Process Improvement Engineer Resume Guide

Process Improvement Engineers analyze business processes to identify areas for improvement, then design and implement changes that increase efficiency. They develop strategies to streamline operations, reduce costs, and improve customer service in order to help their organization achieve its goals.

You have the knowledge and experience to take any organization’s processes to the next level. Yet, hiring managers don’t know who you are. To make them aware of your process improvement skills, craft a resume that stands out from the rest.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

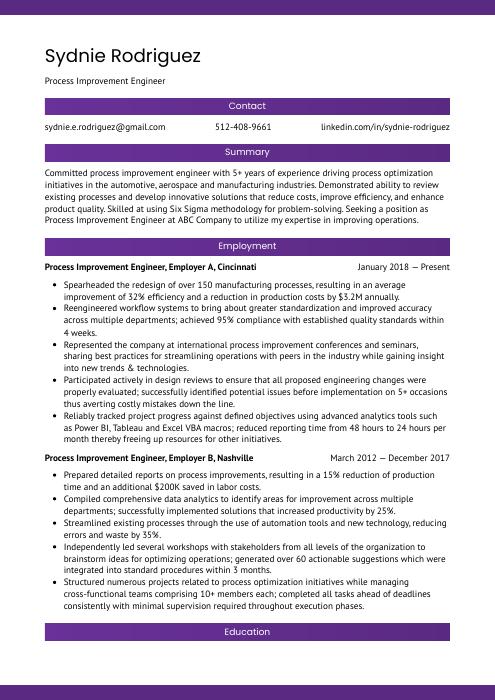

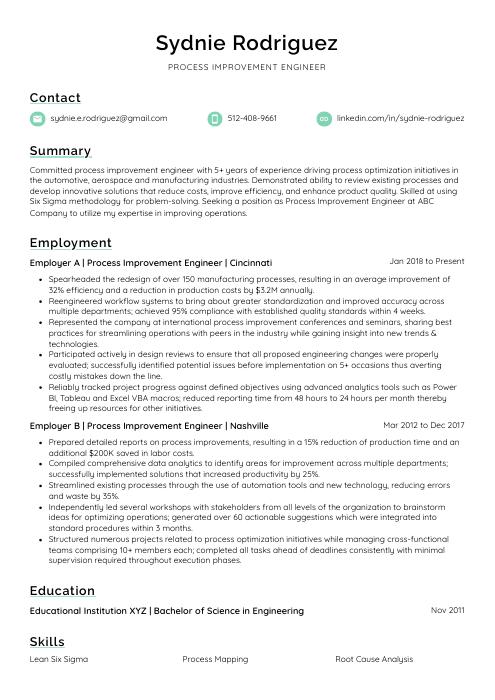

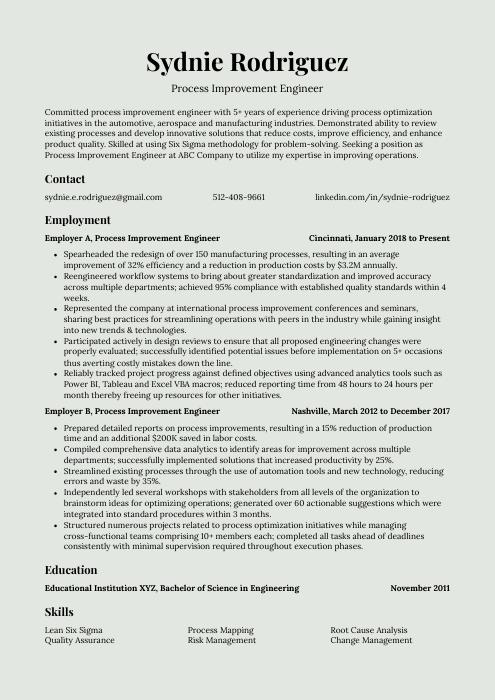

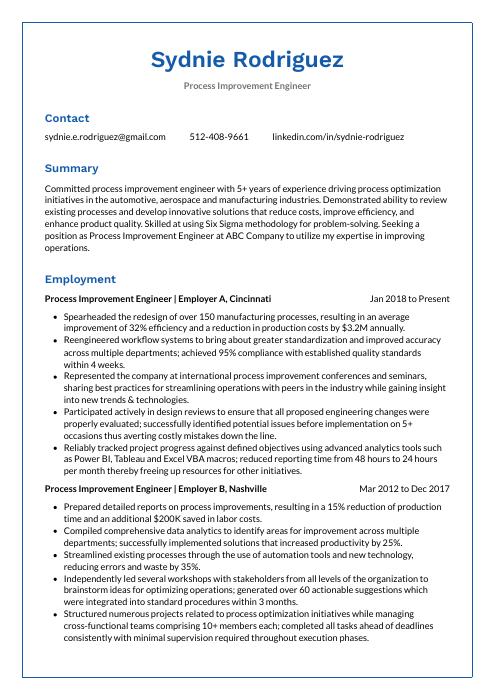

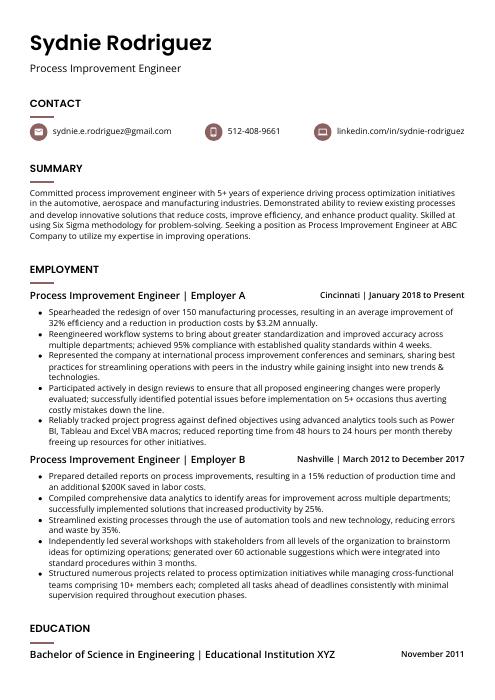

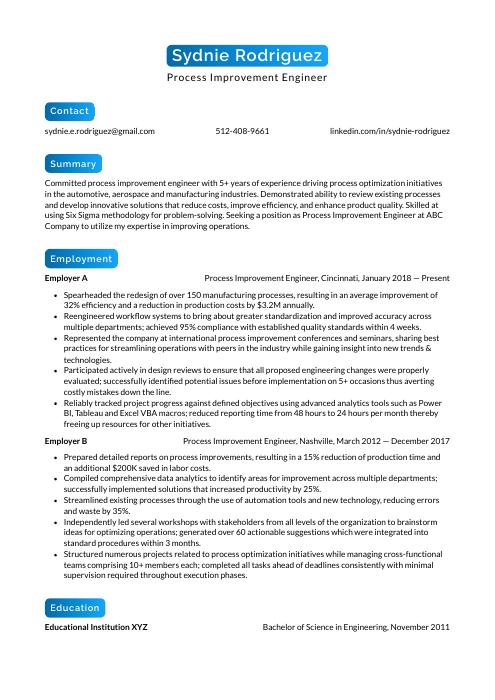

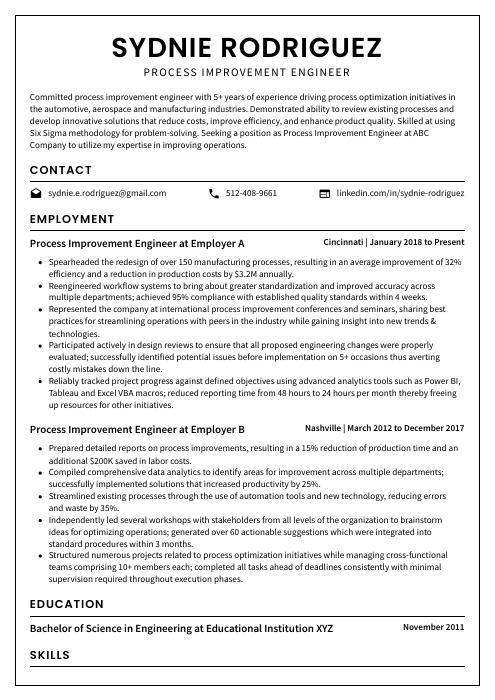

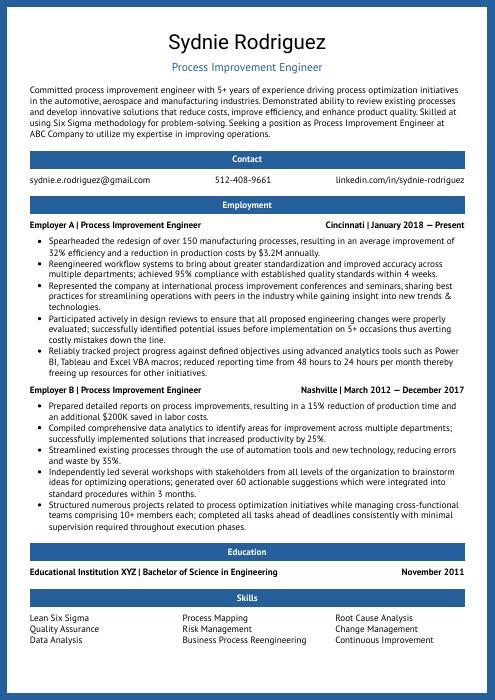

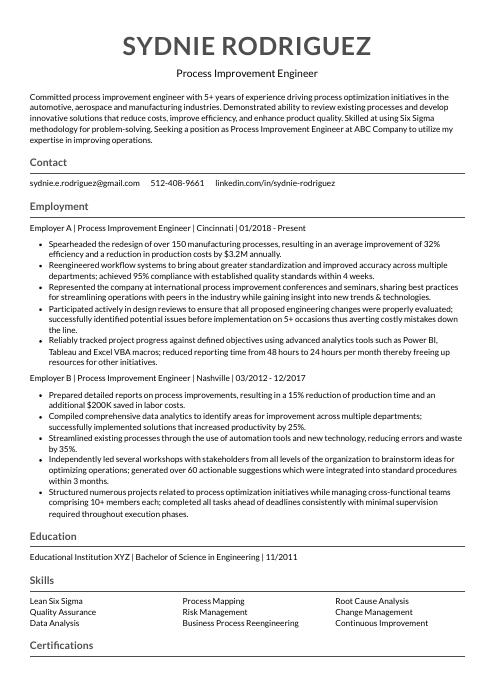

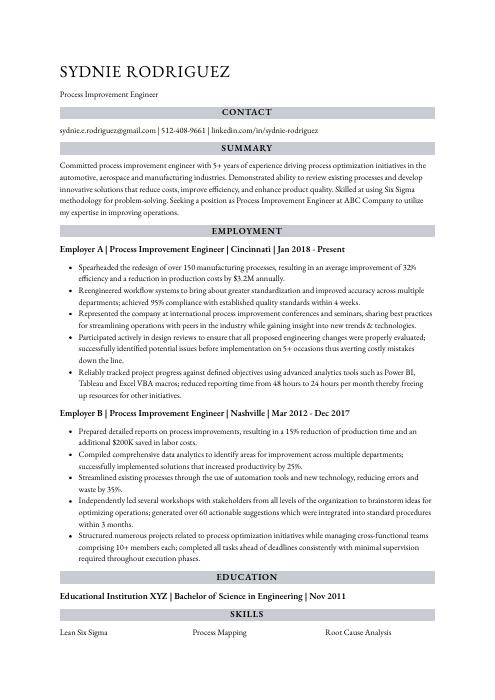

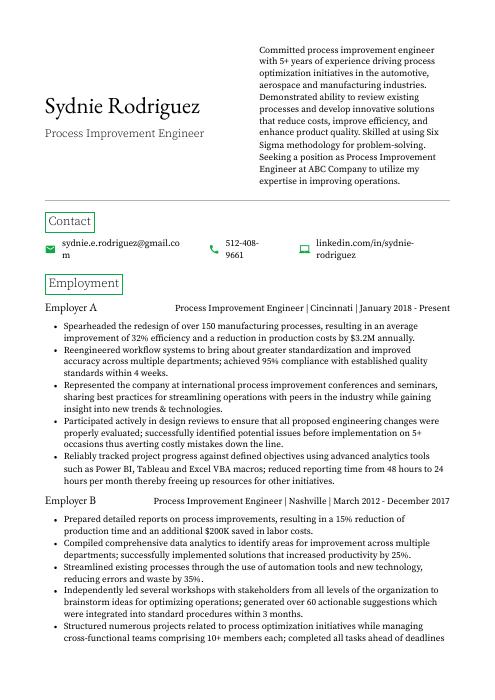

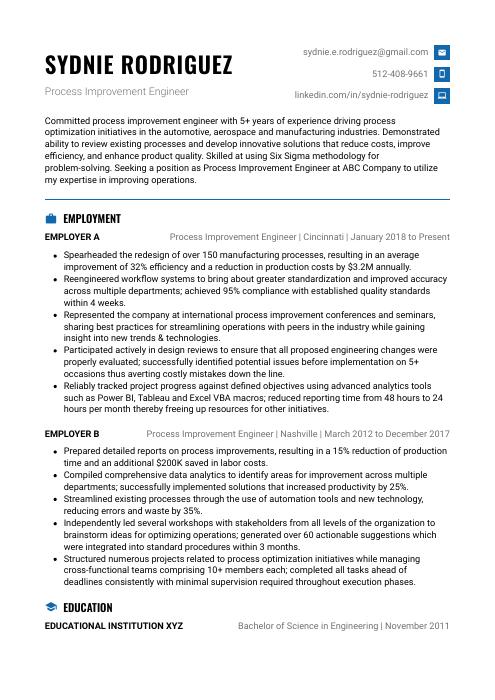

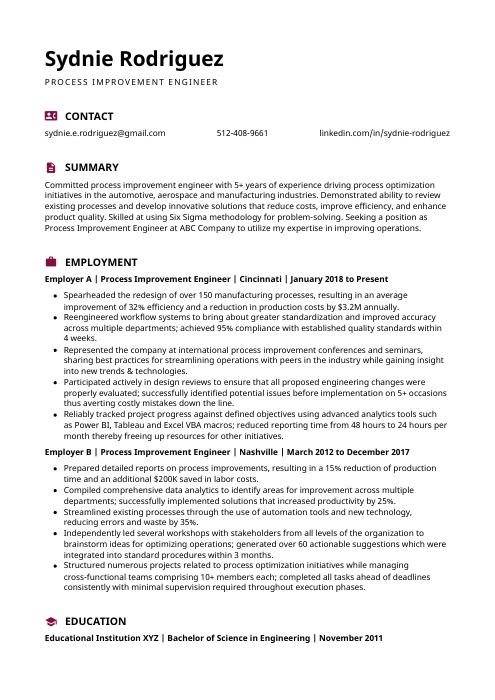

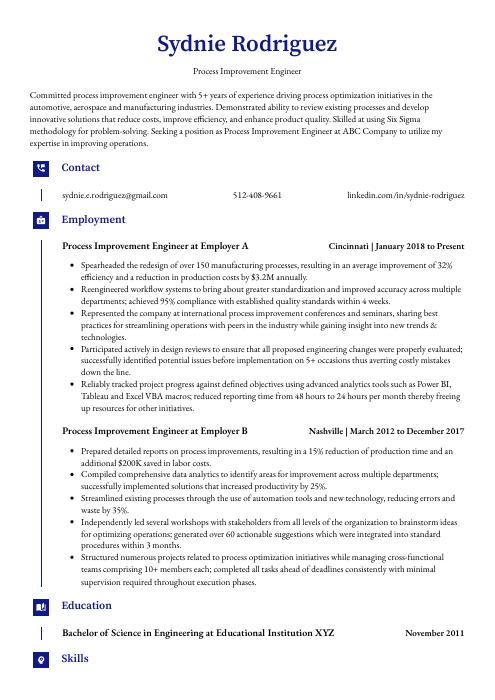

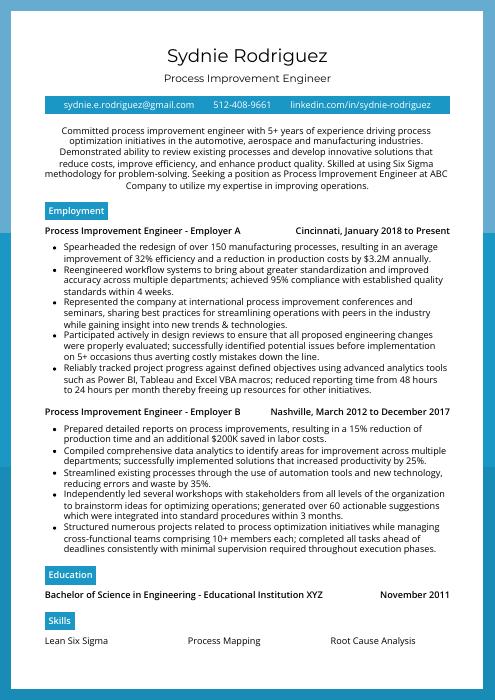

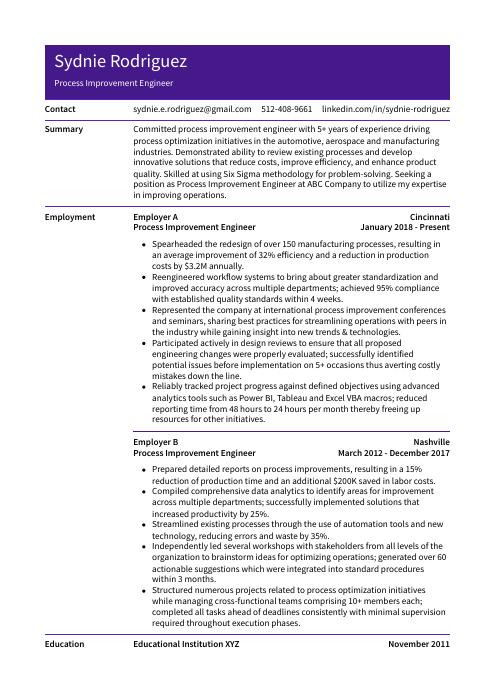

Process Improvement Engineer Resume Sample

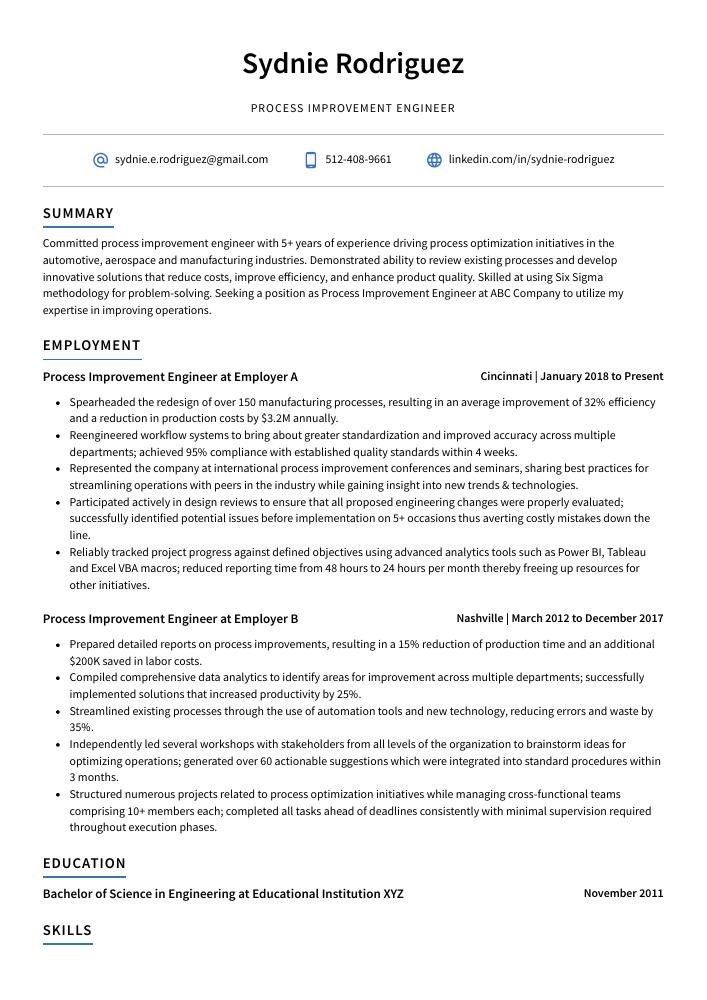

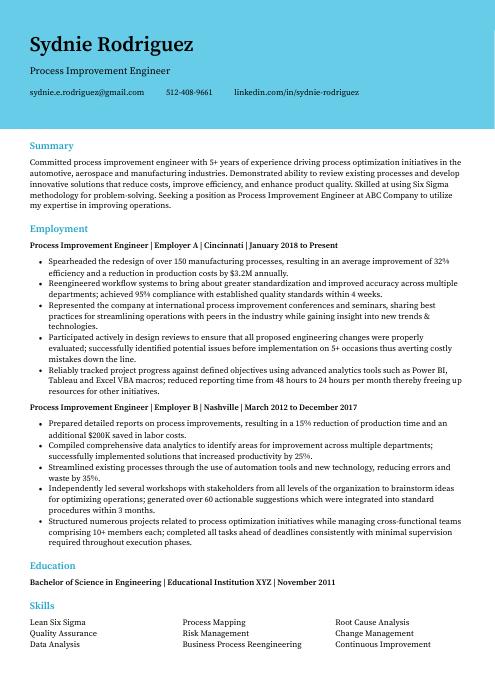

Sydnie Rodriguez

Process Improvement Engineer

[email protected]

512-408-9661

linkedin.com/in/sydnie-rodriguez

Summary

Committed process improvement engineer with 5+ years of experience driving process optimization initiatives in the automotive, aerospace and manufacturing industries. Demonstrated ability to review existing processes and develop innovative solutions that reduce costs, improve efficiency, and enhance product quality. Skilled at using Six Sigma methodology for problem-solving. Seeking a position as Process Improvement Engineer at ABC Company to utilize my expertise in improving operations.

Experience

Process Improvement Engineer, Employer A

Cincinnati, Jan 2018 – Present

- Spearheaded the redesign of over 150 manufacturing processes, resulting in an average improvement of 32% efficiency and a reduction in production costs by $3.2M annually.

- Reengineered workflow systems to bring about greater standardization and improved accuracy across multiple departments; achieved 95% compliance with established quality standards within 4 weeks.

- Represented the company at international process improvement conferences and seminars, sharing best practices for streamlining operations with peers in the industry while gaining insight into new trends & technologies.

- Participated actively in design reviews to ensure that all proposed engineering changes were properly evaluated; successfully identified potential issues before implementation on 5+ occasions thus averting costly mistakes down the line.

- Reliably tracked project progress against defined objectives using advanced analytics tools such as Power BI, Tableau and Excel VBA macros; reduced reporting time from 48 hours to 24 hours per month thereby freeing up resources for other initiatives.

Process Improvement Engineer, Employer B

Nashville, Mar 2012 – Dec 2017

- Prepared detailed reports on process improvements, resulting in a 15% reduction of production time and an additional $200K saved in labor costs.

- Compiled comprehensive data analytics to identify areas for improvement across multiple departments; successfully implemented solutions that increased productivity by 25%.

- Streamlined existing processes through the use of automation tools and new technology, reducing errors and waste by 35%.

- Independently led several workshops with stakeholders from all levels of the organization to brainstorm ideas for optimizing operations; generated over 60 actionable suggestions which were integrated into standard procedures within 3 months.

- Structured numerous projects related to process optimization initiatives while managing cross-functional teams comprising 10+ members each; completed all tasks ahead of deadlines consistently with minimal supervision required throughout execution phases.

Skills

- Lean Six Sigma

- Process Mapping

- Root Cause Analysis

- Quality Assurance

- Risk Management

- Change Management

- Data Analysis

- Business Process Reengineering

- Continuous Improvement

Education

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Six Sigma Black Belt

American Society for Quality

May 2017

1. Summary / Objective

A resume summary/objective for a process improvement engineer should highlight your experience and expertise in streamlining processes, improving efficiency, and driving cost savings. Include any relevant certifications or qualifications you have obtained that demonstrate your knowledge of process improvement techniques. Additionally, mention the number of successful projects you’ve completed in the past as well as any awards or recognition you received for them.

Below are some resume summary examples:

Driven process improvement engineer with 7+ years of experience in process analysis, design and implementation. Proven track record in leading cost reduction initiatives through the optimization of processes such as inventory management, order fulfillment and supply chain logistics. Successfully led projects resulting in a 10% increase in productivity across the organization at XYZ Corporation. Seeking to use my expertise to reduce costs while increasing efficiency at ABC Company.

Amicable process improvement engineer with 5+ years of experience in the manufacturing and engineering industries. Expertise in continuous process improvements to increase efficiency, reduce cost, and enhance customer satisfaction. At XYZ Corporation, identified $500K savings by streamlining production processes. Awarded project manager of the year for successfully leading projects that improved quality control systems and reduced waste levels by 25%.

Skilled process improvement engineer with 6+ years of experience in leading process and cost optimization projects for manufacturing plants. At ABC, managed a team to reduce waste materials by 50% within 3 months. Conducted innovative experiments utilizing Lean Six Sigma tools and techniques that resulted in $2 million savings annually. Committed to creating optimized processes through data-driven decision making and collaboration with stakeholders.

Proficient process improvement engineer with five years of experience in optimizing and streamlining processes for small to medium-sized businesses. At XYZ, developed an automated process that increased productivity by 20%. Experienced in analyzing existing systems, identifying potential bottlenecks or areas of improvement, and developing solutions to improve workflow efficiency. Expertise includes Lean Six Sigma principles and Kaizen methodology.

Dependable process improvement engineer with 5+ years of experience in designing and executing process improvements throughout the manufacturing supply chain. Proven success in identifying areas for cost savings, streamlining processes to maximize efficiency and promoting lean initiatives. Seeking a position at ABC to utilize my skills and knowledge to improve operational performance across all levels of production.

Seasoned process improvement engineer with 6+ years of experience leading process improvements and implementations that have yielded a 20% increase in efficiency. Certified Lean Six Sigma Black Belt, adept at developing innovative solutions to difficult problems. Seeking to join ABC Manufacturing as the lead process improvement engineer where I can use my skillset to improve production processes for optimal results.

Well-rounded process improvement engineer with 7+ years of experience helping companies increase efficiency and reduce operational costs. Seeking to apply my expertise in Six Sigma methodologies, Lean process optimization, and cost analysis to ABC’s projects. At XYZ, reduced downtime by 26% through a combination of proactive maintenance strategies and improved workflow processes.

Professional process improvement engineer with 5+ years of experience in the engineering and manufacturing space. Proven ability to drive operational excellence through process optimization, cost reduction, and automation initiatives. At ABC Tech successfully implemented a Lean Six Sigma system that reduced cycle times by 20% and increased customer satisfaction ratings by 15%.

2. Experience / Employment

For the experience section, you should list your employment history in reverse chronological order, with the most recent role at the top. Stick to bullet points when describing what you did; this allows for a quicker read and makes it easier for the reader to digest what you have written.

When writing each point, make sure to include details of what tasks were completed and any results that were achieved as a result of those actions. For example, instead of saying “Improved process efficiency,” say something like “Implemented new processes which resulted in an average time reduction of 20% across all departments.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Streamlined

- Automated

- Optimized

- Analyzed

- Evaluated

- Implemented

- Monitored

- Resolved

- Documented

- Troubleshot

- Reengineered

- Upgraded

- Reconfigured

- Forecasted

- Standardized

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Structured

- Utilized

Below are some example bullet points:

- Troubleshot over 100 process improvement issues and identified solutions that saved the company $5,000 in costs over 6 months.

- Forecasted supply chain requirements for 10 new products to be launched within a year; improved accuracy of forecasting by 15%.

- Developed lean manufacturing processes to reduce waste and improve efficiency across 5 production lines; achieved an average time reduction of 20 minutes per product.

- Presented findings from analysis on current business processes to senior management, proposing innovative strategies for greater cost savings & customer satisfaction improvements (+20%).

- Accurately evaluated performance metrics monthly with data-driven insights that resulted in a 25% increase in overall productivity levels compared to previous periods.

- Revised manufacturing processes to increase efficiency by 25%, reducing production costs and improving overall quality of products.

- Reorganized production line scheduling, increasing output capacity by 50% while maintaining safety standards and minimizing downtime.

- Actively identified process inefficiencies through data analysis, resulting in improvements that saved approximately $10,000 annually on labor costs alone.

- Introduced Lean Six Sigma methodology to streamline workflow for better utilization of resources; increased productivity by 20%.

- Advised department managers on best practices related to process improvement techniques; trained over 40 staff members in new procedures leading up to successful implementation of changes across the organization.

- Optimized operational processes for a manufacturing company, resulting in an increase of 37% efficiency across all production lines.

- Meticulously analyzed data to identify areas of improvement and develop strategies to enhance workflow; achieved a $4M cost savings within the first year on the job.

- Improved safety protocols by updating policies and training staff members on best practices; reduced workplace injury rates by 22%.

- Evaluated quality control metrics weekly, ensuring that products met industry standards with minimal defects or delays in shipment timeframes; improved customer satisfaction ratings from 73% to 96%.

- Coordinated closely with team members during process analysis initiatives, driving consensus between departments while encouraging collaboration amongst colleagues at every level of management.

- Formulated and implemented innovative process improvement strategies across multiple departments, resulting in a 20% increase of production output within 6 months.

- Documented and maintained detailed records of workflow processes; successfully identified key areas for potential time-saving optimizations and cost savings initiatives that resulted in an additional $3,000 reduction in operational costs annually.

- Facilitated the development of new systems to improve efficiency while reducing manual labor hours by 25%; created user-friendly instructions manuals to simplify training processes for staff members.

- Competently managed all aspects of quality control procedures through regular audits and assessments; improved product accuracy levels from 75% to 95%.

- Solicited feedback from cross-functional teams on new ideas related to process improvements which increased employee engagement by 40%.

- Consistently improved processes across multiple departments, increasing efficiency by 15% and reducing costs by $35K.

- Expedited the turnaround time of projects from 30 days to 10 days through developing streamlined process instructions and workflow diagrams for accompanying teams.

- Reconfigured production systems to improve quality control results; achieved a 4-month reduction in product defects rate from 10% to 3%.

- Mentored new junior engineers on best practices for identifying areas that could be improved with automated processes; contributed to a 50% improvement in productivity within 6 months of implementation.

- Reduced manual labor input required during production stages by 30%, resulting in an increase of overall output per hour from 20 units/hour up to 32 units/hour while maintaining consistent high standards throughout the entire process chain.

- Demonstrated expertise in process improvement engineering by analyzing and assessing current processes, developing solutions to improve efficiency and reduce costs; successfully automated 10 different production operations for a cost savings of $100K.

- Analyzed customer feedback data to identify areas of opportunity for improved service delivery; implemented changes that resulted in an average increase of 17% in customer satisfaction ratings.

- Assessed existing manufacturing systems, identified resource bottlenecks and developed strategies to mitigate them while meeting all safety requirements; increased productivity by 8%.

- Automated multiple manual tasks with enhanced scripting languages such as Python & JavaScript, reducing the overall cycle time from 6 hours to 2 hours per task on average; saved 3200+ man-hours annually.

- Diligently monitored quality control parameters during every phase of the production line and performed regular maintenance checks – minimized errors & wastage occurrences by 20%.

- Upgraded production process of 10+ factories, resulting in a 15% increase in annual profitability.

- Monitored and analyzed production data to identify potential areas for improvement; implemented cost-cutting measures that saved $5,000 per month on operations costs.

- Utilized LEAN principles to create efficient workflow processes within the organization, decreasing average time spent on each task by 20%.

- Resolved complex operational issues quickly and efficiently through effective troubleshooting techniques; reduced downtime by 40 hours over 3 months period.

- Resourcefully identified opportunities for automation across all departments, leading to improved accuracy and increased productivity of 25%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require a candidate to be well-versed in Lean Six Sigma and Organization XYZ may want someone with experience in process mapping.

Therefore, it is important to tailor the skills section of your resume for each job you are applying for. This is because many companies use applicant tracking systems these days which scan resumes for certain keywords before passing them on to human recruiters.

You should also elaborate on some of the most relevant skillset items by discussing them further within other sections such as the summary or work history section.

Below is a list of common skills & terms:

- Business Process Reengineering

- Change Management

- Continuous Improvement

- Data Analysis

- Lean Six Sigma

- Process Mapping

- Quality Assurance

- Risk Management

- Root Cause Analysis

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior work experience, it’s a good idea to include an education section below the objective statement. However, if you have extensive experience working as a process improvement engineer, omitting the education section is perfectly acceptable.

If including an education section is necessary for the job application, try mentioning courses and subjects relevant to engineering or process improvement that demonstrate your knowledge and skillset related to this role.

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your proficiency in certain areas and can be an important factor for employers when considering you as a candidate. Having certifications on your resume shows that you are serious about developing yourself professionally and have taken the initiative to do so.

If there is any certification related to the job role, make sure it is included in this section of your resume. This will give hiring managers confidence that you possess the necessary skillset required for success in their organization.

Certified Six Sigma Black Belt

American Society for Quality

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Sydnie Rodriguez, this would be Sydnie-Rodriguez-resume.pdf or Sydnie-Rodriguez-resume.docx.

7. Cover Letter

Cover letters are a great way to demonstrate your enthusiasm and interest in the job you’re applying for, as well as provide more detail about who you are and why you would be an ideal fit. They typically consist of 2 to 4 paragraphs that explain what makes you uniquely qualified for the role.

Whilst many jobs don’t require cover letters, they can help set yourself apart from other applicants by showcasing your skills and qualifications in greater depth than is possible with just a resume alone. Writing one could make all the difference when it comes to getting noticed!

Below is an example cover letter:

Dear Jovani,

I am writing to apply for the position of Process Improvement Engineer at XYZ Corporation. With more than eight years of experience in process improvement and quality assurance, I am confident I can be an asset to your organization.

In my current role as a Process Improvement Engineer at ABC Corporation, I have led multiple process improvement projects that have resulted in increased efficiency and productivity. I have also developed and implemented quality control procedures that have helped reduce defects by 30%. My experience has given me a strong understanding of Six Sigma methodologies, which I believe would benefit XYZ Corporation.

I am a highly motivated individual with excellent problem-solving skills. I thrive in fast-paced environments and enjoy working on challenging projects. In addition, my ability to effectively communicate with individuals at all levels of an organization makes me an ideal candidate for this position.

I look forward to speaking with you about how my skills and experience can benefit XYZ Corporation as your next Process Improvement Engineer. Thank you for your time and consideration.

Sincerely,

Sydnie

Process Improvement Engineer Resume Templates

Dugong

Dugong Bonobo

Bonobo Axolotl

Axolotl Jerboa

Jerboa Lorikeet

Lorikeet Saola

Saola Markhor

Markhor Fossa

Fossa Kinkajou

Kinkajou Cormorant

Cormorant Ocelot

Ocelot Indri

Indri Numbat

Numbat Quokka

Quokka Echidna

Echidna Hoopoe

Hoopoe Gharial

Gharial Rhea

Rhea Pika

Pika Rezjumei

Rezjumei