Preventative Maintenance Technician Resume Guide

Preventative Maintenance Technicians inspect, maintain and repair equipment in order to prevent potential problems or breakdowns. They also perform regular maintenance checks, troubleshoot any issues that arise and make repairs as necessary.

Your experience and expertise in preventative maintenance would be a great asset to any organization. However, potential employers don’t know who you are yet. To get your foot in the door, it’s important that you write an impressive resume highlighting all of your technical skills.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

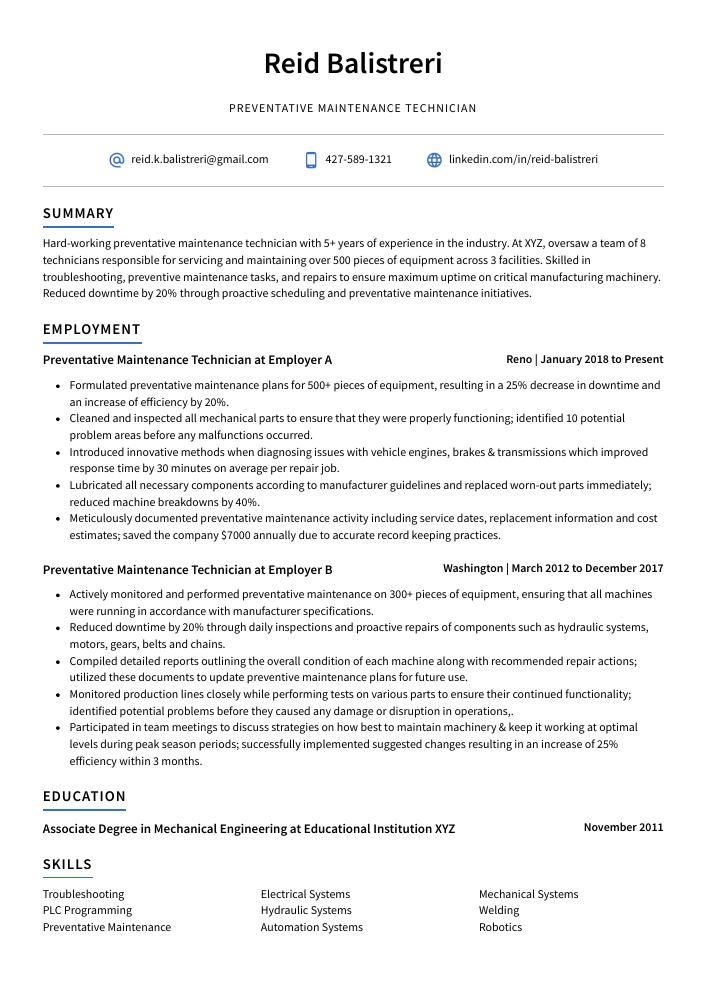

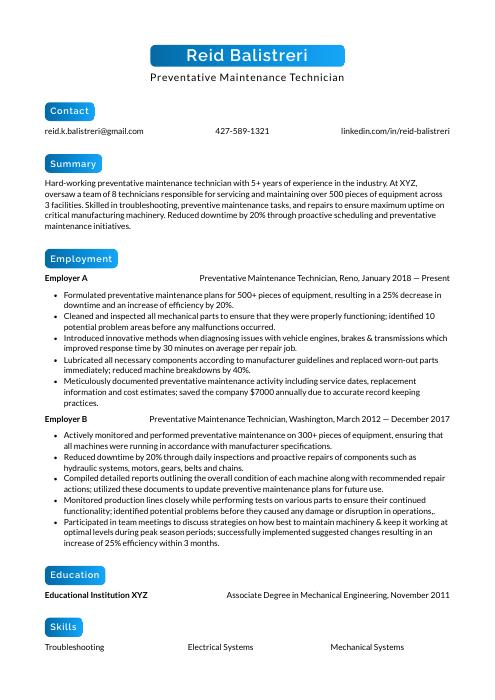

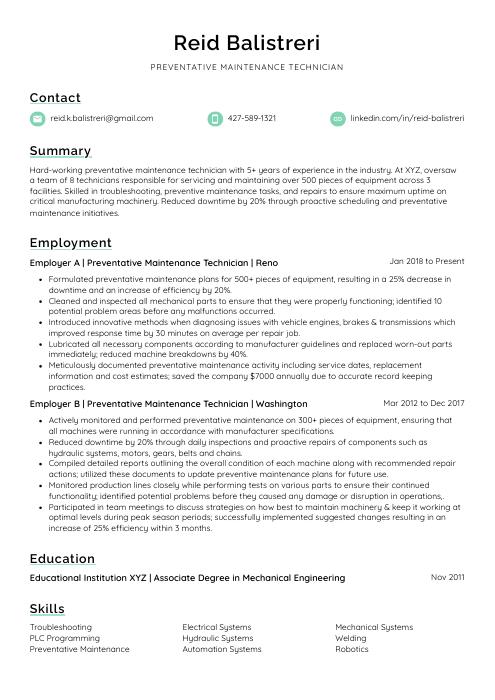

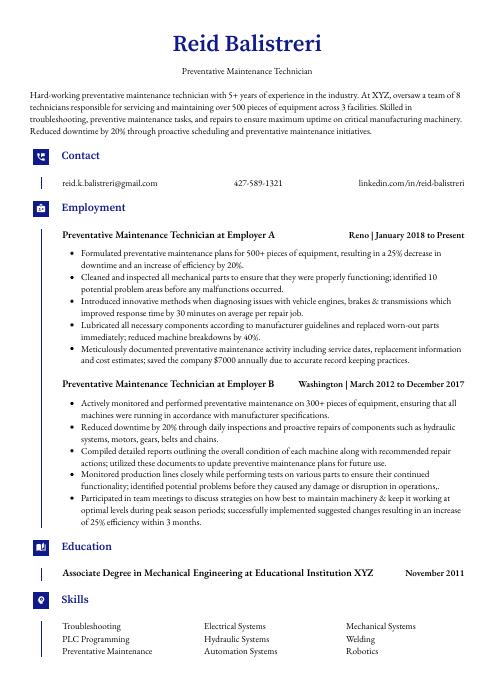

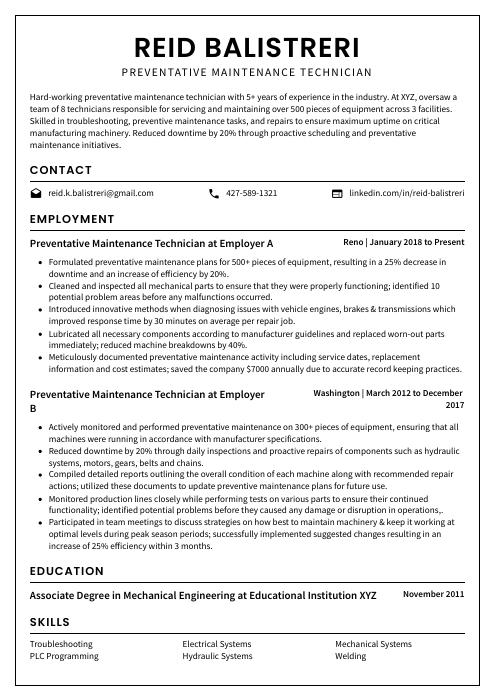

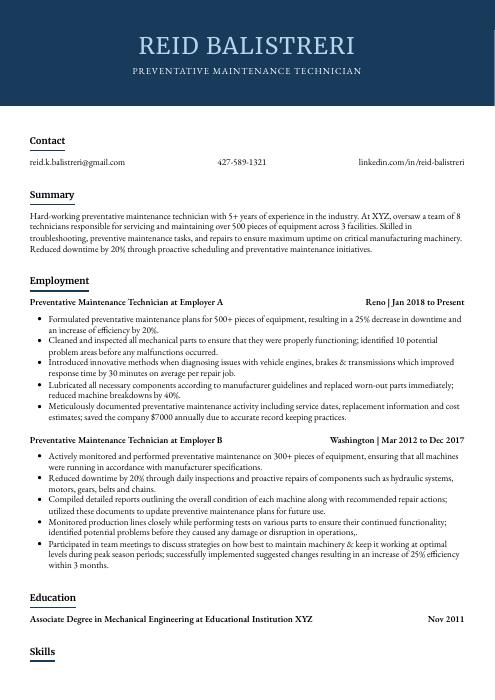

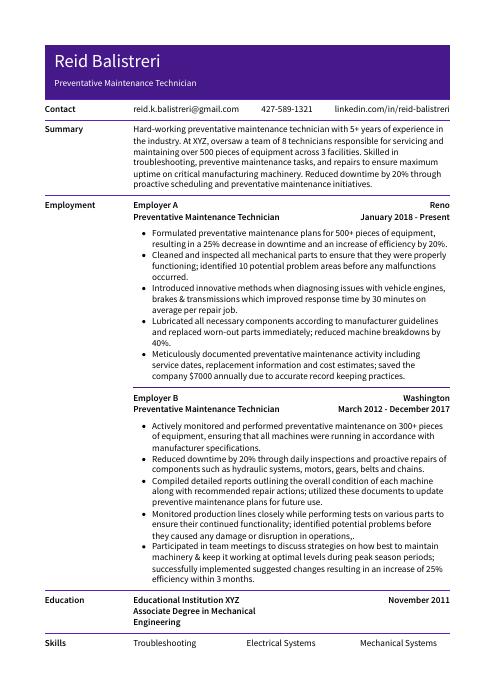

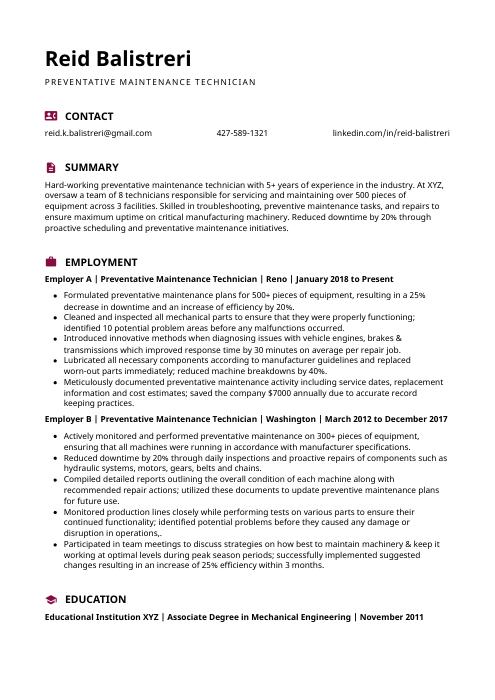

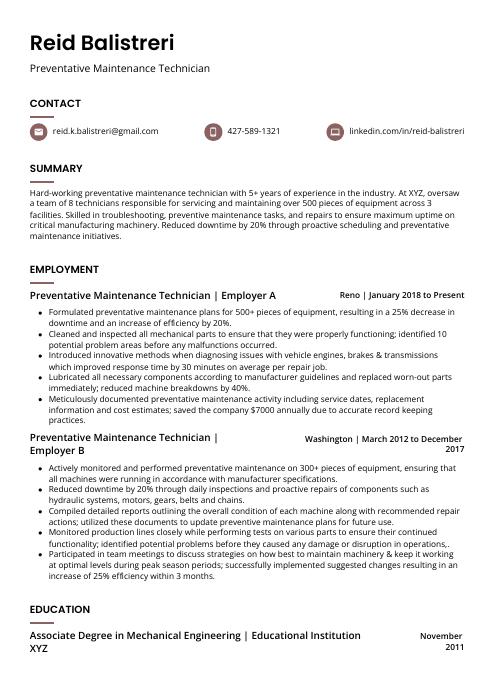

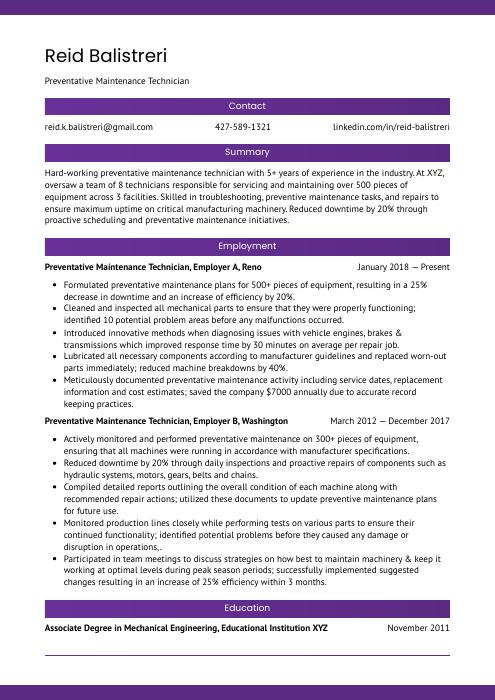

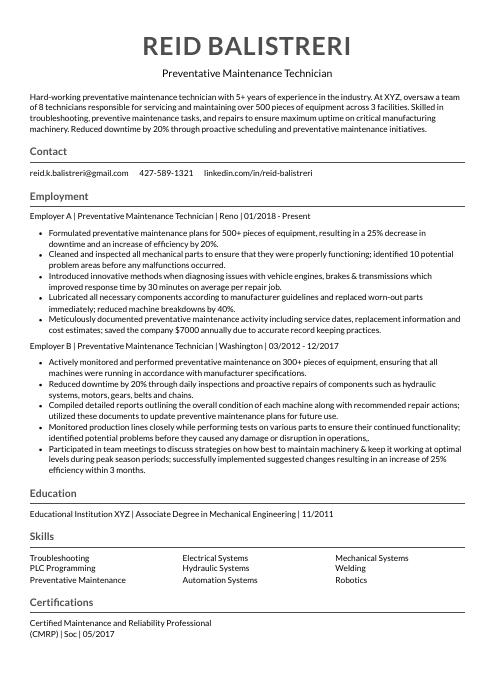

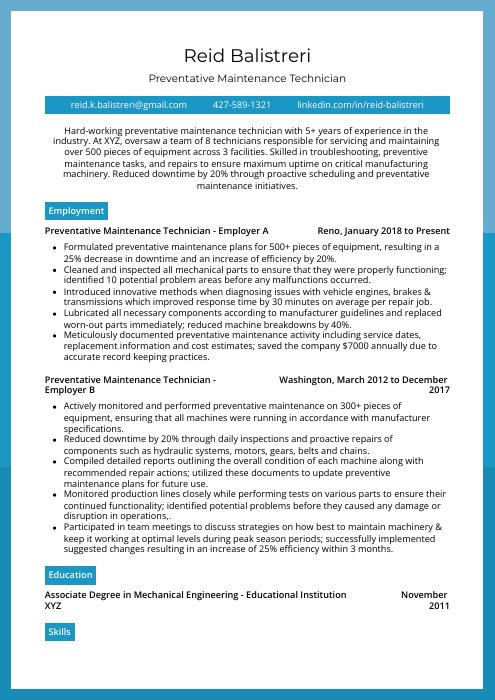

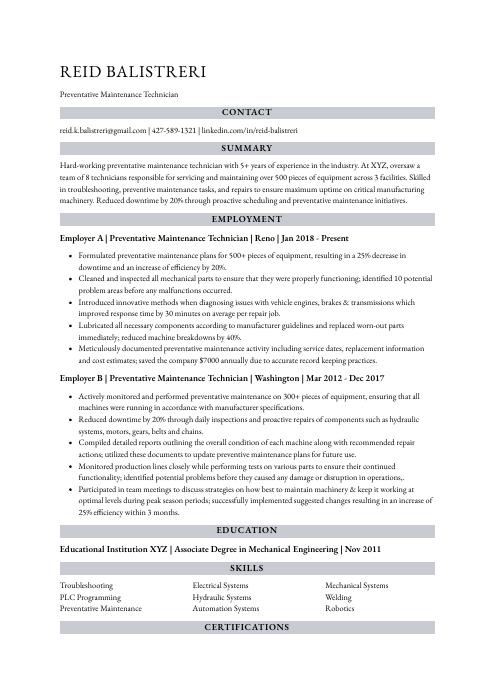

Preventative Maintenance Technician Resume Sample

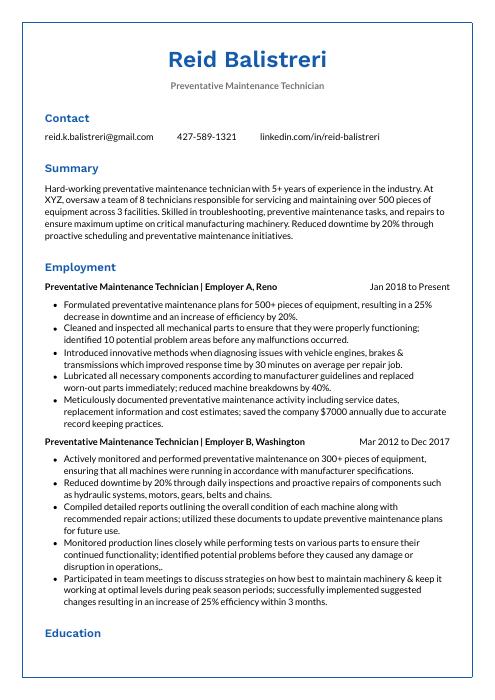

Reid Balistreri

Preventative Maintenance Technician

[email protected]

427-589-1321

linkedin.com/in/reid-balistreri

Summary

Hard-working preventative maintenance technician with 5+ years of experience in the industry. At XYZ, oversaw a team of 8 technicians responsible for servicing and maintaining over 500 pieces of equipment across 3 facilities. Skilled in troubleshooting, preventive maintenance tasks, and repairs to ensure maximum uptime on critical manufacturing machinery. Reduced downtime by 20% through proactive scheduling and preventative maintenance initiatives.

Experience

Preventative Maintenance Technician, Employer A

Reno, Jan 2018 – Present

- Formulated preventative maintenance plans for 500+ pieces of equipment, resulting in a 25% decrease in downtime and an increase of efficiency by 20%.

- Cleaned and inspected all mechanical parts to ensure that they were properly functioning; identified 10 potential problem areas before any malfunctions occurred.

- Introduced innovative methods when diagnosing issues with vehicle engines, brakes & transmissions which improved response time by 30 minutes on average per repair job.

- Lubricated all necessary components according to manufacturer guidelines and replaced worn-out parts immediately; reduced machine breakdowns by 40%.

- Meticulously documented preventative maintenance activity including service dates, replacement information and cost estimates; saved the company $7000 annually due to accurate record keeping practices.

Preventative Maintenance Technician, Employer B

Washington, Mar 2012 – Dec 2017

- Actively monitored and performed preventative maintenance on 300+ pieces of equipment, ensuring that all machines were running in accordance with manufacturer specifications.

- Reduced downtime by 20% through daily inspections and proactive repairs of components such as hydraulic systems, motors, gears, belts and chains.

- Compiled detailed reports outlining the overall condition of each machine along with recommended repair actions; utilized these documents to update preventive maintenance plans for future use.

- Monitored production lines closely while performing tests on various parts to ensure their continued functionality; identified potential problems before they caused any damage or disruption in operations,.

- Participated in team meetings to discuss strategies on how best to maintain machinery & keep it working at optimal levels during peak season periods; successfully implemented suggested changes resulting in an increase of 25% efficiency within 3 months.

Skills

- Troubleshooting

- Electrical Systems

- Mechanical Systems

- PLC Programming

- Hydraulic Systems

- Welding

- Preventative Maintenance

- Automation Systems

- Robotics

Education

Associate Degree in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Maintenance and Reliability Professional (CMRP)

Soc

May 2017

1. Summary / Objective

A resume summary for a preventative maintenance technician should focus on the skills and experience that make you an ideal candidate for the job. For example, you could mention your expertise in troubleshooting complex machinery, knowledge of safety protocols, and ability to work independently or as part of a team. You can also highlight any certifications or training programs related to preventative maintenance that you have completed.

Below are some resume summary examples:

Detail-oriented preventative maintenance technician with 5+ years of experience performing routine and complex maintenance tasks for a variety of industrial machinery. Proven track record in increasing efficiency, reducing downtime, and improving safety by conducting regular inspections and repairs on equipment. At Company X, increased performance ratings from 72% to 95%. Looking to join ABC Tech as the next preventative maintenance technician.

Reliable and experienced preventative maintenance technician with 8+ years of experience in performing scheduled repairs and preventive maintenance on electrical, mechanical, hydraulic equipment. At XYZ Corp., reduced downtime by 30% through regular inspections and proactive troubleshooting. Committed to increasing operational efficiency for all clients through meticulous attention to detail and a focus on quality workmanship.

Driven preventative maintenance technician with over 4 years of experience in the manufacturing industry. Experienced working on complex mechanical and electrical systems, including performing preventative maintenance tasks to ensure optimal performance and longevity. Dedicated to providing safe work environments by strictly adhering to OSHA regulations while maintaining a high level of customer service at all times.

Skilled preventative maintenance technician with 8+ years of experience in maintaining, troubleshooting and repairing mechanical equipment. Maintained a 95% client satisfaction rating while ensuring that all preventative maintenance work was completed on schedule and within budget at XYZ Company. Passionate about joining ABC Company to help improve operational efficiency through proactive preventive care practices.

Professional preventative maintenance technician with 8+ years of experience in a high-volume industrial setting. Successfully troubleshoot and resolve complex issues related to electrical, mechanical, hydraulic systems and more. Skilled at modifying existing equipment and developing new procedures for preventative maintenance operations. Proven track record of reducing downtime and increasing efficiency by 20%.

Dependable preventative maintenance technician with 7+ years of experience maintaining and repairing equipment in a fast-paced industrial environment. Proven track record of troubleshooting, inspecting, and performing preventative maintenance to reduce downtime while improving efficiency. Seeking to join ABC company where I can apply my knowledge and expertise to ensure optimal performance of their machines.

Enthusiastic preventative maintenance technician with 5+ years of experience in installing, maintaining, and troubleshooting a variety of industrial machinery. Proficient in using various tools to inspect for damage or wear-and-tear on equipment. Looking to join ABC Company as a PM Technician where I can utilize my knowledge and skillset to ensure the safety and reliability of all machines.

Proficient preventative maintenance technician with over four years of experience in various industrial settings. Adept at performing routine inspections, troubleshooting and resolving technical issues to reduce downtime and improve equipment performance. Seeking a position at ABC where I can utilize my skills in preventative maintenance to ensure optimal operations.

2. Experience / Employment

The employment (or experience) section is where you talk about your work history. It should be written in reverse chronological order, which means that the most recent job is listed first.

Stick to bullet points primarily when writing this section; doing so makes it easier for the reader to take in what you are saying quickly and easily. When making these bullet points, make sure they provide detail on what you did and any quantifiable results obtained from your efforts.

For example, instead of saying “Performed preventative maintenance,” you could say, “Conducted weekly inspections of all equipment at a manufacturing facility with 100+ machines; identified potential issues before they caused downtime or production delays.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Diagnosed

- Adjusted

- Repaired

- Replaced

- Installed

- Calibrated

- Troubleshot

- Monitored

- Tested

- Serviced

- Aligned

- Lubricated

- Cleaned

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Spearheaded preventative maintenance of equipment, performing visual inspections and routine checkups on over 400 pieces of machinery across the facility; reduced downtime by 20%.

- Streamlined preventative maintenance schedule for entire production line, ensuring that all machines were serviced at regular intervals; identified potential issues with 30% more accuracy than before.

- Thoroughly inspected machine components such as motors and gears to identify any signs of wear or damage in order to develop appropriate repair strategies; decreased total repair costs by $8,000 a year.

- Troubleshot mechanical problems occurring during operation and conducted root cause analysis to determine underlying causes quickly; improved response time from 4 hours to 2 hours per incident on average.

- Adjusted malfunctioning parts as needed during scheduled servicing sessions while adhering strictly to safety protocols at all times; ensured 100% adherence rate for quality assurance checks throughout the plant’s operations.

- Serviced and maintained a variety of manufacturing equipment, reducing downtime by 50% and saving the company $4,000 in repair costs.

- Presented detailed reports on preventative maintenance activities to the head technician; reduced faulty operations from 10 incidents per month to 2 incidents over 6 months.

- Reliably conducted periodic inspections of all mechanical systems, troubleshooting any issues and replacing worn out parts as necessary for optimal performance.

- Calibrated instruments used in production processes with accuracy within 0-1%, increasing productivity by 15%.

- Reorganized spare parts inventory database system according to part numbers and categories, streamlining ordering process efficiency by 35%.

- Mentored and trained a team of 3 junior technicians in preventative maintenance procedures, resulting in an overall 10% reduction on downtime.

- Aligned equipment to meet production targets and optimize machine performance; implemented preventive measures that reduced breakdowns by 30%.

- Optimized oil level management for all machines and monitored the general condition of parts with frequent inspections; identified potential problems before they became costly issues and saved $4,000 last year alone.

- Resourcefully troubleshot any mechanical or electrical faults using diagnostic tools such as multimeters, power probes & scopes within 2 hours without external assistance on average.

- Represented the company at trade shows by demonstrating new machinery operations to visitors while providing technical advice when needed; generated 20+ leads during each event attended.

- Repaired and maintained a wide variety of HVAC, plumbing and electrical systems to ensure optimal functionality in buildings; reduced downtime due to system failures by 25%.

- Achieved an average savings of $10,000 per quarter by performing preventative maintenance checks on all equipment ensuring that any potential issues were identified and resolved before they caused significant disruption or damage.

- Substantially improved the overall quality of facility operations through regular inspections and preventive measures; achieved a reduction rate of 15% for service related callouts over 12 months period.

- Utilized advanced diagnostic tools such as multimeters & thermal imaging cameras when troubleshooting complex problems with air conditioning units, pumps & motors etc.; decreased average repair time from 3 hours to 2 hours per job.

- Improved safety standards within the building premises by regularly inspecting fire alarms, extinguishers and other emergency systems; completed more than 300 maintenance checklists successfully in the last year alone.

- Replaced and maintained 20+ pieces of machinery and equipment, ensuring all safety protocols were followed at all times; decreased downtime by 30%.

- Expedited preventative maintenance tasks such as cleaning, lubricating and adjusting parts to keep machines running smoothly; reduced overall repair costs by $4,000 in the last quarter.

- Revised existing preventive maintenance procedures for greater efficiency when conducting repairs on electrical systems, pumps, motors and other mechanical components.

- Efficiently troubleshot problems with equipment using diagnostic tools such as multimeters and infrared cameras before performing necessary repairs or replacements; completed over 150 service calls in the past year alone.

- Facilitated communication between factory personnel regarding scheduling of regular machine inspections/repairs to ensure production line compliance with industry standards & regulations.

- Coordinated preventative maintenance schedules for 30+ pieces of mechanical equipment, including motors and pumps, ensuring that all necessary inspections were completed on time.

- Assessed malfunctioning parts in order to identify root causes; reduced breakdown incidences by 45% through timely replacement of defective components.

- Independently performed a range of preventive repairs such as lubrication, tightening belts & hoses and replacing filters at least once a month on each machine unit.

- Demonstrated technical ability when troubleshooting problems with precision tools; decreased downtime hours related to repair work by 40%.

- Installed new electrical wiring systems in machines and replaced worn-out bearings where needed; increased efficiency levels across the production line by 25%.

- Inspected and maintained a variety of electrical and mechanical equipment, such as HVAC systems, motors and pumps; implemented preventative maintenance procedures to ensure all machines ran efficiently at all times.

- Prepared detailed documentation for each preventive maintenance task completed; kept track of inventory levels in order to keep the stockroom stocked with necessary supplies.

- Developed comprehensive service schedules based on manufacturers’ specifications and repaired any defective part or system within safety standards guidelines – increased machine operating efficiency by 14%.

- Successfully troubleshot problems using diagnostic tools such as multimeters & oscilloscopes; reduced downtime due to malfunctioning machinery by 58% over three months period.

- Diagnosed various complex technical issues related to automation processes and coordinated repairs with external vendors when needed – saved $10K in repair costs annually compared to previous years’ expenses.

- Tested and inspected electrical systems, hydraulic systems, pumps and HVAC equipment on a daily basis to detect potential malfunctions; identified 5+ major issues in the past year that were repaired before causing further damage.

- Structured preventative maintenance schedules for 500+ pieces of equipment across 10 different business locations and conducted regular follow-ups to ensure adherence.

- Advised customers on cost-effective solutions for repairs or replacements based on their budget constraints; saved the company an average of $4,000 per quarter in unnecessary expenses through efficient resource management practices.

- Confidently diagnosed faults with complex machinery using advanced diagnostic tools such as multimeters and oscilloscopes and successfully completed all repair tasks within 1 hour without having any rework done later.

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may require the candidate to be familiar with a certain type of machinery, while Organization B may require knowledge of different types.

Therefore, you want to tailor the skills section of your resume for each job that you are applying for. This is important because many employers use applicant tracking systems these days which scan resumes for specific keywords before passing them on to a human.

In addition to listing relevant skills in this section, it can also help if you elaborate on some of them in other areas such as the summary or experience sections.

Below is a list of common skills & terms:

- Automation Systems

- Electrical Systems

- Hydraulic Systems

- Mechanical Systems

- PLC Programming

- Pneumatics Systems

- Preventative Maintenance

- Robotics

- Troubleshooting

- Welding

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, mention your education below the resume objective. However, if you have been working as a preventative maintenance technician for years and can showcase plenty of relevant responsibilities from multiple companies, omitting an education section is perfectly fine.

If including an education section is necessary, try to include courses or subjects that directly relate to the job role of a preventative maintenance technician.

Associate Degree in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have a certain level of expertise in the field. They also show that you are committed to staying up-to-date with industry trends and developments, as certifications require ongoing education and training.

Including any relevant certifications on your resume will give hiring managers an indication of your qualifications for the job. Be sure to list all applicable certifications so they can be easily identified by recruiters or HR personnel who may be reviewing your application materials.

Certified Maintenance and Reliability Professional (CMRP)

Soc

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Reid Balistreri, this would be Reid-Balistreri-resume.pdf or Reid-Balistreri-resume.docx.

7. Cover Letter

Attaching a cover letter to your job application is a great way to provide more information about yourself and make a strong impression. It should consist of 2-4 short paragraphs, with each one highlighting an important point or skill that you possess relevant to the position being offered.

Cover letters are not always necessary when applying for jobs, but they can be very helpful in conveying who you are as a professional and why you would be an ideal fit for the role. This makes them well worth writing if given the opportunity!

Below is an example cover letter:

Dear Jasper,

I am writing to apply for the preventative maintenance technician position at XYZ Corporation. As a certified HVAC technician with 5+ years of experience in performing preventative maintenance and repairs on a variety of equipment, I am confident I will be an asset to your organization.

In my previous role as a preventative maintenance technician at ABC Corporation, I was responsible for inspecting and servicing HVAC systems, electrical equipment, and plumbing fixtures on a monthly basis. I also performed quarterly inspections of fire extinguishers and emergency exit lights. When repairs were needed, I would troubleshoot the issue and make the necessary repairs or replacements.

Through my experience, I have developed strong attention to detail and problem-solving skills that enable me to quickly identify issues and find solutions. My positive attitude and willingness to go above and beyond is sure to contribute to the success of your organization.

I’ve attached a copy of my resume detailing my experience in preventive maintenance. I can be reached anytime via phone or email if you should have any questions or would like to schedule an interview at your earliest convenience. Thank you for your time!

Sincerely,

Reid

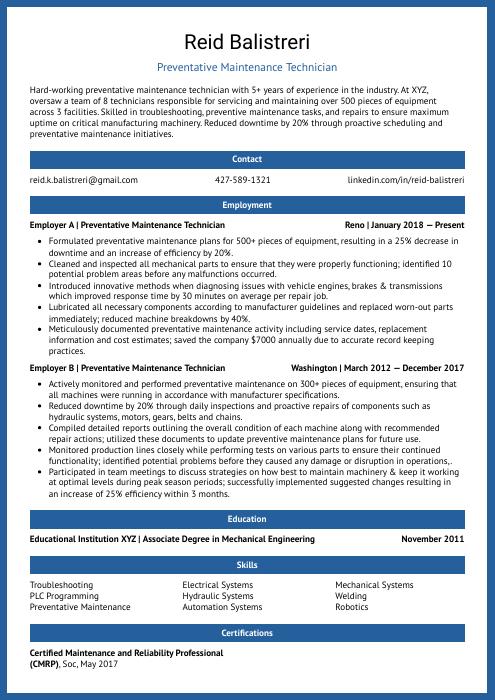

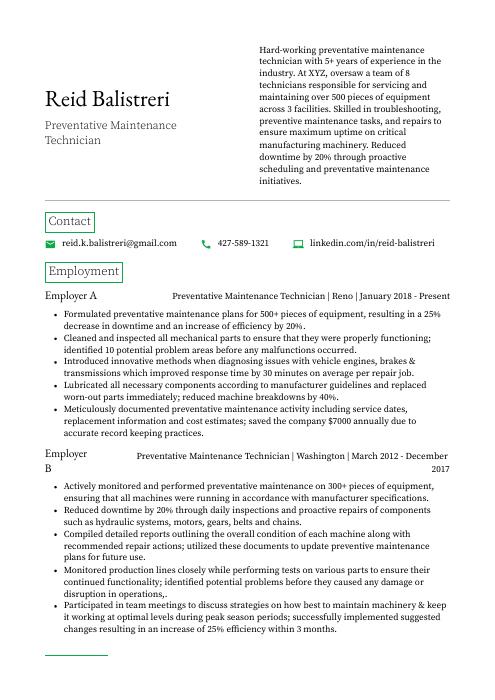

Preventative Maintenance Technician Resume Templates

Axolotl

Axolotl Ocelot

Ocelot Quokka

Quokka Kinkajou

Kinkajou Dugong

Dugong Lorikeet

Lorikeet Saola

Saola Gharial

Gharial Cormorant

Cormorant Bonobo

Bonobo Pika

Pika Hoopoe

Hoopoe Fossa

Fossa Jerboa

Jerboa Indri

Indri Echidna

Echidna Rhea

Rhea Numbat

Numbat Markhor

Markhor Rezjumei

Rezjumei