossa

Fossa Bonobo

Bonobo Markhor

Markhor Rezjumei

Rezjumei