Quality Control Microbiologist Resume Guide

Quality Control Microbiologists work to ensure the safety and quality of food, pharmaceuticals, and other products by testing for microorganisms. They use a variety of methods to analyze samples, detect contamination levels, evaluate product stability over time, perform sterility tests on medical devices, and develop new processes that improve product quality.

You have the expertise to ensure products meet quality standards, but potential employers don’t know about your qualifications. To make them aware of your experience and achievements in microbiology, you need to write a resume that stands out.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

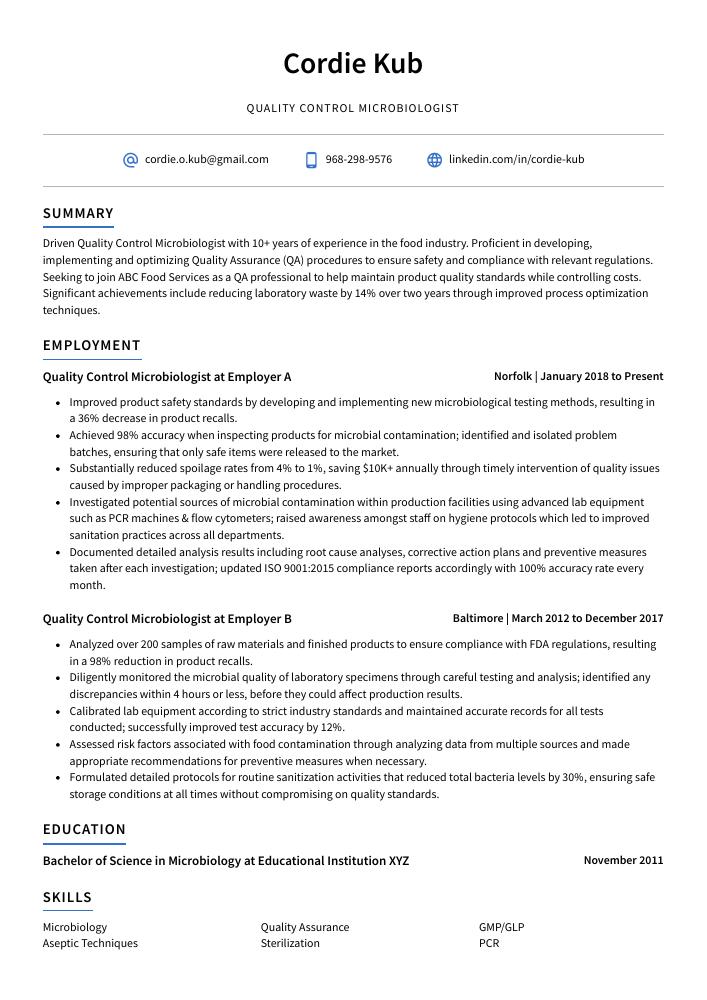

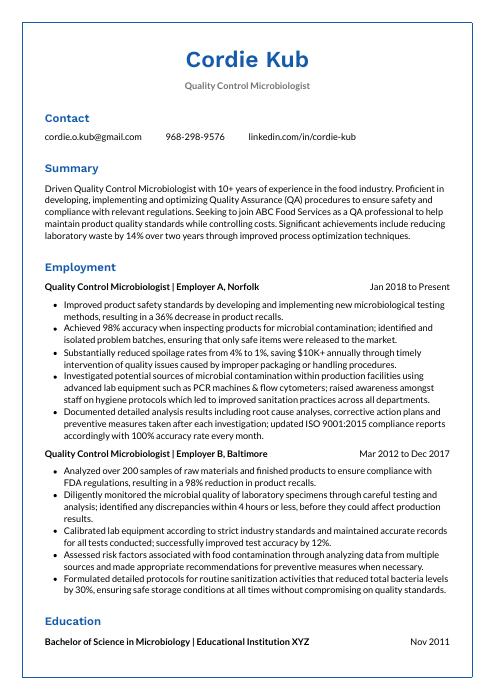

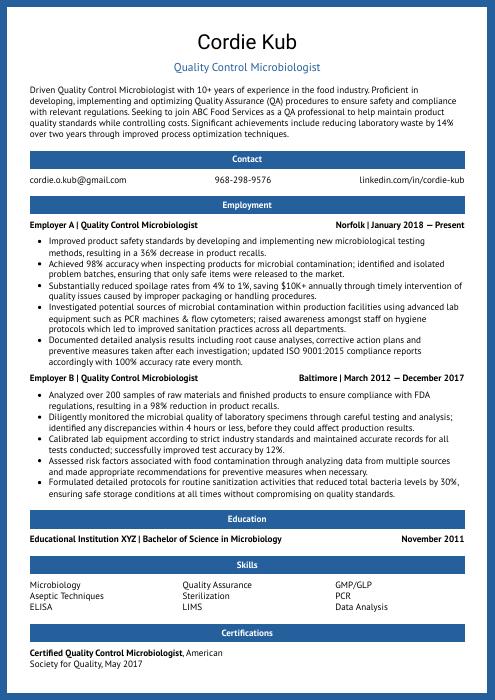

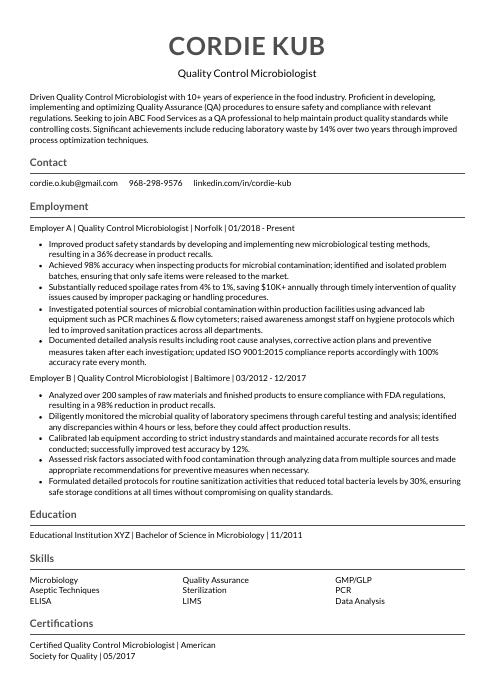

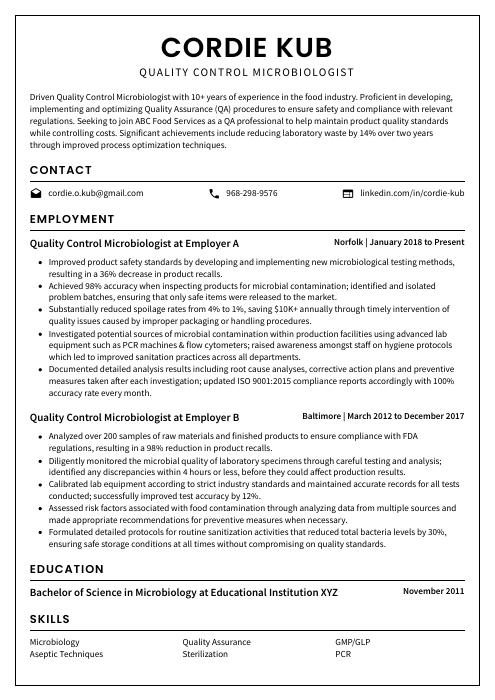

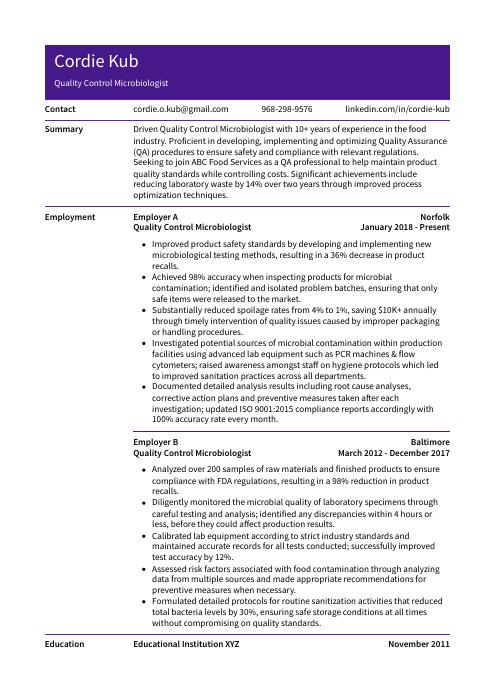

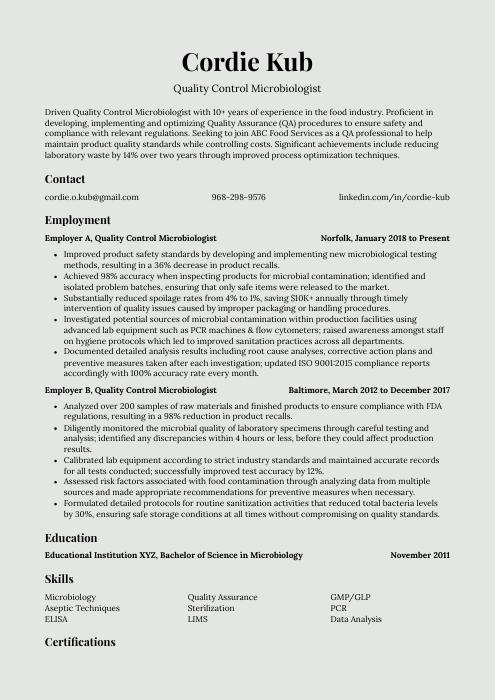

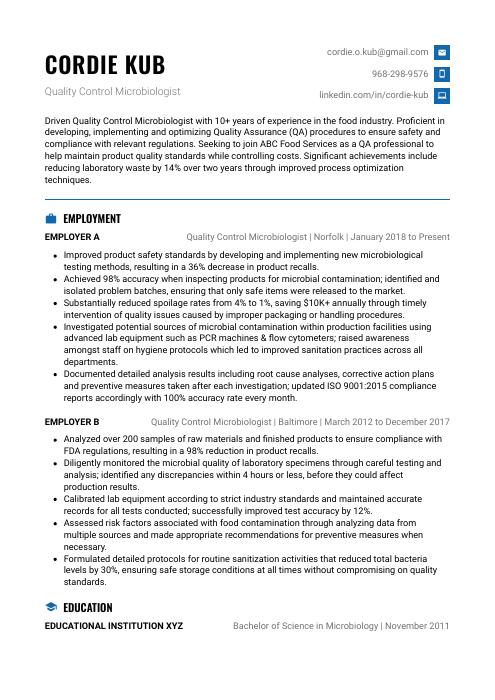

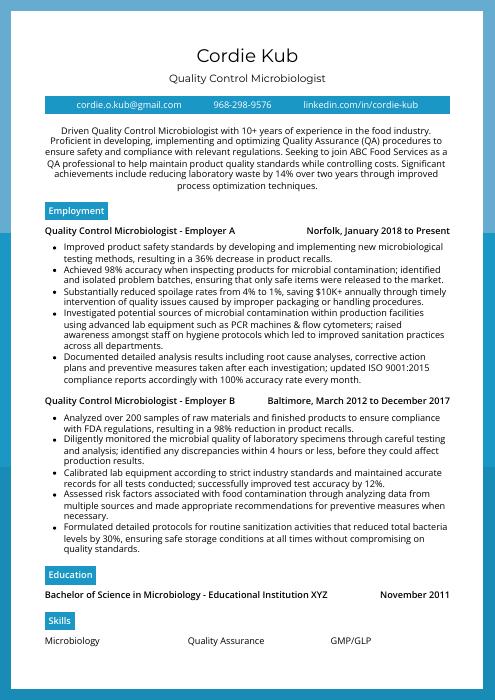

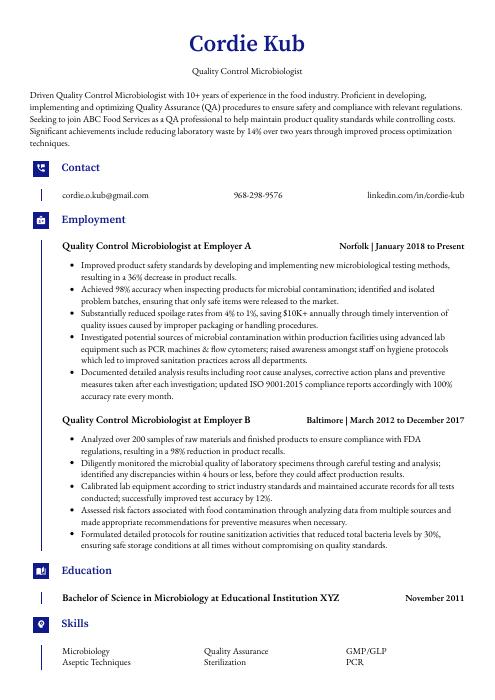

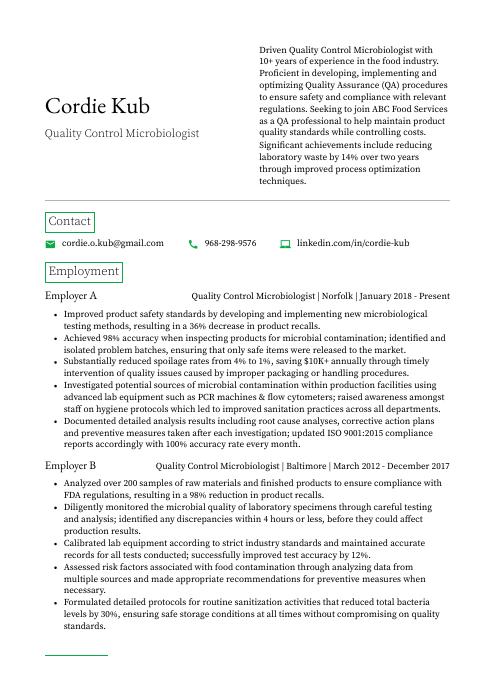

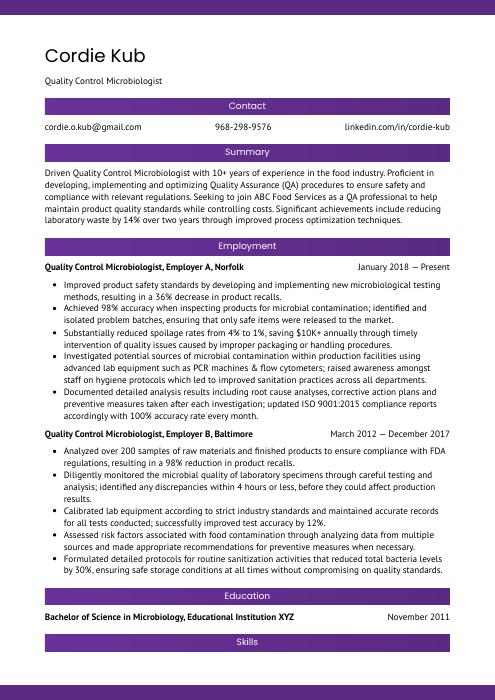

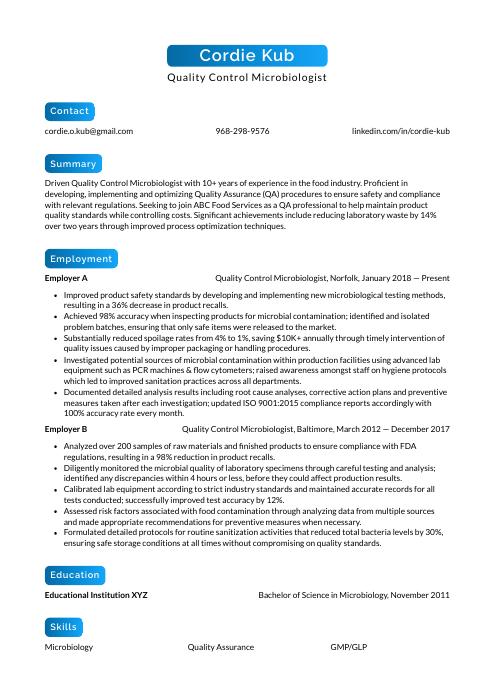

Quality Control Microbiologist Resume Sample

Cordie Kub

Quality Control Microbiologist

cordie.o.kub@gmail.com

968-298-9576

linkedin.com/in/cordie-kub

Summary

Driven Quality Control Microbiologist with 10+ years of experience in the food industry. Proficient in developing, implementing and optimizing Quality Assurance (QA) procedures to ensure safety and compliance with relevant regulations. Seeking to join ABC Food Services as a QA professional to help maintain product quality standards while controlling costs. Significant achievements include reducing laboratory waste by 14% over two years through improved process optimization techniques.

Experience

Quality Control Microbiologist, Employer A

Norfolk, Jan 2018 – Present

- Improved product safety standards by developing and implementing new microbiological testing methods, resulting in a 36% decrease in product recalls.

- Achieved 98% accuracy when inspecting products for microbial contamination; identified and isolated problem batches, ensuring that only safe items were released to the market.

- Substantially reduced spoilage rates from 4% to 1%, saving $10K+ annually through timely intervention of quality issues caused by improper packaging or handling procedures.

- Investigated potential sources of microbial contamination within production facilities using advanced lab equipment such as PCR machines & flow cytometers; raised awareness amongst staff on hygiene protocols which led to improved sanitation practices across all departments.

- Documented detailed analysis results including root cause analyses, corrective action plans and preventive measures taken after each investigation; updated ISO 9001:2015 compliance reports accordingly with 100% accuracy rate every month.

Quality Control Microbiologist, Employer B

Baltimore, Mar 2012 – Dec 2017

- Analyzed over 200 samples of raw materials and finished products to ensure compliance with FDA regulations, resulting in a 98% reduction in product recalls.

- Diligently monitored the microbial quality of laboratory specimens through careful testing and analysis; identified any discrepancies within 4 hours or less, before they could affect production results.

- Calibrated lab equipment according to strict industry standards and maintained accurate records for all tests conducted; successfully improved test accuracy by 12%.

- Assessed risk factors associated with food contamination through analyzing data from multiple sources and made appropriate recommendations for preventive measures when necessary.

- Formulated detailed protocols for routine sanitization activities that reduced total bacteria levels by 30%, ensuring safe storage conditions at all times without compromising on quality standards.

Skills

- Microbiology

- Quality Assurance

- GMP/GLP

- Aseptic Techniques

- Sterilization

- PCR

- ELISA

- LIMS

- Data Analysis

Education

Bachelor of Science in Microbiology

Educational Institution XYZ

Nov 2011

Certifications

Certified Quality Control Microbiologist

American Society for Quality

May 2017

1. Summary / Objective

A resume summary/objective is a great way to give the hiring manager an overview of your qualifications as a quality control microbiologist. In this section, you can highlight some of your best qualities such as knowledge in various laboratory techniques and protocols, experience with different types of microorganisms, and ability to work independently or collaboratively on projects. You could also mention any certifications or awards that demonstrate your expertise in this field.

Below are some resume summary examples:

Accomplished Quality Control Microbiologist with 6+ years of experience in aseptic sampling, environmental monitoring and microbial testing. Skilled in developing quality control processes to ensure compliance with FDA regulations. Proven ability to identify potential problems quickly before they become issues while consistently meeting strict deadlines. Seeking opportunity at ABC Labs where I can utilize my expertise and drive continuous process improvement initiatives.

Amicable and experienced quality control microbiologist with 5+ years of experience in the food industry. Skilled at developing and performing tests on raw materials, finished products, and environmental samples to ensure compliance with FDA guidelines. Expertise includes using advanced laboratory equipment such as PCR machines for sample analysis. Received company award for 100% accuracy rate in all projects undertaken during tenure at XYZ Inc.

Proficient quality control microbiologist with 7+ years of experience in the pharmaceutical industry. Expertise in GMP/GLP, ISO guidelines and FDA regulations. At XYZ Labs, developed a new method to detect microbial contamination that saved $30k yearly on reagents and doubled their throughput rate. Experienced in setting up laboratory equipment for safety tests as well as performing inspections for quality assurance purposes.

Energetic, detail-oriented Quality Control Microbiologist with over 10 years of experience in managing and analyzing microbial testing for pharmaceutical products. At XYZ, developed a comprehensive plan to introduce new microbiological test methods which resulted in an increase of product quality by 30%. Proven ability to work independently as well as collaboratively while ensuring compliance with cGMP standards.

Determined quality control microbiologist with 7+ years of experience in laboratory analysis and quality assurance. Focused on developing efficient methods for testing, analyzing, and validating products to ensure safety standards are met. At XYZ Corporation, reduced contamination levels by 20% and improved product shelf-life by 15%. Looking to join ABC’s team of professionals as a Quality Control Microbiologist.

Seasoned quality control microbiologist with 5+ years of experience in pharmaceutical manufacturing and laboratory settings. Proven track record in developing, implementing and validating quality assurance systems to ensure compliance with regulatory standards. Seeking to apply knowledge and expertise at ABC Pharma while driving continuous improvement initiatives that guarantee product safety and efficacy.

Diligent Quality Control Microbiologist with 5+ years of experience in the food and beverage industry. Expertise in designing, executing and validating microbiological tests on both raw materials and finished products. Skilled at initiating corrective actions to ensure compliance with GMP/HACCP guidelines. At XYZ, implemented a sophisticated monitoring system that improved safety standards by 30%.

Talented Quality Control Microbiologist with 8+ years of experience in the healthcare industry. Skilled at developing, implementing, and validating microbiological protocols to ensure safety and quality standards are met. Seeking a position at ABC Pharma where I can utilize my expertise in laboratory management, project planning and execution to support product development.

2. Experience / Employment

The work history/experience section is where you provide details on your employment history. This should be written in reverse chronological order, meaning the most recent job is listed first.

When stating what you did, stick to bullet points for easy readability and comprehension. You want to take some time to think about the specifics of what you did and the quantifiable results obtained from it.

For example, instead of saying “Performed microbiological tests,” you could say, “Conducted over 500 microbial testing procedures per month using a variety of techniques such as plating and PCR analysis; identified 4 new bacterial strains.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Evaluated

- Analyzed

- Inspected

- Tested

- Recorded

- Investigated

- Calibrated

- Sampled

- Cultured

- Identified

- Isolated

- Documented

- Reported

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Confidently performed microbiological analysis on a wide range of raw materials, in-process products and finished goods; identified contamination levels that were 8% lower than the industry average.

- Recorded detailed test results for over 200 microorganisms according to standard operating procedures (SOPs) and provided quality control reports within an hour when requested by management.

- Introduced new laboratory techniques for testing bacteria populations which improved accuracy and reduced sample preparation time by 25%.

- Compiled comprehensive data sets regarding microbial sampling tests, validations studies & environmental monitoring activities to ensure compliance with regulatory standards such as ISO 9001:2008 & FDA guidelines `for food safety assurance programs`.

- Mentored junior technicians in proper handling of lab equipment while performing experiments to increase productivity by 20%, resulting in quicker completion of projects within budget limits.

- Coordinated with production department to establish quality assurance standards, ensuring that all food and beverage products met safety regulations; successfully reduced product contamination by 25%.

- Facilitated daily inspections of raw materials, in-process ingredients and finished goods for microbial presence; identified over 20 potential problems before they impacted final products.

- Successfully implemented 10 new procedures within the QC laboratory to improve accuracy of testing results and reduce time spent on analysis by 30%.

- Structured detailed reports outlining findings from every test conducted, summarizing any discrepancies or defects observed while monitoring operations at various stages of manufacturing process.

- Advised team members on best practices related to sanitation protocols & proper handling techniques when working with sensitive chemicals & equipment; trained 3 interns in basic microbiology concepts over 2 months period.

- Evaluated over 200 microbiological samples daily to ensure compliance with production quality standards, resulting in a decrease of product rejections by 12%.

- Optimized microbial testing protocols and improved detection limits threefold, ensuring that all products met the necessary safety requirements.

- Sampled finished products on a regular basis to verify hygiene and sanitation procedures were being followed; identified potential issues before they became problems and reduced customer complaints by 10%.

- Reduced environmental microbe populations within the laboratory through rigorous cleaning schedules and proper storage techniques, decreasing overall contamination levels by 22% over 6 months period.

- Consistently monitored raw material suppliers’ test results for bacterial-related processes as part of Good Manufacturing Practices (GMP) enforcement efforts; ensured consistent quality control across supply chain partners at all times.

- Streamlined the laboratory quality control process, decreasing the total time spent on testing samples by 20%.

- Tested and analyzed more than 200 water, soil and food samples daily using advanced microbiology techniques to ensure compliance with safety regulations.

- Accurately identified over 80% of bacterial species present in each sample; tracked results via an electronic database for further analysis & comparison purposes.

- Cultured various types of microorganisms from contaminated sources and observed growth patterns to detect any abnormalities or inconsistencies upon completion of experiments within 2 hours/sample on average.

- Revised existing protocols as per industry standards while working closely with department heads to maximize efficiency in all aspects related to product quality assurance activities.

- Represented the company in quality control review meetings and successfully identified potential process improvement opportunities, resulting in a 10% decrease of defective products.

- Participated in the modernizing of laboratory instruments to accurately test microbial levels; decreased contamination results by 35%.

- Efficiently developed new protocols for environmental monitoring and product testing processes which led to improved customer satisfaction ratings from 81% to 93%.

- Utilized specialized software such as LIMS, pH meters and spectrophotometers when conducting tests on samples; increased accuracy rate from 70% to 98%.

- Spearheaded investigations into non-conforming materials through detailed root cause analysis, enabling management team with timely corrective actions that saved $7500/month on production costs.

- Inspected and tested food, beverage and medical samples for microbial contamination to ensure quality control standards were met; successfully identified over 200 instances of bacterial presence in a single month.

- Presented comprehensive reports on the results of laboratory tests and analysis to senior executives, validating all findings with accuracy up to 99%.

- Isolated bacteria from contaminated specimens using specialized staining techniques, as well as culturing methods such as pour plates and membrane filtration; reduced misidentification rate by 10%.

- Reliably operated advanced lab equipment including spectrophotometers, microscopes and autoclaves with excellent attention to detail when conducting experiments or processing data; improved turnaround times by 15%.

- Developed new protocols for more efficient sample collection procedures that enabled quicker testing without compromising on safety or accuracy levels; saved $1K+ in operational costs annually due to enhanced process efficiency.

- Identified microorganisms in the environment, raw materials and finished products using a variety of laboratory tests; reduced product defects by 25%.

- Thoroughly examined over 200 samples per day to ensure compliance with quality control standards and regulations set by government agencies.

- Reorganized existing QC microbiology protocols to improve consistency of test results while reducing cycle times by 50%.

- Prepared high-quality technical reports summarizing laboratory analysis findings for management review on a daily basis.

- Monitored production processes closely to detect potential contamination sources, eliminated 10% of cross-contamination incidents within 3 months through improved safety measures implementation.

- Demonstrated expertise in carrying out quality control tests on food and beverage products, including microbiological analysis of samples to detect the presence of harmful bacteria; reduced contamination cases by 40%.

- Expedited testing process through implementation of high-tech automated systems, decreasing sampling time from 8 hours to 4 hours per batch.

- Reported test results accurately with strict adherence to sample collection protocols and safety standards; improved compliance rate by 45%.

- Competently trained new staff members on laboratory equipment operation procedures and microbial testing techniques; mentored 2 employees who have since become junior Quality Control Microbiologists.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in the use of PCR technology, while another may be looking for someone with expertise in aseptic technique.

In order to make sure your resume stands out from other applicants, you should tailor the skills section according to each job posting that you are applying for. This will also help applicant tracking systems (ATS) recognize keywords and phrases they deem important when scanning resumes.

You can further elaborate on these skills by discussing them more thoroughly in other sections such as work history or summary statement.

Below is a list of common skills & terms:

- Aseptic Techniques

- Data Analysis

- Documentation and Record Keeping

- ELISA

- GMP/GLP

- LIMS

- Microbiology

- PCR

- Quality Assurance

- Sterilization

4. Education

Including an education section on your resume will depend largely on how far along you are in your career. If you just graduated and have no prior experience, mentioning your education below the resume objective is a great option. However, if you have been working as a quality control microbiologist for some time already with plenty of accomplishments to showcase, omitting an education section altogether might be best.

If including an education section is necessary or desired, try to mention courses related to the job role such as food safety principles and laboratory techniques relevant to quality control microbiology.

Bachelor of Science in Microbiology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field. They show potential employers that you have taken the time and effort to become certified, which indicates that you are committed to staying up-to-date on industry trends and best practices.

If there is any certification relevant to the job for which you are applying, make sure it is included in this section of your resume. This will help give hiring managers an indication of how well suited you may be for the role.

Certified Quality Control Microbiologist

American Society for Quality

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Cordie Kub, this would be Cordie-Kub-resume.pdf or Cordie-Kub-resume.docx.

7. Cover Letter

Submitting a cover letter is an important part of the job application process. It is a document usually made up of 2 to 4 paragraphs that provides recruiters with additional information about you and your professional background.

Cover letters are not always mandatory, but they can be beneficial in giving hiring managers more insight into who you are as a person and why you think you’re the right fit for the role. Writing one gives employers another chance to get to know more about what makes you unique from other applicants.

Below is an example cover letter:

Dear Madaline,

I am writing in response to your Quality Control Microbiologist position. With a Bachelor’s degree in Biology and experience working in quality control for the food and beverage industry, I feel confident I would be an asset to your team.

In my previous role as a Quality Control Analyst, I was responsible for conducting microbial testing on food products to ensure they met state and federal guidelines. I also developed and implemented quality control procedures for the company’s manufacturing process. My attention to detail and commitment to food safety helped me identify areas of improvement within the company’s production line, which led to increased efficiency and decreased waste.

I am knowledgeable of GMP/GLP regulations and have experience developing test methods according to FDA guidelines. I am also proficient in using various microbiological techniques, such as plate counts, PCR, gel electrophoresis, etc. My strong analytical skills allow me to quickly identify issues and develop solutions that improve product quality.

I am excited about the possibility of bringing my knowledge and expertise to [company name]. I look forward to speaking with you soon about this opportunity.

Sincerely,

Cordie

Quality Control Microbiologist Resume Templates

Bonobo

Bonobo Numbat

Numbat Lorikeet

Lorikeet Markhor

Markhor Ocelot

Ocelot Dugong

Dugong Axolotl

Axolotl Indri

Indri Cormorant

Cormorant Pika

Pika Saola

Saola Echidna

Echidna Rhea

Rhea Fossa

Fossa Hoopoe

Hoopoe Gharial

Gharial Quokka

Quokka Jerboa

Jerboa Kinkajou

Kinkajou Rezjumei

Rezjumei