Process Development Engineer Resume Guide

Process development engineers design, develop and optimize manufacturing processes to ensure cost-effective production of products. They analyze existing processes for improvement opportunities and create new process designs based on customer specifications. Additionally, they may also use computer simulations to test the efficiency of their proposed designs.

You have the perfect blend of technical and creative knowledge to be a great process development engineer. But hiring managers don’t know who you are yet, so it’s time to create an eye-catching resume that conveys your expertise and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

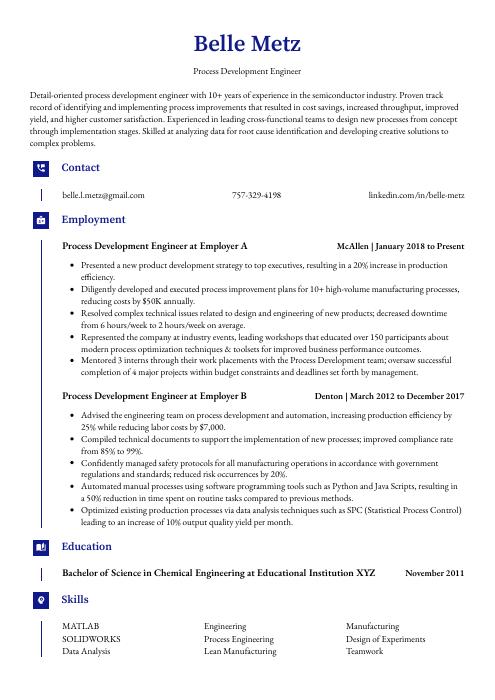

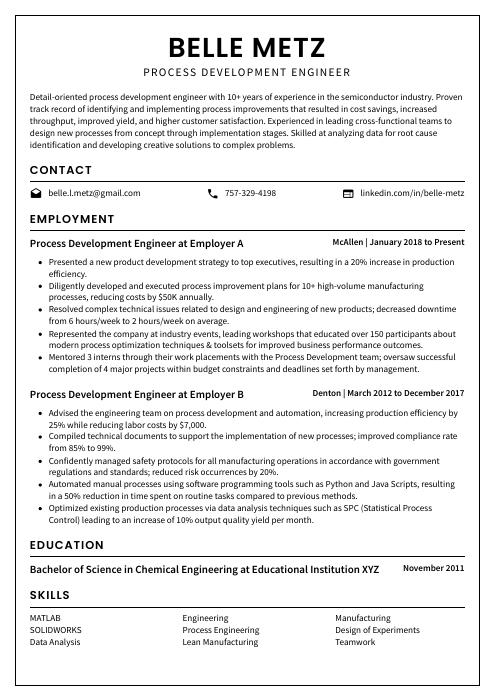

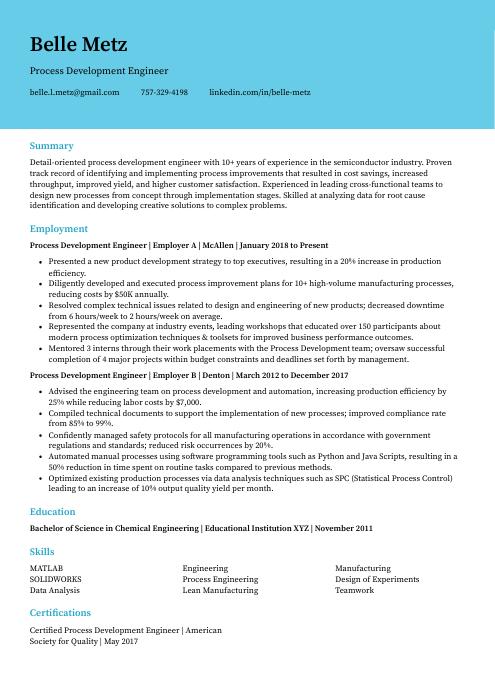

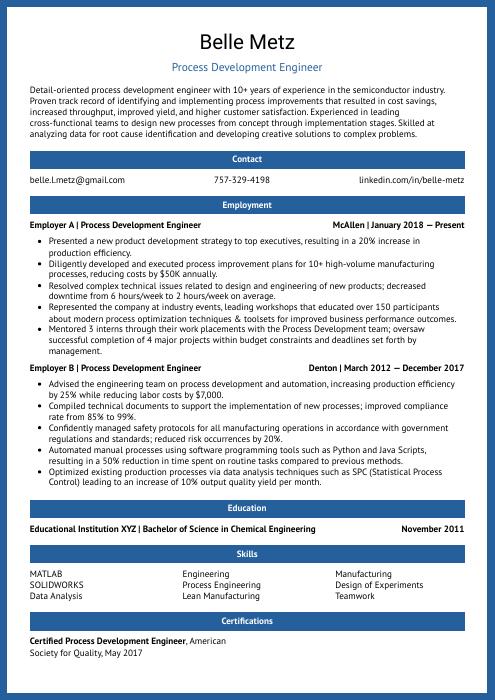

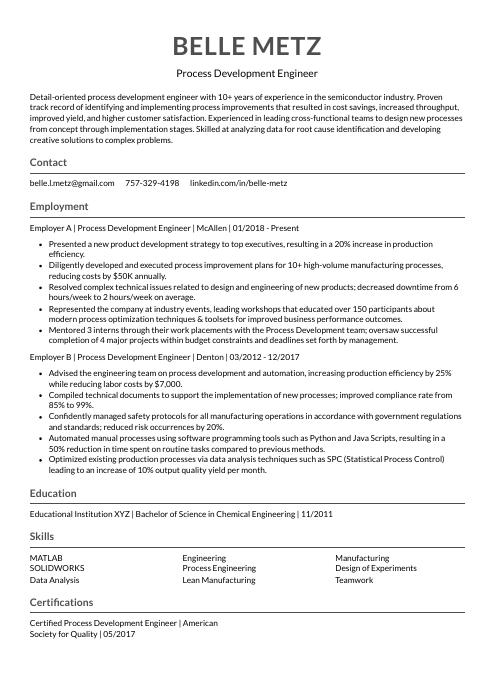

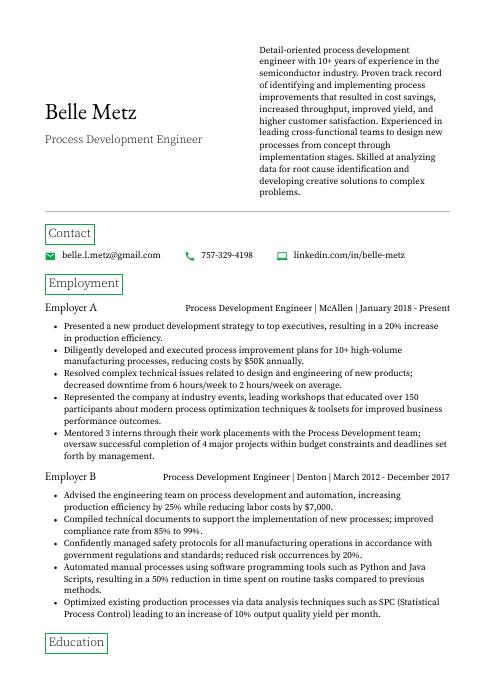

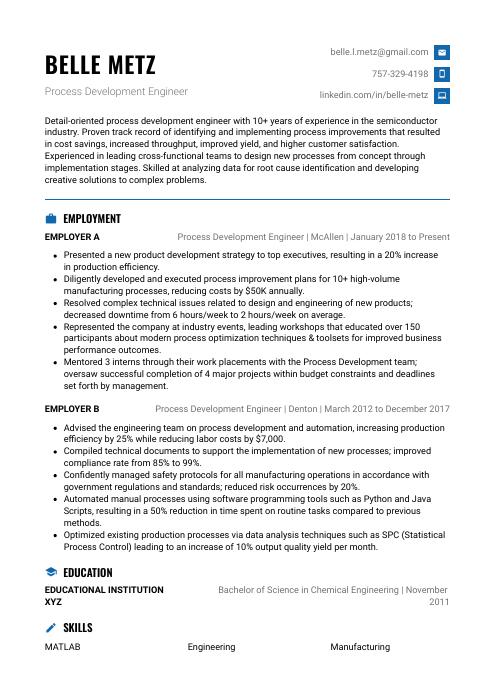

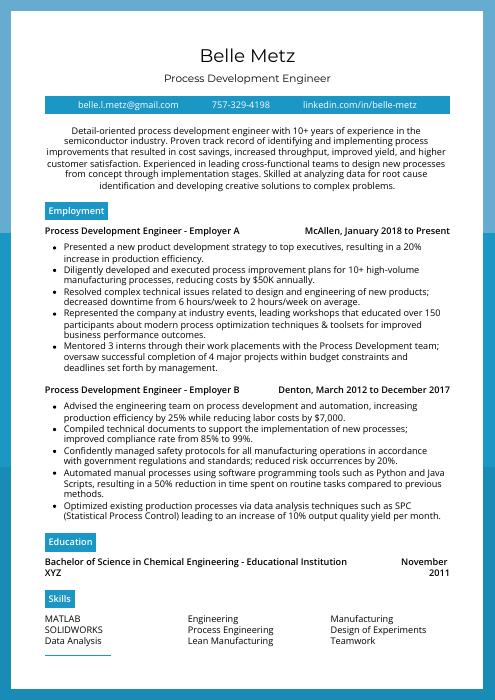

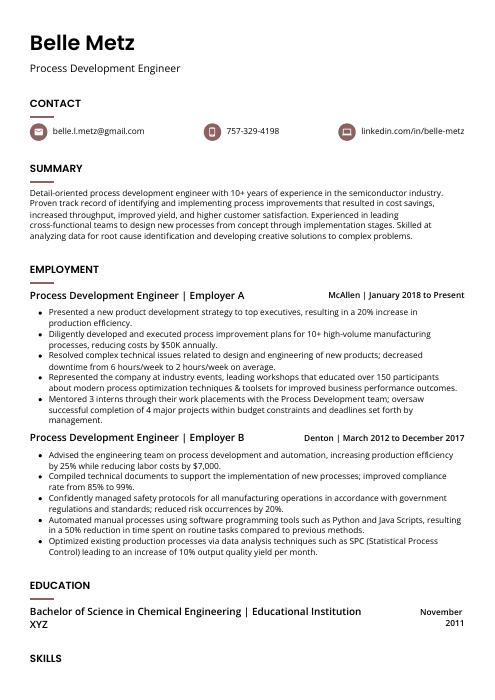

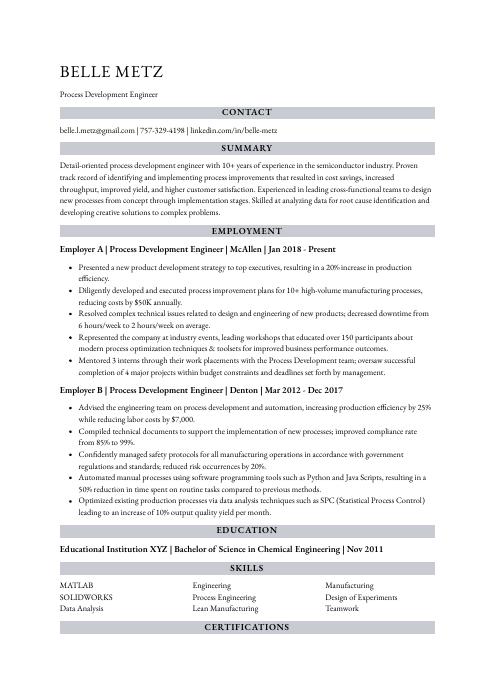

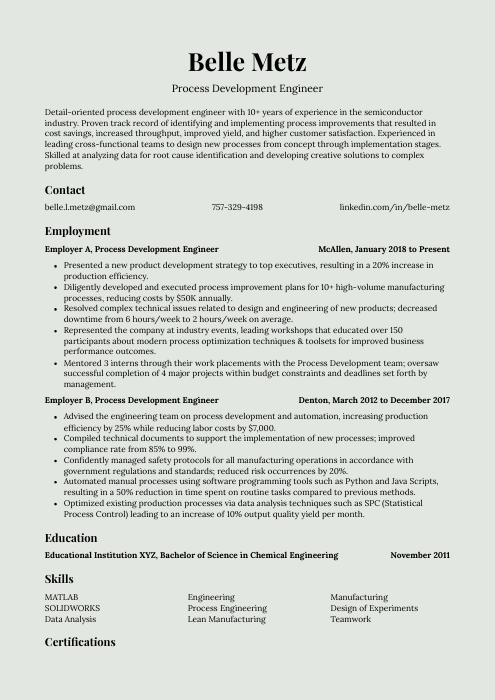

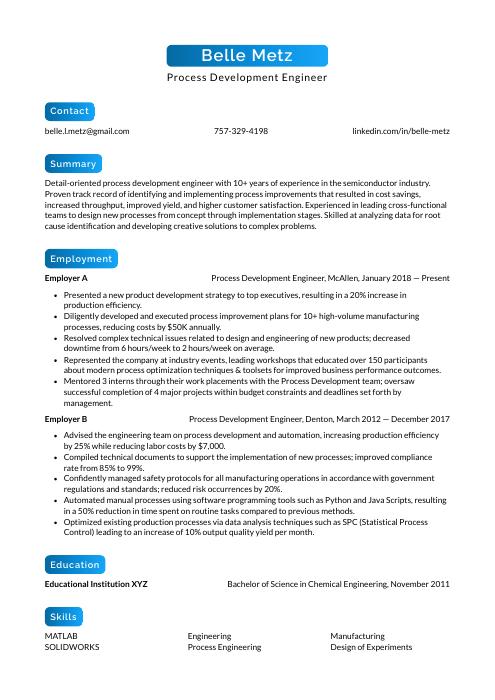

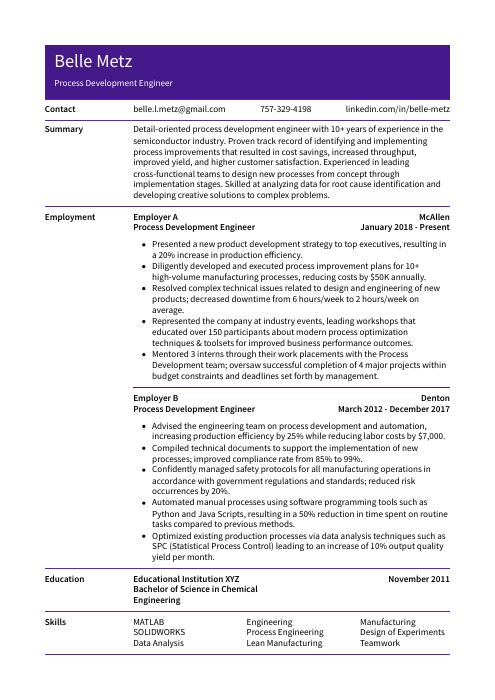

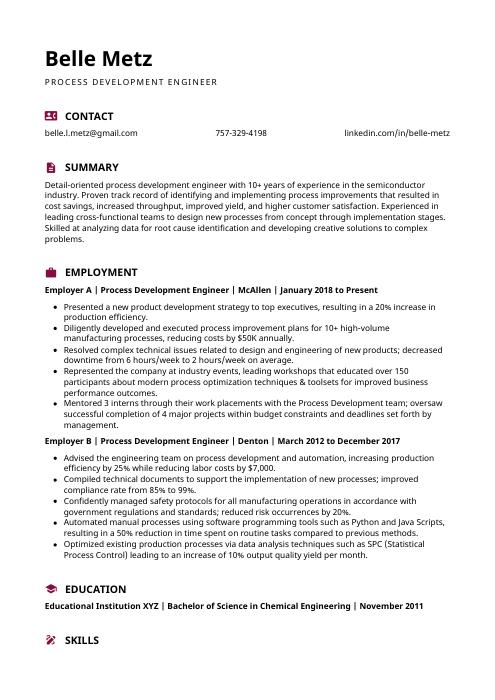

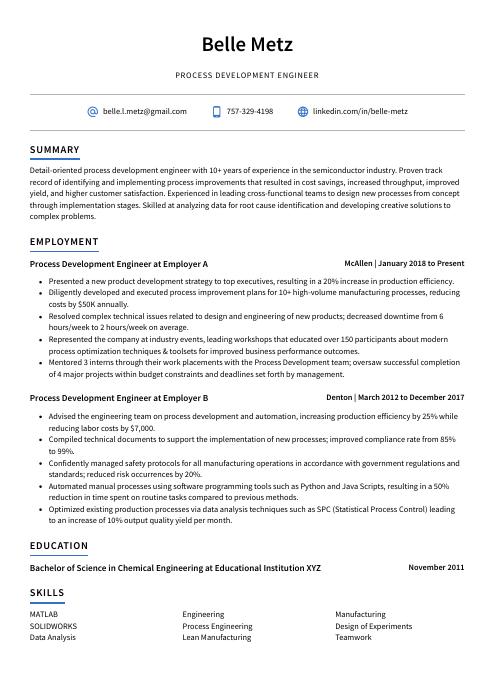

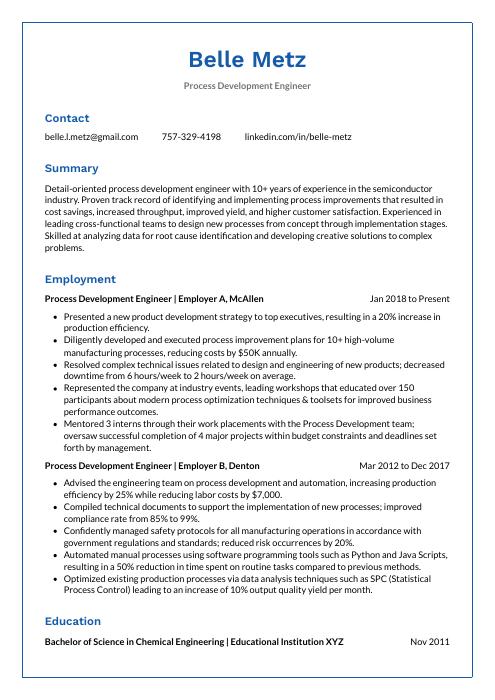

Process Development Engineer Resume Sample

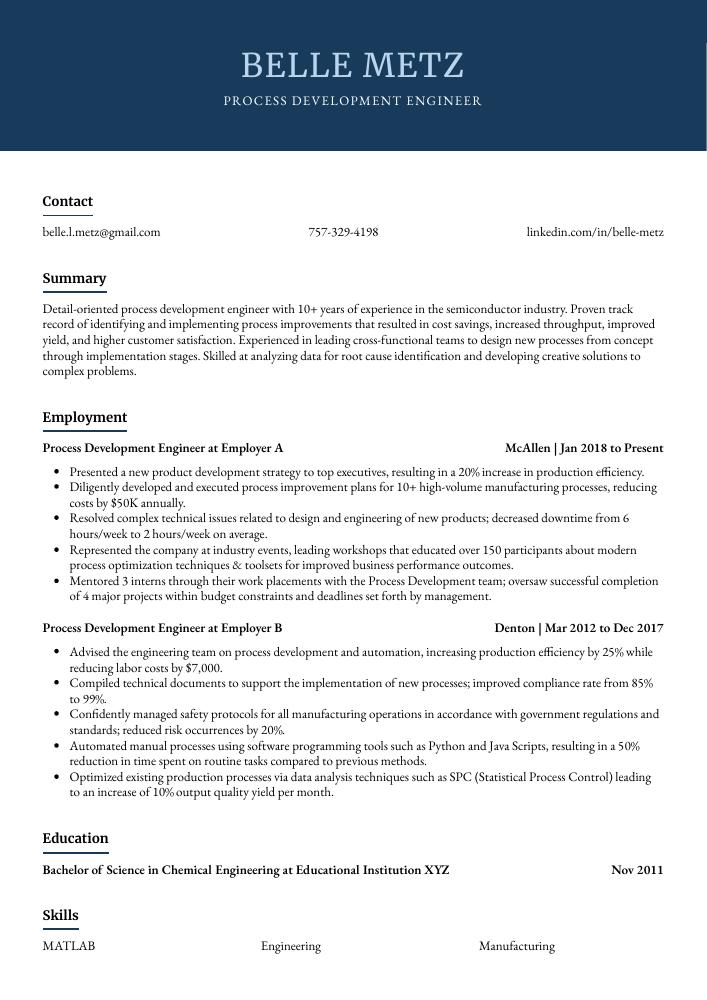

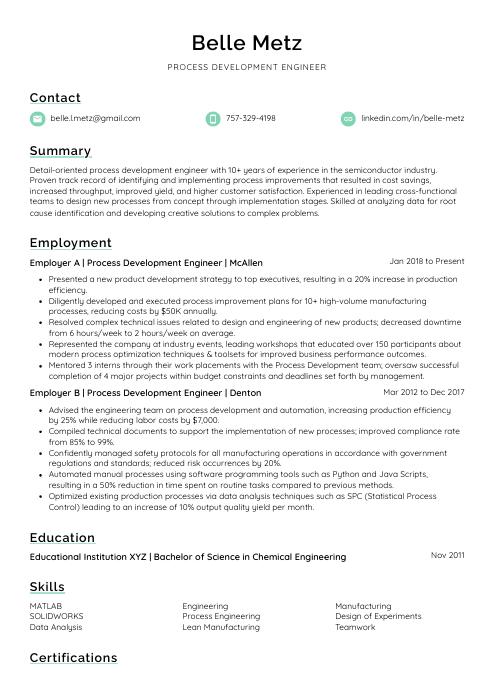

Belle Metz

Process Development Engineer

[email protected]

757-329-4198

linkedin.com/in/belle-metz

Summary

Detail-oriented process development engineer with 10+ years of experience in the semiconductor industry. Proven track record of identifying and implementing process improvements that resulted in cost savings, increased throughput, improved yield, and higher customer satisfaction. Experienced in leading cross-functional teams to design new processes from concept through implementation stages. Skilled at analyzing data for root cause identification and developing creative solutions to complex problems.

Experience

Process Development Engineer, Employer A

McAllen, Jan 2018 – Present

- Presented a new product development strategy to top executives, resulting in a 20% increase in production efficiency.

- Diligently developed and executed process improvement plans for 10+ high-volume manufacturing processes, reducing costs by $50K annually.

- Resolved complex technical issues related to design and engineering of new products; decreased downtime from 6 hours/week to 2 hours/week on average.

- Represented the company at industry events, leading workshops that educated over 150 participants about modern process optimization techniques & toolsets for improved business performance outcomes.

- Mentored 3 interns through their work placements with the Process Development team; oversaw successful completion of 4 major projects within budget constraints and deadlines set forth by management.

Process Development Engineer, Employer B

Denton, Mar 2012 – Dec 2017

- Advised the engineering team on process development and automation, increasing production efficiency by 25% while reducing labor costs by $7,000.

- Compiled technical documents to support the implementation of new processes; improved compliance rate from 85% to 99%.

- Confidently managed safety protocols for all manufacturing operations in accordance with government regulations and standards; reduced risk occurrences by 20%.

- Automated manual processes using software programming tools such as Python and Java Scripts, resulting in a 50% reduction in time spent on routine tasks compared to previous methods.

- Optimized existing production processes via data analysis techniques such as SPC (Statistical Process Control) leading to an increase of 10% output quality yield per month.

Skills

- MATLAB

- Engineering

- Manufacturing

- SOLIDWORKS

- Process Engineering

- Design of Experiments

- Data Analysis

- Lean Manufacturing

- Teamwork

Education

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Process Development Engineer

American Society for Quality

May 2017

1. Summary / Objective

Your resume summary should be a brief but powerful statement that captures the essence of your process development engineering skills and experience. Include information such as how many years you have been in this field, any relevant certifications or qualifications you possess, and examples of successful projects/processes you have developed in the past. This is also an opportunity to highlight your problem-solving abilities and technical knowledge.

Below are some resume summary examples:

Energetic process development engineer with 10+ years of experience in the design and implementation of efficient engineering processes. Skilled at optimizing operations for cost savings, quality assurance, and on-time delivery using innovative solutions. At XYZ Inc., reduced average production time by 25% and improved product yield from 75 to 99%. Looking to join ABC Tech as a process development engineer and use my expertise to improve their business operations.

Dependable process development engineer with 10+ years of experience in the medical device industry. Proficient in process validation and design control, as well as developing risk management plans for ISO 13485 compliance. At XYZ Medical Devices, developed a new manufacturing process that reduced cycle time by 33% and improved product yield by 15%. Demonstrated ability to lead projects from concept through completion while managing resources effectively.

Professional process development engineer with 5+ years’ experience in process engineering and optimization. Proven track record of successful project management, from conception to completion. Skilled at designing processes that optimize production efficiency and reduce waste for increased cost savings. Adept at working with stakeholders and teams across all levels to ensure successful implementation of new technologies and processes.

Well-rounded process development engineer with 7+ years of experience developing, managing, and improving manufacturing processes in the automotive industry. Achieved a 5% reduction in scrap rates by optimizing tooling and process parameters to meet customer requirements while maintaining safety standards. Seeking to apply my knowledge at ABC Company to help them reach their production goals efficiently and cost-effectively.

Seasoned process development engineer with 7+ years of experience in developing, designing and executing manufacturing processes for high-volume production. Proven track record in cost-effectively improving product performance while meeting customer requirements on time. At XYZ, successfully designed a continuous process to reduce cycle times by 50%. Received company recognition award for reducing total costs by 20%.

Reliable process development engineer with 5+ years of experience in the design, implementation and optimization of manufacturing processes. Expertise includes designing new equipment, developing process control protocols, troubleshooting existing systems and providing training to production teams. Looking to leverage strong technical skills at ABC Manufacturing where I can help improve efficiency by 10%.

Enthusiastic process development engineer with 5+ years of experience developing, testing, and optimizing industrial processes. Skilled in troubleshooting process issues while maintaining a safe work environment. At XYZ Corporation, increased production efficiency by 20% through the use of advanced automation technologies. Seeking to bring my expertise to ABC Company’s Process Development team.

Passionate process development engineer with 7+ years of experience designing and developing automation processes. Seeking to apply knowledge, skills, and expertise to drive process improvement initiatives at ABC Corp. Have led multiple projects that reduced production costs by an average of 25%. Also increased overall equipment effectiveness (OEE) by 20% in a manufacturing plant setting.

2. Experience / Employment

The employment (or experience) section is where you list your work history. It should be written in reverse chronological order, meaning the most recent job is listed first.

Stick to bullet points when writing this section; it makes it easier for the reader to take in what you have said quickly and efficiently. You want to provide detail on what you did and any results or achievements that were obtained as a result of your actions.

For example, instead of saying “Developed new processes,” you could say, “Created an automated process which reduced production time by 25%, resulting in increased efficiency.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Implemented

- Optimized

- Automated

- Monitored

- Analyzed

- Investigated

- Resolved

- Documented

- Troubleshot

- Streamlined

- Upgraded

- Programmed

- Tested

- Debugged

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Structured

- Utilized

Below are some example bullet points:

- Effectively designed, tested and implemented over 10 process optimization projects which resulted in a 20% improvement of the production efficiency.

- Coordinated with operations team to revamp existing processes for better utilization of resources and reduced cycle time by 25%.

- Revised key performance indices (KPIs) such as throughput rate, downtime frequency etc., ensuring that all numerical targets were met or exceeded consistently every month; achieved 99% customer satisfaction level since implementation.

- Monitored plant output on an hourly basis using specialized software tools; identified potential bottlenecks early and took appropriate corrective measures before they impacted productivity negatively (+5%).

- Introduced lean manufacturing principles into daily workflows, leading to increased cost savings of $7000 per quarter compared to previous year’s figures without compromising quality standards at any point along the way.

- Resourcefully upgraded current process designs to meet production demands, resulting in a 25% increase of output and improving profitability by $10K.

- Tested new manufacturing processes using rigorous quality assurance methods and identified areas for improvement; consistently met or exceeded safety standards while reducing total downtime by 10%.

- Structured efficient operations plans with cost-conscious materials sourcing initiatives, leading to an 8% reduction in overhead costs within 1 year.

- Improved existing manufacturing systems through the development of innovative technologies that resulted in a 30% decrease in energy usage per unit produced on average.

- Designed and implemented more than 5 successful process control protocols over 3 years, culminating into improved product yields at reduced defect rates (6%).

- Facilitated the development of 6 new processes to improve production efficiency by 25%, resulting in a $2.5M cost savings for the company annually.

- Formulated innovative solutions and strategies to streamline existing manufacturing processes, reducing waste from 30% to 10%.

- Implemented advanced quality control procedures across all stages of process development; improved product accuracy by 40%.

- Prepared detailed reports documenting design parameters, equipment specifications and operating conditions for process engineering projects; saved 200+ hours in project completion time over 2 years period with no errors reported or rework required during initial trials.

- Consistently met deadlines while delivering process optimization initiatives on-time and under budget at least 75% of the time throughout tenure as Process Development Engineer.

- Substantially increased process efficiency by 25% through the implementation of innovative solutions and optimization processes.

- Analyzed existing production systems to identify areas for improvement, leading to an increase in output capacity by 15%.

- Developed a standardized approach for operations that improved quality control standards while decreasing manufacturing costs per unit by 10%.

- Achieved cost savings of $50K within first year as Process Development Engineer through enhanced maintenance procedures and improved product flow management strategies.

- Utilized advanced problem-solving techniques and statistical data analysis skills to troubleshoot machinery issues and resolve problems quickly with minimal downtime or disruption in service levels.

- Thoroughly assessed process flow and identified areas of improvement, resulting in a 20% reduction of labor costs.

- Reduced product defects by 15%, through debugging existing production processes and developing new ones to optimize efficiency.

- Spearheaded the development of automated systems for quality control processes; increased accuracy by 45%.

- Developed safety protocols to comply with required organizational standards; reduced job-related injuries on the shop floor by 35%.

- Implemented cost savings initiatives that saved $50,000 annually while improving quality assurance measures across all levels of production operations.

- Streamlined process development and optimization procedures for a team of 10 engineers, resulting in an 8% increase in production speed.

- Reorganized existing process flow diagrams to maximize efficiency; saved the company over $5,000 in energy costs each month.

- Demonstrated expertise with 3D CAD software to design automated systems that improved product quality by 25%.

- Programmed robotic machines using advanced coding languages such as Python & C++, reducing manual labor hours by 50%.

- Meticulously monitored performance data from all stages of the manufacturing process and managed any deviations promptly to ensure optimal results at all times.

- Reliably designed and implemented process development solutions for 12+ production lines, resulting in a 15% decrease in operational costs.

- Documented the steps of complex industrial processes to ensure efficient product quality control; reduced rework rates by 25%.

- Designed innovative solutions that automated manual operations, reducing labor time by 30 hours each month on average.

- Expedited new project timelines from 18 months to 10 months through resource optimization and improved communication with stakeholders; cut overall budget expenditure by $50K over 6-month period.

- Investigated failures or shortfalls in the existing process structure and identified areas of improvement; successfully completed 3 projects aiming at enhancing efficiency levels within 4 weeks per project timeframe.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual who is proficient in Six Sigma and another may want someone with a strong background in process automation.

It’s important to tailor the skills section of your resume for each job you apply for, as this will help ensure that it passes through any applicant tracking systems used by employers. You can then go on to discuss these skills further throughout other parts of your resume, such as within the summary or experience sections.

Below is a list of common skills & terms:

- 5S

- AFM

- AutoCAD

- Biotechnology

- C++

- CAD

- Characterization

- Chemical Engineering

- Chemistry

- Continuous Improvement

- Cross Functional Team Leadership

- Data Analysis

- Design for Manufacturing

- Design of Experiments

- Electronics

- Engineering

- FMEA

- Failure Analysis

- GMP

- JMP

- LabVIEW

- Lean Manufacturing

- MATLAB

- Manufacturing

- Manufacturing Engineering

- Materials

- Materials Science

- Mechanical Engineering

- Medical Devices

- Minitab

- Nanotechnology

- Problem Solving

- Process Engineering

- Process Improvement

- Process Simulation

- Product Development

- Quality System

- R&D

- Research and Development

- Root Cause Analysis

- SOLIDWORKS

- SPC

- Scanning Electron Microscopy

- Semiconductors

- Six Sigma

- Statistics

- Teamwork

- Testing

- Thin Films

- Time Management

- Validation

4. Education

Including an education section on your resume can be beneficial if you’ve recently graduated, or are still in the early stages of your career. If you have a few years of experience and plenty to showcase, it may not be necessary to include an education section altogether.

If including this information is pertinent, try to mention courses and subjects related to process development engineering that will give potential employers insight into how qualified you are for the role.

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a particular field. When applying for jobs, it is important to include any certifications that are relevant to the position you are applying for as this will help set you apart from other applicants.

Including certifications on your resume shows potential employers that you have taken the time and effort to gain additional qualifications which can be beneficial when competing with others who may not have done so.

Certified Process Development Engineer

American Society for Quality

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Belle Metz, this would be Belle-Metz-resume.pdf or Belle-Metz-resume.docx.

7. Cover Letter

Including a cover letter alongside your resume is a great way to introduce yourself to potential employers and explain why you are the perfect fit for the role. It generally consists of 2 to 4 paragraphs that provide more in-depth information about who you are, what makes you qualified and how your skills can be beneficial.

Although not all job applications require submitting a cover letter, it’s still highly recommended as it gives recruiters an insight into your personality and character traits that simply cannot be conveyed through a CV alone.

Below is an example cover letter:

Dear Chaya,

I am writing to apply for the position of Process Development Engineer at XYZ Corporation. As a highly skilled and experienced process engineer, I am confident that I would be an excellent addition to your team.

Over the course of my career, I have gained extensive experience in process development engineering, with a focus on developing efficient manufacturing processes and improving existing ones. In my current role as Process Development Engineer at ABC Corporation, I lead a team of engineers and technicians in designing and optimizing production processes for our company’s products. Through my efforts, we have been able to reduce production costs by 20% while maintaining high levels of quality control.

In addition to my experience in process development engineering, I also possess strong analytical skills and a keen eye for detail. This has allowed me to identify areas where improvements can be made and develop solutions that increase efficiency while reducing costs. My ability to think critically and solve problems quickly makes me an asset in any fast-paced environment.

I am excited about the opportunity to join XYZ Corporation as it is clear that you are leaders in your industry who are constantly innovating and looking for ways to improve your products and processes. I believe that my skills and experience will contribute greatly to your organization’s success, and I look forward to joining your team soon.

Sincerely,

Belle

Process Development Engineer Resume Templates

Bonobo

Bonobo Jerboa

Jerboa Lorikeet

Lorikeet Gharial

Gharial Cormorant

Cormorant Dugong

Dugong Ocelot

Ocelot Indri

Indri Quokka

Quokka Echidna

Echidna Rhea

Rhea Fossa

Fossa Numbat

Numbat Saola

Saola Kinkajou

Kinkajou Pika

Pika Hoopoe

Hoopoe Axolotl

Axolotl Markhor

Markhor Rezjumei

Rezjumei