Quality Control Associate Resume Guide

Quality Control Associates are responsible for ensuring product quality meets set standards. They inspect incoming materials, in-process and finished products to verify that they meet specifications, and document their results. They also work with production staff to identify areas of improvement, develop corrective actions and monitor the effectiveness of those changes.

You’re a master of quality control, but no one knows it yet. To make sure potential employers recognize your expertise and experience, you should craft an eye-catching resume that stands out from the rest.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

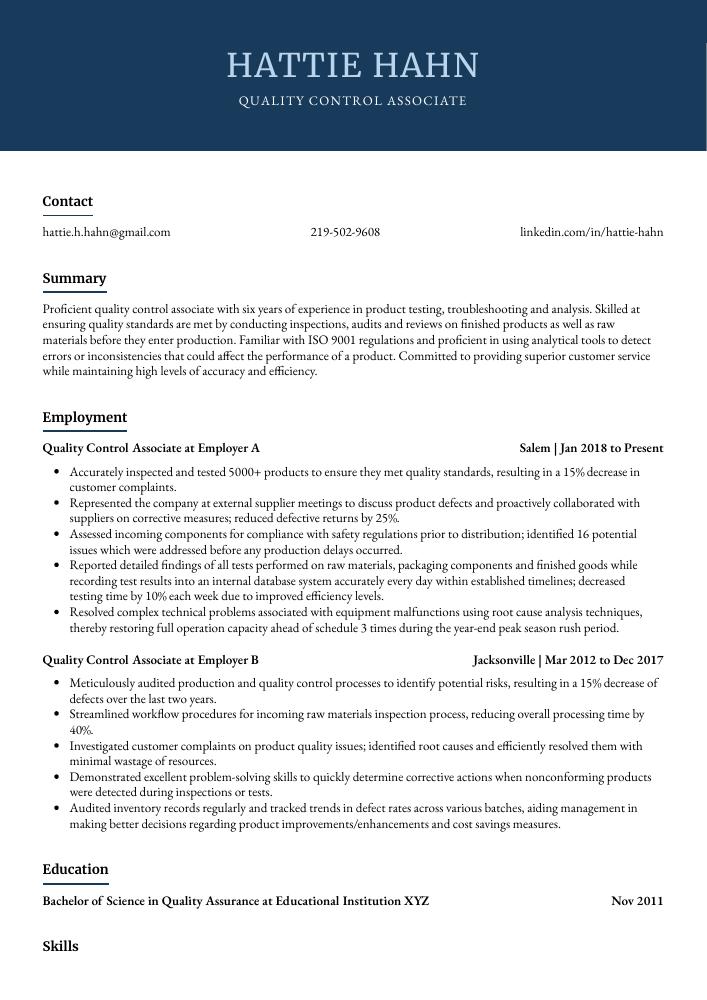

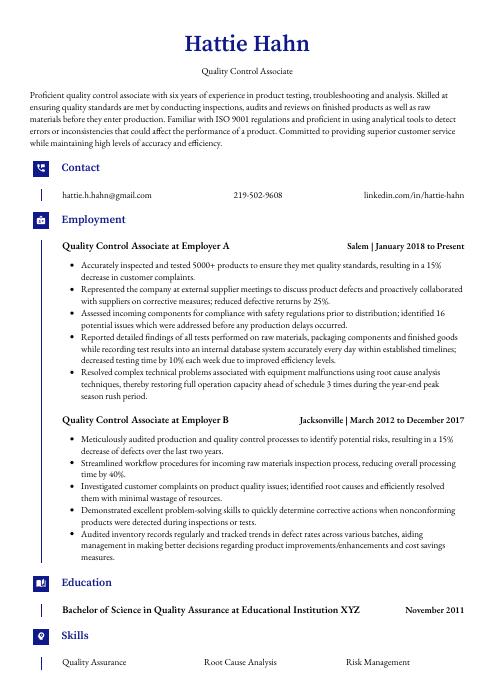

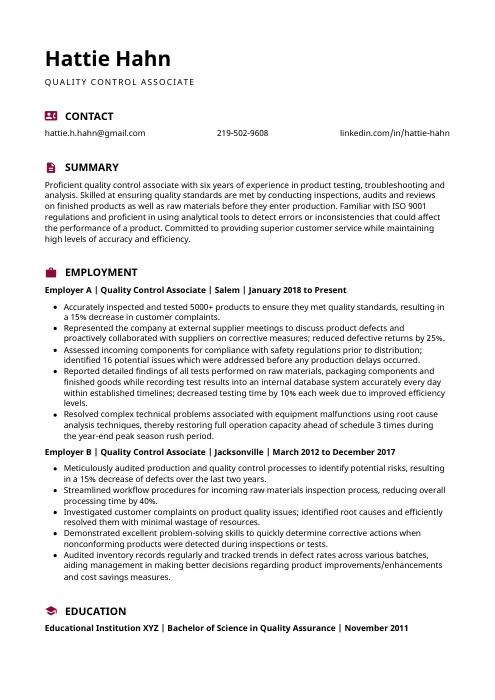

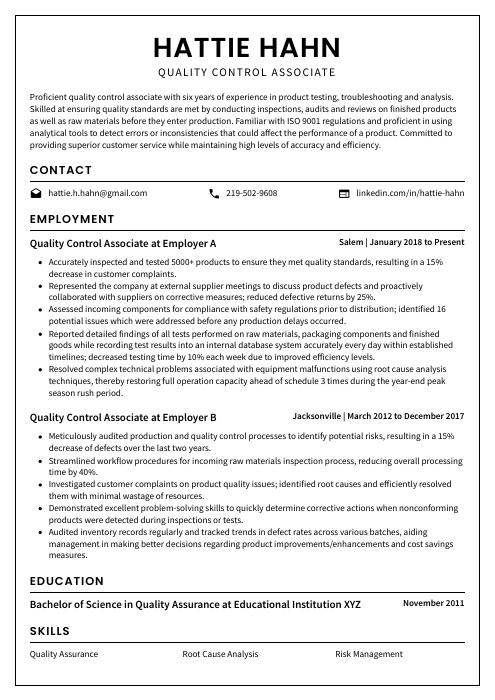

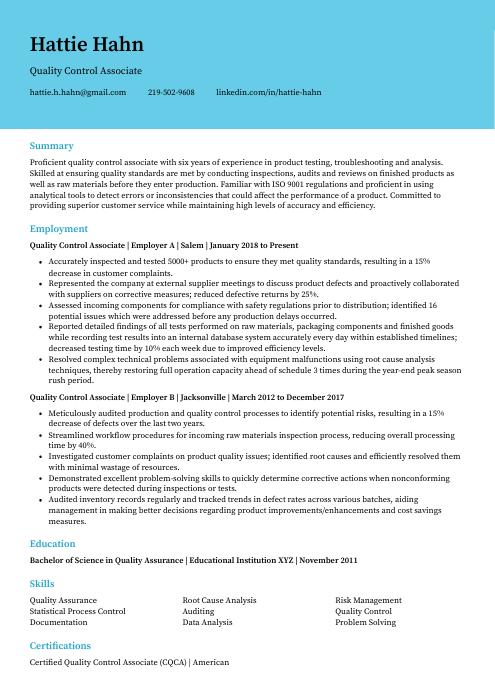

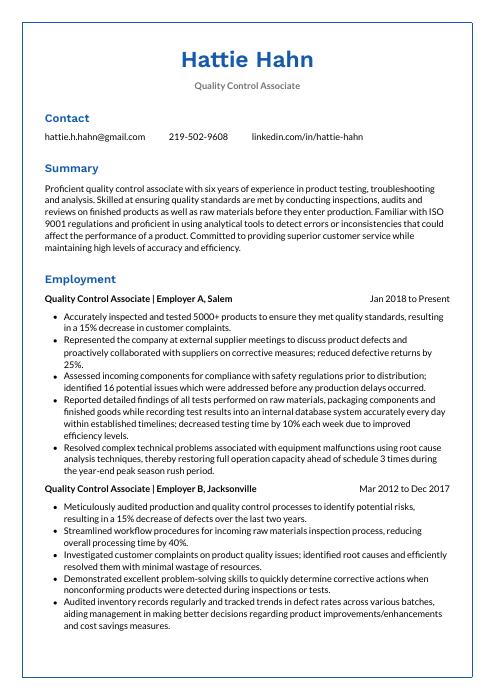

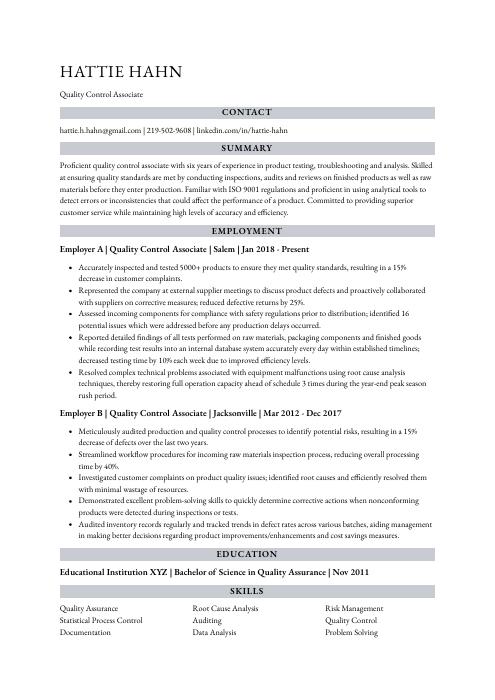

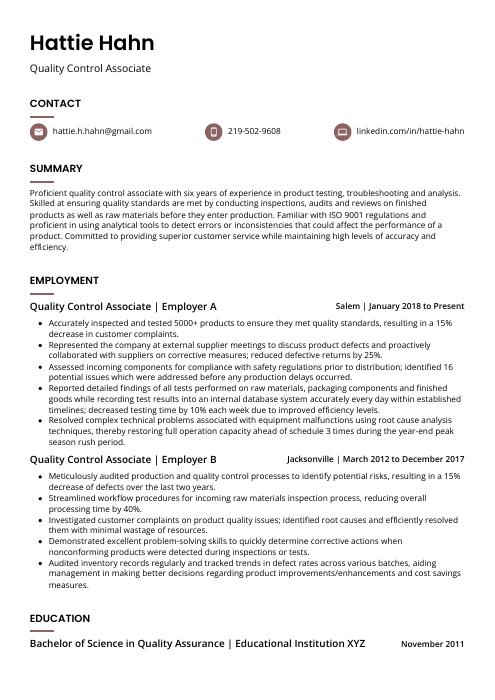

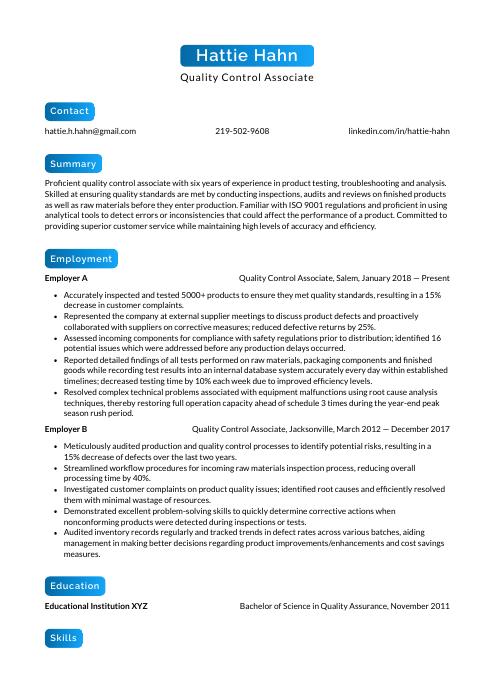

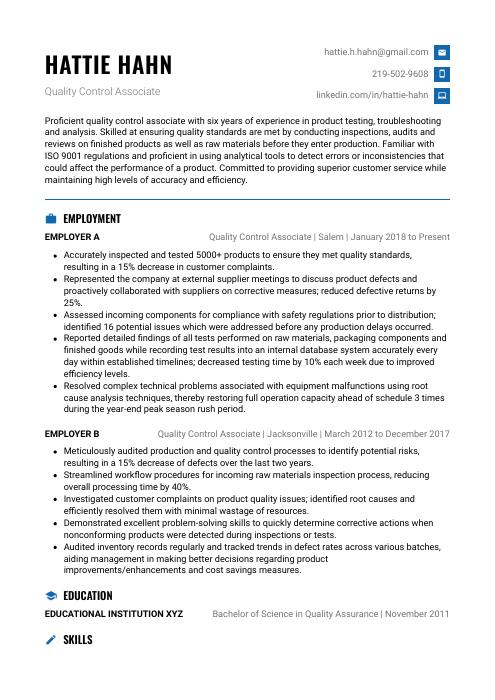

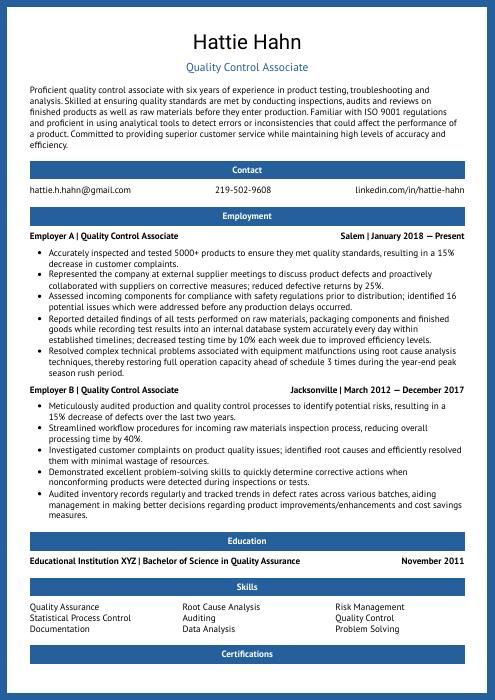

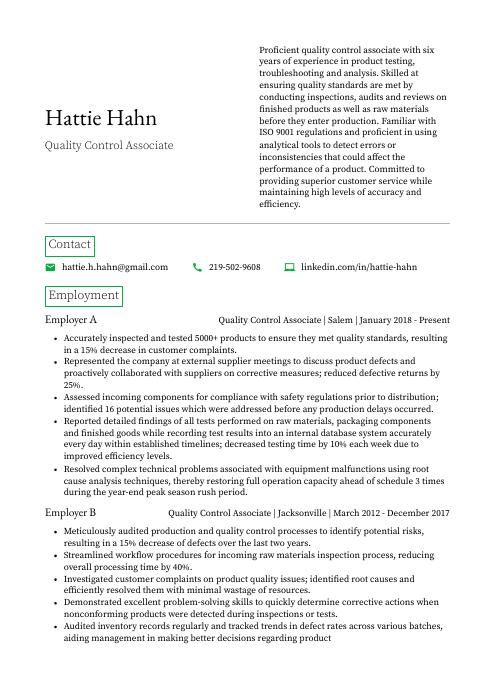

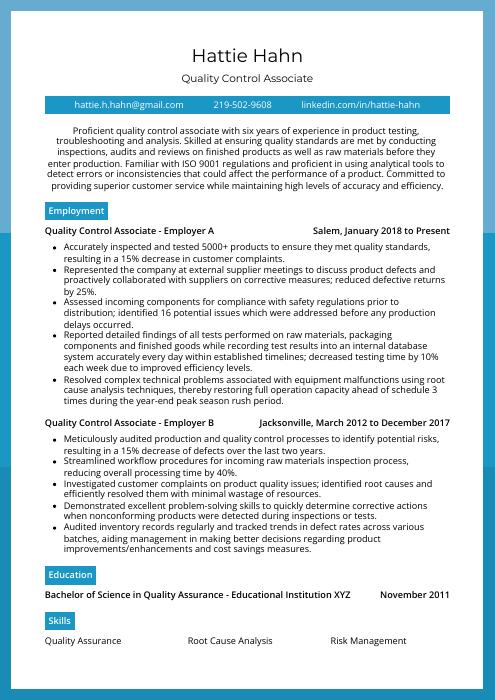

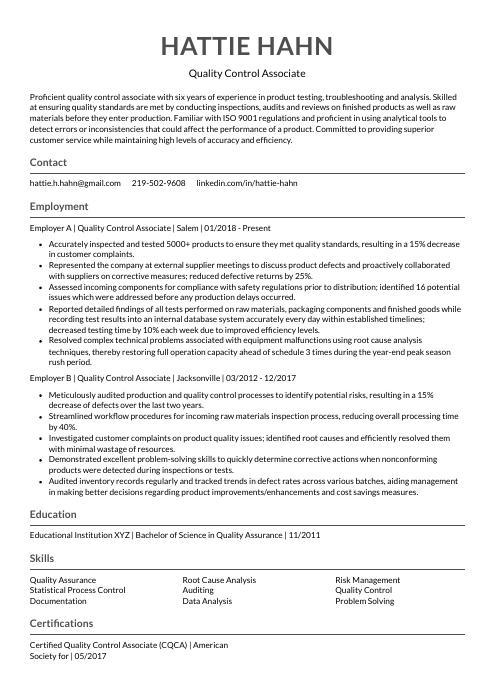

Quality Control Associate Resume Sample

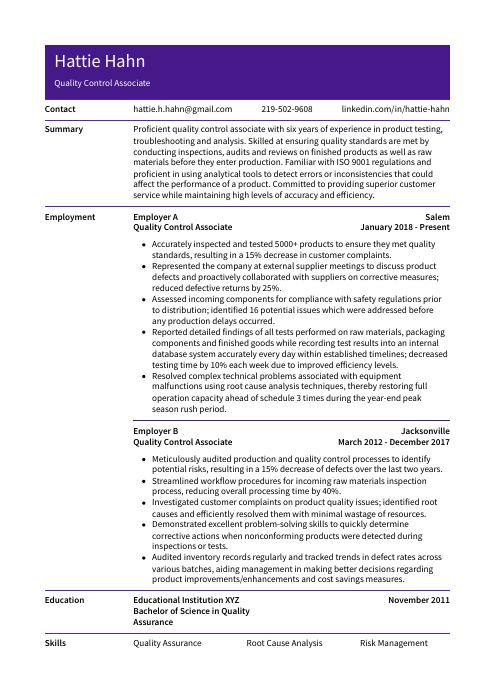

Hattie Hahn

Quality Control Associate

[email protected]

219-502-9608

linkedin.com/in/hattie-hahn

Summary

Proficient quality control associate with six years of experience in product testing, troubleshooting and analysis. Skilled at ensuring quality standards are met by conducting inspections, audits and reviews on finished products as well as raw materials before they enter production. Familiar with ISO 9001 regulations and proficient in using analytical tools to detect errors or inconsistencies that could affect the performance of a product. Committed to providing superior customer service while maintaining high levels of accuracy and efficiency.

Experience

Quality Control Associate, Employer A

Salem, Jan 2018 – Present

- Accurately inspected and tested 5000+ products to ensure they met quality standards, resulting in a 15% decrease in customer complaints.

- Represented the company at external supplier meetings to discuss product defects and proactively collaborated with suppliers on corrective measures; reduced defective returns by 25%.

- Assessed incoming components for compliance with safety regulations prior to distribution; identified 16 potential issues which were addressed before any production delays occurred.

- Reported detailed findings of all tests performed on raw materials, packaging components and finished goods while recording test results into an internal database system accurately every day within established timelines; decreased testing time by 10% each week due to improved efficiency levels.

- Resolved complex technical problems associated with equipment malfunctions using root cause analysis techniques, thereby restoring full operation capacity ahead of schedule 3 times during the year-end peak season rush period.

Quality Control Associate, Employer B

Jacksonville, Mar 2012 – Dec 2017

- Meticulously audited production and quality control processes to identify potential risks, resulting in a 15% decrease of defects over the last two years.

- Streamlined workflow procedures for incoming raw materials inspection process, reducing overall processing time by 40%.

- Investigated customer complaints on product quality issues; identified root causes and efficiently resolved them with minimal wastage of resources.

- Demonstrated excellent problem-solving skills to quickly determine corrective actions when nonconforming products were detected during inspections or tests.

- Audited inventory records regularly and tracked trends in defect rates across various batches, aiding management in making better decisions regarding product improvements/enhancements and cost savings measures.

Skills

- Quality Assurance

- Root Cause Analysis

- Risk Management

- Statistical Process Control

- Auditing

- Quality Control

- Documentation

- Data Analysis

- Problem Solving

Education

Bachelor of Science in Quality Assurance

Educational Institution XYZ

Nov 2011

Certifications

Certified Quality Control Associate (CQCA)

American Society for

May 2017

1. Summary / Objective

Your resume summary should provide the employer with a snapshot of your abilities and qualifications as a quality control associate. This is where you can highlight any certifications or awards that demonstrate your commitment to excellence, such as ISO 9001 certification or an award for outstanding performance in past roles. You could also mention how many years of experience you have in this field, the types of products/services you are familiar with testing, and any innovative processes or techniques you implemented during previous positions.

Below are some resume summary examples:

Reliable and detail-oriented quality control associate with 5+ years of experience in the manufacturing industry. Skilled in using advanced computer systems to document product defects and analyze data for process improvement initiatives. Successfully identified discrepancies that prevented shipments from going out on time, resulting in cost savings of $25,000 at Company X. Looking to join ABC Manufacturing as a quality assurance specialist where I can continue making meaningful contributions.

Passionate quality control associate with 5+ years of experience in the manufacturing industry. Expertise in developing and implementing quality assurance processes, ensuring compliance to safety standards and resolving customer complaints. At XYZ, successfully reduced defective products by 40% while maintaining production levels; earned two awards for excellence from management team. Committed to use my knowledge and expertise to ensure high-quality products that meet customers’ expectations.

Seasoned quality control associate with 5+ years of experience ensuring product quality for a variety of industries. Experienced in designing and executing comprehensive testing plans, analyzing and reporting on test results, and identifying areas for improvement. At XYZ Corporation, developed an automated system to track defects that reduced time spent manually tracking by 40%. Highly adept at working independently as well as collaboratively within cross-functional teams.

Committed and detail-oriented quality control associate with a proven track record of ensuring product reliability. At XYZ, successfully developed and implemented cost-effective inspection plans for new products that reduced defective production costs by 20%. Skilled in troubleshooting issues to identify root cause and develop corrective action plans. Highly organized with excellent communication skills necessary for successful collaboration across departments.

Diligent Quality Control Associate with 5+ years of experience in quality assurance and production. Consistently receive recognition for exceeding standards by delivering highest level of quality, accuracy, and efficiency. Experienced in developing SOPs to streamline operations while maintaining the integrity of products. Committed to achieving customer satisfaction through proactive problem-solving skills and attention to detail.

Detail-oriented Quality Control Associate with 3+ years of experience in quality assurance and product testing. Committed to ensuring customer satisfaction through rigorous product inspection, data analysis, and process improvement. At XYZ Company, reduced defect rates by 17% within the first year of employment. Seeking a challenging role at ABC where I can apply my expertise in Quality Assurance to fulfill company goals.

Determined quality control associate with 8+ years of experience verifying the quality and safety of products. Looking to join ABC Corporation as a QC Associate, leveraging expertise in data analysis and problem-solving skills to ensure customer satisfaction and product compliance. At XYZ, reduced production defects by 25% through improved inspection processes while enforcing strict adherence to company standards.

Dependable Quality Control Associate with 5+ years of experience ensuring product quality in a manufacturing setting. Adept at developing and implementing SOPs, troubleshooting issues, and analyzing data to ensure products meet company standards. Looking to join ABC Industries as their next Quality Manager where I can use my skills to help the organization reach its goals.

2. Experience / Employment

Next comes the work history section, which should be written in reverse chronological order, with your most recent job listed first.

When writing the bullet points for each role, provide detail about what you did and the results achieved. This allows the reader to get a better understanding of your experience level. For example, instead of saying “Performed quality control checks,” you could say “Conducted daily inspections on products according to industry standards; identified 3 instances of defective parts that were successfully replaced prior to shipment.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Monitored

- Analyzed

- Evaluated

- Tested

- Documented

- Resolved

- Investigated

- Tracked

- Reported

- Audited

- Calibrated

- Certified

- Improved

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Actively monitored production processes for quality assurance, inspecting over 4,000 units a day and ensuring all products met established standards; resulted in an improvement of product accuracy by 64%.

- Expedited the resolution of customer complaints regarding defective goods within 24 hours on average, reducing complaint response time by 35%.

- Analyzed data gathered from quality tests to identify process weaknesses and develop plans for continuous improvement; improved product performance rate by 45% compared to industry standard benchmarks.

- Documented findings from inspections using appropriate forms and tools such as checklists & questionnaires; enabled accurate tracking of non-conformance issues with minimal errors or omissions.

- Tracked defect trends through collected data analysis reports which were used as a basis for making informed decisions about changes in manufacturing/production procedures; reduced scrap costs due to defects by 28%.

- Certified in quality control processes and practices, with experience in developing checklists for inspections; identified errors within production process which resulted in a 7% increase in product output.

- Facilitated periodic audits of the factory floor to ensure compliance with safety regulations; successfully enforced necessary corrective action that improved employee health awareness by 17%.

- Prepared detailed reports on quality standards along with recommendations for improvement based on analysis of data collected during inspection rounds; enabled management team to make informed decisions that led to a 5% reduction in defective products over time.

- Resourcefully managed inventory levels across warehouse operations based on seasonal consumer demand fluctuations, ensuring continuous availability of goods without any disruption or delays; decreased stock-outs by 30%.

- Presented findings from ongoing research into new methods and technologies used for improving overall product performance while simultaneously reducing costs associated with manufacturing; generated savings amounting up to $12K annually.

- Participated in ongoing quality control processes, inspecting over 250 products daily and ensuring that all standards were met; reduced faulty items by 30% within the first two months.

- Formulated guidelines for efficient product testing procedures to ensure maximum accuracy in results and eliminated errors due to manual inspection methods.

- Advised cross-functional teams on best practices regarding product design, manufacture & packaging based on identified discrepancies between stated specs & actual samples; reduced manufacturing defects by 25%.

- Reduced turnaround time of quality assurance tasks from 3 days to 2 days through the implementation of automated checking tools such as X-ray machines and scanners.

- Efficiently managed resources while conducting tests using sophisticated equipment including gas analyzers, spectrometers & microscopes; decreased overall test costs by 15%.

- Revised quality control protocols to ensure compliance with industry standards, resulting in a 15% reduction of defects and customer complaints.

- Coordinated the inspection process for incoming raw materials from suppliers; identified deviations from specifications and took corrective action as needed.

- Inspected all finished products before delivery, ensuring that quality was maintained throughout every stage of production; significantly improved product reliability by 10%.

- Proficiently operated various testing equipment such as hardness testers & spectrometers according to safety guidelines; conducted effective tests on sample batches daily for flaws or imperfections.

- Spearheaded multiple initiatives aimed at improving processes related to quality assurance, which led to an increase in productivity by up to 5%.

- Optimized quality control processes by 15%, reducing scrap and rework materials while increasing throughput efficiency.

- Evaluated product quality, rejecting non-conforming products to ensure that customer specifications were met; decreased defective parts rate by 3%.

- Consistently ensured accuracy of incoming raw material inspections and outgoing finished goods testing with no discrepancies in 5 months of service.

- Utilized a variety of standard measuring instruments (calipers, micrometers etc.) as well as automated inspection systems for high-precision evaluations on all assembled components within strict timelines set forth by management team; improved overall production cycle time by 10%.

- Developed an effective training program for new employees on the use of advanced equipment such as CMM machines, vision systems and laser scanners to improve first-time pass rates significantly from 92% to 98%.

- Structured and maintained a rigorous quality control process for incoming raw materials and outgoing finished products, ensuring that all items met the company’s standards before delivery to customers; increased accuracy in product inspections by 18%.

- Independently conducted regular inventory checks of over 500 SKUs and identified discrepancies between physical counts and system records; reduced stock differences from 2% to 0.5% within one month due to improved tracking methods.

- Calibrated testing equipment such as thermometers, pH meters, spectrophotometers etc., according to manufacturers’ instructions on a weekly basis; developed an automated calibration reminder system which saved 8 hours per week in manual labor time.

- Improved existing procedures related to material handling through innovative problem solving techniques resulting in reduced production defects by 25%; facilitated communication with other departments regarding changes which led to greater operational efficiency across the board.

- Compiled comprehensive reports detailing test results, analysis & recommendations for further corrective action where necessary; presented findings at monthly meetings with senior management team leading up overall improvements in quality assurance processes throughout the organization.

- Monitored product quality for a total of 500+ units each day and ensured compliance with established standards, resulting in zero product defects over the past 3 months.

- Diligently inspected incoming raw materials to verify conformance with specifications; identified 5 potential suppliers violating safety regulations, subsequently reducing material costs by 10%.

- Mentored 4 junior employees on quality assurance best practices and regular product defect tracking & analysis procedures; improved the overall accuracy rate of inspections by 20%.

- Reorganized existing processes and introduced new strategies that reduced testing time per unit from 8 minutes to 6 minutes while maintaining high-quality outcomes across all products tested.

- Tested finished goods before shipment using advanced analytical tools like microscopes, thermometers & spectrometers to ensure they meet customer requirements, leading to a 60% reduction in complaints due to defective items over a 12 month period.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might be seeking someone with experience in quality management systems, while another might require knowledge of Six Sigma.

This is why it is important to tailor the skills section of your resume for each job you apply for; a large number of employers now use applicant tracking systems, which are computer programs that scan resumes for certain keywords before passing them on to a human.

Once listed here, you can further elaborate on your skillset by discussing it in more detail elsewhere – such as in the summary or experience sections – and provide examples from past positions where possible.

Below is a list of common skills & terms:

- Auditing

- Data Analysis

- Documentation

- Problem Solving

- Process Improvement

- Quality Assurance

- Quality Control

- Risk Management

- Root Cause Analysis

- Statistical Process Control

4. Education

Mentioning your education on your resume is a personal choice, depending on how far into your career you are. If you just graduated and have no experience yet, be sure to include an education section below your resume objective. However, if you have years of work experience in the quality control field that speaks for itself, omitting the education section might be more appropriate.

If including an education section makes sense for this role, try to mention courses or subjects related to quality control so employers can see that you’ve done relevant coursework before applying.

Bachelor of Science in Quality Assurance

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise and proficiency in a certain field. They can also help you stand out from other applicants, as they show that you have been tested by an accredited organization.

Including certifications on your resume is especially important if the job advert emphasizes specific skills or qualifications that are related to the certification you hold. This will give employers confidence in your abilities and make them more likely to consider hiring you for the role.

Certified Quality Control Associate (CQCA)

American Society for

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Hattie Hahn, this would be Hattie-Hahn-resume.pdf or Hattie-Hahn-resume.docx.

7. Cover Letter

Including a cover letter with your job application is a great way to make yourself stand out from the crowd. It’s an opportunity for you to provide more information about who you are, why you’re interested in the role and how your skills and experience might benefit the organisation.

Cover letters usually consist of 2-4 paragraphs that highlight information not already included in your resume or CV. They give recruiters a better insight into who you are as an individual and can help them decide if they want to consider inviting you for an interview or not.

Below is an example cover letter:

Dear Janiya,

I am writing in response to your posting for a Quality Control Associate. I have four years of experience working as a quality control associate in the food and beverage industry, and I am confident that I can be an asset to your team.

In my previous role, I was responsible for conducting quality assurance tests on raw materials and finished products, as well as investigating customer complaints. I have a keen eye for detail and excellent problem-solving skills, which has allowed me to identify issues early and prevent them from becoming larger problems. Additionally, I have experience training new employees on quality control procedures, which would be beneficial if you are looking for someone who can help train others.

I am knowledgeable of ISO 9001:2015 standards and HACCP principles, and my experience with laboratory equipment such as pH meters and microscopes would enable me to hit the ground running in this role. My goal is always to produce high-quality products that meet or exceed customer expectations, and I believe that I could be an asset to your organization in achieving this goal.

Please find attached a copy of my resume for your review. If you have any questions or would like to discuss further why I believe myself suited for this position at your company, please do not hesitate to contact me at [phone number] or [email address]. Thank you very much for your time; I look forward hearing from you soon!

Sincerely,

Hattie

Quality Control Associate Resume Templates

Gharial

Gharial Jerboa

Jerboa Lorikeet

Lorikeet Bonobo

Bonobo Hoopoe

Hoopoe Cormorant

Cormorant Dugong

Dugong Markhor

Markhor Numbat

Numbat Fossa

Fossa Kinkajou

Kinkajou Echidna

Echidna Axolotl

Axolotl Ocelot

Ocelot Saola

Saola Quokka

Quokka Rhea

Rhea Indri

Indri Pika

Pika Rezjumei

Rezjumei