Piping Engineer Resume Guide

Piping Engineers design, build and install piping systems that transport gases or liquids. They analyze the flow of liquid or gas through a system to ensure it meets all safety requirements, as well as determining any potential issues with pressure and temperature fluctuations. Additionally, they must review drawings for accuracy before installation begins.

Your expertise in piping design and engineering is second to none. But it’s difficult for employers to know who you are without a resume that shows off your capabilities. To get noticed, write a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

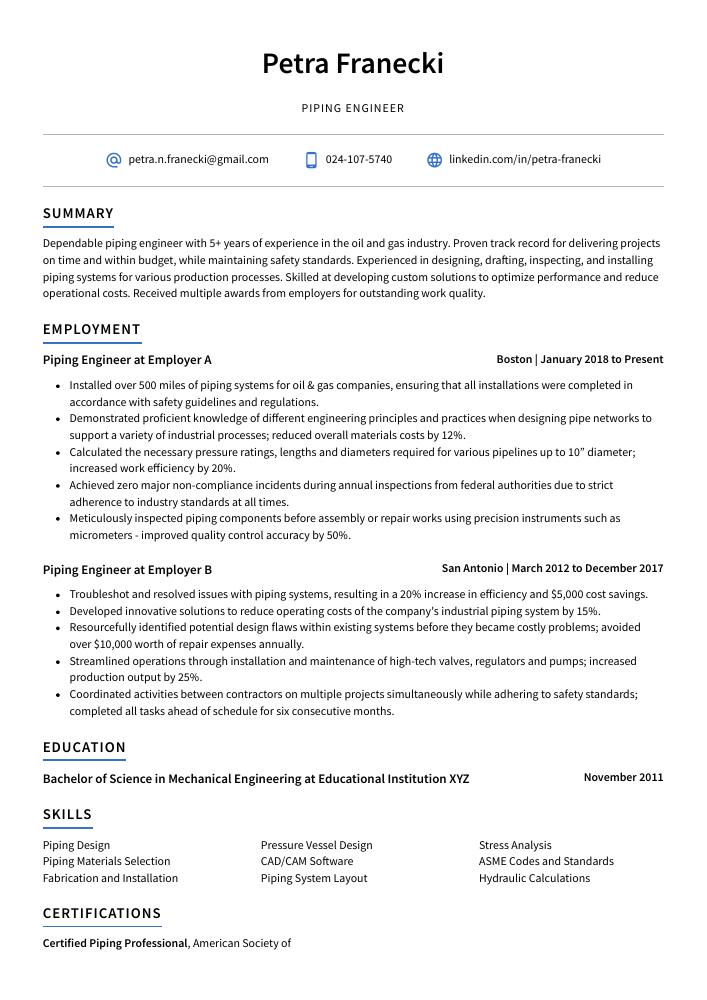

Piping Engineer Resume Sample

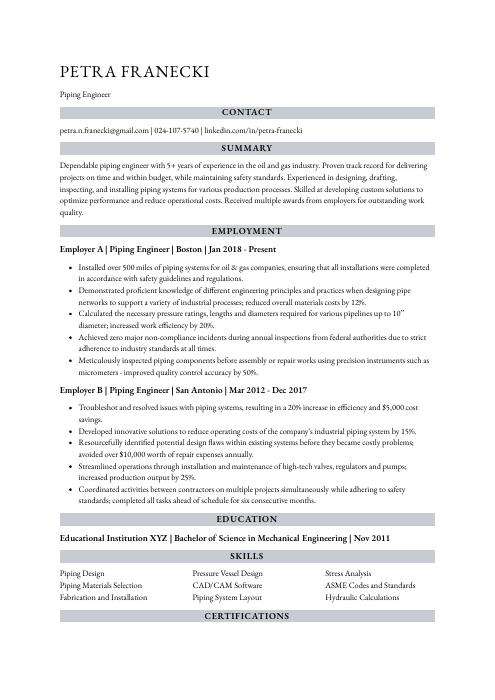

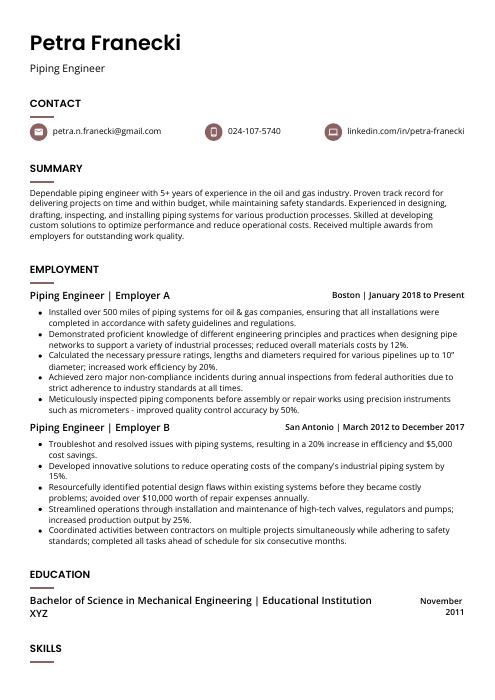

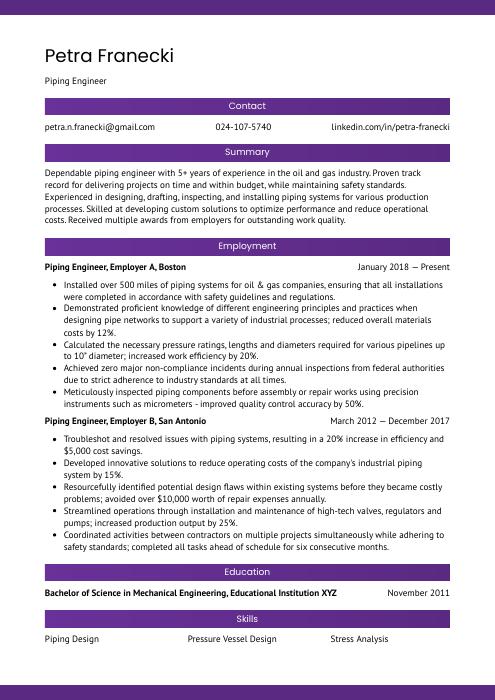

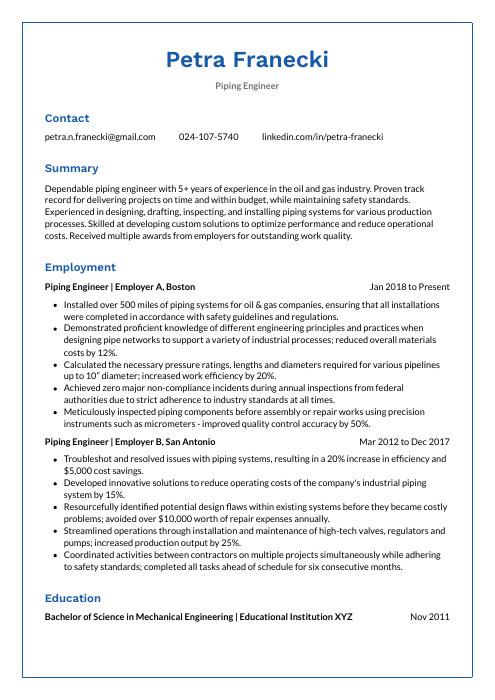

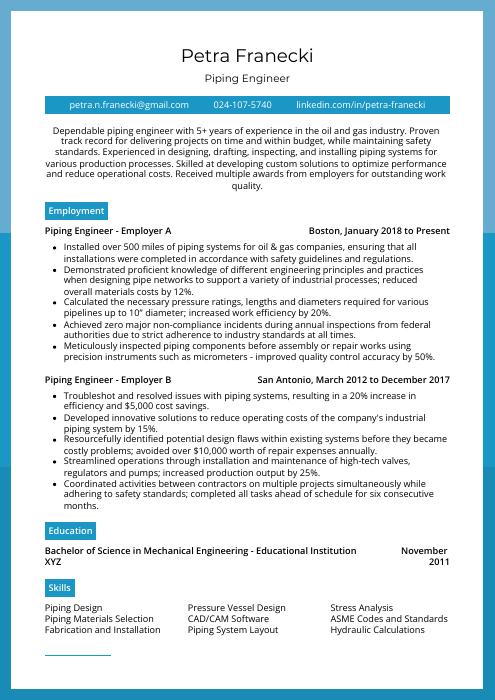

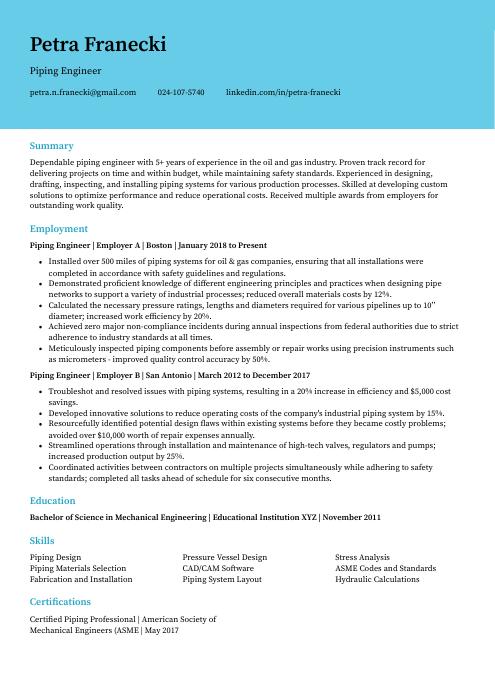

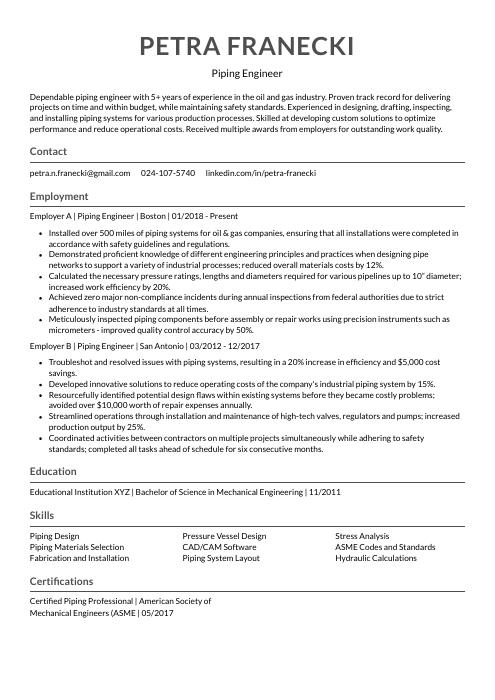

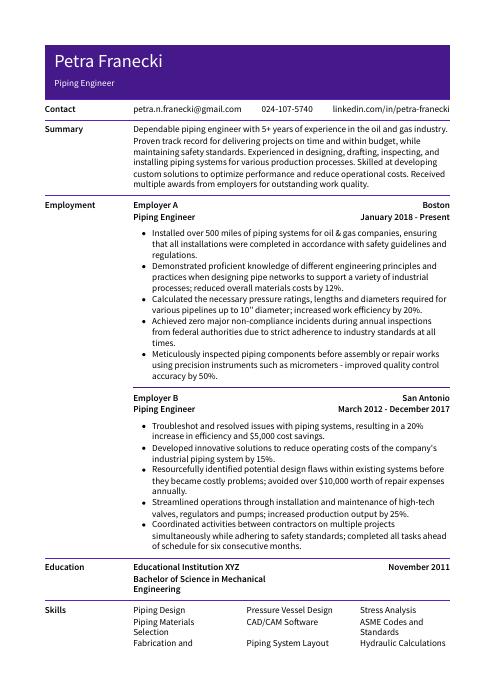

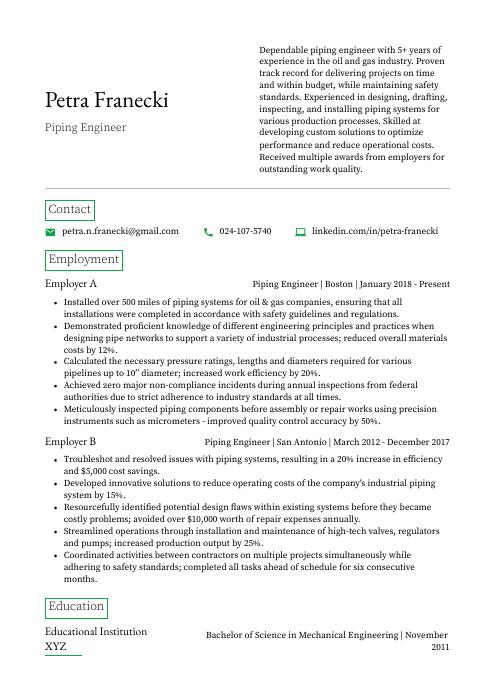

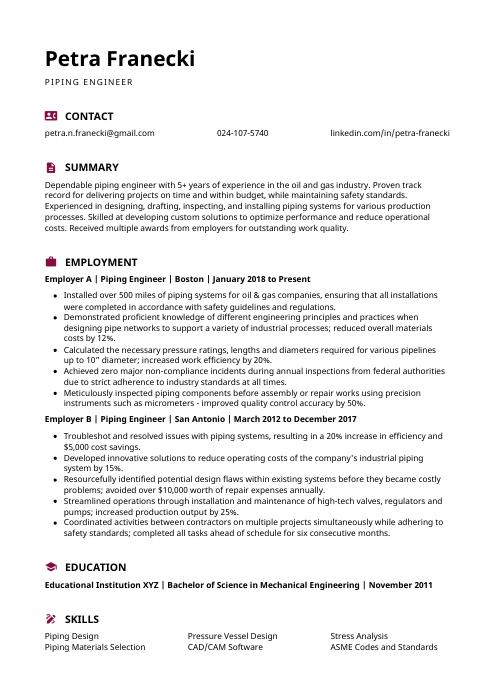

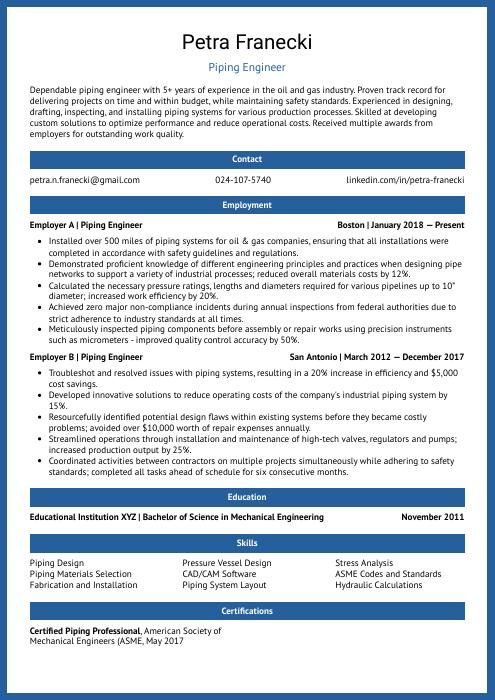

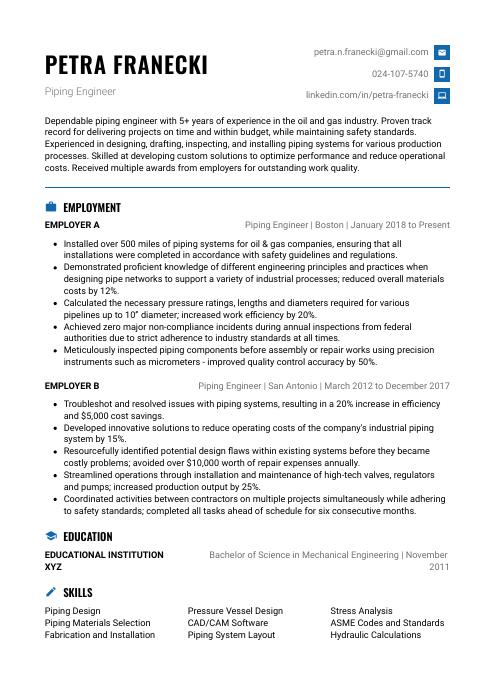

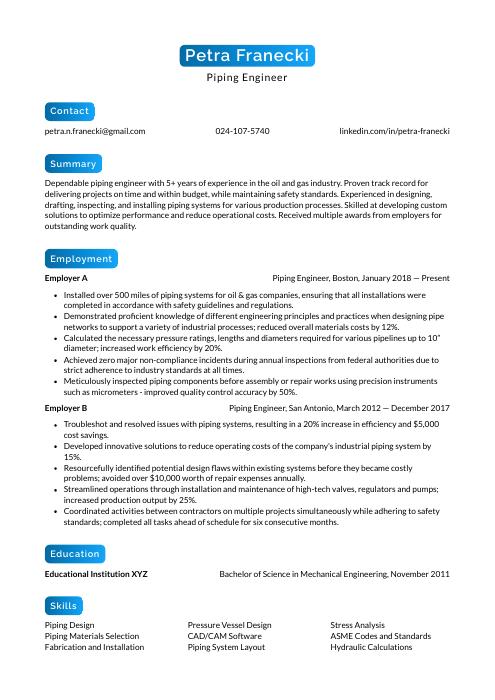

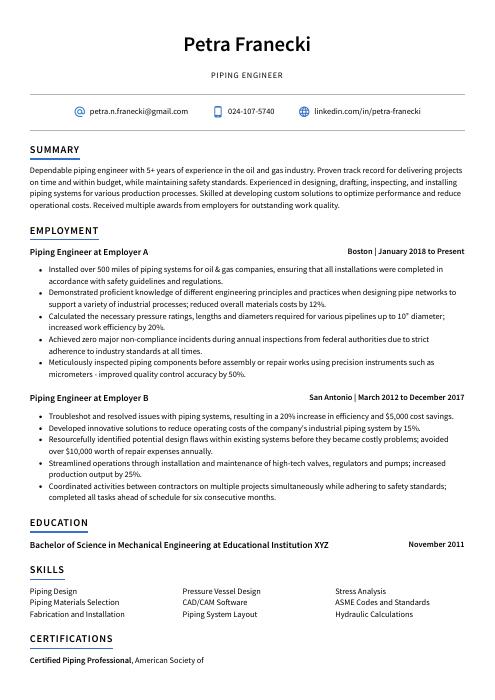

Petra Franecki

Piping Engineer

petra.n.franecki@gmail.com

024-107-5740

linkedin.com/in/petra-franecki

Summary

Dependable piping engineer with 5+ years of experience in the oil and gas industry. Proven track record for delivering projects on time and within budget, while maintaining safety standards. Experienced in designing, drafting, inspecting, and installing piping systems for various production processes. Skilled at developing custom solutions to optimize performance and reduce operational costs. Received multiple awards from employers for outstanding work quality.

Experience

Piping Engineer, Employer A

Boston, Jan 2018 – Present

- Installed over 500 miles of piping systems for oil & gas companies, ensuring that all installations were completed in accordance with safety guidelines and regulations.

- Demonstrated proficient knowledge of different engineering principles and practices when designing pipe networks to support a variety of industrial processes; reduced overall materials costs by 12%.

- Calculated the necessary pressure ratings, lengths and diameters required for various pipelines up to 10” diameter; increased work efficiency by 20%.

- Achieved zero major non-compliance incidents during annual inspections from federal authorities due to strict adherence to industry standards at all times.

- Meticulously inspected piping components before assembly or repair works using precision instruments such as micrometers – improved quality control accuracy by 50%.

Piping Engineer, Employer B

San Antonio, Mar 2012 – Dec 2017

- Troubleshot and resolved issues with piping systems, resulting in a 20% increase in efficiency and $5,000 cost savings.

- Developed innovative solutions to reduce operating costs of the company’s industrial piping system by 15%.

- Resourcefully identified potential design flaws within existing systems before they became costly problems; avoided over $10,000 worth of repair expenses annually.

- Streamlined operations through installation and maintenance of high-tech valves, regulators and pumps; increased production output by 25%.

- Coordinated activities between contractors on multiple projects simultaneously while adhering to safety standards; completed all tasks ahead of schedule for six consecutive months.

Skills

- Piping Design

- Pressure Vessel Design

- Stress Analysis

- Piping Materials Selection

- CAD/CAM Software

- ASME Codes and Standards

- Fabrication and Installation

- Piping System Layout

- Hydraulic Calculations

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Piping Professional

American Society of Mechanical Engineers (ASME

May 2017

1. Summary / Objective

A resume summary/objective is the first thing a hiring manager will read, so it needs to be concise and compelling. As a piping engineer, you can use this section to highlight your experience in designing complex systems for industrial plants, as well as any certifications or awards you have received. You could also mention how many years of experience you have in the field and what specific areas of expertise (e.g., HVAC) that make you an ideal candidate for the job.

Below are some resume summary examples:

Professional piping engineer with 10+ years of experience in the engineering and construction industry, specializing in industrial piping systems. Experienced in developing detailed designs for oil and gas pipelines, compressors stations, refineries, and chemical plants. Proven track record of successfully delivering projects on-time and within budget while adhering to safety protocols. Seeking an opportunity to join ABC Company as a senior piping engineer.

Passionate and experienced piping engineer with 10+ years of experience in the oil and gas industry. Successfully designed, procured, installed, and commissioned several high-pressure pipelines across various locations for ABC Oil & Gas Company. Proven track record of improving efficiency by 20% while ensuring all safety protocols were followed to the letter. Seeking to apply expertise at ABC Corp to deliver superior results within tight timelines.

Driven piping engineer with 8+ years of experience in the design and installation of process piping systems. Expertise in developing detailed engineering drawings, specifications, and reports for efficient plant operations. At XYZ Corporation, led a team to successfully complete two major projects on time within budget limits. Possesses strong analytical skills coupled with an eye for detail that ensures accuracy in all work carried out.

Proficient piping engineer with 10+ years of experience designing and executing piping systems for a variety of industrial projects. Looking to join ABC Engineering as a senior piping engineer and help create safe, efficient, cost-effective solutions for clients from around the world. Significant accomplishments include leading 15 successful projects on time and within budget while maintaining quality standards at all times.

Skilled piping engineer with 7+ years of experience in oil and gas production operations. Proven track record for successfully designing, testing, and managing piping systems that meet industry standards. At XYZ Inc., implemented cost-saving measures resulting in a 16% reduction in operational expenses while delivering on time projects within budget. Adept at working collaboratively across teams to deliver superior results.

Well-rounded piping engineer with 8+ years of experience in the design, development and maintenance of piping systems for industrial applications. Achieved cost savings on projects by 25% through improved material selection and optimized supply chain management. Seeking to join ABC Company as a Piping Engineer to leverage my expertise in process optimization, problem-solving, safety compliance and team leadership.

Accomplished piping engineer with 7+ years of experience in the oil and gas industry. Proficient at developing piping systems, creating drawings using AutoCAD, and inspecting work to ensure compliance with regulations. At XYZ Petroleum Corporation, designed a new production line that increased efficiency by 25%. Received awards for initiative and completed projects on time or ahead of schedule.

Talented piping engineer with 5+ years of experience designing and testing industrial piping systems. Seeking to bring expertise in process design, layout engineering, and maintenance support for ABC’s projects. At XYZ Corp., increased safety by 44% through the implementation of a new system that monitored pipe pressure levels on an ongoing basis.

2. Experience / Employment

In the experience section, you should provide details on your employment history. This section should be written in reverse chronological order, meaning the most recent role is listed first.

When writing about what you did and achieved at each job, stick to bullet points; this allows readers to quickly digest the information. You want to take some time to think about the specifics of what you did and any quantifiable results obtained from it.

For example, instead of saying “Installed piping systems,” try something like “Designed and installed a complex system of pipes for an industrial plant that reduced water consumption by 32%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Installed

- Fabricated

- Inspected

- Calculated

- Operated

- Assembled

- Commissioned

- Troubleshot

- Welded

- Monitored

- Programmed

- Analyzed

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Revised technical drawings of piping systems to increase efficiency, resulting in a 15% reduction in construction costs.

- Reduced downtime and maintenance costs by 10%, through the implementation of innovative designs for complex pipe networks.

- Represented company at industry events and conferences, demonstrating leading-edge technologies for streamlining engineering processes.

- Actively collaborated with project managers to develop detailed plans for system installations; completed 3 projects on time and within budget over the last quarter alone.

- Compiled reports outlining potential risks associated with new pipeline structures, ensuring safety regulations were strictly adhered to at all times.

- Efficiently designed and constructed over 150 pipe systems to transport water, gas, oil and other fluids within infrastructure projects; completed all tasks ahead of schedule with no cost overruns.

- Fabricated a total of 10 kilometers of pipeline for both onshore and offshore applications in accordance with the industry’s best practice guidelines.

- Spearheaded a project that resulted in increasing the efficiency rate for welding operations by 25%, saving an estimated $4 million dollars per year in labor costs.

- Introduced innovative piping solutions that improved safety standards by reducing potential leaks from pipes by 41%.

- Participated as part of team-based initiatives to upgrade existing pipelines at commercial sites, successfully completing these upgrades within 2 weeks compared to previous estimates of 4 weeks or more.

- Competently designed, installed and maintained industrial piping systems for manufacturing plants; improved efficiency of the process by 15%.

- Facilitated the construction of new pipelines across a variety of locations with different soil compositions, completing projects 3 days ahead of schedule on average.

- Reorganized existing pipes to improve flow rates and minimize downtime in production facilities; reduced maintenance costs by $5,000 annually.

- Improved safety protocols in line with local regulations when handling hazardous materials during pipeline installation or repair operations; decreased accidents frequency rate within 2 months after implementation by 30%.

- Prepared comprehensive reports detailing pipe conditions as well as recommendations for repairs or replacements over 500 miles worth of pipes every year.

- Analyzed pressure losses in piping systems and created detailed reports to assess optimal design layouts for new projects, resulting in a 20% increase in efficiency of operational expenses.

- Presented engineering solutions through comprehensive written proposals that addressed customer needs and expectations; gained the confidence of 12+ clients with successful outcomes.

- Confidently formulated designs based on established project requirements while considering cost-effectiveness, quality control measures, safety standards and other relevant criteria; improved overall production time by 25%.

- Utilized CAD software such as AutoCAD & SolidWorks to develop plans for mechanical assemblies including tubing constructions, valves and pumps; achieved an average error rate reduction of 10%.

- Expedited the fabrication process at various job sites for pipefitting installations by providing expert guidance on installation procedures; saved 30 hours over 4 weeks due to faster completion times than initially scheduled timeline.

- Optimized existing piping systems for three major industrial plants, resulting in improved efficiency and cost savings of 12%.

- Formulated design plans for a variety of complex sanitary and hydraulic pipeline systems; successfully installed over 500 different pipe sections within budget.

- Reliably inspected all existing pipelines to ensure compliance with safety regulations; identified 50+ defective parts/segments that were promptly replaced as per protocol.

- Designed detailed drawings and sketches of new piping layouts based on customer specifications; reduced overall project time by 2 weeks through efficient planning methods.

- Monitored daily construction progress to verify that work met quality standards while staying up-to-date on the latest engineering techniques & technologies used in the industry.

- Mentored and trained 4+ junior engineers in piping design, system integration and troubleshooting techniques; improved team productivity by 25% over the course of one year.

- Advised on pipe routing for 15+ projects involving different types of process systems; ensured that all designs were compliant with industry standards and regulations.

- Operated a wide range of industrial tools such as hydraulic presses, plasma cutters and welding machines to fabricate piping components according to client specifications.

- Consistently met tight deadlines while providing high-quality pipeline installations across multiple sites within budget parameters (+$10K saved annually).

- Programmed CAD software (such as Autodesk AutoCAD) to develop 2D/3D models for pipes, fixtures and other equipment used in construction workflows; reduced debugging time per project by 20 hours on average.

- Diligently assessed and planned the piping layout of 10 new industrial plants, resulting in a 25% reduction in installation costs.

- Assembled, connected, tested and inspected over 500 valves, pumps and pressure vessels to ensure all safety parameters were met within budgeted time frames.

- Welded together pipes using TIG welding techniques while adhering to quality control standards; completed 100+ jobs with zero defects or rework required for any project.

- Commissioned high-pressure systems including boilers, chillers and chemical reactors; decreased system downtime by 15%.

- Developed 3D models of complex piping layouts to better visualize customer requests; reduced design errors by 30%.

- Documented and managed the design, installation and testing of over 300+ piping systems in accordance with company safety standards; substantially reduced system downtime by 10%.

- Inspected all valves, joints and other components for leaks or damage after each maintenance cycle to ensure optimal performance at all times.

- Substantially improved the efficiency of existing pipe networks through strategic restructuring that resulted in cost savings of $4,000 per month.

- Structured a team training program to better equip 15+ technicians on proper handling & maintenance techniques for complex piping systems; trained staff achieved an average 20% increase in daily productivity rates within 3 months.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require a piping engineer with experience in oil and gas, while Organization XYZ may need one who is knowledgeable about water systems.

It is important to tailor the skills section of your resume to each job you are applying for as many employers use applicant tracking systems these days. These computer programs scan resumes for certain keywords before passing them on to a human.

In addition, it would be beneficial if you could elaborate more on your key qualifications by discussing them in other areas such as the summary or work experience sections of your resume.

Below is a list of common skills & terms:

- ASME Codes and Standards

- CAD/CAM Software

- Fabrication and Installation

- Hydraulic Calculations

- Pipe Stress Analysis Software

- Piping Design

- Piping Materials Selection

- Piping System Layout

- Pressure Vessel Design

- Stress Analysis

4. Education

Adding an education section to your resume depends on how far along you are in your career. If you just graduated and have no experience, list it below your resume objective. However, if you have a long history of piping engineering work to showcase, then leaving out the education section is perfectly acceptable.

If an education section is included, try to mention courses or subjects that relate directly to the role of a piping engineer for which you are applying.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your proficiency in a given field. Employers will be interested in seeing what certifications you have obtained and if you are actively keeping up with the latest industry trends.

Including any relevant certifications on your resume can help show potential employers that you possess the necessary skills for the job, making it easier for them to decide whether or not they should hire you.

Certified Piping Professional

American Society of Mechanical Engineers (ASME

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Petra Franecki, this would be Petra-Franecki-resume.pdf or Petra-Franecki-resume.docx.

7. Cover Letter

Including a cover letter with your job application can be the difference between being considered for a role and not. It provides you with an opportunity to explain why you’re the ideal candidate, as well as give recruiters a better understanding of who you are and what makes you unique.

Cover letters are typically made up of 2 to 4 paragraphs that provide additional detail about yourself, such as relevant skills or experiences which aren’t mentioned in your resume. Although many employers won’t require one, writing a cover letter is highly recommended if it means increasing chances of getting hired.

Below is an example cover letter:

Dear Rosalind,

I am writing in response to your ad for a Piping Engineer. With over 10 years of experience in the engineering field, I believe I am more than qualified for the position. My experience includes working on various piping projects, both small and large scale. In addition, I have experience working with different materials and have a strong understanding of how they work together.

One of my most recent projects was overseeing the installation of a new pipeline system for a water treatment plant. This project required me to be very detail oriented as well as able to work with a team of engineers. I was responsible for making sure that all the pipes were installed correctly and that they met all safety standards. In addition, I also helped train the staff on how to use the new system once it was up and running.

I am confident that I would be an asset to your company and would love the opportunity to put my skills to work on your next project. If you have any questions or would like to discuss my qualifications further, please do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration; I look forward hearing from you soon!

Sincerely,

Petra

Piping Engineer Resume Templates

Cormorant

Cormorant Gharial

Gharial Bonobo

Bonobo Numbat

Numbat Fossa

Fossa Jerboa

Jerboa Lorikeet

Lorikeet Markhor

Markhor Rhea

Rhea Dugong

Dugong Indri

Indri Pika

Pika Quokka

Quokka Hoopoe

Hoopoe Ocelot

Ocelot Echidna

Echidna Kinkajou

Kinkajou Axolotl

Axolotl Saola

Saola Rezjumei

Rezjumei