Product Quality Engineer Resume Guide

Product Quality Engineers ensure that products meet the necessary quality standards before being released to the public. They analyze product design and performance, identify defects, troubleshoot problems with existing designs, and develop testing procedures for new products. Additionally, they also create reports documenting their findings so that any issues can be addressed in a timely manner.

You have the technical know-how and eye for detail to make sure that any product meets its highest standards. But potential employers don’t know about your experience yet. To get them interested in you, create a resume that stands out from the competition.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

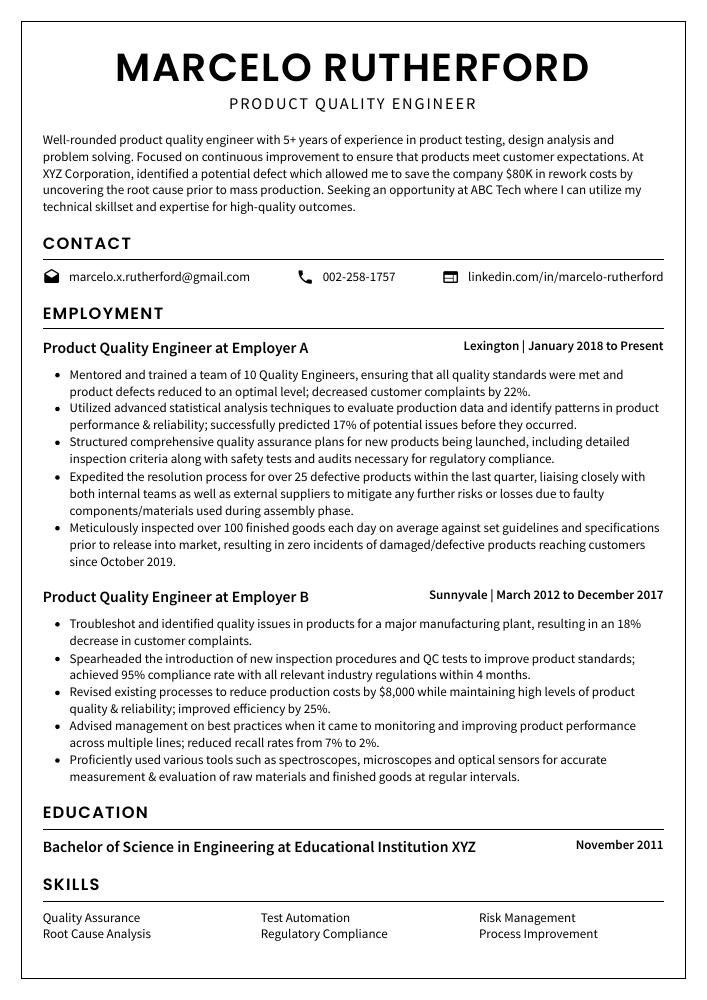

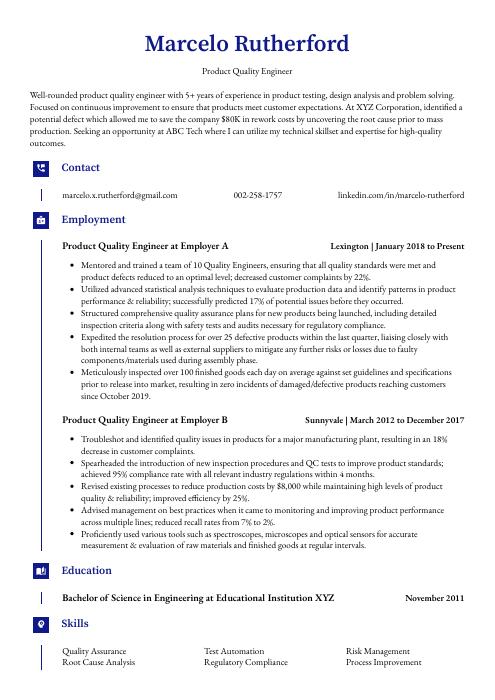

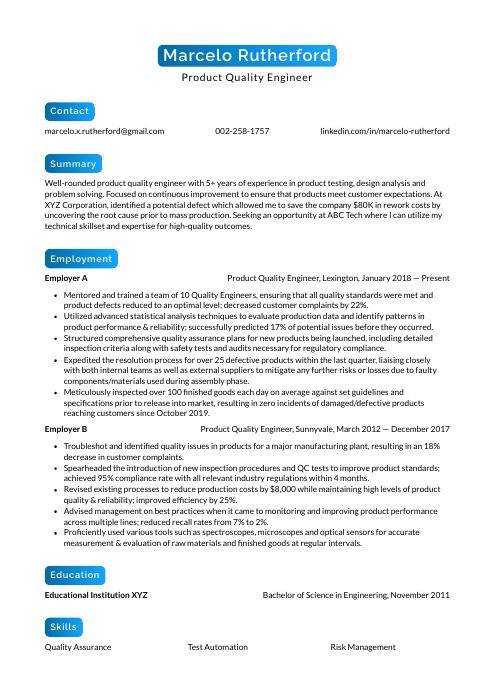

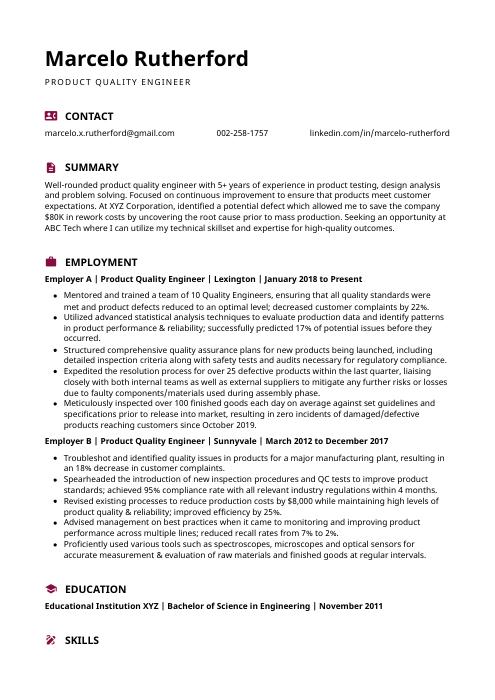

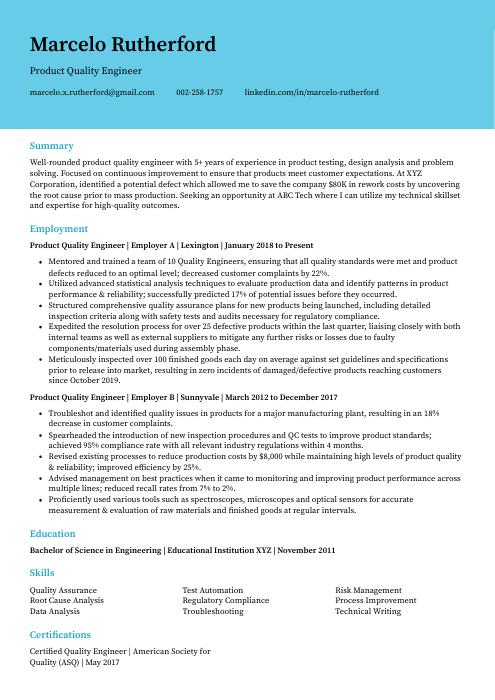

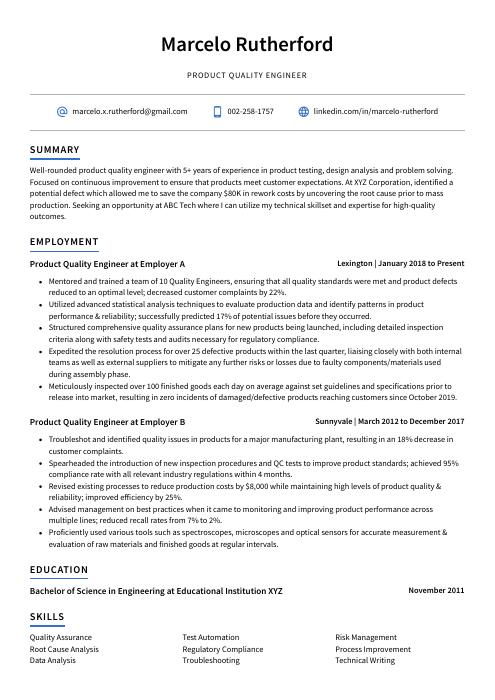

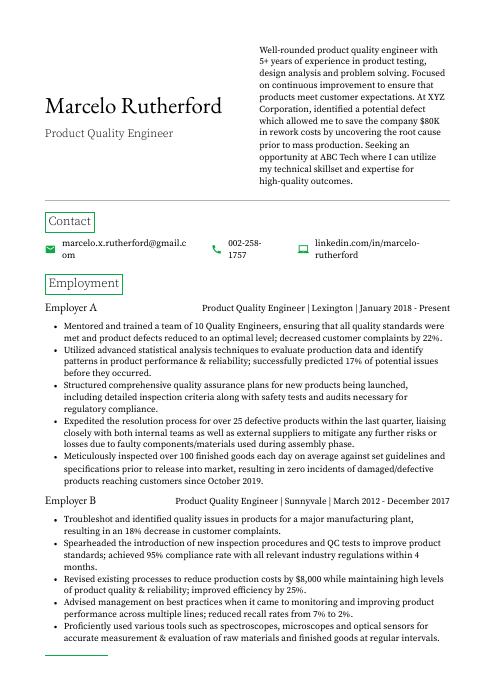

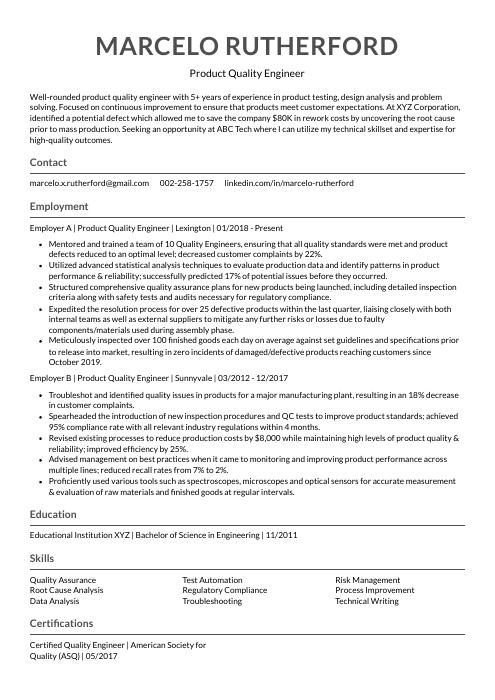

Product Quality Engineer Resume Sample

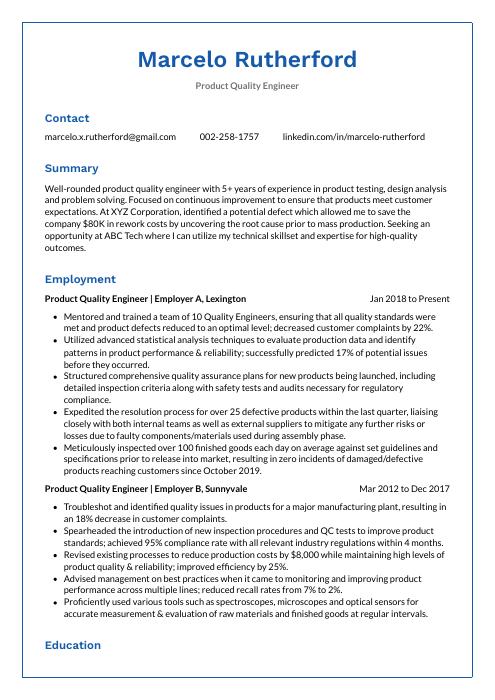

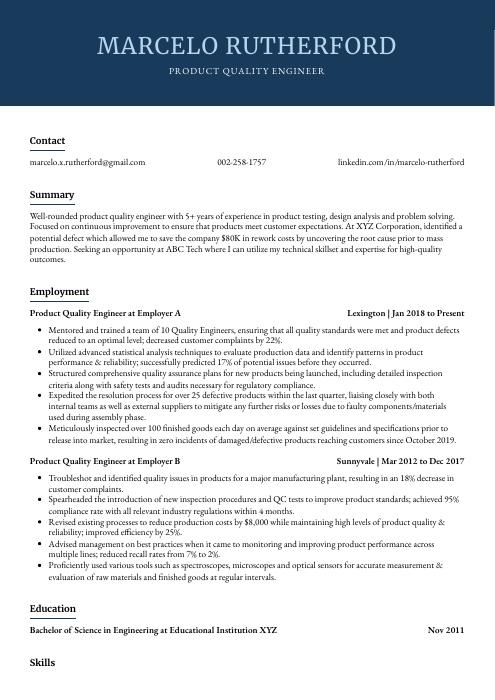

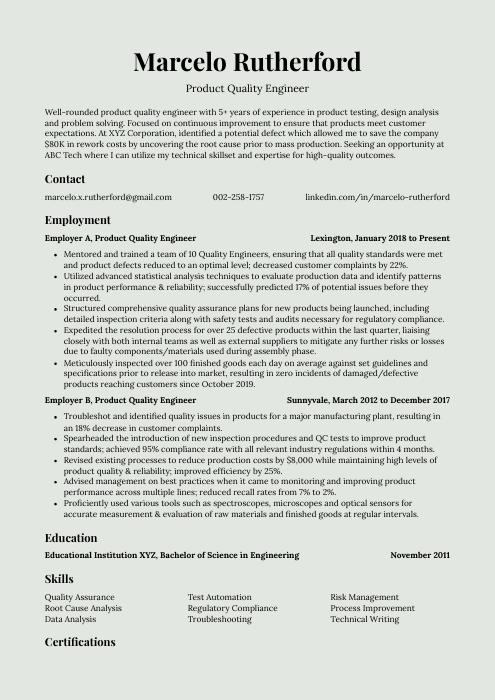

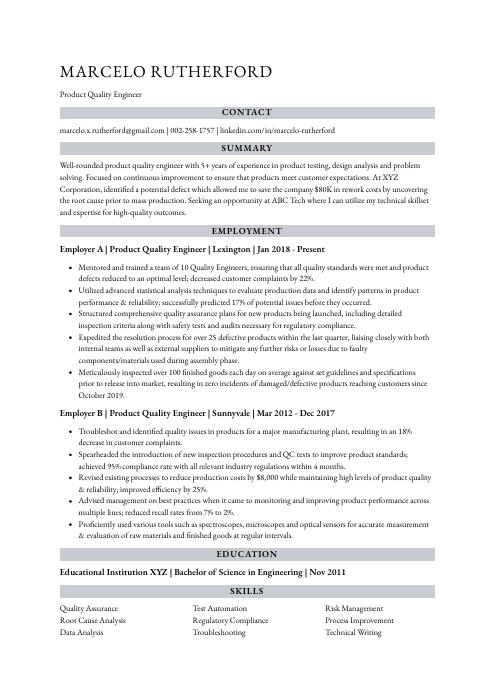

Marcelo Rutherford

Product Quality Engineer

[email protected]

002-258-1757

linkedin.com/in/marcelo-rutherford

Summary

Well-rounded product quality engineer with 5+ years of experience in product testing, design analysis and problem solving. Focused on continuous improvement to ensure that products meet customer expectations. At XYZ Corporation, identified a potential defect which allowed me to save the company $80K in rework costs by uncovering the root cause prior to mass production. Seeking an opportunity at ABC Tech where I can utilize my technical skillset and expertise for high-quality outcomes.

Experience

Product Quality Engineer, Employer A

Lexington, Jan 2018 – Present

- Mentored and trained a team of 10 Quality Engineers, ensuring that all quality standards were met and product defects reduced to an optimal level; decreased customer complaints by 22%.

- Utilized advanced statistical analysis techniques to evaluate production data and identify patterns in product performance & reliability; successfully predicted 17% of potential issues before they occurred.

- Structured comprehensive quality assurance plans for new products being launched, including detailed inspection criteria along with safety tests and audits necessary for regulatory compliance.

- Expedited the resolution process for over 25 defective products within the last quarter, liaising closely with both internal teams as well as external suppliers to mitigate any further risks or losses due to faulty components/materials used during assembly phase.

- Meticulously inspected over 100 finished goods each day on average against set guidelines and specifications prior to release into market, resulting in zero incidents of damaged/defective products reaching customers since October 2019.

Product Quality Engineer, Employer B

Sunnyvale, Mar 2012 – Dec 2017

- Troubleshot and identified quality issues in products for a major manufacturing plant, resulting in an 18% decrease in customer complaints.

- Spearheaded the introduction of new inspection procedures and QC tests to improve product standards; achieved 95% compliance rate with all relevant industry regulations within 4 months.

- Revised existing processes to reduce production costs by $8,000 while maintaining high levels of product quality & reliability; improved efficiency by 25%.

- Advised management on best practices when it came to monitoring and improving product performance across multiple lines; reduced recall rates from 7% to 2%.

- Proficiently used various tools such as spectroscopes, microscopes and optical sensors for accurate measurement & evaluation of raw materials and finished goods at regular intervals.

Skills

- Quality Assurance

- Test Automation

- Risk Management

- Root Cause Analysis

- Regulatory Compliance

- Process Improvement

- Data Analysis

- Troubleshooting

- Technical Writing

Education

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Quality Engineer

American Society for Quality (ASQ)

May 2017

1. Summary / Objective

Your resume summary is like a movie trailer – it provides the hiring manager with essential bits of information and, if written correctly, should compel them to read on. This is where you can showcase your best qualities as a product quality engineer. For example, you could mention the engineering principles and processes that are second nature to you, the experience in developing test plans for complex products or systems, and how your attention to detail has led to improved customer satisfaction ratings.

Below are some resume summary examples:

Determined product quality engineer with 5+ years of experience in the consumer electronics industry. Experienced in developing and executing product testing plans, resolving customer complaints, creating detailed reports on test results, and recommending corrective actions to meet safety standards. Skilled at using statistical methods to identify root causes of product failures and proposing cost-effective solutions to improve overall product performance.

Proficient Product Quality Engineer with 5+ years of experience in product development for large-scale consumer electronics. Possesses expertise in testing, analysis, and problem solving to identify issues before products are released. Well-versed in ISO 9001 standards and regulations as well as customer requirements. At XYZ Company achieved a 98% success rate from the introduction of new products into production by driving process improvement initiatives.

Professional product quality engineer with 5+ years of experience in the consumer electronics industry. Skilled at utilizing statistical methods to ensure product safety and performance, as well as inspecting products for accuracy and compliance with standards. At XYZ, identified process improvements that resulted in a 10% reduction in warranty claims costs. Highly knowledgeable about ISO 9001:2015 Quality Management System implementation and maintenance.

Diligent product quality engineer with 5+ years of experience developing, testing and maintaining high-quality products. Experienced in leading product evaluations to ensure adherence with safety regulations and customer requirements. At XYZ Company, improved product reliability by 25%, resulting in a 35% increase in client satisfaction ratings. Seeking to leverage my expertise at ABC Corporation to help improve the overall quality of their products.

Amicable product quality engineer with 5+ years of experience in the manufacturing industry. Proven track record of reducing product defects by 40% at XYZ, resulting in a 10% increase in customer satisfaction ratings. Skilled problem-solver who excels working across departments to ensure products are developed and tested according to company standards and regulations. Adept at quickly identifying potential issues before they become costly failures.

Talented product quality engineer with 8+ years of experience in developing and implementing product quality plans for a variety of products. Skilled at driving process improvements, conducting failure analysis tests, and mitigating risks to ensure the highest standard of product safety. Seeking to join ABC Company as Quality Engineer where I can use my expertise to maintain high levels of customer satisfaction across all products.

Enthusiastic and detail-oriented product quality engineer with 8+ years of experience in developing, executing and maintaining test plans for consumer products. Proven track record of successfully improving the overall quality standards through improved testing procedures resulting in a 20% reduction in customer complaints. Looking to join ABC as a Quality Engineer to continue driving top-notch product reliability and performance.

Detail-oriented product quality engineer with 5+ years of experience designing and executing product testing plans to ensure functional, aesthetic, and safety compliance. Skilled in identifying defects using root cause analysis methods and creating reports for stakeholders. Recently reduced customer returns at XYZ by 38% through the implementation of rigorous QA protocols.

2. Experience / Employment

The work history/experience section is where you list your job titles and the duties that were associated with them. This should be written in reverse chronological order, meaning your most recent role is listed first.

When writing about each position, use bullet points to make it easier for the reader to take in what you’re saying quickly. You want to provide detail on what exactly you did and any results or achievements obtained from those tasks.

For example, instead of saying “Performed quality assurance tests,” you could say, “Conducted rigorous QA testing on new products which resulted in a 95% success rate.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Evaluated

- Monitored

- Assessed

- Investigated

- Analyzed

- Resolved

- Documented

- Inspected

- Tested

- Troubleshot

- Improved

- Trained

- Reported

- Certified

Other general verbs you can use are:

- Achieved

- Advised

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Investigated and resolved more than 100 customer complaints related to product quality issues, leading to a 20% reduction in the total number of returns.

- Facilitated and led quarterly quality assurance reviews for all products, ensuring that they met required standards with minimal defects; improved internal audit scores by 17%.

- Introduced several process improvement initiatives which resulted in an average decrease of 10 hours per product cycle while maintaining high levels of accuracy and precision.

- Regularly monitored production processes and identified potential areas for improvement across all departments; implemented solutions which reduced scrap rates by 15%.

- Consistently ensured compliance with relevant safety regulations throughout the entire manufacturing process, resulting in zero non-compliance incidents during inspections over 3 years period.

- Prepared comprehensive quality control plans and enforced rigorous standards to improve product reliability; reduced customer complaints by 45% within the first six months.

- Reduced production lead times and costs through careful evaluations of raw materials, components, manufacturing processes and finished products.

- Confidently managed supplier relationships in accordance with ISO 9001:2015 regulations while optimizing performance goals.

- Optimized existing Quality Management System (QMS) procedures to ensure compliance with internal policies & industry regulations; audited all aspects of product development for accuracy and completeness on a regular basis.

- Developed innovative strategies for identifying defects during pre-production stages that saved time and resources when finalizing designs before release into market place.

- Presented product quality improvement plans to senior management, resulting in a 20% increase in product reliability and a 15% reduction in customer complaints.

- Substantially improved the accuracy of defect analysis by introducing automated testing measures; lowered scrap rate by 10%.

- Improved the overall consistency of products through regular laboratory tests, audits and inspections; saved $4K on raw material costs over 6 months time period.

- Demonstrated expertise when troubleshooting production problems related to materials, processes or designs within short duration periods; reduced machine downtime from 8 hours per month to 4 hours/month.

- Represented company at several industry events as an expert on product performance optimization with focus on increasing customer satisfaction levels; achieved 25+ positive reviews online for the brand’s quality standards.

- Actively monitored and inspected products for compliance with quality standards, resulting in a 10% reduction of defective parts over three months.

- Achieved success in resolving customer complaints by working closely with staff from other departments to identify root causes of product issues; reduced turnaround times from 48 hours to 24 hours on average.

- Streamlined the production process by identifying potential risk factors, developing preventive measures and implementing them across all stages of the manufacturing cycle; achieved an 8-point improvement in overall product reliability scores.

- Trained new employees on good manufacturing practices (GMPs) as well as proper usage and maintenance of equipment; decreased employee onboarding time by 50%.

- Certified auditor for ISO 9001:2015 Quality Management System requirements; conducted regular audits to ensure that processes were updated regularly according to latest industry regulations & standards.

- Inspected and tested over 400 products for quality assurance and compliance with industry standards, resulting in a reduction of customer complaints by 14%.

- Resourcefully identified potential defects and design flaws through detailed visual inspections, functionality tests and performance evaluations; improved product reliability by 20%.

- Participated in new product development teams to provide feedback on product designs, ensuring that all products met end-user requirements before launch.

- Formulated comprehensive testing plans based on specifications provided, successfully verifying the accuracy of data inputs within ±5% margin of error each time.

- Documented test results accurately in accordance with internal guidelines while creating defect reports as needed; tracked trends to improve future production processes accordingly.

- Monitored product quality performance by inspecting samples from production runs and testing for defects, resulting in a 20% decrease in product customer complaints over 6 months.

- Reported on findings to management regarding the overall performance of products under various conditions; proposed solutions that improved reliability by 30%.

- Evaluated new materials for incoming parts to ensure compliance with company standards, helping reduce total expenses related to returns and recalls by $15,000 annually.

- Analyzed supplier data using statistical techniques such as SPC (Statistical Process Control) and DOE (Design of Experiments), leading to an increase in process efficiency rate of 10%.

- Independently identified potential areas requiring improvement across all stages of product development cycle; implemented changes which resulted in a 25% reduction defect rates within 2 months.

- Compiled detailed engineering reports on product quality, analyzing data from over 200 test cases and identifying any potential failure points; successfully reduced defective products by 15%.

- Assessed all incoming raw materials for compliance with industry standards, inspecting 500+ components per day to confirm their safety and reliability before usage in manufacturing processes.

- Reorganized the existing quality control system according to ISO 9001 requirements, streamlining workflows & procedures while maintaining consistent output levels of 95% or higher throughout production cycles.

- Coordinated closely with other departments within the organization to ensure that finished goods met customer expectations; saved an average of 25 hours a month due to improved communication across teams.

- Reliably tested each manufactured item against pre-defined criteria prior to shipment, rejecting any items which failed inspection and ensuring zero defects reached customers at all times during shipping process.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization may be looking for a product quality engineer with expertise in Six Sigma, while another may require someone who is well-versed in ISO 9001.

It’s important to tailor the skills section of your resume according to each job you are applying for since many employers use applicant tracking systems these days. These computer programs scan resumes and filter out those that don’t have the required keywords or characteristics they deem necessary before passing them on to human recruiters.

You can also elaborate further on any key skills mentioned here by discussing them more thoroughly in other sections such as the summary or experience areas.

Below is a list of common skills & terms:

- Data Analysis

- Process Improvement

- Quality Assurance

- Regulatory Compliance

- Risk Management

- Root Cause Analysis

- Technical Writing

- Test Automation

- Troubleshooting

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, include an education section below your resume objective. However, if you have significant experience working as a product quality engineer that demonstrates the skills necessary for the job, omitting an education section is perfectly acceptable.

If including an education section, try to mention courses related to engineering or product quality that demonstrate knowledge of the field relevant to the position being applied for.

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have been tested and certified by an authoritative organization, making you more qualified than other applicants.

Including certifications on your resume is especially important if the job advert emphasizes certain skills or qualifications. If you are officially certified in these areas, make sure to include them prominently so hiring managers can easily recognize it.

Certified Quality Engineer

American Society for Quality (ASQ)

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Marcelo Rutherford, this would be Marcelo-Rutherford-resume.pdf or Marcelo-Rutherford-resume.docx.

7. Cover Letter

Attaching a cover letter to your job application is a great way to make yourself stand out from the competition. It should be made up of 2 to 4 paragraphs and provide recruiters with more detailed information about who you are, what you have achieved in your career so far and why you think you’d be an ideal fit for the role.

Cover letters also allow hiring managers to get a sense of your personality which can help them decide whether or not they want to invite you for an interview. Even if it’s not required by the employer, writing one can give you that extra edge over other candidates applying for the same position.

Below is an example cover letter:

Dear Heather,

I am writing to apply for the Product Quality Engineer position at XYZ Corporation. As a quality engineer with more than six years of experience in the automotive industry, I am confident I can be an asset to your team.

In my current role as a quality engineer at ABC Motors, I am responsible for conducting audits, analyzing data, and leading improvement projects. I have also developed strong relationships with suppliers and internal customers, which has resulted in improved communication and collaboration across departments. My experience has provided me with the skills and knowledge necessary to excel in this role at XYZ Corporation.

I am knowledgeable of ISO/TS 16949 requirements and have experience implementing corrective actions to address nonconformities. I also have a solid understanding of statistical methods and root cause analysis tools, which I use regularly to identify process improvements. In addition, I am proficient in Microsoft Office applications such as Excel, Word, PowerPoint, and Project.

My interpersonal skills are just as strong as my technical abilities; I work well independently or on a team, and I have no problem taking initiative when needed. In my previous roles, colleagues have praised me for being detail-oriented while still keeping the big picture in mind; this skill will come in handy when managing multiple projects simultaneously while ensuring that all products meet or exceed customer expectations. Finally – although it is not always required – Spanish is my second language; being bilingual gives me an edge when working with suppliers based in Mexico or South America who may not be fluent English speakers. Based on my qualifications , i feel confident that i would make great contributions to your organization if given the chance.

Thank you for your time & consideration. Please do not hesitate contact me if you require any additional information.

Sincerely,

Marcelo

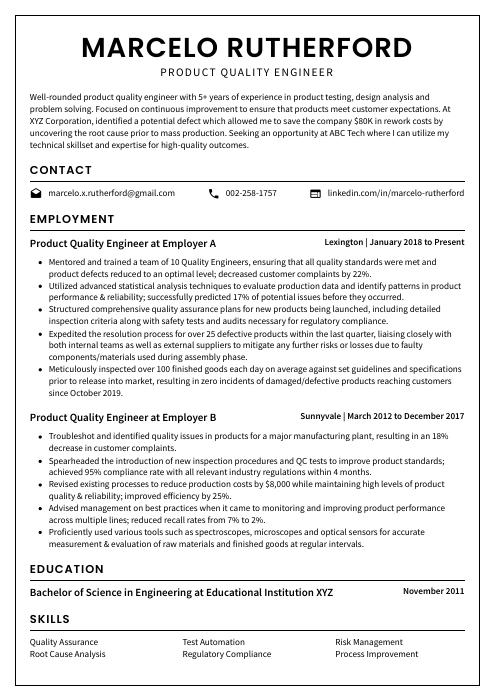

Product Quality Engineer Resume Templates

Gharial

Gharial Fossa

Fossa Ocelot

Ocelot Kinkajou

Kinkajou Lorikeet

Lorikeet Jerboa

Jerboa Rhea

Rhea Markhor

Markhor Bonobo

Bonobo Saola

Saola Numbat

Numbat Hoopoe

Hoopoe Cormorant

Cormorant Pika

Pika Echidna

Echidna Dugong

Dugong Axolotl

Axolotl Quokka

Quokka Indri

Indri Rezjumei

Rezjumei