Pipeline Integrity Engineer Resume Guide

Pipeline integrity engineers are responsible for ensuring the safety and functionality of pipelines. They inspect, monitor, analyze and evaluate pipeline systems to ensure they meet industry regulations as well as company standards. Pipeline integrity engineers also develop plans for maintenance or repairs in order to maintain the highest level of reliability and performance on existing pipelines.

Your expertise in pipeline integrity engineering is unparalleled, but potential employers don’t know who you are. To make them aware of your unique skills and abilities, you must write a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

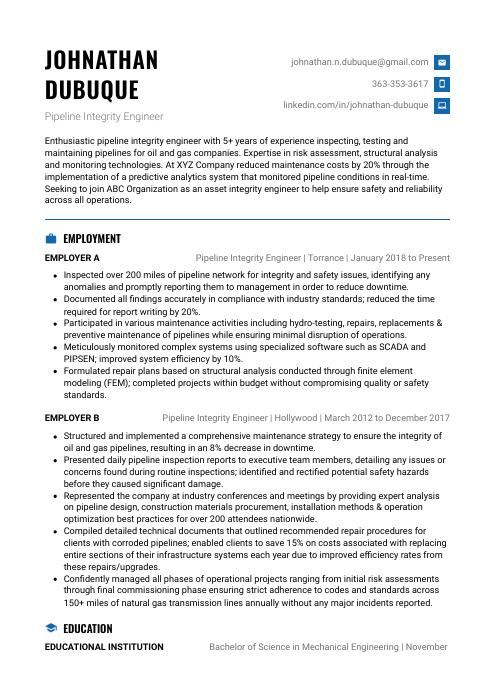

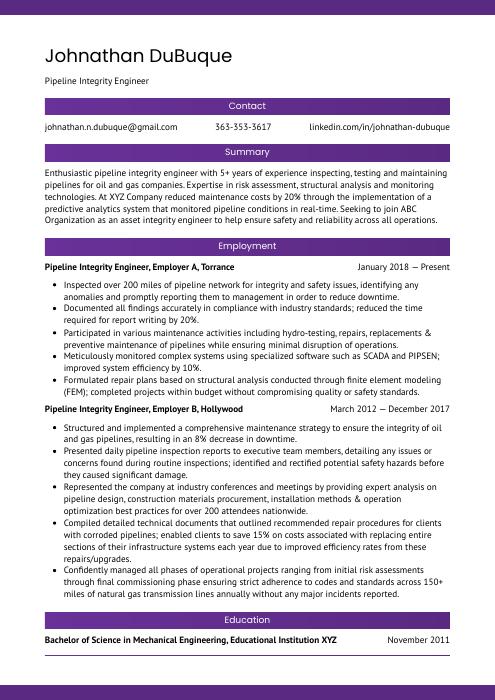

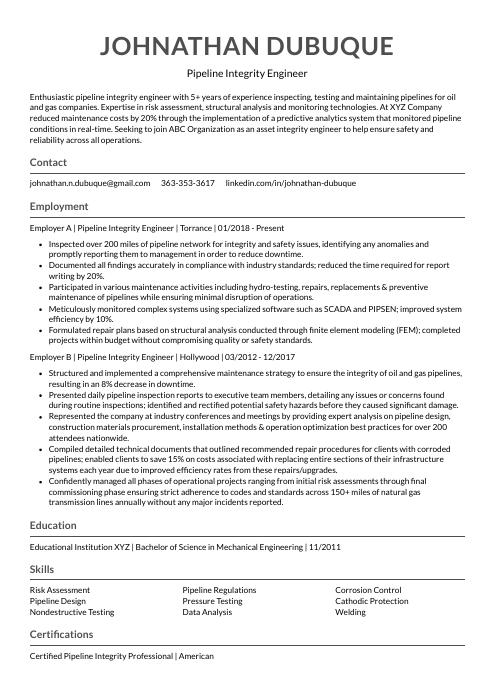

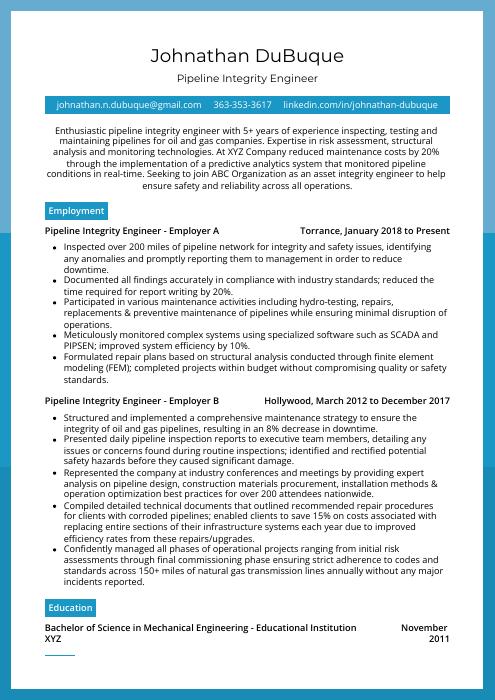

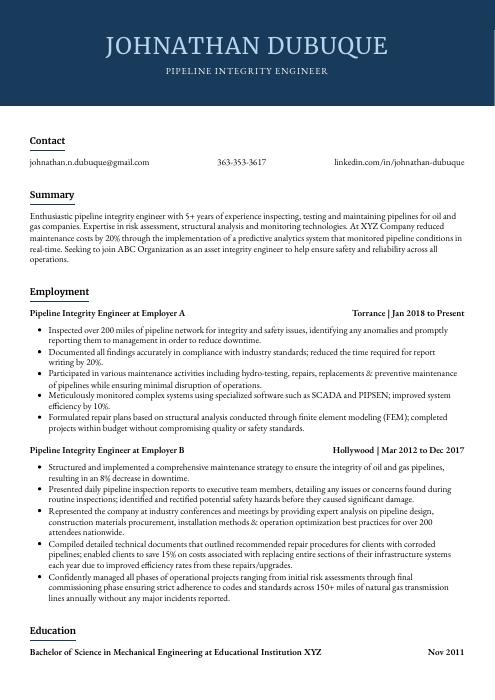

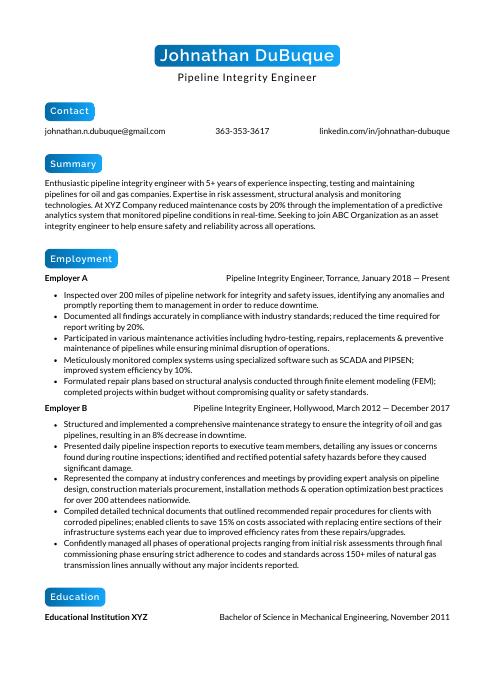

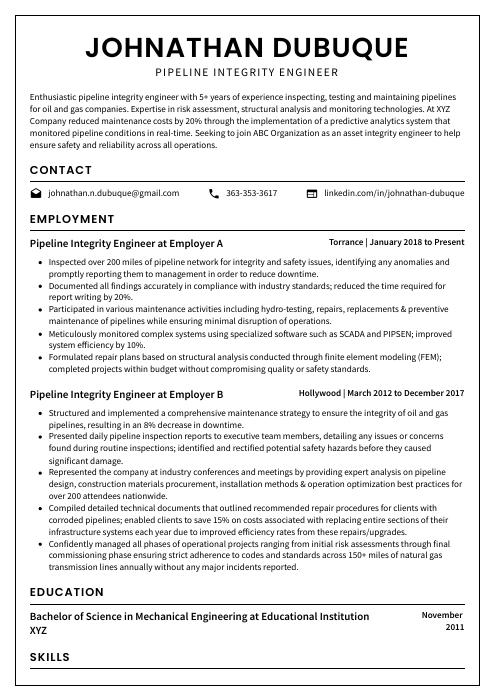

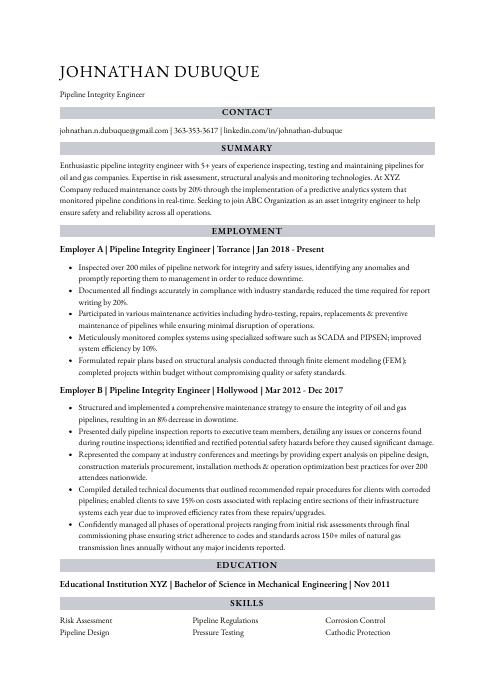

Pipeline Integrity Engineer Resume Sample

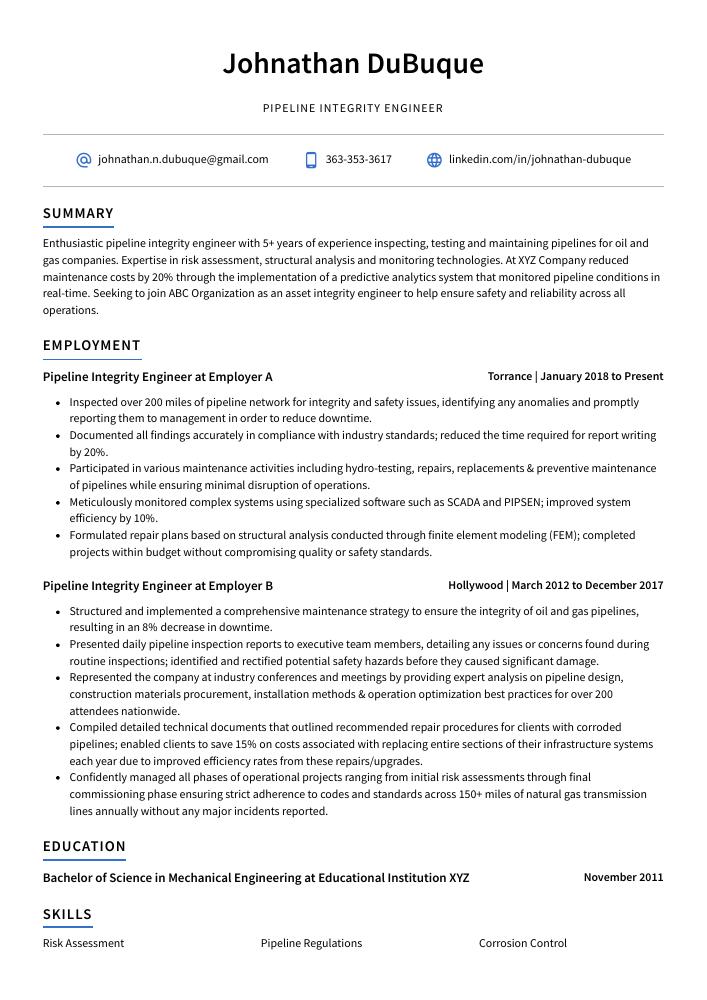

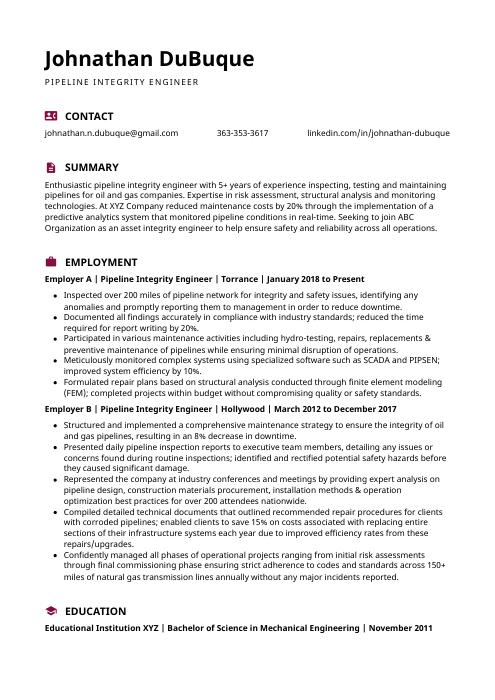

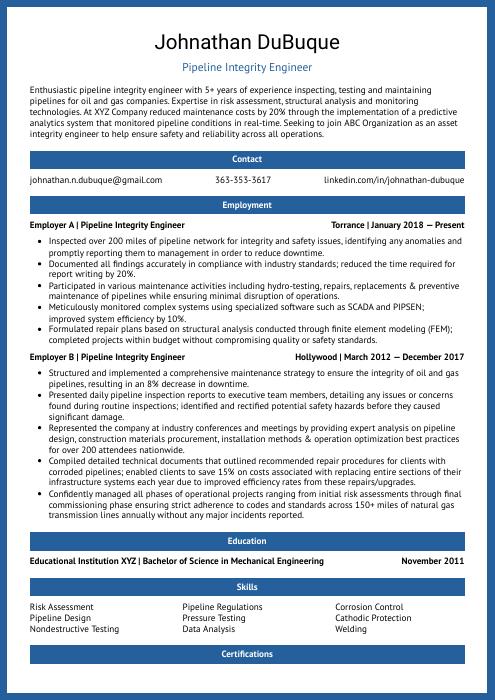

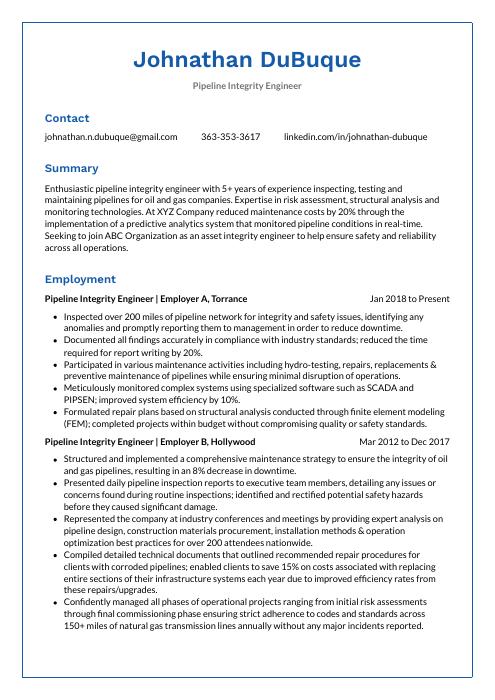

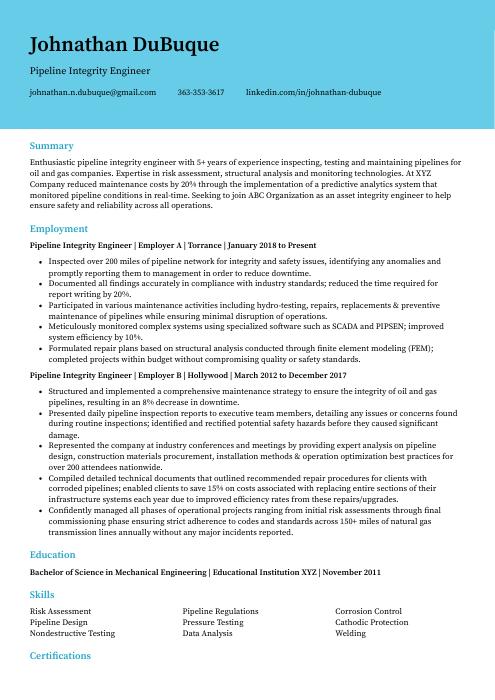

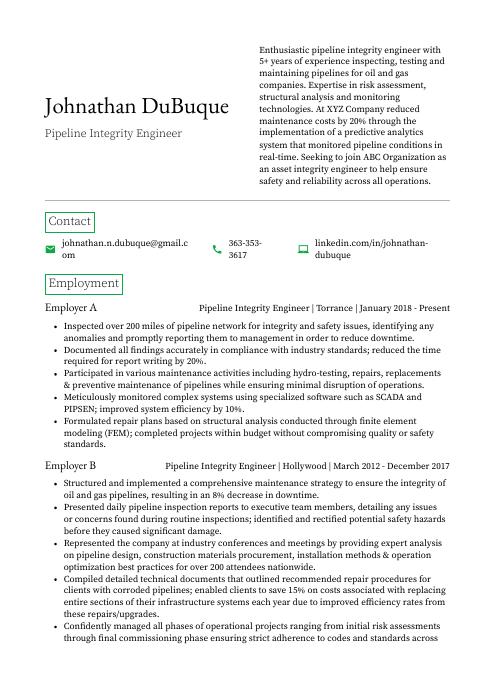

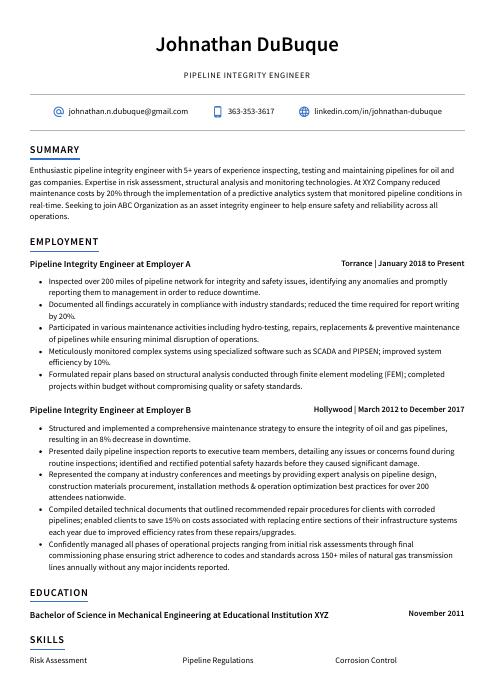

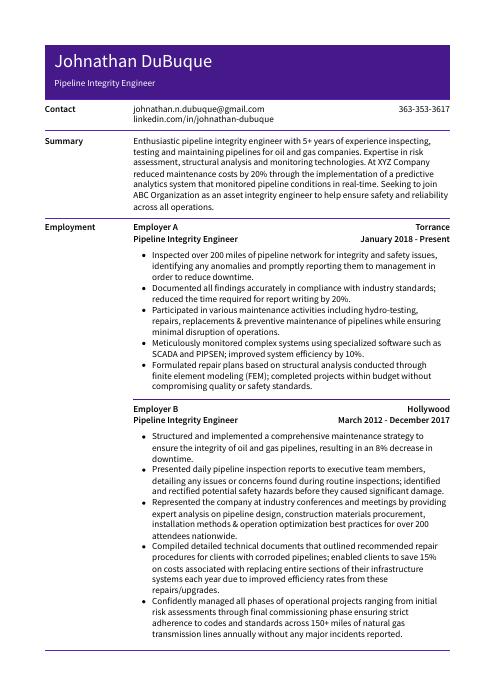

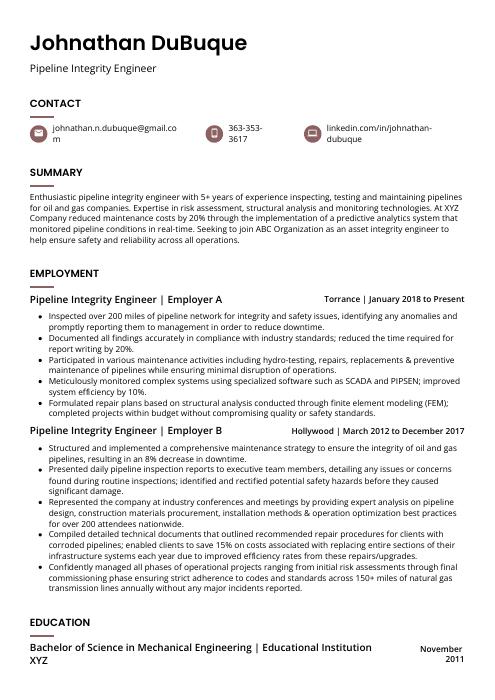

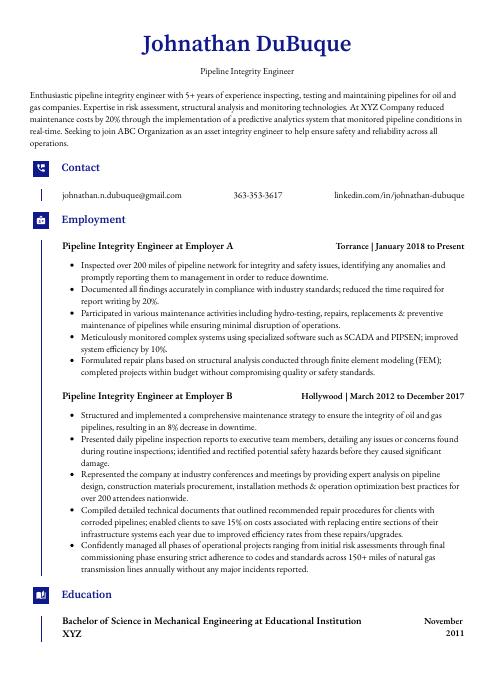

Johnathan DuBuque

Pipeline Integrity Engineer

[email protected]

363-353-3617

linkedin.com/in/johnathan-dubuque

Summary

Enthusiastic pipeline integrity engineer with 5+ years of experience inspecting, testing and maintaining pipelines for oil and gas companies. Expertise in risk assessment, structural analysis and monitoring technologies. At XYZ Company reduced maintenance costs by 20% through the implementation of a predictive analytics system that monitored pipeline conditions in real-time. Seeking to join ABC Organization as an asset integrity engineer to help ensure safety and reliability across all operations.

Experience

Pipeline Integrity Engineer, Employer A

Torrance, Jan 2018 – Present

- Inspected over 200 miles of pipeline network for integrity and safety issues, identifying any anomalies and promptly reporting them to management in order to reduce downtime.

- Documented all findings accurately in compliance with industry standards; reduced the time required for report writing by 20%.

- Participated in various maintenance activities including hydro-testing, repairs, replacements & preventive maintenance of pipelines while ensuring minimal disruption of operations.

- Meticulously monitored complex systems using specialized software such as SCADA and PIPSEN; improved system efficiency by 10%.

- Formulated repair plans based on structural analysis conducted through finite element modeling (FEM); completed projects within budget without compromising quality or safety standards.

Pipeline Integrity Engineer, Employer B

Hollywood, Mar 2012 – Dec 2017

- Structured and implemented a comprehensive maintenance strategy to ensure the integrity of oil and gas pipelines, resulting in an 8% decrease in downtime.

- Presented daily pipeline inspection reports to executive team members, detailing any issues or concerns found during routine inspections; identified and rectified potential safety hazards before they caused significant damage.

- Represented the company at industry conferences and meetings by providing expert analysis on pipeline design, construction materials procurement, installation methods & operation optimization best practices for over 200 attendees nationwide.

- Compiled detailed technical documents that outlined recommended repair procedures for clients with corroded pipelines; enabled clients to save 15% on costs associated with replacing entire sections of their infrastructure systems each year due to improved efficiency rates from these repairs/upgrades.

- Confidently managed all phases of operational projects ranging from initial risk assessments through final commissioning phase ensuring strict adherence to codes and standards across 150+ miles of natural gas transmission lines annually without any major incidents reported.

Skills

- Risk Assessment

- Pipeline Regulations

- Corrosion Control

- Pipeline Design

- Pressure Testing

- Cathodic Protection

- Nondestructive Testing

- Data Analysis

- Welding

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Pipeline Integrity Professional

American Petroleum Institute (API)

May 2017

1. Summary / Objective

Your resume summary/objective should be a concise overview of your qualifications as a pipeline integrity engineer. Include any relevant certifications or training you have completed, the number of years’ experience in this field, and any special skills that make you stand out from other candidates. You could also mention how you successfully identified potential risks to pipelines and implemented solutions to ensure their safety.

Below are some resume summary examples:

Accomplished pipeline integrity engineer with 10+ years of experience in the oil and gas industry. Proven track record of success in developing, implementing, and maintaining pipeline systems for optimal performance. Skilled at interpreting complex data to troubleshoot issues; identifying risks before they become problems; and improving safety procedures for improved compliance. Committed to ensuring the efficiency, reliability, and longevity of pipelines through proactive maintenance activities.

Diligent pipeline integrity engineer with 7+ years of experience in managing and maintaining the safe, reliable operation of large-scale pipelines. Skilled at developing risk assessments and ensuring compliance with all applicable safety regulations. At XYZ, identified a leak due to corrosion in an offshore pipeline that prevented $250K worth of damage for the company. Received recognition from upper management for exceptional work on high-pressure projects requiring quick turnaround times.

Talented pipeline integrity engineer with 8+ years of experience in oil and gas industry. Experienced in performing detailed engineering analysis to identify, assess, and mitigate risks associated with pipeline operation. Possesses a solid understanding of the relevant codes and standards related to pipeline safety. Proven track record of successfully managing high-pressure projects while maintaining compliance with all requirements set by regulatory agencies.

Dependable pipeline integrity engineer with 5+ years of experience in performing inspections and assessments for oil and gas pipelines. Certified Robotics Inspector (CRI) from the American Petroleum Institute (API). Expertise in assessing pipeline corrosion, leak detection systems, and other critical components to ensure safe operation. Seeking to join ABC Energy as a Pipeline Integrity Engineer to help maintain operational excellence while driving innovation.

Passionate pipeline integrity engineer with 5+ years of experience in pipeline management and maintenance. Skilled at developing comprehensive inspection plans, conducting analyses to identify risks and threats to pipelines, performing repairs on damaged lines, and overseeing projects from start to finish. Seeking an opportunity at ABC Tech where I can utilize my knowledge for effective management of operations across the company’s global network.

Professional pipeline integrity engineer with over 8 years of experience in oil and gas pipeline operations. Adept at performing inspections, analyzing data, and implementing corrective measures to ensure compliant operation of pipelines. Proven track record for successful completion of projects on time and within budget. Seeking an opportunity to utilize my skillset as a Pipeline Integrity Engineer for ABC Company’s offshore exploration efforts.

Determined pipeline integrity engineer with 10+ years of experience in the oil and gas industry. Skilled at developing detailed inspection plans, analyzing data from inspections, providing technical recommendations for pipeline repair/replacement activities, and ensuring compliance with all applicable regulations. At XYZ Systems Inc., developed an effective risk-based maintenance program resulting in a 25% decrease in system downtime.

Skilled pipeline integrity engineer with 7+ years of experience assessing and managing pipeline systems in various industrial environments. Skilled at inspecting, maintaining, repairing and replacing pipelines while adhering to safety regulations. Seeking a position at ABC Company to utilize expertise in providing safe operations by monitoring system pressure levels using advanced software solutions.

2. Experience / Employment

In the experience section, you should list your employment history in reverse chronological order. This means that the most recent job is listed first.

When writing this section, stick to bullet points primarily; it makes it easier for the reader to take in all of the information quickly. When describing what you did and achieved at each role, try to be as detailed as possible with quantifiable results when applicable.

For example, instead of saying “Reviewed pipeline integrity data,” you could say “Analyzed monthly pipeline integrity reports from over 100+ pipelines across five states using proprietary software tools resulting in a 10% decrease in operational costs.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Monitored

- Analyzed

- Evaluated

- Assessed

- Designed

- Installed

- Operated

- Repaired

- Tested

- Troubleshot

- Documented

- Upgraded

- Certified

Other general verbs you can use are:

- Achieved

- Advised

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Assessed pipelines for structural integrity and corrosion using advanced non-destructive testing methods, resulting in a 15% increase in the prevention of hazardous leakages.

- Repaired more than 100 pipeline defects by welding new components according to engineering specifications; reduced downtime costs by $5,000 over the past year.

- Analyzed data from pressure tests, ultrasonic inspections and flow simulations to determine potential weak spots; identified 25 faulty pipelines before any damage occurred.

- Developed maintenance protocols and inspection plans which increased safety standards while cutting operational expenses by 10%.

- Effectively trained 12 junior engineers on quality control best practices for pipeline integrity projects during their first year with the company.

- Installed over 50 pipeline systems and upgraded existing infrastructure, increasing efficiency by 30% while reducing operational costs by $50,000.

- Actively monitored the integrity of pipelines throughout their life cycle; identified potential issues early to prevent incidents or damage in over 75 cases.

- Advised clients on best practices for design optimization and enhancements based on regulatory standards; facilitated acquisition of permits from relevant authorities in 100+ projects with a success rate of 95%.

- Developed comprehensive inspection reports outlining maintenance recommendations for pipeline assets; increased compliance rating to 90%, ensuring safety regulations were met at all times.

- Evaluated condition assessment data obtained from inline inspections (ILI) using advanced analytical models including automated corrosion detection algorithms; designed solutions that reduced repair time by 50 hours per incident on average.

- Facilitated the installation, inspection and maintenance of over 500 miles of pipeline integrity systems with a special focus on safety protocols; decreased emergency situations by 24%.

- Efficiently managed the integrity engineering operations in-house while reducing overhead costs by 20% within 6 months.

- Reorganized operational procedures to ensure compliance with industry codes & regulations thereby optimizing workflow efficiency across teams; reduced project delivery timeframes by 15%.

- Monitored pipelines for any signs of corrosion or damage using advanced diagnostic tools such as hydrostatic testing and ultrasonic thickness gauging; averted potential hazards that could have affected 2,000+ households in the region.

- Expedited completion times for projects involving pipeline repairs through effective resource planning and scheduling techniques; completed 10+ repair jobs ahead of schedule which saved $10K in additional labor costs per month.

- Reduced pipeline integrity incidents by 40% through in-depth risk assessments and inspections of pipelines to identify potential hazards.

- Operated a variety of sophisticated inspection tools (such as MFL, UT, IRIS) for detecting corrosion levels and ensuring the safety of pipeline systems; monitored over 100 miles of pipeline each month.

- Resourcefully identified cost savings opportunities when analyzing maintenance data from NDT scans to recommend repair plans that increased efficiency while maintaining quality standards.

- Mentored junior engineers on proper techniques for using various computer programs such as AutoCAD/AECOsim Building Designer, ArcGIS & Pipeline Toolbox software applications related to pipeline mapping projects.

- Prepared comprehensive reports outlining findings from all inspections conducted which included details regarding existing conditions and recommended repairs or corrective actions necessary to ensure safe operation at all times.

- Coordinated a team of 8 engineers and technicians to inspect, monitor and maintain the integrity of over 60 miles of oil & gas pipelines; improved safety levels by 20%.

- Tested pipeline systems for structural fatigue, corrosion damage and other potential risks using specialized equipment such as X-ray machines, ultrasonic testing devices & hydrostatic pressure tests; reduced repair costs by 15%.

- Introduced a preventive maintenance system that monitored pipe sections on a daily basis via remote sensors in order to identify any potential threats before they occurred.

- Spearheaded an innovative project which used automated drones equipped with infrared cameras to conduct routine inspections across long distances at minimal cost compared to traditional methods; shortened inspection time per mile from 5 hours to 2 hours on average.

- Successfully analysed data collected from all sources (sensors/drones) then generated detailed reports which were presented directly to senior management for review purposes; decreased evaluation time by 45%.

- Demonstrated extensive knowledge in pipeline integrity and safety regulations, enabling successful reviews of over 200+ pipelines with no major compliance issues.

- Revised existing pipeline maintenance protocols to ensure timely completion of all inspections; cut inspection times by 25%.

- Reliably identified potential threats, weaknesses or risks related to any pipelines at a given time and swiftly addressed them using appropriate solutions.

- Optimized the use of resources for detecting pipe corrosion through non-destructive testing (NDT) methods such as ultrasonic scanning & x-ray radiography; reduced costs associated with NDT by 15%.

- Utilized computer aided design (CAD) software to create 3D models for analyzing pressure buildup in pipes and accurately forecast future trends; improved decision making accuracy by 20%.

- Certified in welding and non-destructive testing techniques, successfully inspected more than 200+ pipelines for structural integrity with zero errors.

- Improved overall pipeline performance by troubleshooting and repairing 20+ defects each month; reduced downtime due to malfunctions by 30%.

- Troubleshot equipment failures in a timely manner, ensuring that production flow remained consistent at all times during emergency situations.

- Designed numerous preventative maintenance strategies to ensure the safe operation of gas compressor stations while minimizing environmental impacts; decreased hazardous emissions levels by 60%.

- Substantially increased inspection efficiency through automation initiatives, reducing turnaround time from 24 hours to 2 hours on average per job request.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with an in-depth knowledge of corrosion control and the other may be looking for someone with a strong understanding of pipeline inspection technologies.

It is essential to tailor your skills section according to each job you are applying for, as many employers use applicant tracking systems that scan resumes for certain keywords before passing them on to a human.

In addition, it would also be beneficial if you elaborate on some of your most important skills/qualifications in other areas such as the summary or experience sections.

Below is a list of common skills & terms:

- Cathodic Protection

- Corrosion Control

- Data Analysis

- Nondestructive Testing

- Pipeline Design

- Pipeline Mapping

- Pipeline Regulations

- Pressure Testing

- Risk Assessment

- Welding

4. Education

Mentioning your education is an important part of any resume, especially when you are applying for a pipeline integrity engineer role. If you just graduated and have no prior work experience, include your education below your resume objective. On the other hand, if you have been working in this field for years with plenty of accomplishments to showcase, omitting the education section is perfectly fine.

If including an education section on your resume, make sure to mention courses and subjects related to pipeline integrity engineering that will help demonstrate why you’re qualified for the job.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field. They show potential employers that you have taken the time and effort to become certified, which is an indication of dedication and commitment.

If you are applying for a job that requires specific certifications, make sure to include them on your resume as it will give you an edge over other applicants who don’t possess these qualifications.

Certified Pipeline Integrity Professional

American Petroleum Institute (API)

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Johnathan DuBuque, this would be Johnathan-DuBuque-resume.pdf or Johnathan-DuBuque-resume.docx.

7. Cover Letter

Writing a cover letter is a great way to give yourself an edge when applying for a job. It’s typically composed of 2 – 4 paragraphs and serves as an opportunity to explain why you’re the perfect candidate for the role. Unlike resumes, cover letters allow you to include more personality and demonstrate your enthusiasm for the position.

Whilst not every employer will require one, having a well-crafted cover letter can make all the difference in getting hired. It gives recruiters valuable insight into who you are as an individual and how passionate you are about joining their team!

Below is an example cover letter:

Dear Madeline,

I am writing to apply for the Pipeline Integrity Engineer position at XYZ Corporation. With more than 10 years of experience in the oil and gas industry, I have a deep understanding of pipeline integrity management programs and how to ensure their success. In my previous role as a senior engineer at ABC Company, I was responsible for managing a team of engineers and technicians who conducted regular inspections of pipelines and related infrastructure.

In addition to my experience in managing pipeline integrity programs, I also have extensive experience in conducting risk assessments, developing inspection plans, and overseeing repairs. My ability to identify potential problems and take corrective action has resulted in significant cost savings for my previous employers. I am confident that I can provide similar results for XYZ Corporation.

I am eager to put my skills and experience to work for your company and contribute to the success of your pipeline integrity program. I look forward to speaking with you soon about this opportunity. Thank you for your time and consideration.

Sincerely,

Johnathan

Pipeline Integrity Engineer Resume Templates

Hoopoe

Hoopoe Ocelot

Ocelot Lorikeet

Lorikeet Echidna

Echidna Saola

Saola Jerboa

Jerboa Indri

Indri Rhea

Rhea Bonobo

Bonobo Kinkajou

Kinkajou Cormorant

Cormorant Numbat

Numbat Markhor

Markhor Dugong

Dugong Quokka

Quokka Axolotl

Axolotl Pika

Pika Fossa

Fossa Gharial

Gharial Rezjumei

Rezjumei