Process Control Engineer Resume Guide

Process control engineers design and develop systems that monitor, measure, and adjust variables in industrial processes. They use their knowledge of engineering principles to optimize safety and efficiency while also reducing costs.

You have the skills and experience to be a great process control engineer, but potential employers don’t know who you are. To make them aware of your abilities, you must create an eye-catching resume that highlights all your qualifications.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

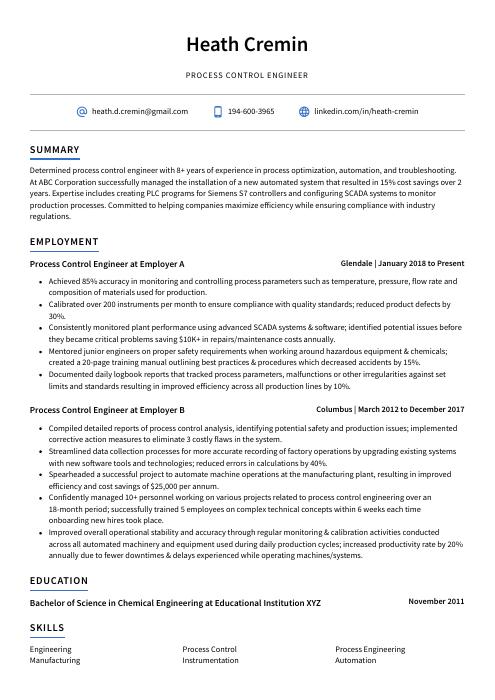

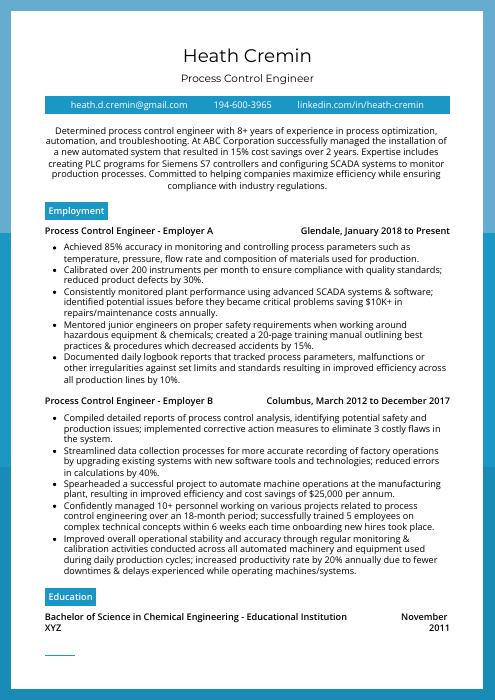

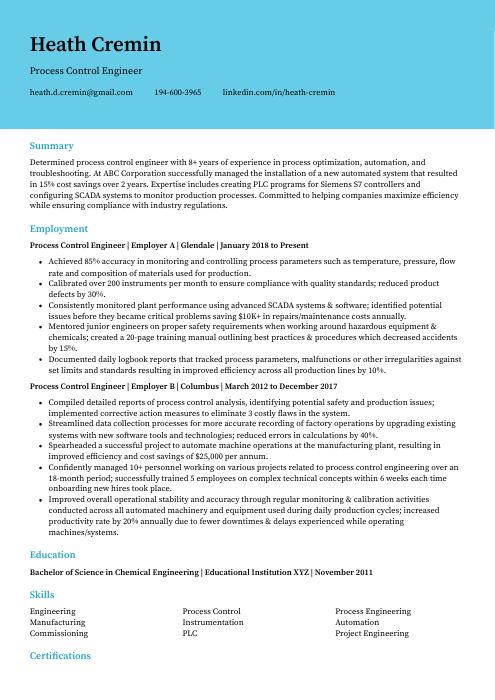

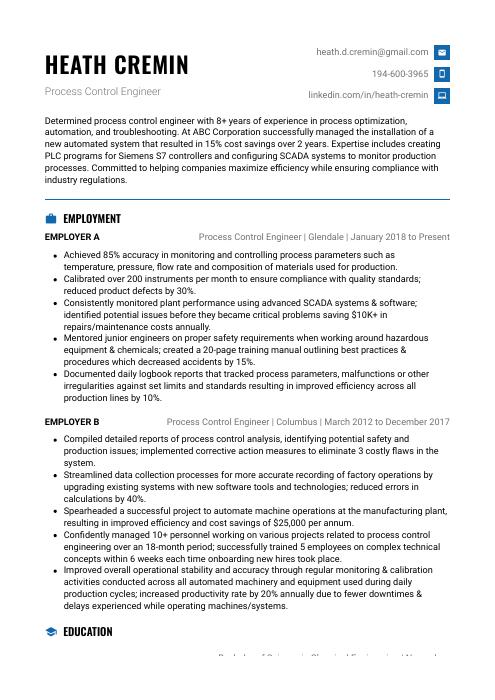

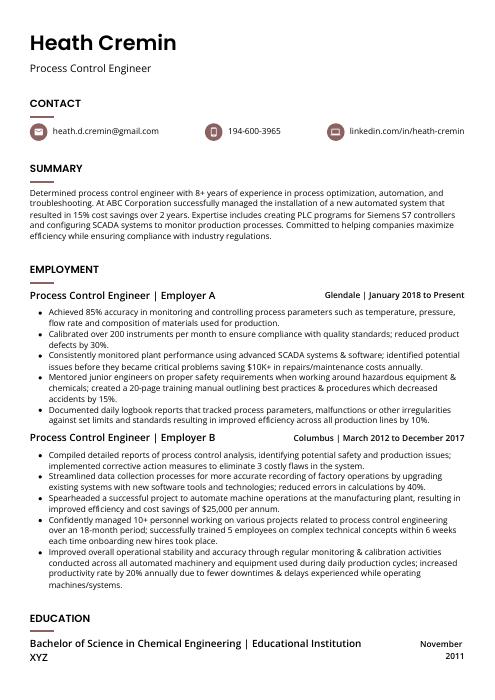

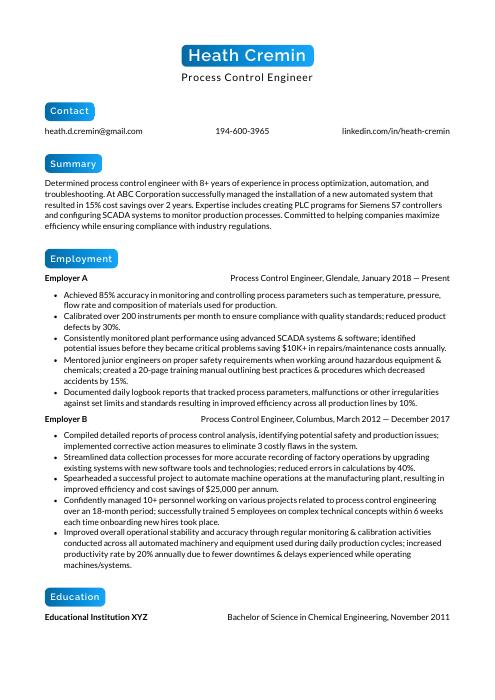

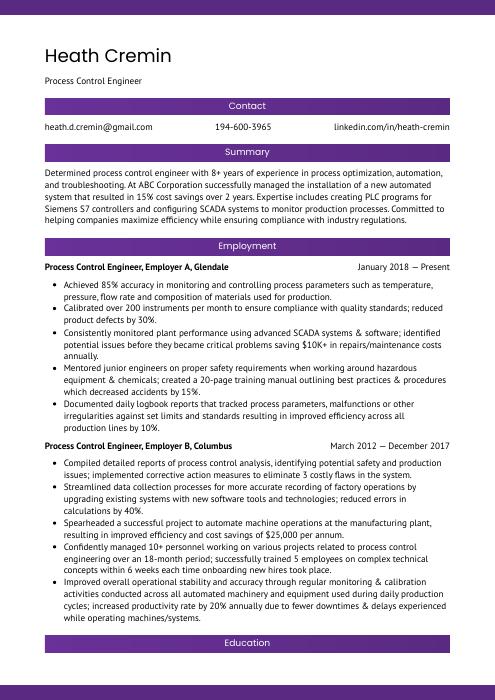

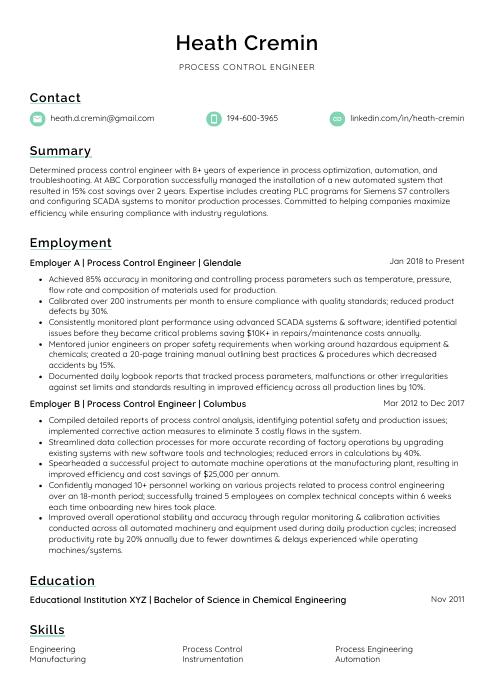

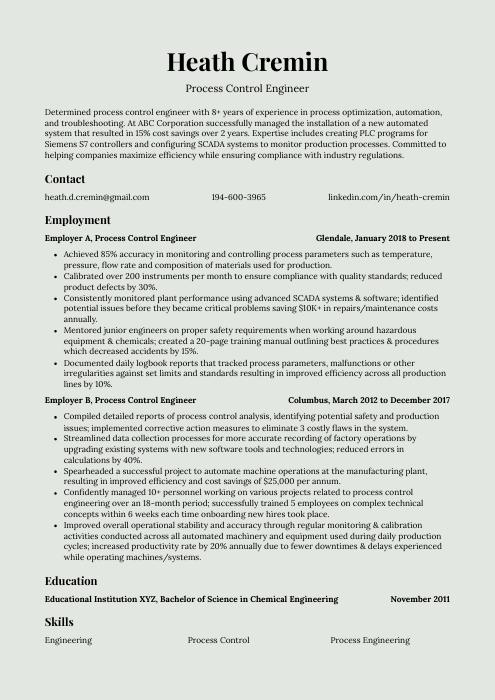

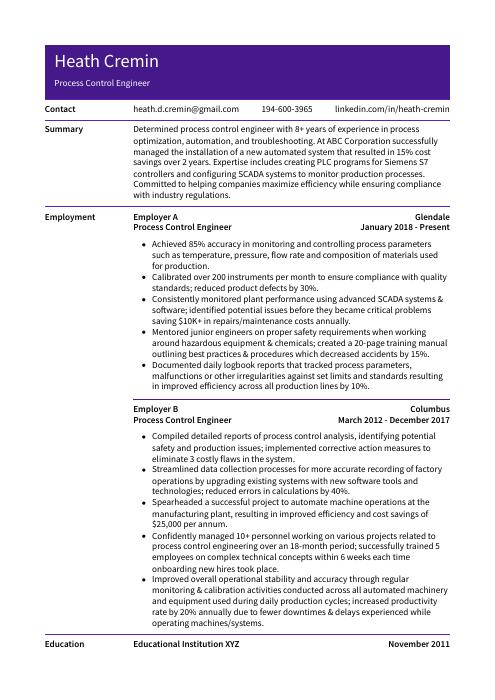

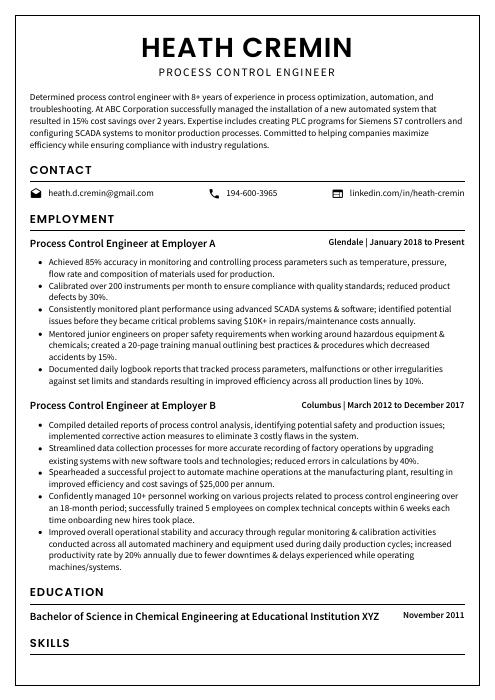

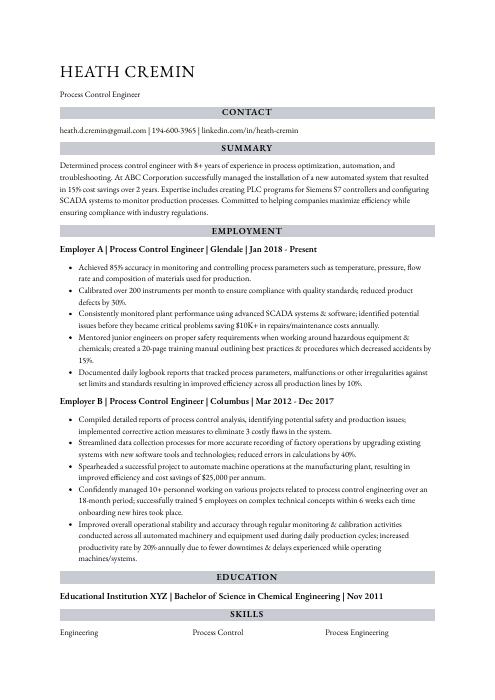

Process Control Engineer Resume Sample

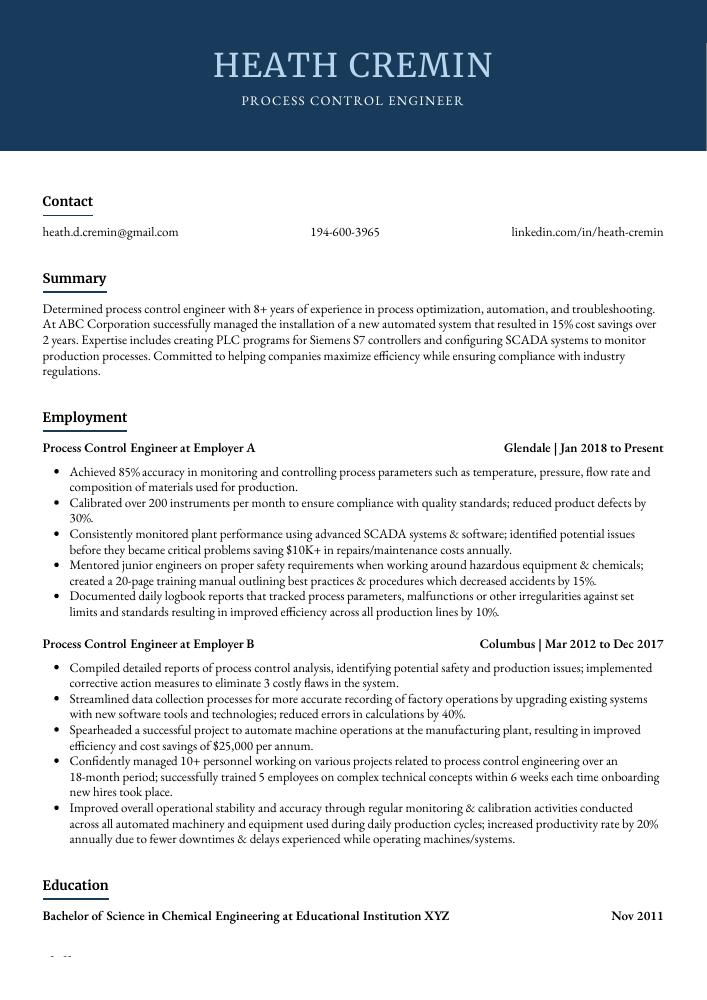

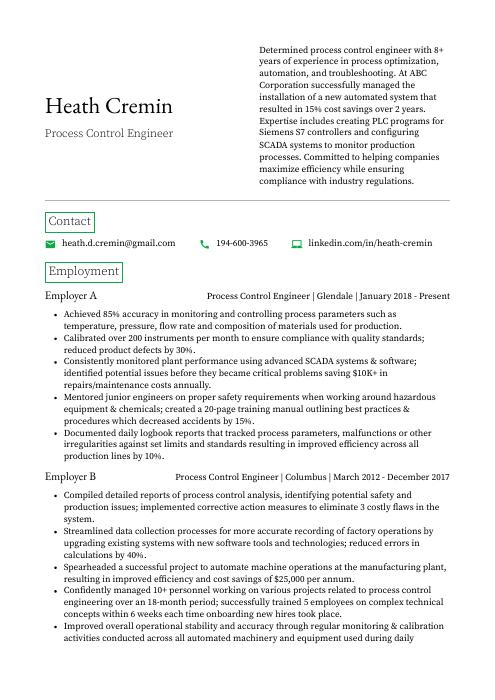

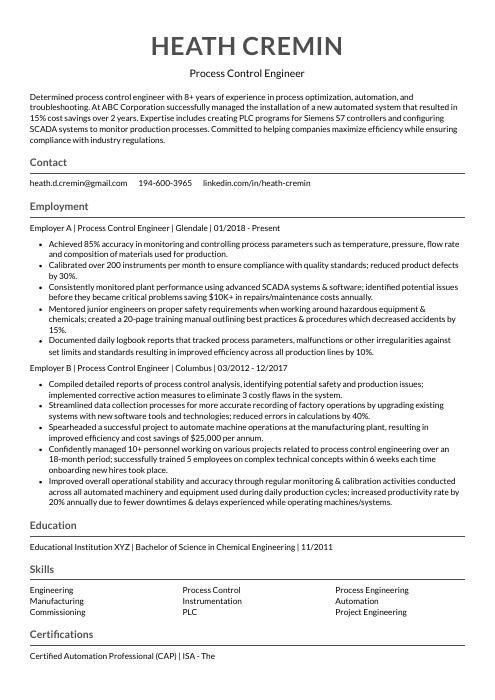

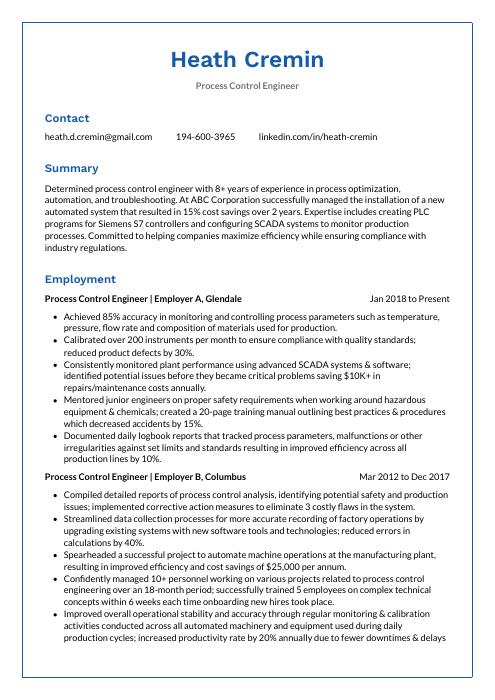

Heath Cremin

Process Control Engineer

[email protected]

194-600-3965

linkedin.com/in/heath-cremin

Summary

Determined process control engineer with 8+ years of experience in process optimization, automation, and troubleshooting. At ABC Corporation successfully managed the installation of a new automated system that resulted in 15% cost savings over 2 years. Expertise includes creating PLC programs for Siemens S7 controllers and configuring SCADA systems to monitor production processes. Committed to helping companies maximize efficiency while ensuring compliance with industry regulations.

Experience

Process Control Engineer, Employer A

Glendale, Jan 2018 – Present

- Achieved 85% accuracy in monitoring and controlling process parameters such as temperature, pressure, flow rate and composition of materials used for production.

- Calibrated over 200 instruments per month to ensure compliance with quality standards; reduced product defects by 30%.

- Consistently monitored plant performance using advanced SCADA systems & software; identified potential issues before they became critical problems saving $10K+ in repairs/maintenance costs annually.

- Mentored junior engineers on proper safety requirements when working around hazardous equipment & chemicals; created a 20-page training manual outlining best practices & procedures which decreased accidents by 15%.

- Documented daily logbook reports that tracked process parameters, malfunctions or other irregularities against set limits and standards resulting in improved efficiency across all production lines by 10%.

Process Control Engineer, Employer B

Columbus, Mar 2012 – Dec 2017

- Compiled detailed reports of process control analysis, identifying potential safety and production issues; implemented corrective action measures to eliminate 3 costly flaws in the system.

- Streamlined data collection processes for more accurate recording of factory operations by upgrading existing systems with new software tools and technologies; reduced errors in calculations by 40%.

- Spearheaded a successful project to automate machine operations at the manufacturing plant, resulting in improved efficiency and cost savings of $25,000 per annum.

- Confidently managed 10+ personnel working on various projects related to process control engineering over an 18-month period; successfully trained 5 employees on complex technical concepts within 6 weeks each time onboarding new hires took place.

- Improved overall operational stability and accuracy through regular monitoring & calibration activities conducted across all automated machinery and equipment used during daily production cycles; increased productivity rate by 20% annually due to fewer downtimes & delays experienced while operating machines/systems.

Skills

- Engineering

- Process Control

- Process Engineering

- Manufacturing

- Instrumentation

- Automation

- Commissioning

- PLC

- Project Engineering

Education

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Automation Professional (CAP)

ISA – The International Society

May 2017

1. Summary / Objective

A resume summary/objective is an opportunity to showcase your best qualities as a process control engineer. For example, you could mention the automation systems and processes you are most familiar with, the recent certification in industrial engineering that you obtained, and how your expertise has helped streamline operations at previous companies.

Below are some resume summary examples:

Detail-oriented process control engineer with 7+ years of experience in the oil and gas industry. Proven track record of success improving process performance, optimizing plant operations, and ensuring safety compliance. Responsible for designing automation systems that reduce downtime by 38%. Highly proficient in PLC programming languages such as Ladder Logic and Siemens S7-300/400 series software. Aiming to join ABC Technologies’ team to help drive operational excellence.

Accomplished process control engineer with 7+ years of experience developing process automation systems and leading teams in the efficient operation of production facilities. Proven track record of delivering cost-effective solutions that meet safety regulations, improve efficiency by 14%, and increase profitability margins by 21%. Looking to join ABC Technologies as a Process Control Engineer to help develop innovative solutions for their clients.

Amicable process control engineer with 6+ years of experience in the oil and gas industry. Experienced in process engineering, automation, instrumentation/control design and troubleshooting. Successfully managed over 10 projects that saved an estimated $3 million by optimizing processes while ensuring safety compliance. Proven track record of identifying potential problems before they occur to reduce downtime and increase production efficiency.

Proficient process control engineer with 5+ years of experience in developing and installing process control systems for industrial facilities. Skilled in troubleshooting, maintaining, and optimizing computer-based automation systems to ensure quality assurance. At XYZ Inc., optimized the process monitoring system by 20%, reducing downtime by 35%. Received “Outstanding Employee” award for contribution towards improving operational efficiency.

Skilled process control engineer with 8+ years of experience developing and optimizing process automation systems. At XYZ, designed an automated system that reduced manufacturing cycle times by 17%. Developed a unique approach to predictive maintenance which increased safety in the plant by 14%. Highly experienced in working on PLCs, SCADA systems and HMIs; adept at programming languages such as C++, Java and Python.

Reliable process control engineer with 8+ years of experience in a variety of industrial settings. Expertise in optimizing production processes, ensuring efficient utilization of resources and maintaining product quality standards. Experienced in process automation using PLCs, SCADA systems, PID controllers and other related technologies. At XYZ Corporation developed an automated system that reduced downtime by 20%.

Seasoned process control engineer with 8+ years of experience driving process improvements in manufacturing plants. Specialize in designing, deploying, and troubleshooting automated systems to optimize production processes. At XYZ Co., reduced downtime by 20% through the implementation of a new HMI system and improved efficiency by 12%. Looking for an opportunity to join ABC Tech as a Process Control Engineer.

Professional process control engineer with 7+ years of experience in instrumentation and automation. Skilled in designing, programming, and troubleshooting systems for a wide range of industrial applications. Successfully led an implementation project that improved process efficiency by 17% at Company X. Seeking to bring this expertise to ABC Tech as the next Process Control Engineer.

2. Experience / Employment

In the experience section, you should provide details on your employment history. As with the other sections of a resume, this should be written in reverse chronological order, meaning that your most recent role is listed at the top.

When writing about what you did for each job, use bullet points to make it easier for the reader to take in all of the information quickly and effectively. You want to give some detail as well as quantifiable results where possible; instead of saying “Managed process control systems,” try something like “Developed and implemented automated process control systems which improved production efficiency by 25%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Automated

- Optimized

- Programmed

- Analyzed

- Troubleshot

- Calibrated

- Configured

- Implemented

- Tested

- Debugged

- Documented

- Designed

- Upgraded

- Commissioned

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Debugged complex process control systems for 30+ machines, resulting in a 20% increase in production output and an overall improvement of machine efficiency.

- Effectively managed the integration of new process control technologies into existing operational processes; lowered expenses by $10,000 over last quarter.

- Reorganized manufacturing processes to increase throughput while reducing material wastage by 25%; improved cycle times across all product lines within 3 months.

- Structured and maintained detailed documentation on system maintenance operations & troubleshooting protocols, ensuring compliance with safety regulations at all times during operation hours.

- Prepared comprehensive monthly reports tracking performance metrics related to process controls including temperature checks, alarms management and energy consumption levels; monitored key indicators for potential problems or opportunities for optimization purposes.

- Expedited process control systems installation for 4 large-scale production facilities, reducing deployment time by 25%.

- Participated in the development of process control engineering best practices and standards; improved overall efficiency levels by 30% over a 12 month period.

- Configured automated processes to optimize system flow, yielding an 18% increase in cost savings and resource utilization on 3 projects within 6 months.

- Successfully maintained user access protocols across 8 software applications while ensuring security compliance with the company’s IT policies; reduced vulnerability risk factors by 40%.

- Coordinated testing and implementation of new process controls equipment across multiple plant locations, resulting in a 20% improvement in safety performance rankings year-on-year.

- Developed and implemented process control systems to monitor and optimize production processes, resulting in a 10% increase in efficiency.

- Facilitated the integration of automation technologies into existing manufacturing lines, reducing manual labor by 40%.

- Tested various components such as pumps, valves and motors for functionality before installation; reduced machine down-time by 20 hours/week on average.

- Upgraded process control software every 6 months to ensure accuracy of readings and maintain regulatory compliance standards; improved data analysis capabilities by 30%.

- Diligently monitored all aspects of production processes via SCADA (Supervisory Control And Data Acquisition) system with 100% accuracy rate within 3 minutes response time from any irregularities detected across multiple sites simultaneously.

- Actively monitored, maintained and calibrated process control systems to ensure system compliance with internal and external standards; reduced downtime by 10%, resulting in a cost savings of $25,000.

- Reduced energy consumption levels by 15% through the implementation of automated processes for production machinery maintenance schedules.

- Commissioned new plant equipment per engineering specifications while ensuring safety regulations were followed at all times; advised cross-functional teams on process improvement protocols for more efficient operations management.

- Advised senior management on automation projects, helping them make informed decisions that enhanced efficiency gains across multiple manufacturing departments over time.

- Introduced innovative methods to optimize machine performance within existing parameters such as cycle time reduction or quality/output improvements – achieving up to 30% improvement in workflow productivity overall.

- Represented the process control engineering team in various improvement projects, resulting in a 50% reduction of downtime costs and an increase of production speed by 25%.

- Troubleshot mechanical faults quickly and efficiently to avoid any disruptions to the manufacturing process; successfully identified defects within 8 minutes on average before they became major issues.

- Formulated new protocols for implementing advanced automation systems related to plant processes that improved overall equipment efficiency by 20%.

- Optimized existing processes using Six Sigma methodology and Lean Manufacturing principles, reducing waste materials output while increasing cost savings by $10,000 each year.

- Competently analyzed data collected from instruments utilized during laboratory experiments; developed recommendations which led to successful implementation of quality control measures across all departments without any safety or environmental risks.

- Presented technical process control engineering solutions to reduce production costs by 17%, resulting in a $200,000 annual savings.

- Monitored and adjusted parameters of automated processes to ensure optimal performance; improved product quality rating from 2/5 stars to 4/5 stars over the course of 6 months.

- Demonstrated expert knowledge in conducting root cause analysis for equipment malfunctions and proposed corrective action plans with 95% accuracy rate.

- Reliably maintained up-to-date documentation on all work performed, reporting any changes or new information accurately within 24 hours of completion every time.

- Analyzed complex data sets related to process optimization using proprietary software tools and achieved 5% greater efficiency levels than previously forecasted results.

- Assessed and monitored process control systems to ensure compliance with safety regulations, resulting in an 11% decrease of hazardous incidents.

- Utilized advanced automation technology and current engineering principles to develop innovative solutions for operational problems; improved production efficiency by 15%.

- Revised existing process controls procedures, increasing accuracy levels by 30%, while reducing system downtime from 4 hours per week to 2 hours or less.

- Accurately collected data on all plant processes and compiled reports for management review; identified areas of improvement that increased overall throughput by 10%.

- Programmed new PLCs (Programmable Logic Controllers) based on customer needs, enabling clients to reduce energy consumption costs by $6,000/yearly basis through automated monitoring functions.

- Implemented process control improvements in existing production systems, resulting in a 15% increase in product throughput.

- Designed and developed sophisticated process control strategies to optimize plant operations; increased efficiency by 25%.

- Automated manual processes with cutting-edge software solutions that reduced costs by $5,000 per month.

- Resourcefully identified potential malfunctions or discrepancies within the system before they could become costly issues; saved over 300 hours of corrective maintenance time annually.

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may be looking for experience with PLC programming and Organization B may be interested in someone who is familiar with SCADA systems.

It is important to tailor the skills section of your resume to each job you are applying for because many employers use applicant tracking systems these days, which scan resumes for certain keywords before passing them on to a human.

You should also elaborate on your most relevant skills in other areas of the resume such as the summary or experience sections.

Below is a list of common skills & terms:

- 5S

- Allen Bradley

- Aspen HYSYS

- Aspen Plus

- AutoCAD

- Automation

- C++

- Chemical Engineering

- Commissioning

- Continuous Improvement

- Control Systems Design

- DCS

- Data Analysis

- Distributed Control System

- Electrical Engineering

- Electricians

- Electronics

- Energy

- Engineering

- Factory

- Gas

- HAZOP

- Instrumentation

- Lean Manufacturing

- MATLAB

- Maintenance Management

- Manufacturing

- P&ID

- PLC

- PLC Programming

- Petrochemical

- Petroleum

- Preventive Maintenance

- Process Automation

- Process Control

- Process Engineering

- Process Improvement

- Process Optimization

- Process Safety

- Process Simulation

- Product Development

- Programmable Logic Controller

- Programming

- Project Engineering

- Refinery

- Root Cause Analysis

- SCADA

- SOLIDWORKS

- Six Sigma

- Teamwork

- Testing

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your degree below the resume objective. However, if you already have significant work experience to showcase, omitting an education section is perfectly acceptable.

If including an education section, try to list courses or subjects related to process control engineering that demonstrate a deeper understanding of the field than what was learned in school alone.

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field and can be an invaluable asset when applying for jobs. Employers are always looking for candidates who have taken the initiative to stay up-to-date with industry trends, so having certifications on your resume will show that you take professional development seriously.

Be sure to include any relevant certifications that you may possess in this section of your resume as it could give you an edge over other applicants.

Certified Automation Professional (CAP)

ISA – The International Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Heath Cremin, this would be Heath-Cremin-resume.pdf or Heath-Cremin-resume.docx.

7. Cover Letter

Providing a cover letter alongside your resume is an excellent way to introduce yourself and highlight the skills and experience that make you suitable for a role. Cover letters are made up of 2-4 paragraphs, providing more detail than what’s found on resumes alone.

Cover letters don’t always need to be included with a job application, but they can be beneficial in showing employers why you’re the right fit for their organization. They provide recruiters with greater insight into who you are as a professional and help demonstrate how your experiences align with their position’s requirements.

Below is an example cover letter:

Dear Cooper,

I am writing to apply for the process control engineer position at ABC Corporation. As a highly skilled and experienced engineer with more than 10 years of experience in process control engineering, I am confident that I can make a significant contribution to your organization.

At XYZ Corporation, where I currently work, I am responsible for designing, developing, and implementing process control systems for manufacturing plants. In this role, I have gained extensive experience in PLC programming and SCADA system development. Additionally, I have played a key role in commissioning new plants and providing technical support to existing ones.

Through my work experiences, I have developed strong problem-solving skills that would enable me to effectively address any issues that may arise during the course of a project. My analytical skills are also well-honed, which allows me to quickly identify problems and develop solutions accordingly. Furthermore, my excellent communication skills allow me to effectively collaborate with other members of a project team as well as customers/clients.

I believe that my qualifications make me an ideal candidate for the position at ABC Corporation. Once given the opportunity to join your company, I will do everything in my power to exceed your expectations and contribute to your success. Thank you very much for your time and consideration; I look forward hearing from you soon about this exciting opportunity.

Sincerely,

Heath

Process Control Engineer Resume Templates

Quokka

Quokka Indri

Indri Markhor

Markhor Axolotl

Axolotl Rhea

Rhea Ocelot

Ocelot Gharial

Gharial Dugong

Dugong Echidna

Echidna Fossa

Fossa Kinkajou

Kinkajou Jerboa

Jerboa Lorikeet

Lorikeet Bonobo

Bonobo Hoopoe

Hoopoe Saola

Saola Pika

Pika Cormorant

Cormorant Numbat

Numbat Rezjumei

Rezjumei