Refrigeration Technician Resume Guide

Refrigeration technicians install, maintain and repair commercial and industrial refrigeration systems. They diagnose malfunctions, replace worn parts and ensure that the systems are operating safely to meet customer needs.

You know your way around a refrigerator like the back of your hand, but employers won’t be able to tell that without seeing an impressive resume. To show them why you’re the perfect fit for their refrigeration team, make sure your resume stands out from all the rest.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

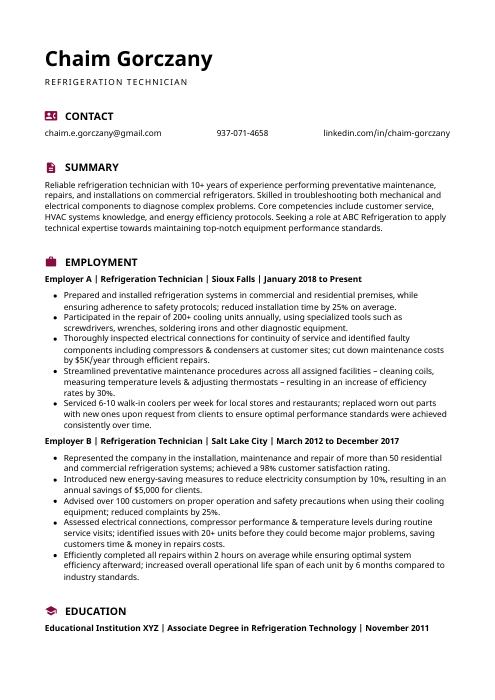

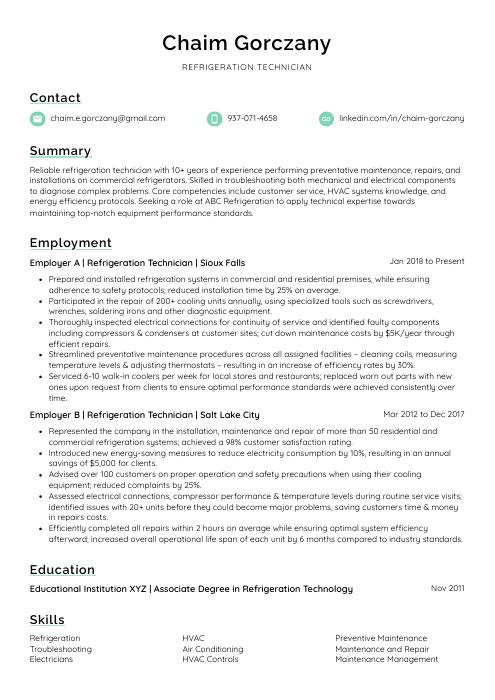

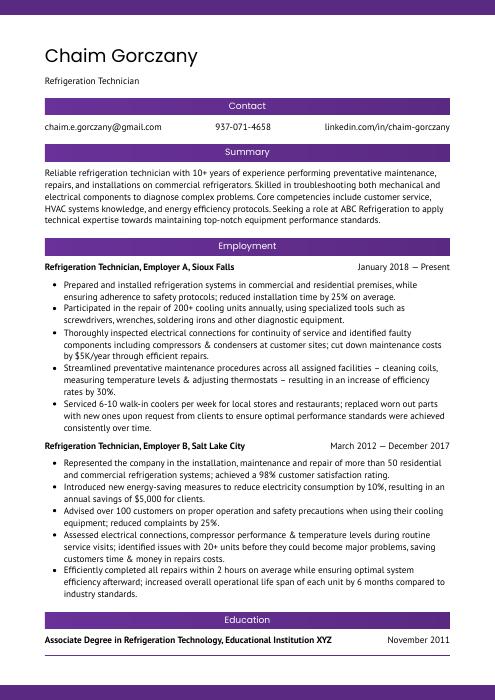

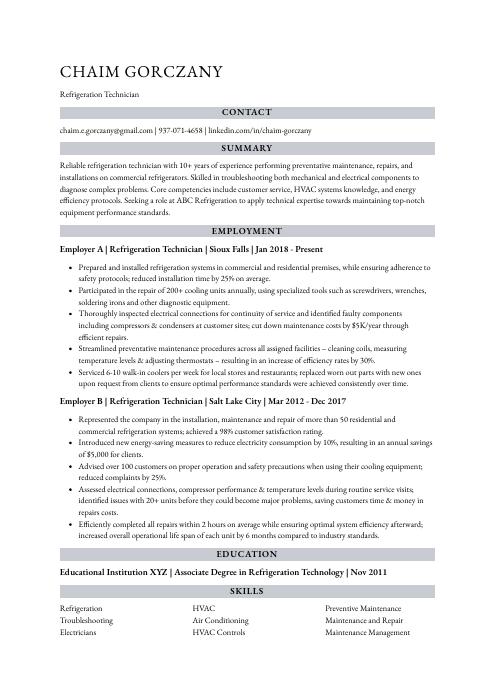

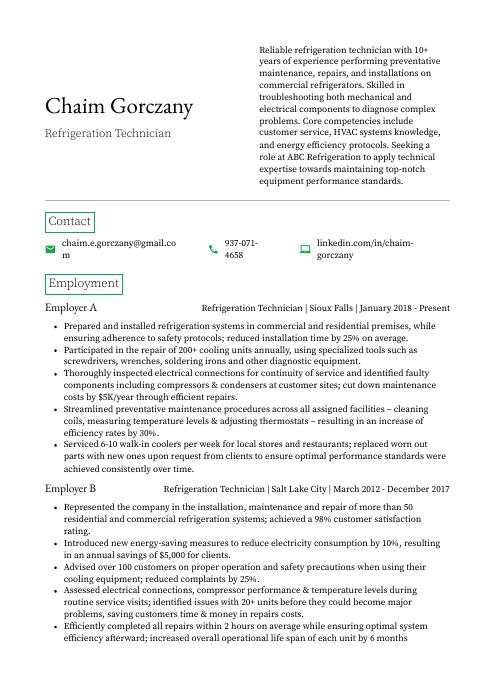

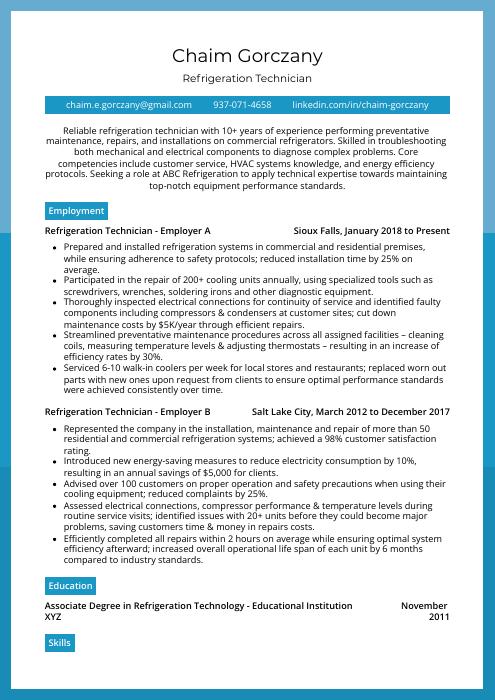

Refrigeration Technician Resume Sample

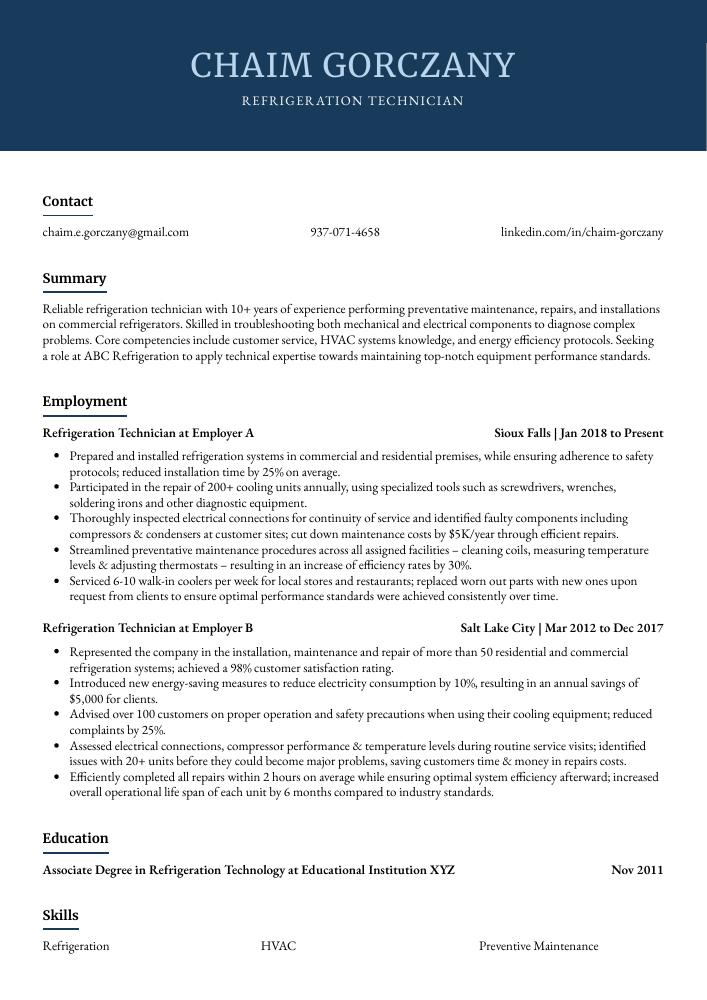

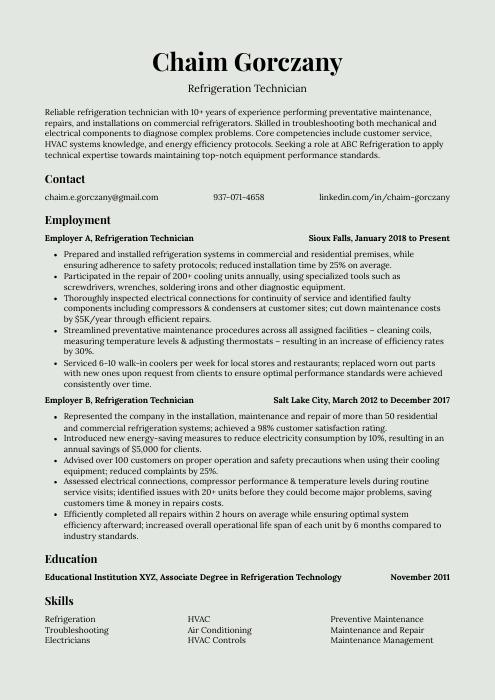

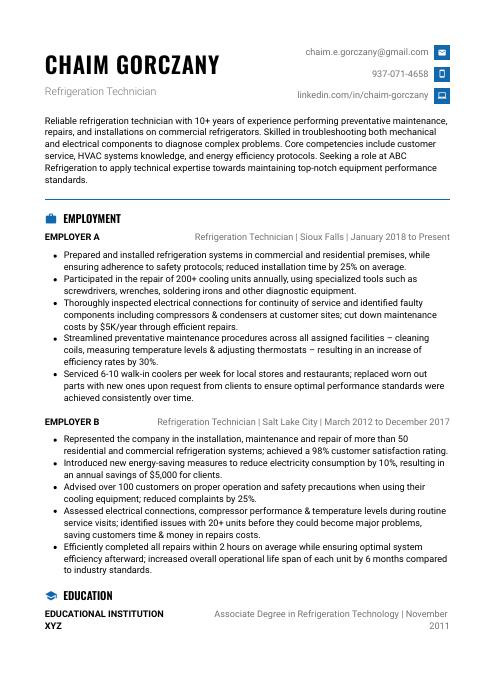

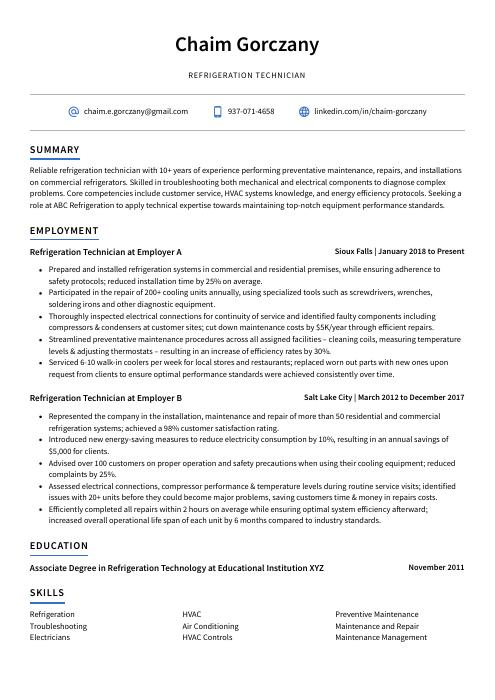

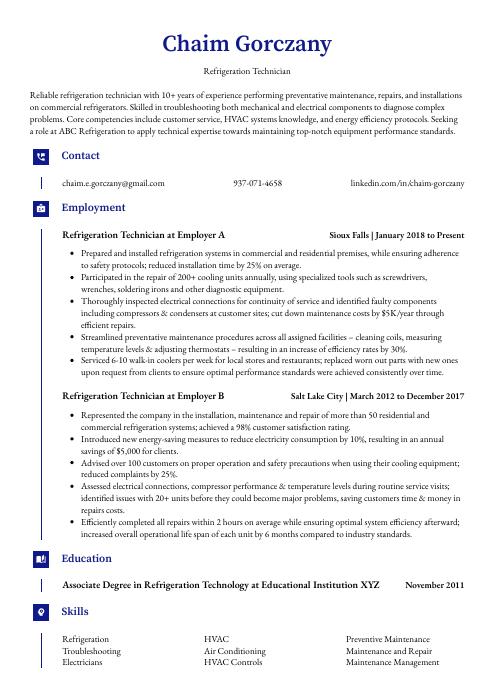

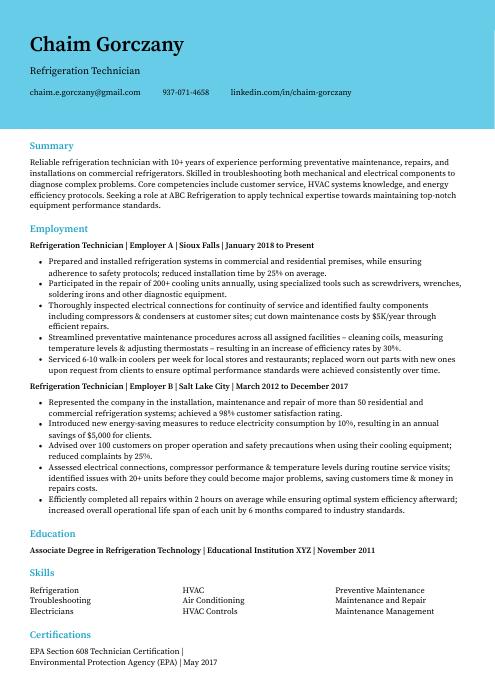

Chaim Gorczany

Refrigeration Technician

[email protected]

937-071-4658

linkedin.com/in/chaim-gorczany

Summary

Reliable refrigeration technician with 10+ years of experience performing preventative maintenance, repairs, and installations on commercial refrigerators. Skilled in troubleshooting both mechanical and electrical components to diagnose complex problems. Core competencies include customer service, HVAC systems knowledge, and energy efficiency protocols. Seeking a role at ABC Refrigeration to apply technical expertise towards maintaining top-notch equipment performance standards.

Experience

Refrigeration Technician, Employer A

Sioux Falls, Jan 2018 – Present

- Prepared and installed refrigeration systems in commercial and residential premises, while ensuring adherence to safety protocols; reduced installation time by 25% on average.

- Participated in the repair of 200+ cooling units annually, using specialized tools such as screwdrivers, wrenches, soldering irons and other diagnostic equipment.

- Thoroughly inspected electrical connections for continuity of service and identified faulty components including compressors & condensers at customer sites; cut down maintenance costs by $5K/year through efficient repairs.

- Streamlined preventative maintenance procedures across all assigned facilities – cleaning coils, measuring temperature levels & adjusting thermostats – resulting in an increase of efficiency rates by 30%.

- Serviced 6-10 walk-in coolers per week for local stores and restaurants; replaced worn out parts with new ones upon request from clients to ensure optimal performance standards were achieved consistently over time.

Refrigeration Technician, Employer B

Salt Lake City, Mar 2012 – Dec 2017

- Represented the company in the installation, maintenance and repair of more than 50 residential and commercial refrigeration systems; achieved a 98% customer satisfaction rating.

- Introduced new energy-saving measures to reduce electricity consumption by 10%, resulting in an annual savings of $5,000 for clients.

- Advised over 100 customers on proper operation and safety precautions when using their cooling equipment; reduced complaints by 25%.

- Assessed electrical connections, compressor performance & temperature levels during routine service visits; identified issues with 20+ units before they could become major problems, saving customers time & money in repairs costs.

- Efficiently completed all repairs within 2 hours on average while ensuring optimal system efficiency afterward; increased overall operational life span of each unit by 6 months compared to industry standards.

Skills

- Refrigeration

- HVAC

- Preventive Maintenance

- Troubleshooting

- Air Conditioning

- Maintenance and Repair

- Electricians

- HVAC Controls

- Maintenance Management

Education

Associate Degree in Refrigeration Technology

Educational Institution XYZ

Nov 2011

Certifications

EPA Section 608 Technician Certification

Environmental Protection Agency (EPA)

May 2017

1. Summary / Objective

Your resume summary should be a brief but powerful statement that captures the attention of potential employers. As a refrigeration technician, you can highlight your experience in installing and maintaining commercial cooling systems, as well as any certifications or qualifications you have obtained. You could also mention how many years’ experience you have in this field, any awards or recognition received for outstanding performance, and the number of successful projects completed on time and within budget.

Below are some resume summary examples:

Determined refrigeration technician with 5+ years of experience servicing and repairing refrigerators, freezers, coolers, ice makers, and other commercial cooling systems. Skilled in troubleshooting mechanical and electrical issues quickly to reduce downtime. Highly knowledgeable in HVAC technology related to temperature control equipment. Looking to apply skills at ABC Refrigeration where I can help maintain customer satisfaction while meeting company goals.

Proficient refrigeration technician with 10+ years of experience in repairing and servicing a variety of refrigeration systems. At XYZ, installed over 400 walk-in coolers/freezers using up to date technologies that increased energy efficiency by 20%. Dedicated to providing excellent customer service while ensuring the highest safety standards are met. Possesses strong problem solving skills and is comfortable working independently or as part of a team.

Skilled refrigeration technician with 8 years of experience in servicing, repairing, and troubleshooting commercial refrigeration systems. At XYZ Corp., identified a malfunctioning component in an HVAC system preventing the cooling unit from working efficiently which resulted in a 10% reduction in energy costs for their client. Possess strong knowledge of industrial safety regulations to ensure proper handling and disposal of hazardous materials.

Energetic refrigeration technician with 5+ years of experience in installing, troubleshooting and maintaining commercial refrigeration systems. Skilled at reading blueprints and diagrams, repairing components of the system as needed, ensuring all safety protocols are followed while working onsite. At XYZ Company, identified an incorrectly installed component that could have resulted in a catastrophic failure had it not been discovered.

Amicable and experienced refrigeration technician with over 10 years of experience in the field. Proven track record of successfully troubleshooting and repairing a wide range of HVAC, cooling, and refrigeration systems while adhering to industry standards. Looking to join ABC Company as a Refrigeration Technician where I can utilize my extensive knowledge and skill sets for the benefit of customers across different locations.

Committed refrigeration technician with 8+ years of experience in the HVAC industry. Seeking to join ABC Refrigeration as a lead refrigeration technician, using my knowledge and expertise to install, repair, maintain and troubleshoot commercial air conditioning systems. At XYZ Company achieved an outstanding 97% customer satisfaction rating by providing high-quality repairs on time and within budget.

Driven refrigeration technician with 6+ years of experience in repairing and maintaining commercial refrigerators. Proven track record of troubleshooting issues, identifying system malfunctions, and providing preventative maintenance to ensure optimal performance. Aiming to leverage expertise at ABC Company to provide superior service while ensuring customer satisfaction.

Dependable refrigeration technician with 5+ years of experience in residential and commercial refrigeration. Skilled at diagnosing, repairing, and installing various types of refrigeration systems. At XYZ Company I have effectively serviced over 500 customers on a wide range of HVAC issues while consistently achieving customer satisfaction ratings above 90%.

2. Experience / Employment

In the experience section, you should list your employment history in reverse chronological order. This means that the most recent job is listed first.

When writing about what you did at each job, use bullet points to make it easier for the reader to take in all of the information quickly. You want to provide detail and explain how your work resulted in tangible outcomes; this will demonstrate why you are a great candidate for the role.

For example, instead of saying “Installed refrigeration systems,” you could say, “Successfully installed 10+ commercial-grade walk-in coolers/freezers per week with minimal disruption to business operations.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Repaired

- Inspected

- Troubleshot

- Adjusted

- Calibrated

- Tested

- Replaced

- Monitored

- Operated

- Assembled

- Configured

- Diagnosed

- Serviced

- Refilled

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Compiled detailed reports of all preventative maintenance, repair and installation services performed on commercial refrigeration systems; identified potential issues before they arose and reduced customer downtime by 15%.

- Actively monitored operational performance metrics to ensure proper functioning of cooling units in supermarkets, restaurants and other businesses across a 5-mile radius.

- Coordinated with HVAC team members for proactive repairs or system replacements as necessary; completed jobs within the specified timeline while maintaining quality control standards throughout.

- Adjusted air conditioning settings to optimize energy efficiency, resulting in savings of $7000 over 12 months period due to lower operating costs & electricity bills per unit block facility wise.

- Presented comprehensive training sessions for employees on safe use & handling procedures at client sites; improved safety compliance rates from 85% to 95%.

- Demonstrated advanced knowledge of industrial refrigeration systems by diagnosing and repairing issues with compressors, condensers, evaporators and valves in commercial-grade chillers.

- Formulated preventive maintenance plans to reduce downtime on all units; successfully lowered non-operational time by 25% over a 12 month period.

- Repaired or replaced faulty electrical components such as circuit boards, switches & wiring harnesses to restore operability in malfunctioning equipment within 2 hours on average.

- Tested cooling coils for leaks using pressure gauges and other specialized tools; identified 3 major leak sources which were rectified before further damage occurred saving the company $5K in repair costs annually.

- Successfully installed AC systems into tight spaces without damaging existing plumbing fixtures or HVAC lines while adhering to established safety protocols at all times.

- Structured and installed high-efficiency refrigeration systems in commercial and residential buildings, resulting in a 40% decrease in energy consumption.

- Assembled compressors, condensers, evaporators and other components of mechanical refrigeration equipment according to manufacturer specifications; identified root causes for system failures within minutes through troubleshooting techniques.

- Resourcefully managed all phases of service calls from initial customer contact to successful completion; serviced over 200 units during the year with zero safety incidents or product malfunctions reported by customers afterwards.

- Optimized existing refrigeration systems for maximum efficiency using advanced testing tools such as thermocouples, manometers and hygrometers; reduced utility bills by an average of 15%.

- Mentored two apprentice technicians on basic repair procedures while assisting them with complex tasks throughout their training period; contributed towards producing quality professionals ready to join the workforce at the end of their apprenticeship program.

- Monitored and tested temperature and pressure levels of over 100 refrigeration systems daily, ensuring that food safety regulations were adhered to at all times.

- Troubleshot existing issues with malfunctioning equipment, reducing repair time by 25% on average; lowered costs associated with major repairs by $4,000 in the last quarter alone.

- Diligently conducted preventive maintenance checks on condensing units and evaporators across commercial properties; identified potential problems before they became costly repairs or replacements saving clients thousands of dollars a year in repairs/replacement fees.

- Calibrated thermometers & hygrometers weekly per manufacturer’s recommendations to ensure accurate readings for proper operation of refrigeration systems and reduce energy consumption by 15%.

- Facilitated installation and set-up services for newly purchased refrigerator units within 1 hour or less upon delivery.

- Configured, repaired and maintained industrial-grade refrigeration systems, air conditioners and other HVAC equipment; reduced downtime by 30%.

- Replaced defective parts in large commercial cooling units and recharged coolant levels to improve performance by 20%.

- Inspected all components of a walk-in refrigerator onsite for signs of wear/tear or damage; identified faulty connections that had been leaking ozone depleting gases into the atmosphere, thus avoiding an environmental disaster.

- Independently installed new residential A/C units in 10+ homes this summer season while adhering strictly to safety protocols at all times with zero incidents reported amongst customers.

- Reorganized the entire warehouse cold storage system to reduce energy consumption rates by 25%, resulting in annual savings of $7,000 for the business owners.

- Reduced downtime by 50% across all refrigeration systems through regularly scheduled preventative maintenance checks.

- Reliably repaired, installed and maintained over 100 commercial and residential refrigeration units daily to ensure optimal functioning in compliance with industry standards.

- Spearheaded the installation of 15+ new cooling systems at various sites within a month; reduced labor costs by $1,000 due to efficient project management techniques employed during installations.

- Diagnosed malfunctions using diagnostic tools such as multimeters, megohmmeters and ammeters; replaced faulty parts such as compressors, thermostats & valves promptly for maximum system efficiency.

- Refilled freon levels on existing cooling systems when necessary according to EPA guidelines; monitored pressure readings throughout each filling process for safety purposes.

- Improved the efficiency of refrigeration systems by up to 20%, saving the company $2,500 in energy costs annually.

- Operated and maintained a fleet of 25+ commercial cooling units with utmost accuracy and safety; reduced downtime due to malfunctions from 120 hours/month to 30 hours/month over an 8-month period.

- Developed preventative maintenance procedures for more than 100 types of cold storage equipment, ensuring smooth operation through routine inspections & repairs on timeframes specified in service contracts.

- Expedited emergency repair jobs within 24-48 hour timeframes at multiple sites across the state; minimized customer complaints related to malfunctioning refrigeration systems by 90%.

- Substantially increased departmental productivity levels by organizing parts inventory and ordering additional spare components as needed for timely completion of tasks assigned per job schedule requirements.

- Utilized specialized tools, such as refrigerant recovery systems and circuit analyzers to inspect, maintain and repair 25+ commercial grade refrigeration units on an annual basis.

- Achieved 15% cost savings by retrofitting all existing units with energy efficient compressors and condensers; reduced monthly electricity bills by $200.

- Revised technical documents outlining the standard operating procedures for handling/servicing of cooling equipment; improved safety standards at 5 industrial sites in the area.

- Installed new thermostats, fan-motors & evaporator coils in 20 walk-in coolers/freezers per month; decreased maintenance costs due to fewer malfunctions or breakdowns reported over time frame of 6 months.

- Competently diagnosed air conditioning issues within residential homes across the state; completed repairs within 4 hours on average while ensuring customer satisfaction levels remained high throughout entire process.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for someone with experience in commercial refrigeration systems, whereas Organization XYZ may need a technician that has worked on industrial cooling systems.

It is essential to keep this in mind because of the applicant tracking systems utilized by many companies. Their role is to analyze resumes for certain characteristics (such as specific keywords), filtering out those they deem not to be a high-quality match for that particular job.

Besides just listing skills in this section, you should also elaborate on the most important ones elsewhere within your resume; such as under relevant work experience or education sections.

Below is a list of common skills & terms:

- Air Compressors

- Air Conditioning

- Boilers

- Commissioning

- Continuous Improvement

- Contract Negotiation

- Cooling Water

- Customer Satisfaction

- Electrical Troubleshooting

- Electricians

- Energy Management

- Engineering

- Facilities Management

- Food Industry

- Food Processing

- Food Safety

- Forklift Operator

- HVAC

- HVAC Controls

- Heating

- Inspection

- Maintenance

- Maintenance Management

- Maintenance and Repair

- Manufacturing

- Operations Management

- Plumbing

- Pneumatics

- Preventive Maintenance

- Process Improvement

- Purchasing

- Refrigeration

- Supervisory Skills

- Team Leadership

- Troubleshooting

- Ventilation

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below your resume objective. However, if you have been working as a refrigeration technician for years and at multiple companies with plenty of different responsibilities to showcase, omitting the education section is perfectly fine.

If an education section is included, try to list courses and subjects related to the refrigeration technician job you are applying for that demonstrate relevant skills or knowledge.

Associate Degree in Refrigeration Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the necessary skills and knowledge for a particular job. It also shows that you are committed to professional development in your field, as certifications require time and effort to obtain.

Including any relevant certifications on your resume can help give hiring managers confidence in your abilities, so make sure they are up-to-date and accurate.

EPA Section 608 Technician Certification

Environmental Protection Agency (EPA)

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Chaim Gorczany, this would be Chaim-Gorczany-resume.pdf or Chaim-Gorczany-resume.docx.

7. Cover Letter

Providing a cover letter with your job application is an excellent way to make a great first impression. It’s a document that should be made up of 2-4 paragraphs and provide more detail about your qualifications, experience, and skills than what’s on the resume.

Cover letters are not always required when applying for jobs but they can give recruiters insight into who you are as a candidate beyond just facts and figures. They also let you explain why you’re the perfect fit for the role in question – which could help set yourself apart from other applicants!

Below is an example cover letter:

Dear Halie,

I am writing to apply for the Refrigeration Technician position at your company. I have eight years of experience working as a refrigeration technician, and my skills and qualifications match the requirements listed in your job posting.

In my current role, I maintain and repair industrial refrigeration systems. I troubleshoot issues using diagnostic equipment, make repairs as needed, and perform preventative maintenance to avoid future problems. My work has resulted in increased efficiency and decreased downtime for my employer.

I am certified by the EPA to handle refrigerants, and I have experience working with ammonia-based systems. In addition, I hold a journeyman’s license from the state of [state name]. My education and certification combined with my hands-on experience make me confident that I can excel in this role at your company.

I would appreciate the opportunity to discuss my qualifications further with you in person or over the phone at your earliest convenience. Thank you for your time; I look forward to hearing from you soon.

Sincerely,

Chaim

Refrigeration Technician Resume Templates

Indri

Indri Markhor

Markhor Cormorant

Cormorant Hoopoe

Hoopoe Lorikeet

Lorikeet Jerboa

Jerboa Numbat

Numbat Saola

Saola Bonobo

Bonobo Fossa

Fossa Kinkajou

Kinkajou Echidna

Echidna Axolotl

Axolotl Gharial

Gharial Dugong

Dugong Quokka

Quokka Rhea

Rhea Ocelot

Ocelot Pika

Pika Rezjumei

Rezjumei