Production Support Engineer Resume Guide

Production Support Engineers ensure that applications, systems and services are running smoothly in production environments. They monitor performance metrics, troubleshoot system issues, identify root causes of problems and provide technical support to end users. Additionally, they implement changes or upgrades to existing software solutions as required.

You have the technical know-how to support and maintain production systems, but employers don’t yet recognize your name. To make them aware of your qualifications, you must write a resume that highlights all of your accomplishments.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

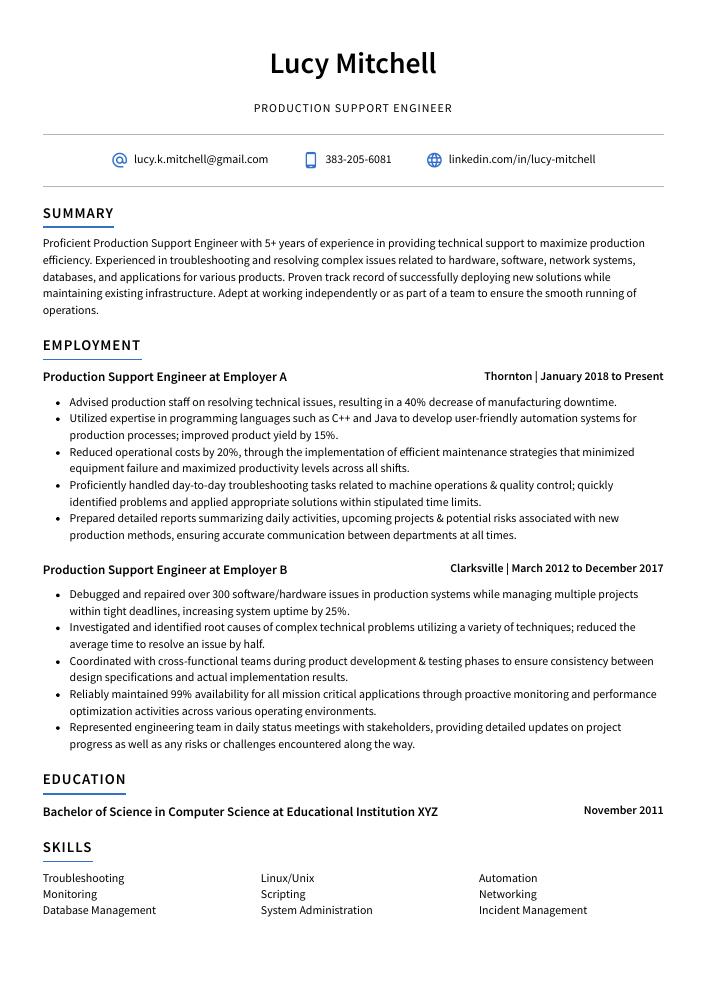

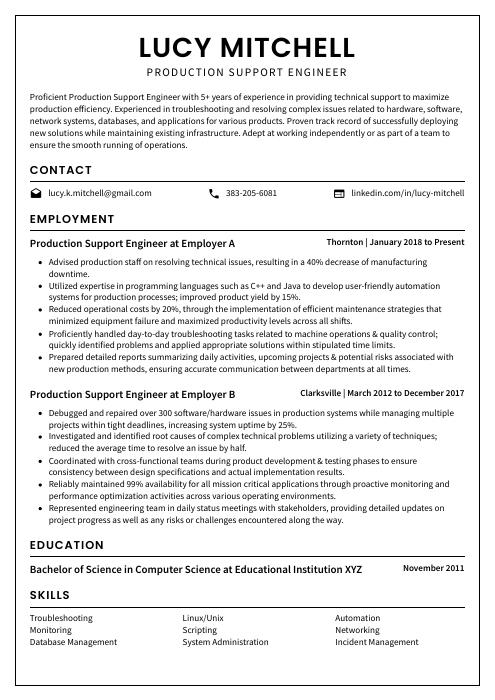

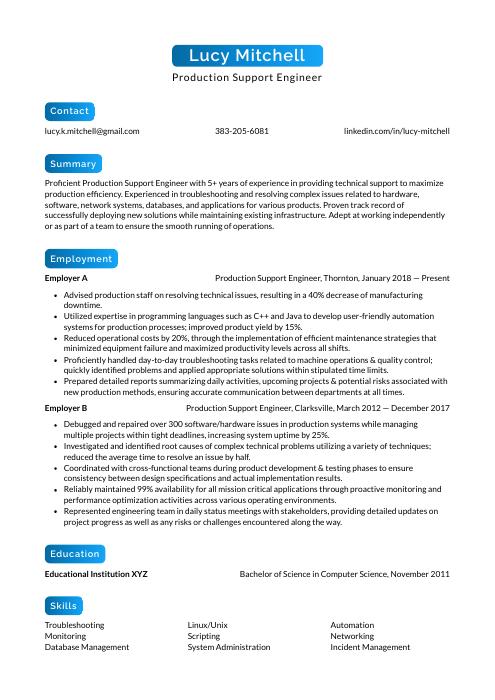

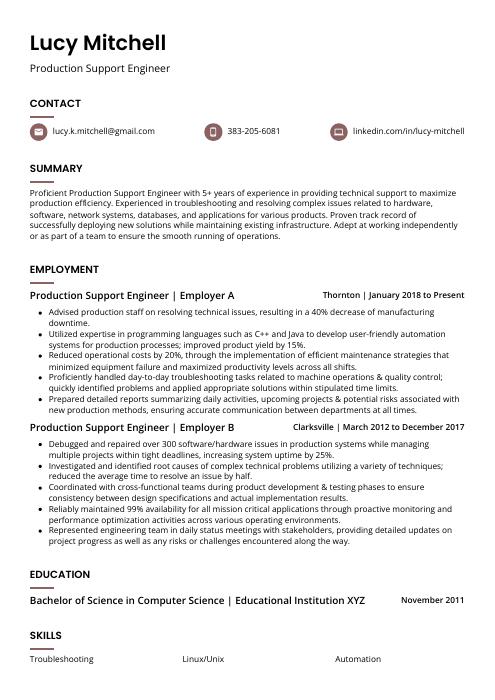

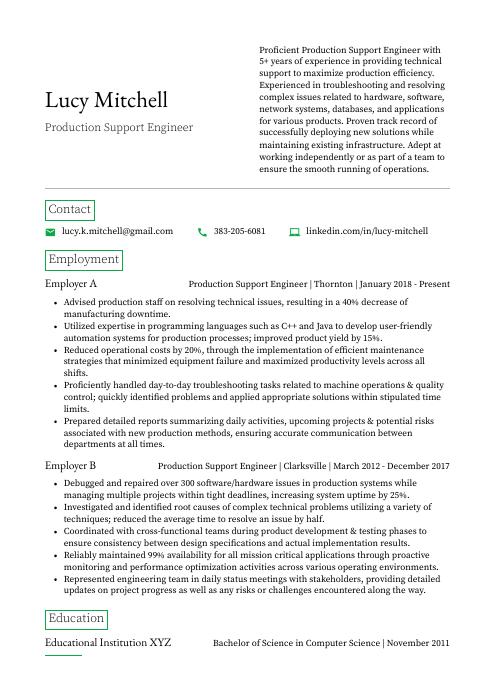

Production Support Engineer Resume Sample

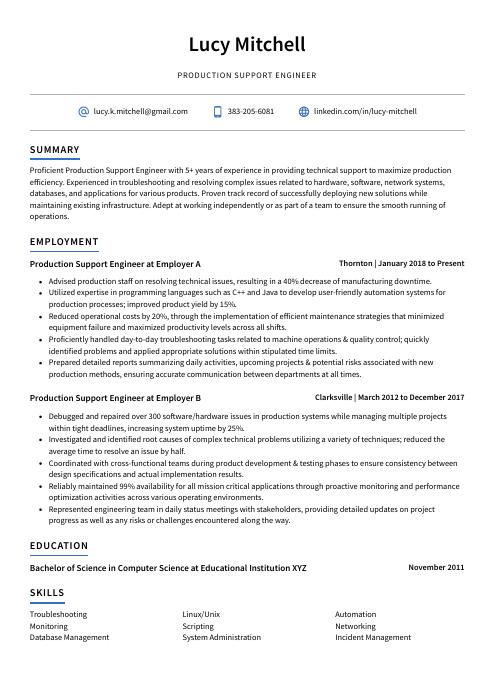

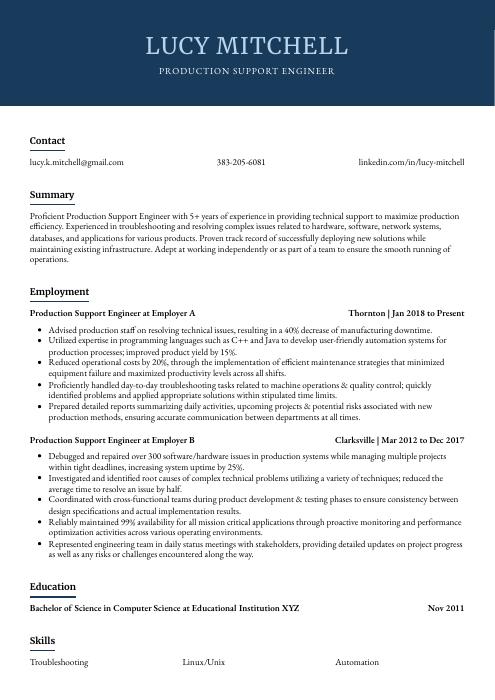

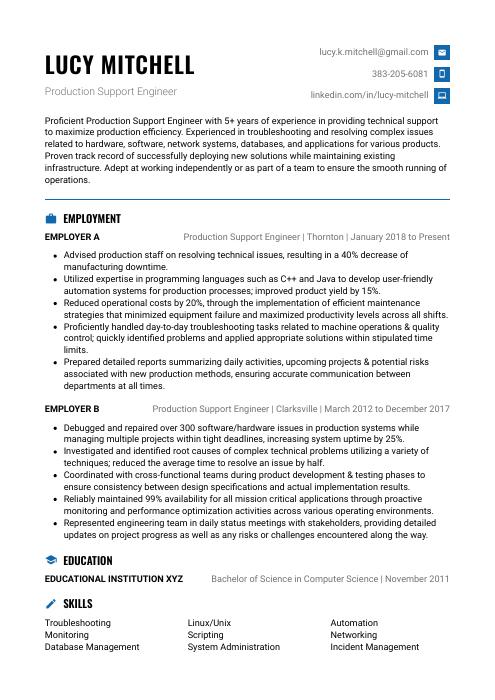

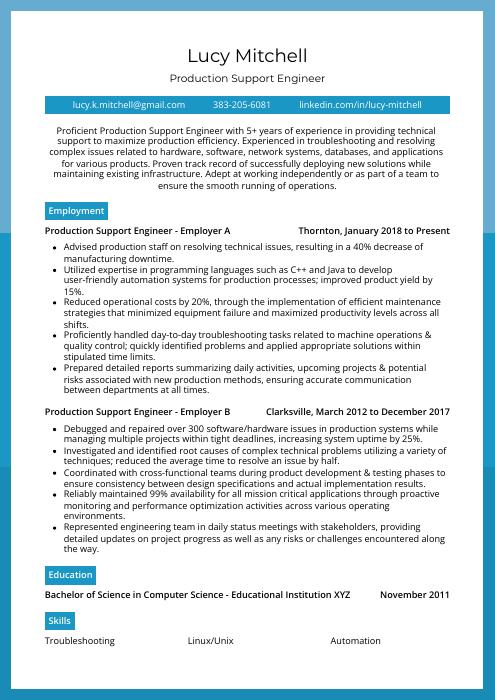

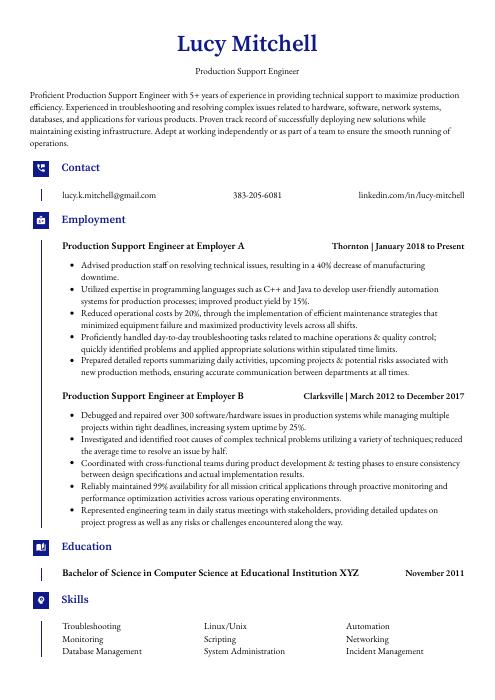

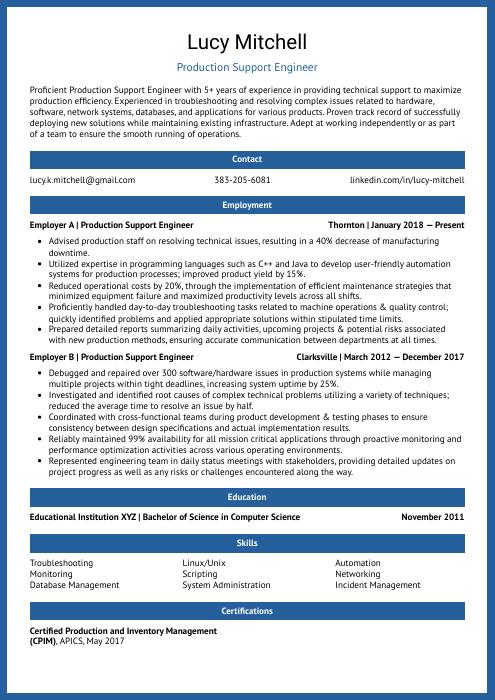

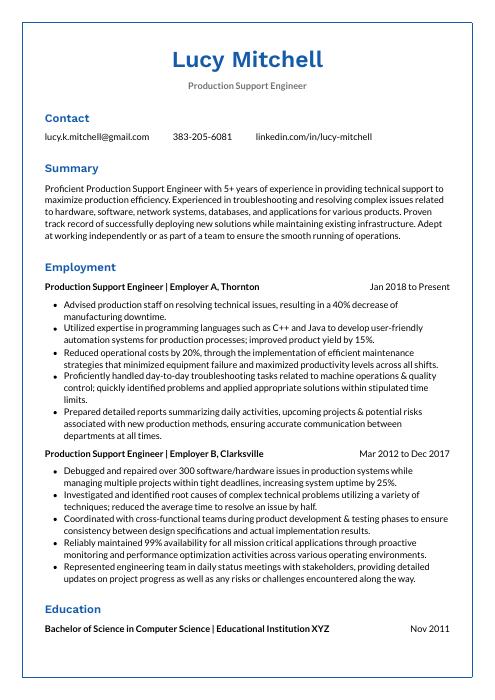

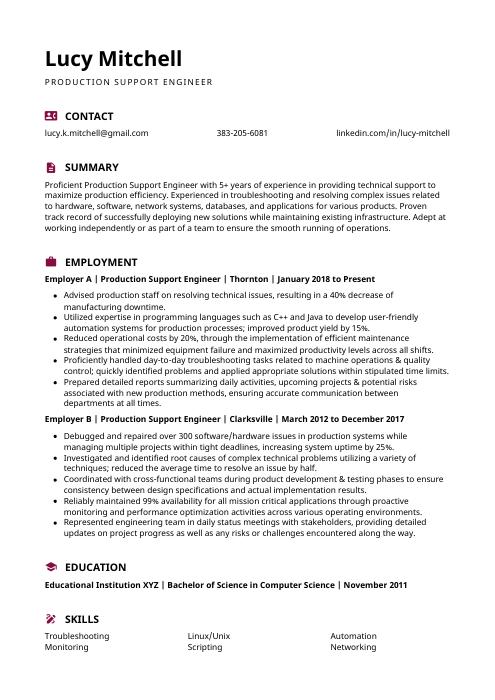

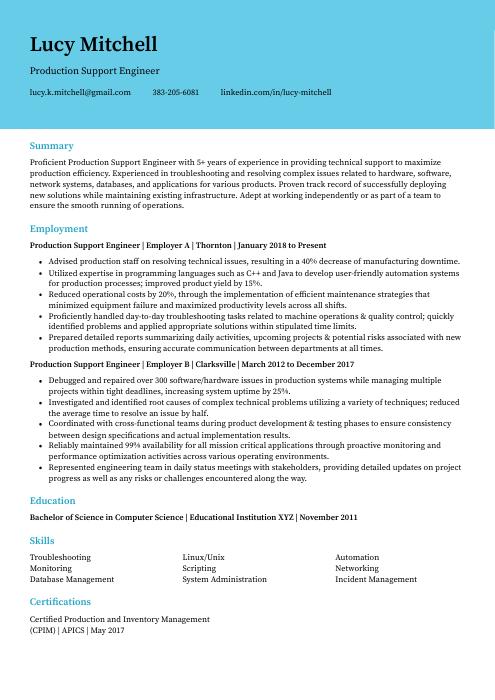

Lucy Mitchell

Production Support Engineer

[email protected]

383-205-6081

linkedin.com/in/lucy-mitchell

Summary

Proficient Production Support Engineer with 5+ years of experience in providing technical support to maximize production efficiency. Experienced in troubleshooting and resolving complex issues related to hardware, software, network systems, databases, and applications for various products. Proven track record of successfully deploying new solutions while maintaining existing infrastructure. Adept at working independently or as part of a team to ensure the smooth running of operations.

Experience

Production Support Engineer, Employer A

Thornton, Jan 2018 – Present

- Advised production staff on resolving technical issues, resulting in a 40% decrease of manufacturing downtime.

- Utilized expertise in programming languages such as C++ and Java to develop user-friendly automation systems for production processes; improved product yield by 15%.

- Reduced operational costs by 20%, through the implementation of efficient maintenance strategies that minimized equipment failure and maximized productivity levels across all shifts.

- Proficiently handled day-to-day troubleshooting tasks related to machine operations & quality control; quickly identified problems and applied appropriate solutions within stipulated time limits.

- Prepared detailed reports summarizing daily activities, upcoming projects & potential risks associated with new production methods, ensuring accurate communication between departments at all times.

Production Support Engineer, Employer B

Clarksville, Mar 2012 – Dec 2017

- Debugged and repaired over 300 software/hardware issues in production systems while managing multiple projects within tight deadlines, increasing system uptime by 25%.

- Investigated and identified root causes of complex technical problems utilizing a variety of techniques; reduced the average time to resolve an issue by half.

- Coordinated with cross-functional teams during product development & testing phases to ensure consistency between design specifications and actual implementation results.

- Reliably maintained 99% availability for all mission critical applications through proactive monitoring and performance optimization activities across various operating environments.

- Represented engineering team in daily status meetings with stakeholders, providing detailed updates on project progress as well as any risks or challenges encountered along the way.

Skills

- Troubleshooting

- Linux/Unix

- Automation

- Monitoring

- Scripting

- Networking

- Database Management

- System Administration

- Incident Management

Education

Bachelor of Science in Computer Science

Educational Institution XYZ

Nov 2011

Certifications

Certified Production and Inventory Management (CPIM)

APICS

May 2017

1. Summary / Objective

Your resume summary/objective should be a concise, yet powerful statement that captures the attention of hiring managers. For example, you could mention your expertise in troubleshooting complex technical issues and developing innovative solutions to improve system performance; or highlight your experience with scripting languages and automation tools. Additionally, you can emphasize any certifications or awards related to production support engineering that demonstrate your commitment to excellence in this field.

Below are some resume summary examples:

Seasoned production support engineer with 10+ years of experience providing technical assistance and troubleshooting for software platforms. Highly skilled in identifying issues, diagnosing system malfunctions, developing code fixes and analyzing customer feedback. Proven track record of reducing downtime by an average of 25% through effective problem-solving techniques. Looking to join ABC Tech as a production support engineer to help enhance their software systems efficiency.

Well-rounded production support engineer with 7+ years of experience in maintaining and troubleshooting software systems. Experienced in diagnosing, debugging, and resolving production issues to ensure continuity of operations. Proven track record for quickly identifying root causes leading to successful resolution of critical incidents. Adept at gathering customer requirements, developing technical specifications as well as providing training on new technologies/processes.

Enthusiastic production support engineer with 6+ years of experience providing technical solutions to complex software issues in a fast-paced environment. Able to quickly identify, diagnose and resolve production incidents for both on-premise and cloud systems. At XYZ Inc., reduced system downtime by 15%, resulting in improved customer satisfaction ratings. Looking to join ABC Company as a Production Support Engineer where I can continue leveraging my expertise.

Determined and organized Production Support Engineer with 5+ years of experience providing technical support. Expert in designing, engineering and implementing IT solutions to improve operational efficiency. At XYZ Corporation I worked closely with the production team to ensure seamless operations and minimal downtime. Proven track record of managing complex projects within tight deadlines while maintaining high quality standards for customer satisfaction.

Dependable production support engineer with 5+ years of experience in delivering technical solutions and troubleshooting production issues. Adept at analyzing, identifying, and resolving system performance issues quickly to minimize downtime. Proven ability to work collaboratively with development teams on design changes for scalability improvements. Experienced in scripting automation processes for improved efficiency in a fast-paced environment.

Amicable production support engineer with 5+ years of experience in resolving technical issues, deploying software updates and providing on-site support. At XYZ, successfully managed the production environment for 20 applications across 3 data centers in different geographies. Recognized for adeptly troubleshooting complex problems to reduce downtime by up to 75%. Exceptional problem-solving skills make me an ideal candidate for this role.

Passionate production support engineer with 5+ years of experience in resolving complex production issues and ensuring peak performance. Achieved 98% uptime for critical business systems at XYZ Company through proactive maintenance and troubleshooting. Seeking to join ABC Tech where I can apply my technical knowledge, organizational skills, and problem-solving abilities to enhance the quality of service delivery.

Talented production support engineer with 5+ years of experience in system and application operations. Proven track record of successful deployments, uptime optimization, incident resolution, data management and customer satisfaction. Seeking to join ABC as a production support engineer to leverage my technical expertise in optimizing the performance of their mission-critical systems.

2. Experience / Employment

In the experience section, you should provide details on your work history. This section is written in reverse chronological order, meaning the most recent job is listed first.

When providing information about what you did at each role, use bullet points to make it easier for the reader to digest this information quickly. You want to take some time and think of quantifiable results that were obtained due to your actions or efforts. For example, instead of saying “Provided technical support,” you could say “Resolved over 200 customer queries per month through remote access software and phone calls; resulting in a 15% decrease in call-back requests.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Investigated

- Resolved

- Automated

- Configured

- Implemented

- Documented

- Troubleshot

- Analyzed

- Optimized

- Tested

- Debugged

- Upgraded

- Managed

- Supported

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Spearheaded the production process of over 5,000 components with a 98% accuracy rate, reducing the average time per unit by 2 hours.

- Assessed and optimized factory equipment performance to ensure productivity targets were met; improved output efficiency by 15%.

- Demonstrated strong troubleshooting skills when resolving technical issues in production machinery; decreased downtime due to equipment malfunctioning by 27%.

- Achieved cost savings of $5,500 through proactive maintenance and preventive repairs on automated assembly line machines during 3-month period.

- Thoroughly inspected quality control standards throughout the entire manufacturing process for compliance with industry regulations and customer specifications requirements.

- Revised manufacturing processes and procedures to improve overall production efficiency by 17%, reducing time-to-market for new products significantly.

- Independently identified, analyzed and resolved over 300 technical issues related to assembly lines, machines & equipment in a timely manner.

- Improved workplace safety standards within the factory environment; lowered employee injury rates from 5% to 1%.

- Optimized existing production systems with innovative solutions such as automated quality control tools and IoT sensors; saved 20 hours of manual labor per week in total.

- Formulated data-driven reports based on manufacturing performance metrics which were presented at monthly management meetings; increased profits by $25K annually due to improved decision making capabilities enabled by insights gained from data analysis.

- Participated in the design, development and implementation of production support processes that increased throughput by 25% while reducing downtime incidents by 20%.

- Supported up to 5 concurrent projects in a fast-paced environment; troubleshooted complex technical issues onsite within an average time frame of 3 hours.

- Developed comprehensive training materials for new employees and delivered 120+ effective onboarding sessions over 2 years; improved process efficiency across teams by 10%.

- Documented all processes related to engineering projects and equipment maintenance activities accurately with clear instructions for future reference; reduced errors due to miscommunication or misunderstanding among team members by 15%.

- Consistently provided excellent customer service when responding to inquiries or resolving problems reported via phone, email or online chat platforms within 24 hours on average.

- Actively monitored the production environment and ensured efficient functioning of all equipment, resulting in a 20% improvement in overall productivity.

- Mentored 10 junior engineers on software development best practices and troubleshooting techniques to support their daily operations with minimal downtime.

- Compiled detailed reports on system performance across multiple platforms as well as any issues encountered; identified areas for process improvements that drove an increase of $25K in annual savings.

- Automated critical processes related to ensuring product quality using scripting languages such as Python & JavaScript, reducing manual labor costs by 30%.

- Resolved technical problems within tight deadlines while maintaining high standards of customer service; successfully completed 50+ projects over the course of 6 months without major glitches or delays.

- Tested, debugged, and resolved technical issues related to software systems for over 200 production machines; improved system stability by 30%.

- Managed the installation of new hardware components, operating systems upgrades, and software updates on an assigned fleet of manufacturing equipment; executed 10+ preventive maintenance tasks daily across 15+ production lines.

- Confidently diagnosed complex root cause problems in a timely manner while providing high-quality solutions without disrupting critical operations or machine downtime; increased user satisfaction rate by 25%.

- Expedited issue resolution through excellent communication with senior leadership teams as well as other IT support staff members throughout all stages of troubleshooting processes; decreased mean time to repair (MTTR) from 4 hours to 2 hours per incident on average.

- Configured network settings for newly acquired devices according to corporate standards & protocols set forth by the organization’s IT department; optimized resources utilization leading to a 20% decrease in operational expenses annually.

- Troubleshot, diagnosed and resolved production system issues within 45 minutes, improving the uptime of all manufacturing equipment by 25%.

- Monitored program performance metrics on a daily basis, identified potential risks and recommend preventive maintenance measures to reduce downtime for up to 95% of all machines.

- Substantially improved product quality control processes in line with industry standards; reduced defective products by 30%, resulting in $10,000 savings per month.

- Introduced automated testing tools and systems that significantly enhanced process efficiency; increased productivity rate by 20% while reducing labor costs by $9,500 annually.

- Implemented new updates and patches across manufacturing operations platforms regularly to ensure compatibility with other software programs on the network; minimized disruption time from 3 hours down to 15 minutes per update cycle.

- Upgraded production systems to improve efficiency and cut down on downtime, resulting in a 15% decrease in production costs.

- Streamlined processes to reduce manual labor costs by 20%, leading to an increase of $25,000 per quarter in savings.

- Analyzed existing infrastructure for potential improvements; identified 25 areas that could be optimized, saving the organization over 100 hours of labor during peak season.

- Structured efficient workflow plans that improved throughput rate by 10% while reducing faults & errors in delivery timescales by 14%.

- Efficiently troubleshot hardware and software issues related to production support operations, cutting repair time from 3 days down to 1 day or less for 75% of reported incidents.

- Resourcefully maintained and troubleshot production systems, programs and networks to ensure that all equipment operated efficiently; decreased downtime by 15%.

- Facilitated weekly meetings with engineering team members to discuss plans for upcoming projects; shared ideas on how to reduce costs while improving efficiency.

- Presented proposals outlining the benefits of using new technology in order to improve existing processes, resulting in a 10% reduction in production costs over the last year.

- Reorganized databases containing product information which enabled faster retrieval times and increased customer satisfaction levels by 30%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require the candidate to be proficient in Linux while Organization XYZ may prefer someone with Windows experience.

It is important to tailor your skills section accordingly as many employers use applicant tracking systems (ATS) these days, which are computer programs that scan resumes for certain keywords before passing them on to a human.

Once listed here, you can further elaborate on your skill set by discussing it in more detail elsewhere; such as the summary or work experience sections of your resume.

Below is a list of common skills & terms:

- Automation

- Cloud Computing

- Database Management

- Incident Management

- Linux/Unix

- Monitoring

- Networking

- Scripting

- System Administration

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below your resume objective. However, if you have significant work experience to showcase, it may be better to omit the education section altogether.

If an education section is included, make sure to list courses or subjects that relate directly to the production support engineer role for which you’re applying.

Bachelor of Science in Computer Science

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have taken the time and effort to gain knowledge and experience in an area, which can be beneficial when applying for jobs.

Including certifications on your resume is important as it allows hiring managers to quickly assess if you are qualified for the job they are offering. It also shows that you take initiative by investing in yourself professionally, making you more attractive as a candidate.

Certified Production and Inventory Management (CPIM)

APICS

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Lucy Mitchell, this would be Lucy-Mitchell-resume.pdf or Lucy-Mitchell-resume.docx.

7. Cover Letter

Writing a cover letter is an important step when applying for a job. It is your chance to show potential employers why you are the ideal candidate and should be considered for the position.

Cover letters typically consist of 2 to 4 paragraphs that introduce yourself and explain what makes you suitable for the role. They offer recruiters more information than what’s available on your resume, allowing them to gain a better understanding of who you are as a professional and how well suited you would be to their company.

Below is an example cover letter:

Dear Elian,

I am writing to apply for the Production Support Engineer position at XYZ Company. I am a recent graduate of ABC University with a degree in computer science and have gained valuable experience working as a production support engineer at DEF Corporation. In my current role, I provide level 1 and 2 support for software applications used by internal customers. I also work closely with developers to troubleshoot issues and create technical documentation.

The skills and knowledge I have acquired make me an ideal candidate for the Production Support Engineer position at your company. My ability to quickly learn new technologies, strong analytical skills, and excellent problem-solving abilities would be beneficial in this role. Additionally, my outstanding communication skills would enable me to effectively interact with customers and other stakeholders.

I am eager to utilize my skills and experience in a challenging environment where I can continue to develop professionally while making positive contributions to your organization’s success. I look forward to speaking with you soon about this opportunity. Thank you for your time and consideration.

Sincerely,

Lucy

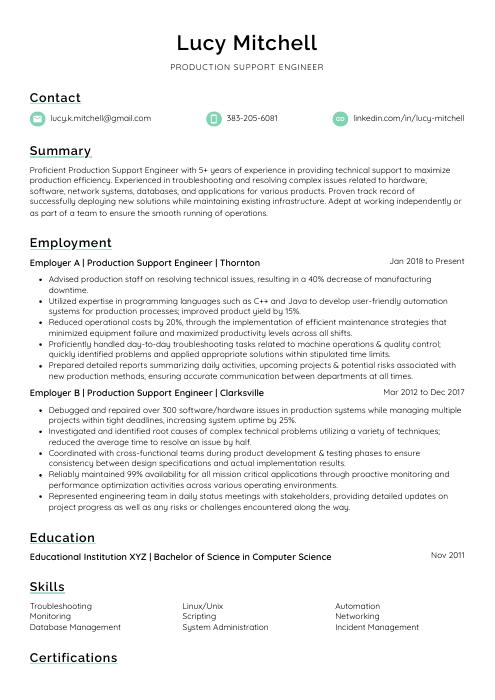

Production Support Engineer Resume Templates

Lorikeet

Lorikeet Numbat

Numbat Indri

Indri Axolotl

Axolotl Bonobo

Bonobo Saola

Saola Echidna

Echidna Rhea

Rhea Gharial

Gharial Ocelot

Ocelot Jerboa

Jerboa Pika

Pika Cormorant

Cormorant Kinkajou

Kinkajou Fossa

Fossa Quokka

Quokka Markhor

Markhor Hoopoe

Hoopoe Dugong

Dugong Rezjumei

Rezjumei