Process Engineering Manager Resume Guide

Process Engineering Managers are responsible for overseeing the design and implementation of processes in order to improve operational efficiency. They must also ensure that safety regulations, quality standards, cost objectives and production schedules are met. Additionally, they provide guidance to process engineers and manage resources such as budgets and personnel.

You have the experience and expertise to be a great process engineering manager at any organization. But employers don’t know who you are yet, so you must write a resume that will grab their attention and highlight your qualifications.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

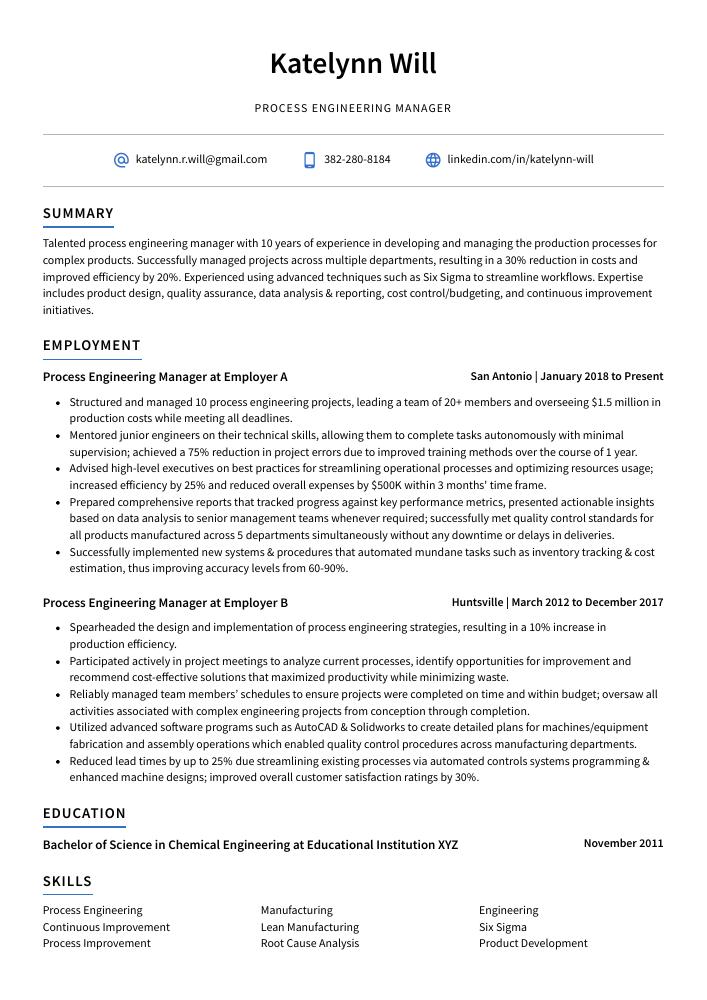

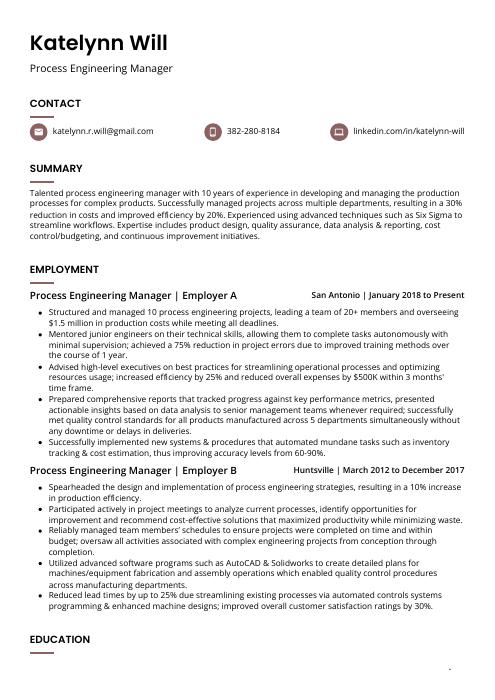

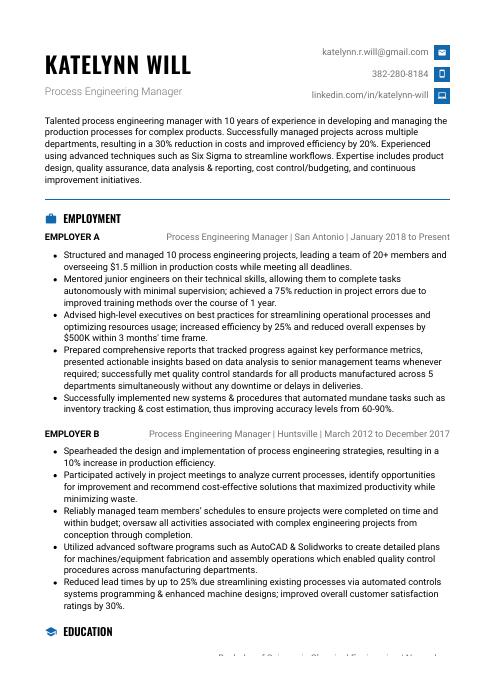

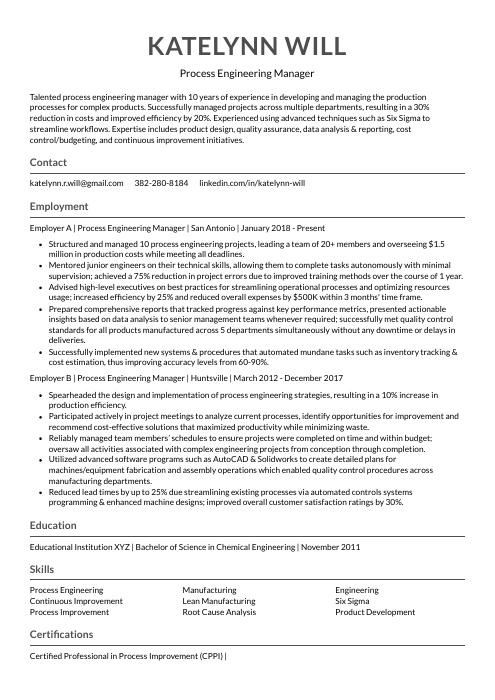

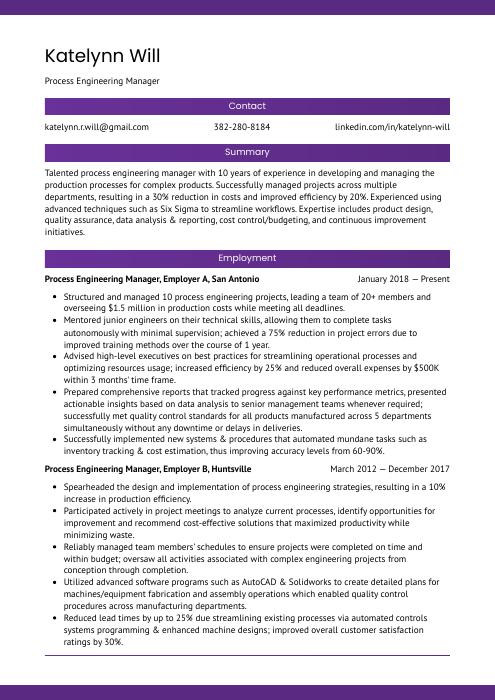

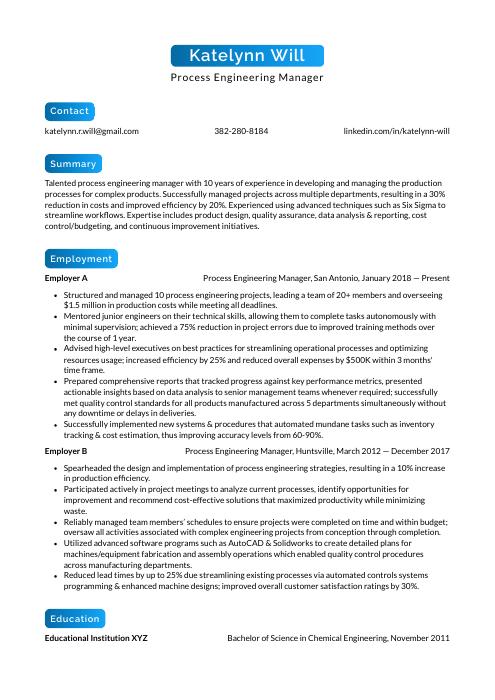

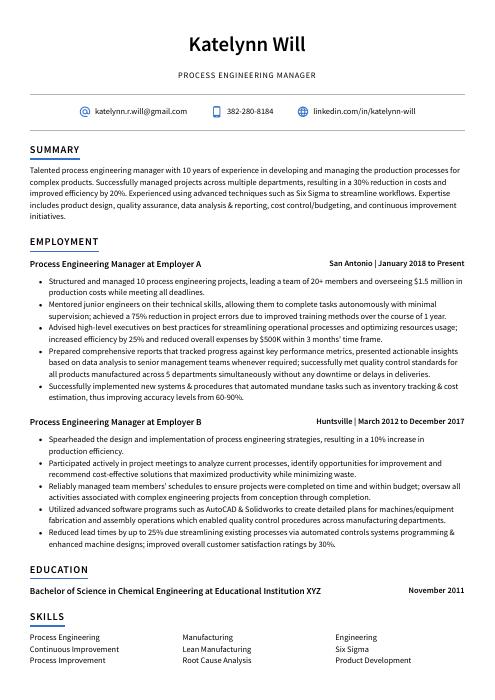

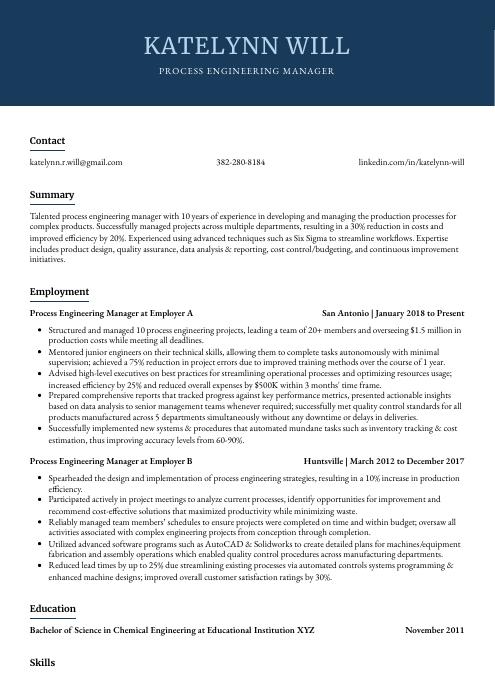

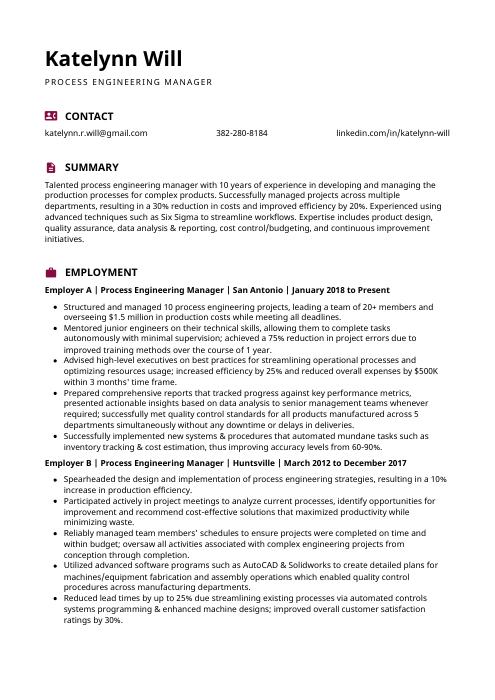

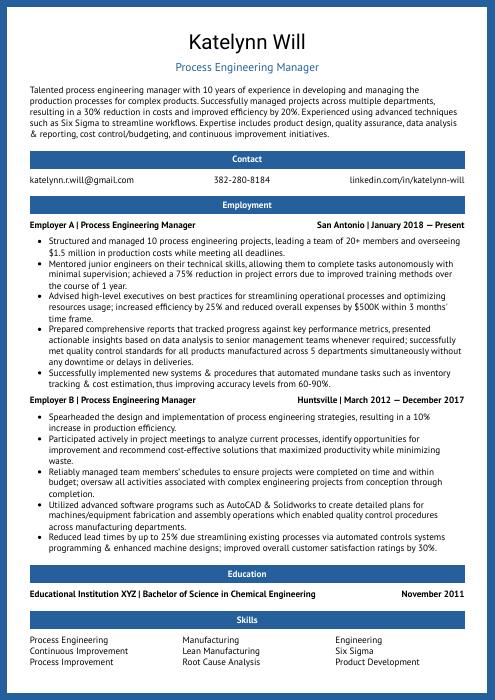

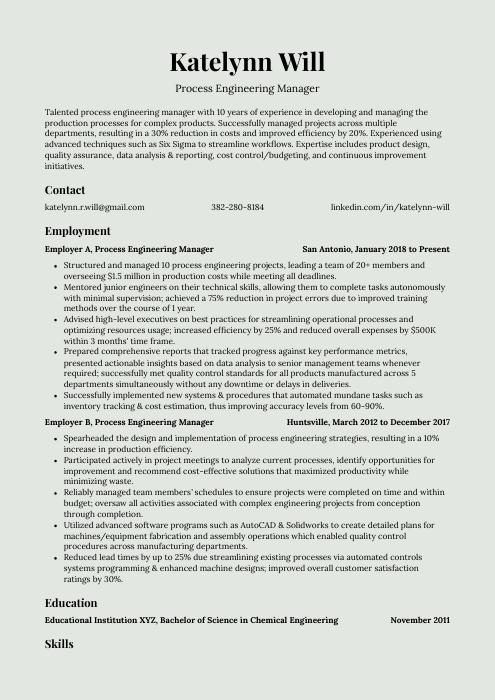

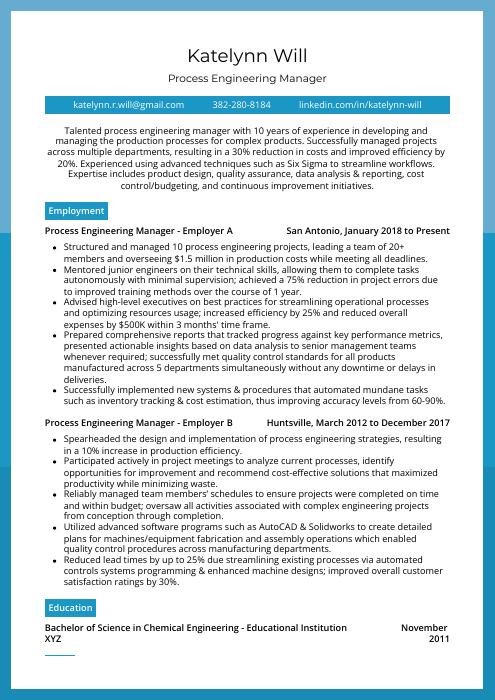

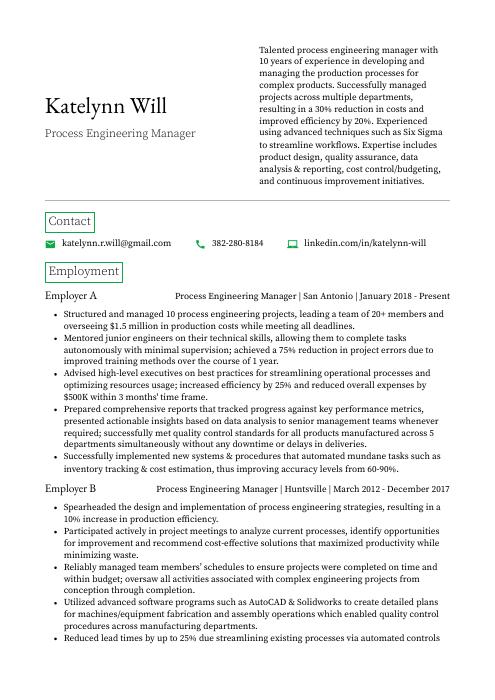

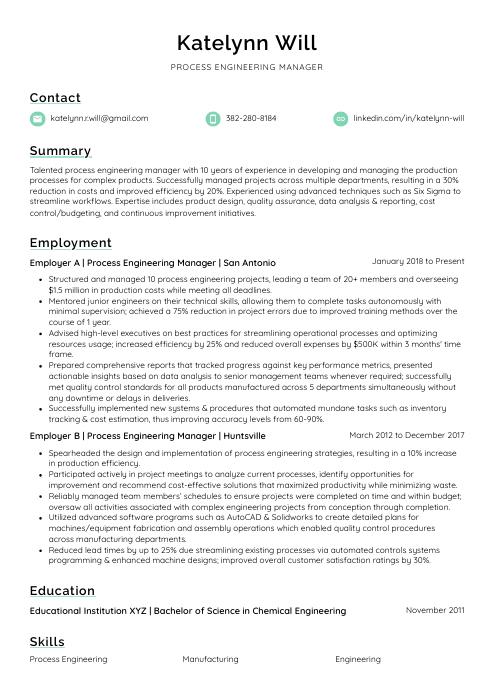

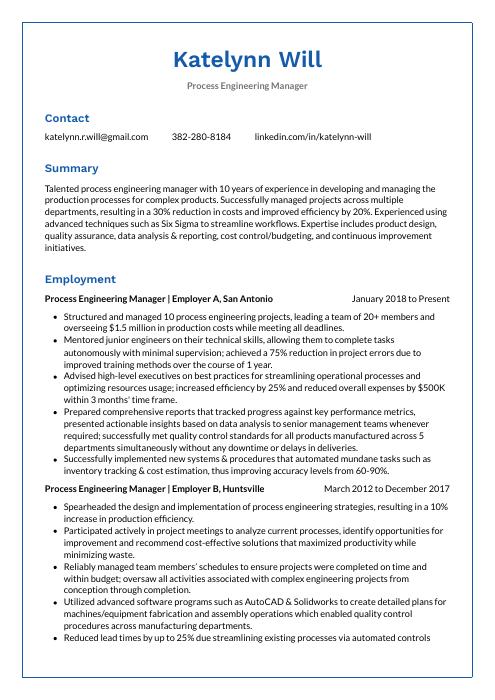

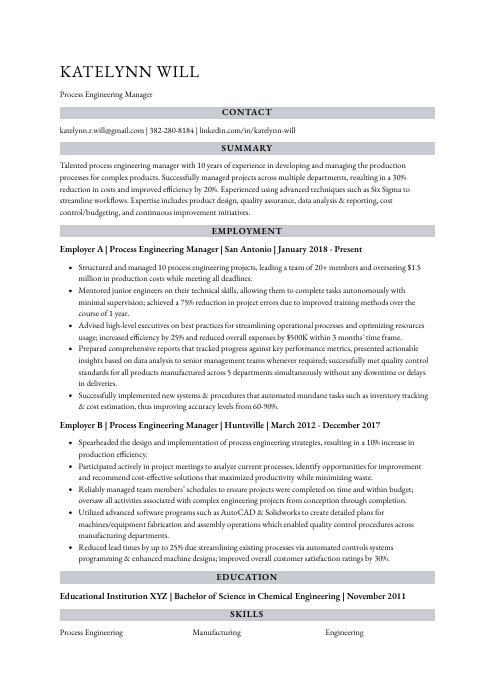

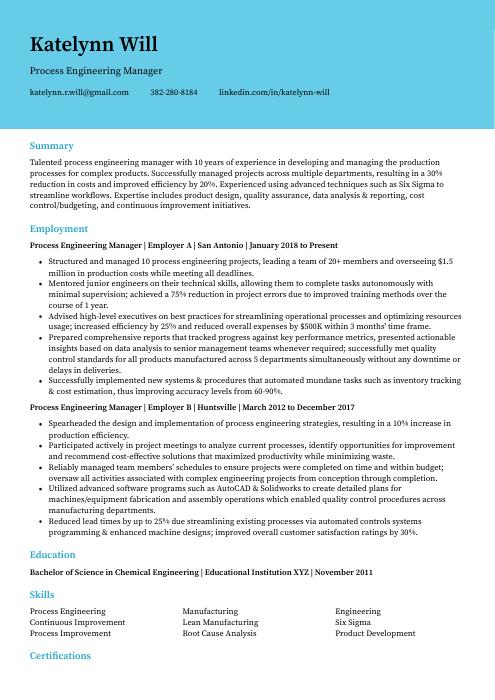

Process Engineering Manager Resume Sample

Katelynn Will

Process Engineering Manager

[email protected]

382-280-8184

linkedin.com/in/katelynn-will

Summary

Talented process engineering manager with 10 years of experience in developing and managing the production processes for complex products. Successfully managed projects across multiple departments, resulting in a 30% reduction in costs and improved efficiency by 20%. Experienced using advanced techniques such as Six Sigma to streamline workflows. Expertise includes product design, quality assurance, data analysis & reporting, cost control/budgeting, and continuous improvement initiatives.

Experience

Process Engineering Manager, Employer A

San Antonio, Jan 2018 – Present

- Structured and managed 10 process engineering projects, leading a team of 20+ members and overseeing $1.5 million in production costs while meeting all deadlines.

- Mentored junior engineers on their technical skills, allowing them to complete tasks autonomously with minimal supervision; achieved a 75% reduction in project errors due to improved training methods over the course of 1 year.

- Advised high-level executives on best practices for streamlining operational processes and optimizing resources usage; increased efficiency by 25% and reduced overall expenses by $500K within 3 months’ time frame.

- Prepared comprehensive reports that tracked progress against key performance metrics, presented actionable insights based on data analysis to senior management teams whenever required; successfully met quality control standards for all products manufactured across 5 departments simultaneously without any downtime or delays in deliveries.

- Successfully implemented new systems & procedures that automated mundane tasks such as inventory tracking & cost estimation, thus improving accuracy levels from 60-90%.

Process Engineering Manager, Employer B

Huntsville, Mar 2012 – Dec 2017

- Spearheaded the design and implementation of process engineering strategies, resulting in a 10% increase in production efficiency.

- Participated actively in project meetings to analyze current processes, identify opportunities for improvement and recommend cost-effective solutions that maximized productivity while minimizing waste.

- Reliably managed team members’ schedules to ensure projects were completed on time and within budget; oversaw all activities associated with complex engineering projects from conception through completion.

- Utilized advanced software programs such as AutoCAD & Solidworks to create detailed plans for machines/equipment fabrication and assembly operations which enabled quality control procedures across manufacturing departments.

- Reduced lead times by up to 25% due streamlining existing processes via automated controls systems programming & enhanced machine designs; improved overall customer satisfaction ratings by 30%.

Skills

- Process Engineering

- Manufacturing

- Engineering

- Continuous Improvement

- Lean Manufacturing

- Six Sigma

- Process Improvement

- Root Cause Analysis

- Product Development

Education

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Professional in Process Improvement (CPPI)

American Society for

May 2017

1. Summary / Objective

A resume summary for a process engineering manager should be concise and to the point. It should include your most relevant qualifications, such as experience in leading teams of engineers on complex projects, knowledge of different manufacturing processes, and expertise with specific software programs. It is also important to mention any certifications or awards you have earned that demonstrate your commitment to excellence in this field. Finally, make sure to emphasize how you can use these skills and experiences to benefit the company if hired for the position.

Below are some resume summary examples:

Enthusiastic and experienced process engineering manager with over 10 years of experience in the field. Proven track record for successfully leading teams to improve production process efficiency, reduce costs, and increase customer satisfaction. Skilled at developing strategies that drive cost reduction through optimization of processes while maintaining product quality standards. Experienced in troubleshooting complex technical issues related to manufacturing equipment and systems.

Accomplished Process Engineering Manager with 10+ years of experience developing and implementing innovative process improvement solutions. Skilled in leading cross-functional teams to reduce waste, improve quality control, and speed up production times while keeping costs down. At XYZ Inc., saved $500K annually by optimizing processes across three plants. Seeking a challenging role at ABC Corp where I can leverage my expertise to drive organizational growth.

Determined process engineering manager with 10+ years of experience in designing and implementing efficient processes for the manufacturing industry. Expertise in project management, process optimization, cost estimation, workflow analysis, and problem solving. At XYZ Corporation managed a team of 15 engineers to improve production efficiency by 25%. Seeking to leverage my experience at ABC Company to develop an even more efficient process engineering system.

Driven process engineering manager with 10+ years of experience leading process improvement projects and managing teams. Developing cross-functional partnerships to execute plans for optimizing operations, reducing costs, and increasing efficiency. At XYZ Corp., led a successful project that increased automation capabilities by 25%. Looking to leverage this expertise at ABC Tech in order to make meaningful contributions towards the company’s success.

Dependable process engineering manager with 8+ years of experience driving process improvement initiatives and managing cross-functional teams. Proven track record in reducing costs, streamlining operations, and improving production efficiency for ABC Corporation. At XYZ Inc., increased throughput by 18% while maintaining quality standards. Successfully implemented a new manufacturing tracking system that improved inventory accuracy by 12%.

Passionate process engineering manager with 8+ years of experience managing and leading process improvement initiatives for a variety of manufacturing industries. Skilled in developing, overseeing, and executing strategies that result in cost savings, improved safety standards, increased efficiency and productivity. Seeking to join ABC Company as the lead Process Engineer Manager to drive further improvements throughout their operations.

Reliable and experienced process engineering manager with 13 years of experience leading teams in the manufacturing industry. At XYZ, managed 10 projects simultaneously while also ensuring regulatory compliance for all operations. Adept at streamlining processes to maximize efficiency and improve production quality. Committed to developing a safe working environment that encourages teamwork and innovation.

Hard-working process engineering manager with 10+ years of experience leading teams in the design, development and optimization of industrial processes. Proven track record of success in improving safety standards, maintaining quality control and increasing throughput efficiency. Seeking to join ABC Tech to use my expertise to manage complex projects while driving innovation within manufacturing systems.

2. Experience / Employment

Next comes the work history section, which should be written in reverse chronological order. This means your most recent role is listed first.

When writing about what you did, stick to bullet points for the sake of clarity and conciseness. Take some time to think about the details of what you accomplished and how it impacted the organization or team’s performance.

For example, instead of saying “Managed process engineering department,” you could say, “Led a team of 10+ engineers in designing new processes that increased productivity by 25% while decreasing costs by 15%.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Achieved a 10% increase in process efficiency through optimization of production processes, resulting in an annual savings of $500K.

- Compiled detailed reports on engineering process analysis and performance metrics to identify areas for improvement and ensure full operational compliance with safety regulations.

- Reorganized manufacturing plants by streamlining workflow procedures and implemented new protocols that increased output speed by 20%.

- Optimized existing systems to reduce energy consumption levels by 30%, leading to decreased costs associated with utilities bills over the course of 6 months.

- Thoroughly inspected machines on a daily basis to maintain quality assurance standards; identified and rectified technical issues before they caused any further disruption or damage within 3 hours on average per incident.

- Effectively managed a team of 12+ process engineers, overseeing the design and development of new processes to increase efficiency while reducing costs by 20%.

- Facilitated cross-functional collaboration between operations, product management and engineering teams to ensure smooth implementation of newly developed processes.

- Presented at multiple industry events on process improvement techniques; led workshops for over 50 attendees in topics such as Six Sigma methodologies & Lean Manufacturing practices.

- Streamlined production cycles through innovative automation solutions, resulting in an average reduction of 3 hours per day across all departments during peak times.

- Expedited project completion timelines by 30% using daily task prioritization strategies and close monitoring/mentoring approaches with junior staff members.

- Coordinated the activities of a team of 15 process engineers to optimize the production line, resulting in a 10% increase in productivity.

- Improved manufacturing processes by developing and implementing innovative solutions that reduced costs by $50,000 per month.

- Demonstrated strong leadership skills while managing projects from conception through completion within an average timeline of 8 weeks or less; consistently generated quality outputs on time and within budget constraints.

- Revised existing industry standards for safety protocols when handling hazardous materials, ensuring that all regulations were met with zero incidents reported over two years working as Process Engineering Manager with XYZ Company Ltd.

- Meticulously monitored operating metrics such as cycle times & throughputs to evaluate performance effectiveness against established targets; successfully achieved 99% uptime across multiple sites during 2-year tenure at ABC Co Inc..

- Introduced a new process engineering system resulting in an 8% increase in efficiency and productivity, reducing manufacturing costs by $50,000 annually.

- Efficiently managed 10+ production lines to ensure the optimal use of resources and minimal wastage; achieved zero unplanned downtime for 6 consecutive months.

- Developed comprehensive protocols for efficient product development processes that were adopted across 5 global facilities with positive results; reduced development time from 12 weeks to 9 weeks on average.

- Formulated improvement strategies based on feedback from customers & employees which resulted in improved customer satisfaction ratings by 15%.

- Assessed current capabilities & identified areas of improvement through extensive data analysis, allowing the organization to save over 1 million dollars every year due to streamlined operations & cost-cutting initiatives implemented as a result.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for a process engineering manager with expertise in Lean Six Sigma, while Organization XYZ may require experience in Kaizen.

It is important to tailor the skills section of your resume to each job that you are applying for because many employers use applicant tracking systems these days, which scan resumes for certain keywords before passing them on to a human.

Once listed here, you can further elaborate on your skillset by discussing it in more detail elsewhere; such as the summary or experience sections.

Below is a list of common skills & terms:

- 5S

- Aspen HYSYS

- AutoCAD

- Automation

- Automotive

- Business Process Improvement

- Characterization

- Chemical Engineering

- Commissioning

- Continuous Improvement

- Cross Functional Team Leadership

- DMAIC

- Data Analysis

- Design for Manufacturing

- Design of Experiments

- EPC

- Electronics

- Energy

- Engineering

- Engineering Management

- FMEA

- Factory

- Failure Analysis

- Feed

- GMP

- Gas

- HAZOP

- ISO

- Industrial Engineering

- Injection Molding

- Kaizen

- Lean Manufacturing

- MATLAB

- Manufacturing

- Manufacturing Engineering

- Manufacturing Operations Management

- Materials

- Materials Science

- Mechanical Engineering

- Minitab

- Oil and Gas

- Operations Management

- P&ID

- PPAP

- Petrochemical

- Petroleum

- Plastics

- Process Control

- Process Engineering

- Process Improvement

- Process Optimization

- Process Safety

- Process Simulation

- Product Development

- Program Management

- Project Engineering

- Project Planning

- Quality Assurance

- Quality Management

- Quality System

- R&D

- Refinery

- Root Cause Analysis

- SOLIDWORKS

- SPC

- Semiconductor Industry

- Semiconductors

- Six Sigma

- Supply Chain Management

- Team Leadership

- Testing

- Thin Films

- Troubleshooting

- Validation

- Value Stream Mapping

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and don’t have much work experience, put it below your resume objective. However, if you have been working as a process engineering manager for years with plenty of different responsibilities to showcase, omitting the education section is perfectly fine.

If an education section is included, try to mention courses and subjects relevant to the process engineering manager role that you are applying for.

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the knowledge and skills necessary for a particular job. They can also show that you are committed to staying up-to-date on industry trends, as certifications often require continuing education or regular renewal.

If you possess any relevant certifications related to the position, make sure they are prominently featured in your resume so hiring managers will take notice.

Certified Professional in Process Improvement (CPPI)

American Society for

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Katelynn Will, this would be Katelynn-Will-resume.pdf or Katelynn-Will-resume.docx.

7. Cover Letter

Providing a cover letter is a great way to show prospective employers that you have taken the time to really think about the position and how your skillset can be beneficial for them. It should include 2-4 paragraphs of relevant information, such as why you are interested in this job and what makes you an ideal candidate.

Cover letters also give hiring managers an insight into who you are beyond just work experience and qualifications. By including some personal details, it helps build a more meaningful connection with recruiters which could help set yourself apart from other applicants.

Below is an example cover letter:

Dear Shakira,

When I saw the opening for a Process Engineering Manager at XYZ Corporation, I knew it was the perfect opportunity for me. With more than 10 years of experience in process engineering and management, I am confident that I have the skills and knowledge to be successful in this role.

In my current position as a Process Engineer at ABC Company, I am responsible for leading a team of engineers and technicians in developing new processes and improving existing ones. In addition to my technical expertise, I have excellent project management skills and am able to successfully manage multiple projects simultaneously while meeting deadlines. My interpersonal skills are also top-notch, which has been essential in building relationships with clients and vendors.

I believe that my combination of technical expertise, project management experience, and interpersonal skills would make me an asset to your organization. I am eager to put my knowledge and experience to work for you by developing efficient processes that improve productivity and quality while reducing costs.

I will call you next week to follow up on this application. In the meantime, if you have any questions or need any additional information from me, please do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration; I look forward to hearing from you soon!

Sincerely,

Katelynn

Process Engineering Manager Resume Templates

Fossa

Fossa Echidna

Echidna Indri

Indri Jerboa

Jerboa Kinkajou

Kinkajou Axolotl

Axolotl Bonobo

Bonobo Hoopoe

Hoopoe Ocelot

Ocelot Saola

Saola Rhea

Rhea Quokka

Quokka Pika

Pika Gharial

Gharial Cormorant

Cormorant Lorikeet

Lorikeet Markhor

Markhor Numbat

Numbat Dugong

Dugong Rezjumei

Rezjumei