Process Safety Engineer Resume Guide

Process safety engineers are responsible for identifying, assessing and controlling hazards associated with industrial processes. They develop risk management strategies to reduce the chance of accidents involving hazardous materials or equipment, as well as ensuring compliance with relevant regulations. Additionally, they analyze process data to identify potential risks and recommend changes that improve safety measures in the workplace.

Your expertise in process safety engineering is beyond compare. But without a resume to prove it, potential employers won’t know how valuable you are. Crafting an eye-catching and professional resume will get your name out there and increase your chances of getting hired.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

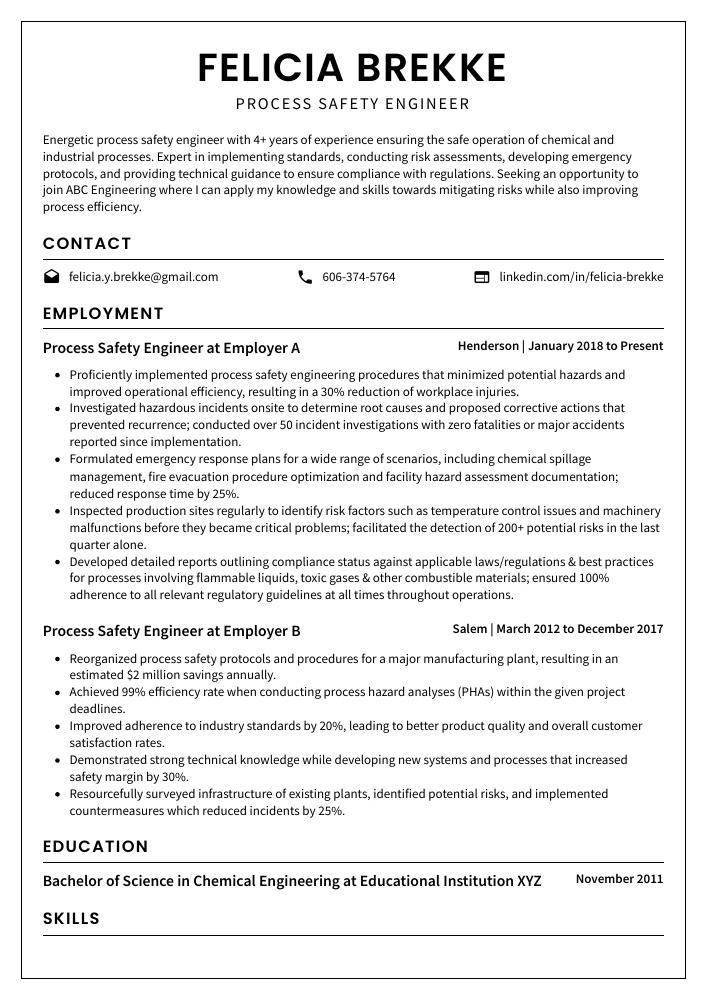

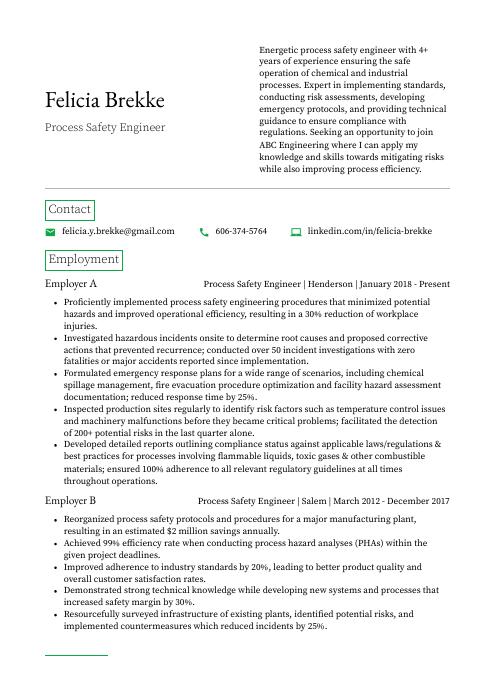

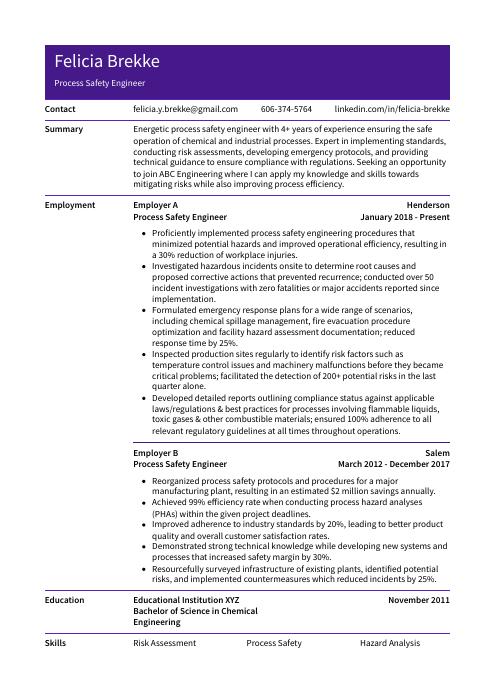

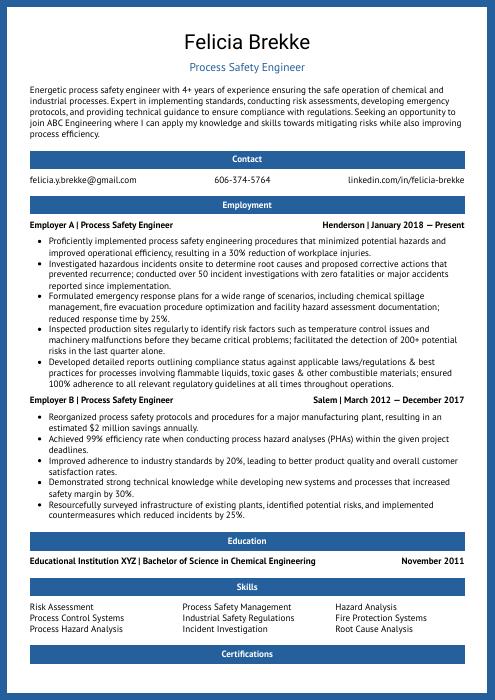

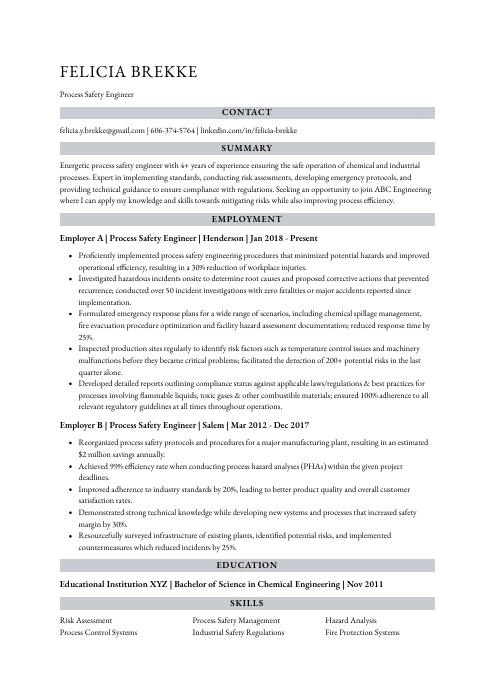

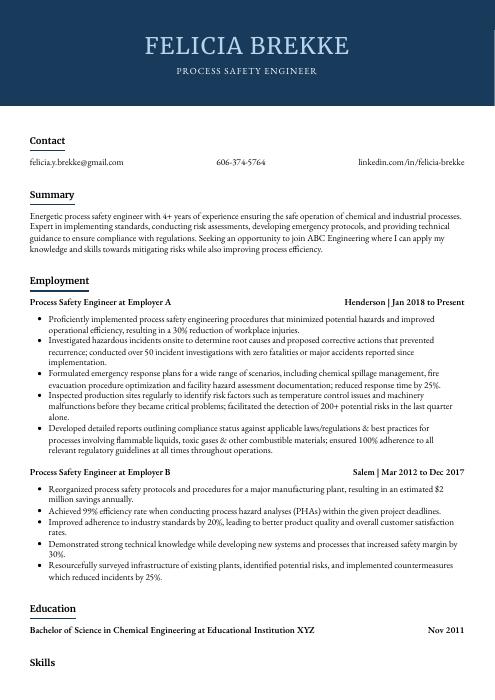

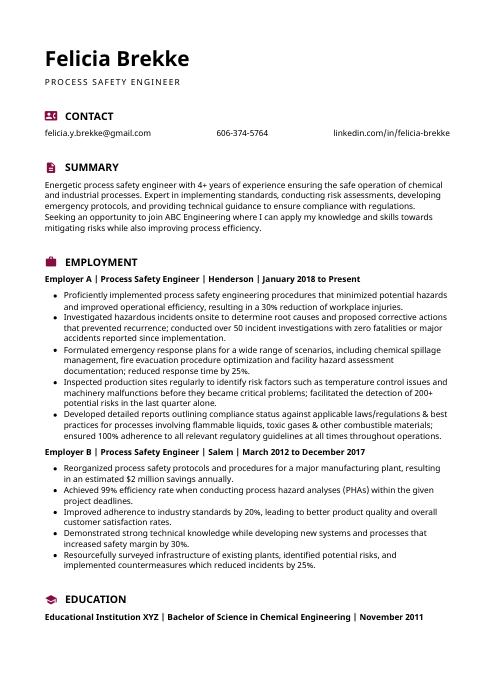

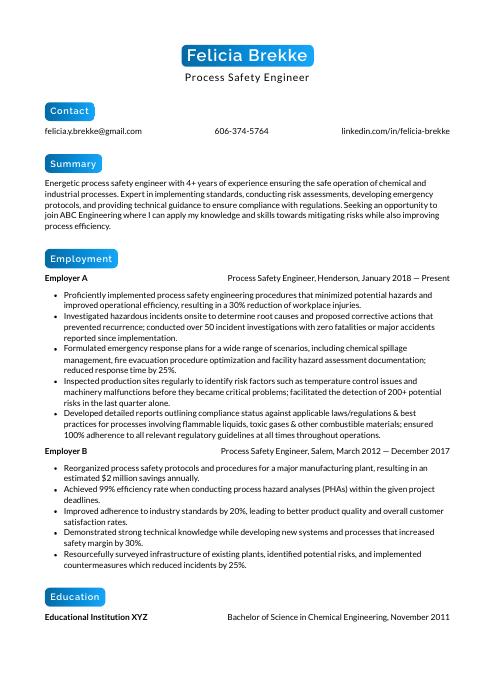

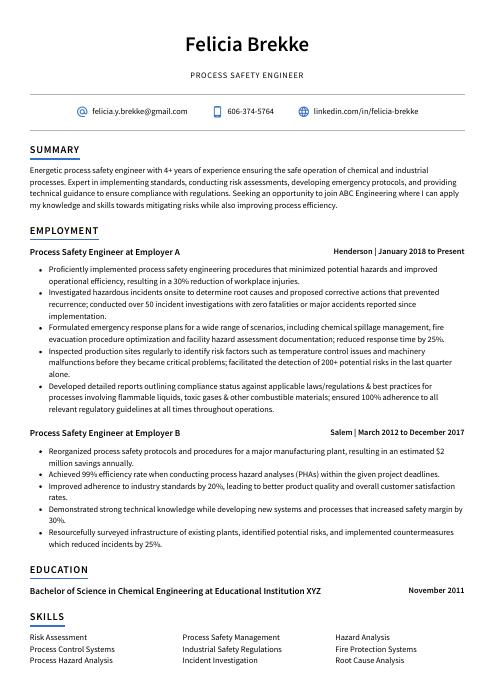

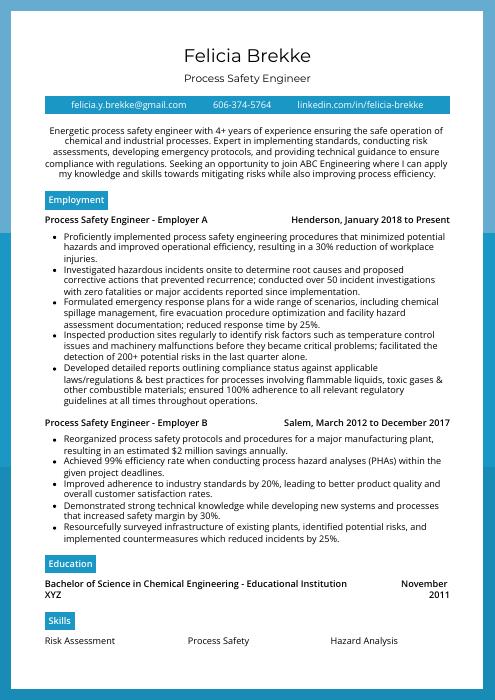

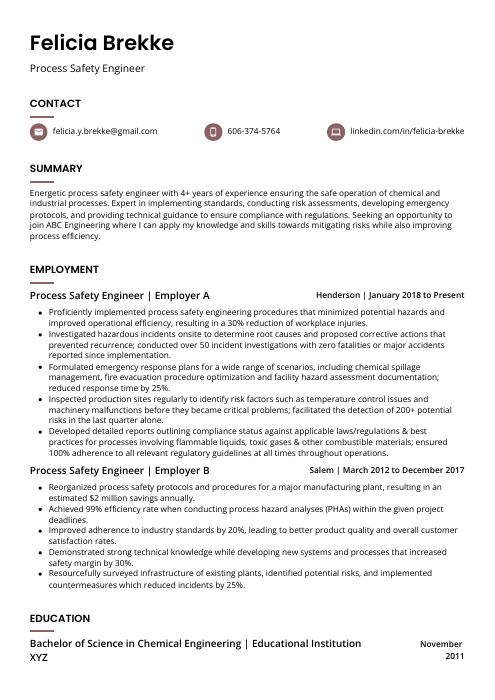

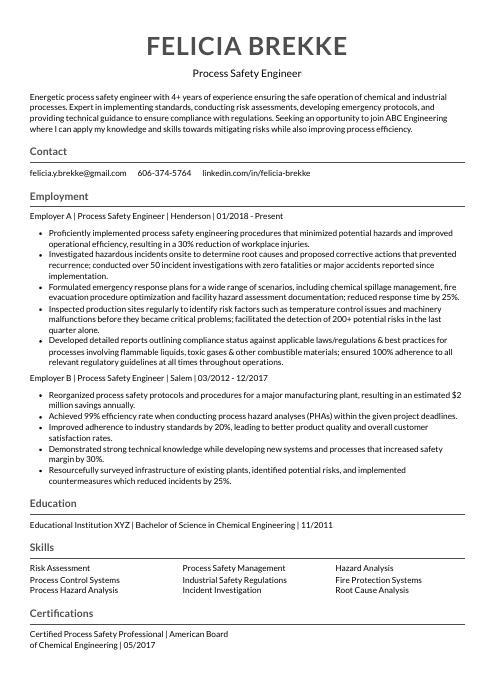

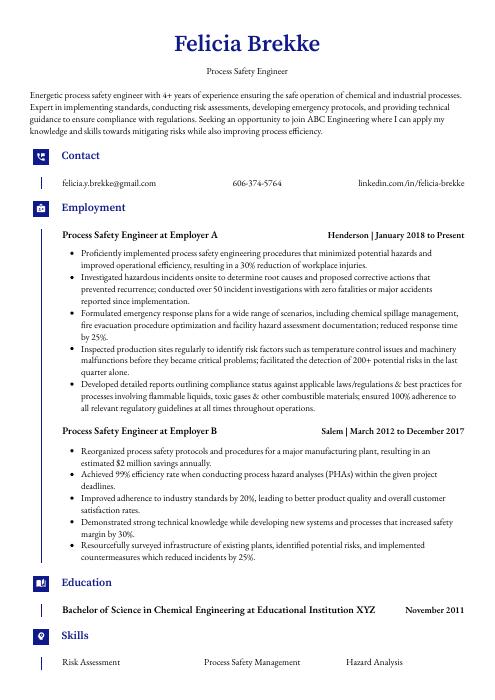

Process Safety Engineer Resume Sample

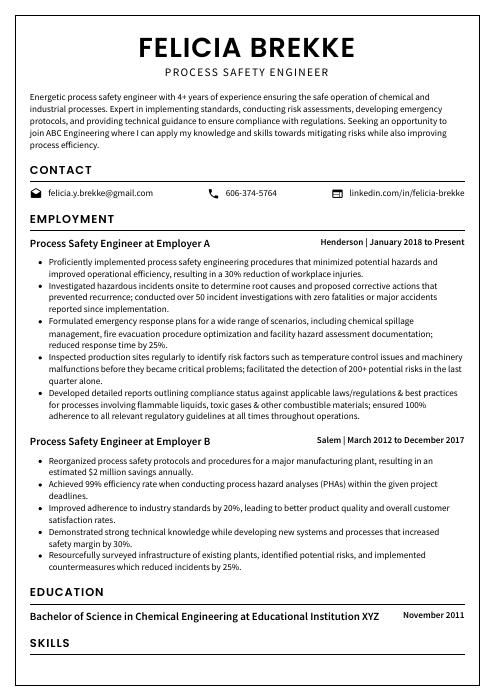

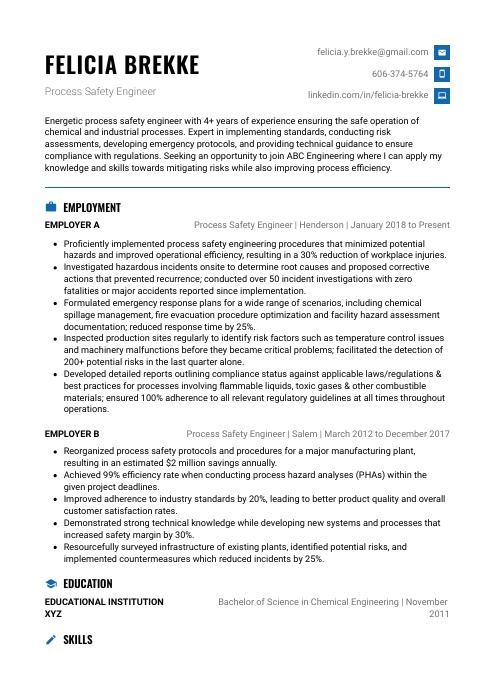

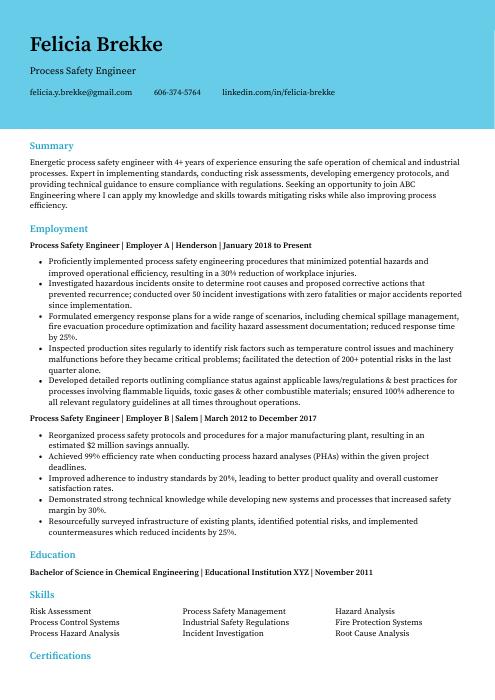

Felicia Brekke

Process Safety Engineer

[email protected]

606-374-5764

linkedin.com/in/felicia-brekke

Summary

Energetic process safety engineer with 4+ years of experience ensuring the safe operation of chemical and industrial processes. Expert in implementing standards, conducting risk assessments, developing emergency protocols, and providing technical guidance to ensure compliance with regulations. Seeking an opportunity to join ABC Engineering where I can apply my knowledge and skills towards mitigating risks while also improving process efficiency.

Experience

Process Safety Engineer, Employer A

Henderson, Jan 2018 – Present

- Proficiently implemented process safety engineering procedures that minimized potential hazards and improved operational efficiency, resulting in a 30% reduction of workplace injuries.

- Investigated hazardous incidents onsite to determine root causes and proposed corrective actions that prevented recurrence; conducted over 50 incident investigations with zero fatalities or major accidents reported since implementation.

- Formulated emergency response plans for a wide range of scenarios, including chemical spillage management, fire evacuation procedure optimization and facility hazard assessment documentation; reduced response time by 25%.

- Inspected production sites regularly to identify risk factors such as temperature control issues and machinery malfunctions before they became critical problems; facilitated the detection of 200+ potential risks in the last quarter alone.

- Developed detailed reports outlining compliance status against applicable laws/regulations & best practices for processes involving flammable liquids, toxic gases & other combustible materials; ensured 100% adherence to all relevant regulatory guidelines at all times throughout operations.

Process Safety Engineer, Employer B

Salem, Mar 2012 – Dec 2017

- Reorganized process safety protocols and procedures for a major manufacturing plant, resulting in an estimated $2 million savings annually.

- Achieved 99% efficiency rate when conducting process hazard analyses (PHAs) within the given project deadlines.

- Improved adherence to industry standards by 20%, leading to better product quality and overall customer satisfaction rates.

- Demonstrated strong technical knowledge while developing new systems and processes that increased safety margin by 30%.

- Resourcefully surveyed infrastructure of existing plants, identified potential risks, and implemented countermeasures which reduced incidents by 25%.

Skills

- Risk Assessment

- Process Safety Management

- Hazard Analysis

- Process Control Systems

- Industrial Safety Regulations

- Fire Protection Systems

- Process Hazard Analysis

- Incident Investigation

- Root Cause Analysis

Education

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Process Safety Professional

American Board of Chemical Engineering

May 2017

1. Summary / Objective

Your resume summary/objective should be a brief but powerful introduction to your process safety engineering skills and experience. In this section, you can mention the certifications or qualifications that make you stand out from other applicants, such as OSHA 30-hour certification or Six Sigma Green Belt training. You could also highlight any recent projects where you implemented successful process safety protocols in an industrial setting.

Below are some resume summary examples:

Driven process safety engineer with 5+ years of experience providing technical support to develop and implement effective, safe processes. Expertise in process hazard analysis (PHA), risk assessment, compliance inspections, and project management. At ABC Engineering Solutions, achieved a 25% reduction in hazardous incidents by introducing new safety protocols. Seeking to use my analytical skills at XYZ Corporation for their next big project.

Professional process safety engineer with 7+ years of experience in the oil and gas industry. Highly experienced in designing, implementing, and maintaining process safety management systems to ensure regulatory compliance while minimizing risk exposure. Recently completed a project that reduced incident rates by 40% at Company X. Seeking to join ABC Tech as a Process Safety Engineer to use my expertise for their expanding business needs.

Passionate process safety engineer with 5+ years of experience in process safety management and risk assessment. Experienced in developing, implementing, and maintaining effective process safety systems for various industries. At XYZ, successfully implemented a comprehensive system which reduced the potential for incidents by 65%. Proven ability to identify risks and develop cost-effective solutions that meet industry standards.

Talented process safety engineer with 5+ years of experience in designing safe and secure processes for a variety of industrial, manufacturing, and petrochemical operations. At XYZ Industries, developed comprehensive process safety plans that implemented new technologies to reduce risk while ensuring compliance with OSHA regulations. Received the National Safety Award from ABC Corporation for reducing workplace incidents by 25%.

Skilled process safety engineer with 5+ years of experience in developing and implementing process safety management systems. Strong understanding of regulatory requirements, engineering principles, and risk assessments to ensure safe working conditions for personnel. At ABC Company, achieved a 98% compliance rate on federal regulations regarding environmental protection, workplace safety, and hazardous materials handling.

Diligent Process Safety Engineer with 8 years of experience in the oil and gas industry. Experienced in identifying, evaluating, and controlling process hazards to ensure safe working conditions for personnel. At XYZ Inc., developed a rigorous safety program that reduced the number of accidents by 25%. Skilled at preparing risk assessments and developing management systems compliant with OSHA regulations.

Amicable process safety engineer with 5+ years of experience designing, implementing and monitoring process systems to meet industry standards. Proven ability in coordinating across multiple departments to ensure a safe working environment while meeting production goals. Seeking an opportunity at ABC Company where I can use my knowledge to develop new ways of mitigating risks for the company’s operations.

Dependable process safety engineer with 7+ years of experience assessing and managing process-related risks. At XYZ, developed a system that reduced the risk of potential chemical releases by 30%. Expertise in creating hazard analyses, utilizing root cause analysis techniques to identify organizational improvement areas, and developing safety plans compliant with OSHA regulations.

2. Experience / Employment

In the experience section, you want to provide details on your work history. This should be written in reverse chronological order, meaning the most recent job is listed first.

When writing this section, stick primarily to bullet points; doing so allows the reader to quickly take in what you have said and understand it better. You also want to make sure that each point contains detail about what you did and any results achieved from those actions.

For example, instead of saying, “Developed safety protocols,” say something like, “Created detailed process safety management plans for three industrial sites which resulted in a 45% reduction of hazardous incidents.”

To write effective bullet points, begin with a strong verb or adverb. Industry-specific verbs to use are:

- Evaluated

- Monitored

- Assessed

- Investigated

- Analyzed

- Implemented

- Developed

- Designed

- Inspected

- Documented

- Trained

- Coordinated

- Enforced

- Optimized

Other general verbs you can use are:

- Achieved

- Advised

- Compiled

- Demonstrated

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Monitored 15+ process safety systems and equipment on a daily basis, ensuring that all processes were in accordance with the company’s regulatory standards.

- Assessed potential occupational hazards associated with existing/new chemical processes, identified critical control points to reduce risks by 25%, and ensured compliance of safety regulations across the production facility.

- Trained over 200 employees on safe operating procedures for hazardous chemicals, improving overall awareness of workplace health & safety policies by 50%.

- Actively participated in developing emergency response plans (ERPs) through simulations; reduced average incident response time from 5 hours to 2 hours within one year period following ERP implementation.

- Structured regular audit programs for plant operations as well as process plants equipment; reviewed performance metrics data monthly and presented detailed reports outlining areas requiring improvement or correction at management meetings quarterly.

- Participated in the development of safety-related plans and procedures, including risk assessments and process hazard analyses; reduced workplace accidents by 15% annually.

- Represented company in external meetings to discuss potential hazards with local authorities, clarified regulatory compliance requirements while preserving business operations.

- Expedited incident investigations related to hazardous material exposure/release incidents utilizing root cause analysis techniques; identified corrective actions which prevented similar occurrences from happening again in the future.

- Utilized data collection tools such as interviews & surveys to identify safety concerns within all departments of organization; developed actionable solutions that improved overall employee well-being by 20%.

- Effectively communicated process improvements & best practices for minimizing risks associated with handling hazardous materials throughout entire facility; achieved a reduction of 30% in near misses over two years’ time period.

- Coordinated process safety management programs across 8 industrial sites, developing and implementing best practices that reduced the risk of environmental incidents by 28%.

- Confidently identified potential hazards in plant process systems, analyzing data to generate recommendations to improve fire protection systems and reduce flammability issues by 42%.

- Analyzed real-time system parameters during production processes, proactively identifying anomalies before they caused any major disruptions; decreased downtime due to unplanned shutdowns by 10 hours per month on average.

- Spearheaded hazardous materials training for over 500 personnel at all plant locations; increased employee safety awareness score from 78% to 93% within 6 months of implementation.

- Mentored a team of 15 junior engineers in process safety engineering standards & principles; successfully completed 20+ projects with zero critical errors or violations reported from regulatory agencies.

- Developed and implemented process safety management plans for over 50 industrial plants, resulting in a 35% decrease in hazardous material incidents.

- Compiled and maintained detailed records of plant operations to ensure compliance with all applicable national and international regulations; educated personnel on health & safety protocols as needed.

- Streamlined operational processes through analysis of existing systems, reducing production costs by 20%.

- Meticulously monitored equipment performance regularly to detect any potential issues before they could cause harm or disruption; identified several flaws before major accidents occurred during the last quarter alone.

- Presented findings from risk assessments at weekly meetings, developing strategies for minimizing risks associated with chemical exposure, fire hazards and other dangerous conditions within the workplace environment.

- Introduced safety procedures and best practices, resulting in a 20% reduction of workplace accidents over the past year.

- Evaluated existing safety protocols for compliance with OSHA regulations to ensure that facility operations ran smoothly and efficiently; identified areas of improvement which resulted in an additional $1 million savings through process optimization.

- Reduced company liability by implementing risk assessment strategies to identify hazardous situations and implement preventative measures before any incidents occurred; averted estimated losses up to $5 million due to successful implementation of these strategies within one month from the start date.

- Revised safety training programs for new employees, ensuring all personnel were knowledgeable about industry standards as well as internal policies; developed an online tutorial program which was completed by 500+ employees within 2 weeks time frame with 95% passing rate on assessments administered at end-of-course completion stage.

- Diligently monitored production processes throughout shifts while following Quality Management Systems (QMS) guidelines, providing guidance when needed or requested while maintaining high levels of accuracy and attention-to detail across all projects assigned during duration of employment contract period.

- Optimized process safety risk management procedures by carrying out HAZOP assessments and hazard identification exercises, resulting in a 10% reduction of potential risks.

- Documented process safety regulations & standards such as OSHA 1910/1926, NFPA 85, API RP 521 and EPA 40 CFR to ensure compliance with current industry requirements & regulations.

- Prepared detailed reports on findings from process hazard analyses (PHAs) utilizing tools including What-if Analysis, Failure Mode Effects Analysis (FMEA), Bow Tie Diagrams etc., which were used to develop preventive measures to reduce the probability of any incidents occurring.

- Advised operations teams on best practices for safe production processes while providing guidance during emergency response drills; reduced total incident time by 30%.

- Thoroughly analyzed various scenarios before making decisions regarding changes in existing workplace environment or new capital projects and provided recommendations accordingly that improved operational efficiency by 20%.

- Facilitated the development, implementation and maintenance of process safety management (PSM) systems across 10 operational plants; reduced hazardous incidents by 32% over two years.

- Designed comprehensive risk assessments to test the effectiveness of PSM procedures in mitigating potential hazards; identified 23 risks that were later addressed through targeted engineering solutions.

- Enforced regulatory compliance standards for all operations including OSHA 1910 & 1926 requirements and EPA regulations; achieved a perfect score on annual audits with zero non-compliance issues noted.

- Competently utilized specialized software tools like HazOp/Lopa Analysis, PHA Pro and Bowtie XP to analyze existing processes and recommend improvements for increased safety performance.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for an engineer with expertise in safety engineering, while the other might want someone who is knowledgeable about process control systems.

It’s important to tailor your skills section of your resume to each job you are applying for; this will help ensure that it passes through any applicant tracking system used by employers. You can list a variety of relevant qualifications here, such as knowledge of OSHA regulations and experience using risk assessment tools like HAZOP or FMEA. Additionally, feel free to elaborate on these points further in other parts of your resume (e.g., summary/experience).

Below is a list of common skills & terms:

- Emergency Response Planning

- Fire Protection Systems

- Hazard Analysis

- Incident Investigation

- Industrial Safety Regulations

- Process Control Systems

- Process Hazard Analysis

- Process Safety Management

- Risk Assessment

- Root Cause Analysis

4. Education

Including an education section on your resume will depend on the level of experience you have. If you are just starting out and don’t have much work experience, mention your education below your resume objective. However, if you already have a few years of professional experience in process safety engineering, omitting an education section might be more appropriate for highlighting all the relevant skills and responsibilities that make up this role.

If including an education section is necessary or preferred, try to list courses related to process safety engineering as well as any research projects or activities that may be applicable to the job position.

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a particular field. They are also an indication that you have taken the initiative to stay up-to-date with industry standards and trends.

If you hold any certifications related to the job you’re applying for, make sure they are included on your resume as this could be what sets you apart from other applicants.

Certified Process Safety Professional

American Board of Chemical Engineering

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Felicia Brekke, this would be Felicia-Brekke-resume.pdf or Felicia-Brekke-resume.docx.

7. Cover Letter

Cover letters play an important role in the job application process. They are usually made up of 2 to 4 paragraphs and provide a brief overview of who you are, what makes you suitable for the position, and why you’re passionate about it.

Although writing a cover letter is not always mandatory when applying for jobs, doing so can help distinguish your application from other candidates. It allows recruiters to get an insight into your personality as well as providing them with more information about yourself that cannot be found on your resume alone.

Below is an example cover letter:

Dear Francesco,

I am writing to apply for the Process Safety Engineer position at ABC Company. With my experience in chemical engineering and process safety management, I am confident I would be a valuable asset to your organization.

In my current role as Process Safety Engineer at XYZ Company, I am responsible for developing and implementing process safety programs that meet regulatory requirements and company standards. I have experience conducting hazard assessments, managing incident investigations, and leading root cause analysis teams. I also have a strong understanding of risk management principles and how to apply them to complex processes.

I believe my skills and experience would benefit ABC Company in many ways. In particular, my ability to develop effective process safety programs would help you improve compliance with regulations while reducing the likelihood of accidents or incidents. My analytical skills would also be valuable in identifying potential risks and developing mitigation strategies.

I look forward to discussing how my skills and experience can benefit ABC Company as your next Process Safety Engineer. Thank you for your time and consideration!

Sincerely,

Felicia

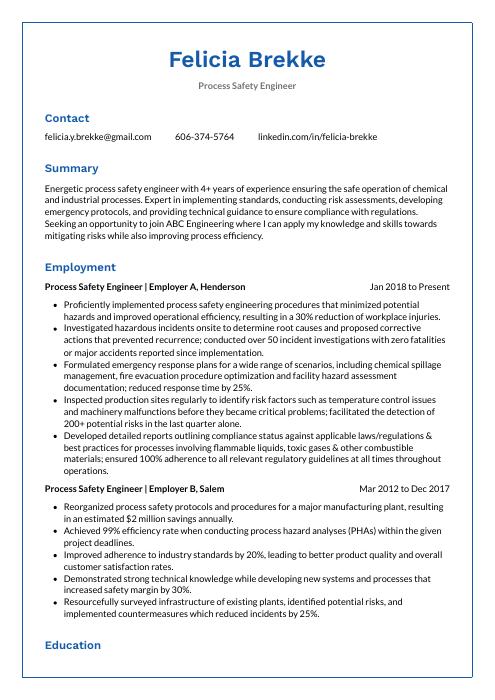

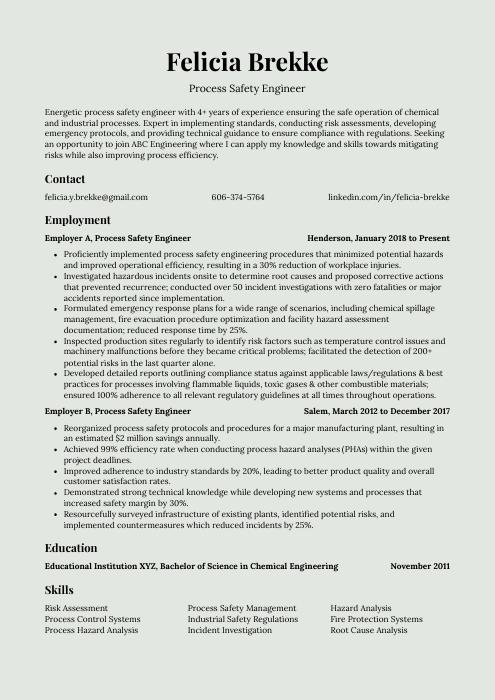

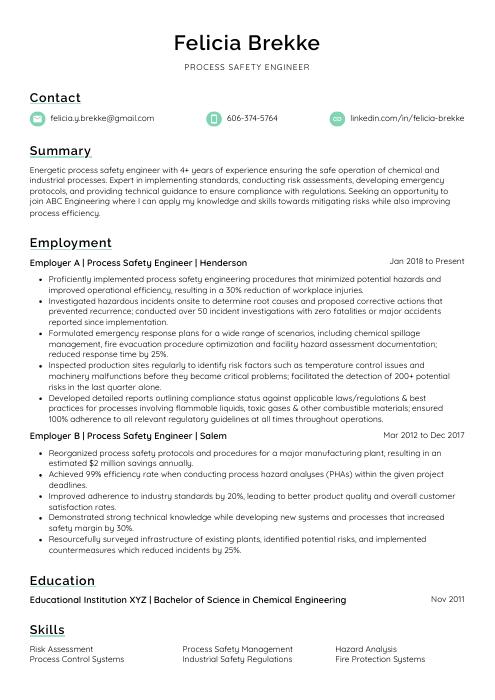

Process Safety Engineer Resume Templates

Markhor

Markhor Saola

Saola Lorikeet

Lorikeet Quokka

Quokka Pika

Pika Ocelot

Ocelot Numbat

Numbat Bonobo

Bonobo Hoopoe

Hoopoe Kinkajou

Kinkajou Axolotl

Axolotl Rhea

Rhea Fossa

Fossa Indri

Indri Gharial

Gharial Cormorant

Cormorant Echidna

Echidna Dugong

Dugong Jerboa

Jerboa Rezjumei

Rezjumei