Packaging Technician Resume Guide

Packaging Technicians are responsible for ensuring that products meet safety and quality standards before they can be shipped. They inspect, assemble, package and label items in accordance with company guidelines, as well as prepare product shipments to customers. Additionally, packaging technicians may also help troubleshoot issues on the production line related to packing materials or processes.

You have a knack for creating packaging solutions, but employers don’t know who you are. To make yourself known and stand out from other candidates, you must write an impactful resume that highlights your achievements in the field.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Packaging Technician Resume Sample

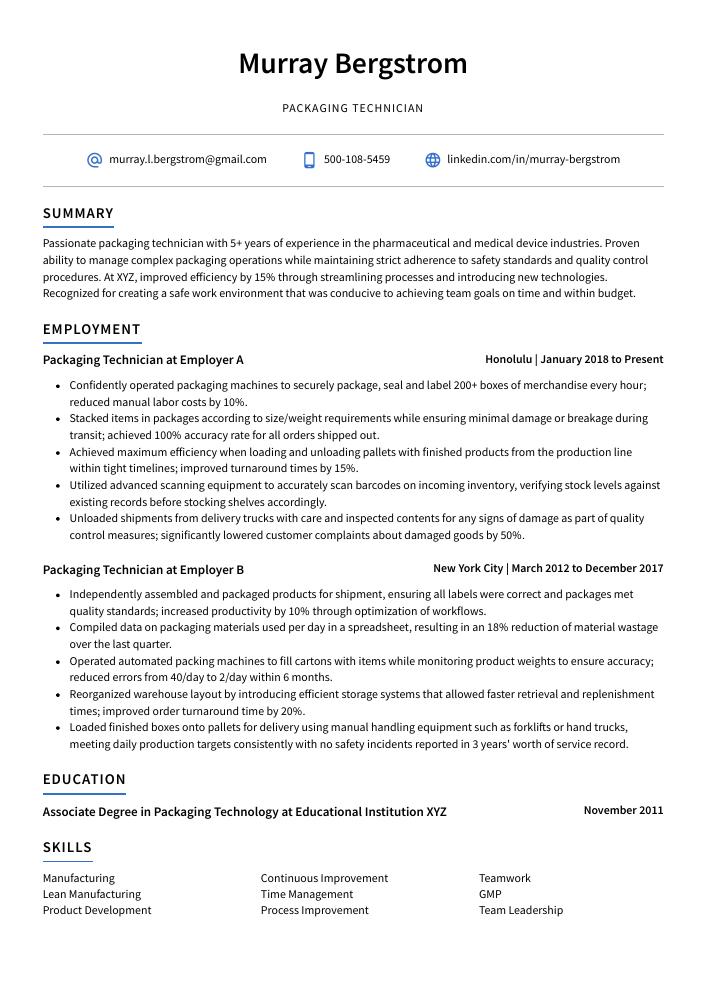

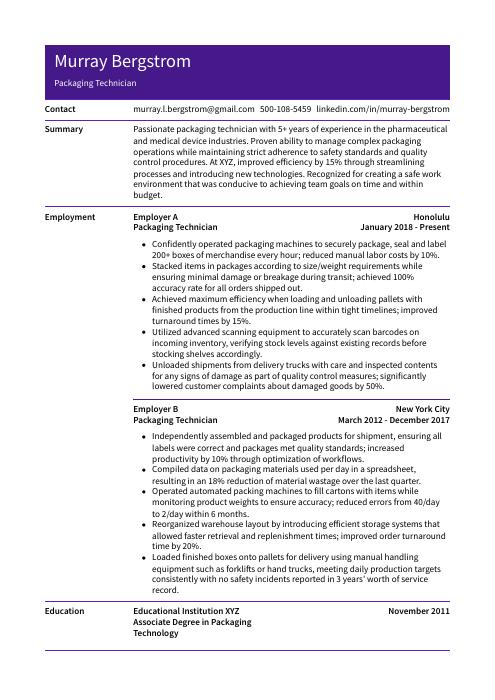

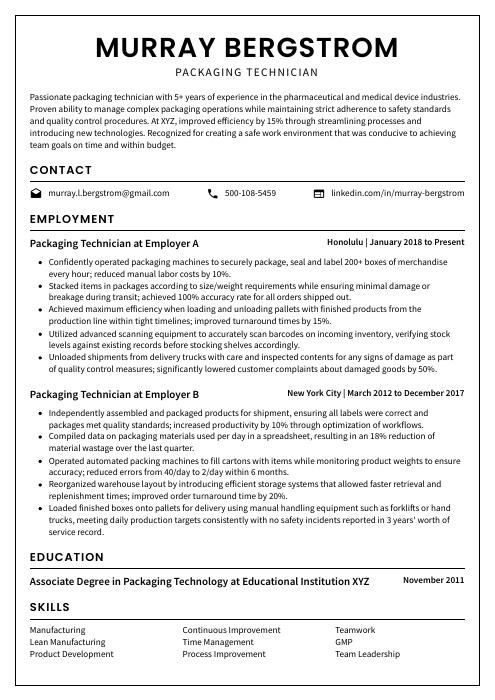

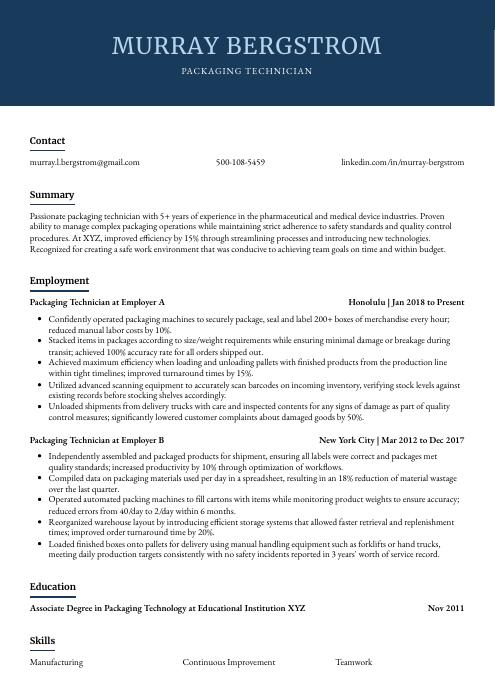

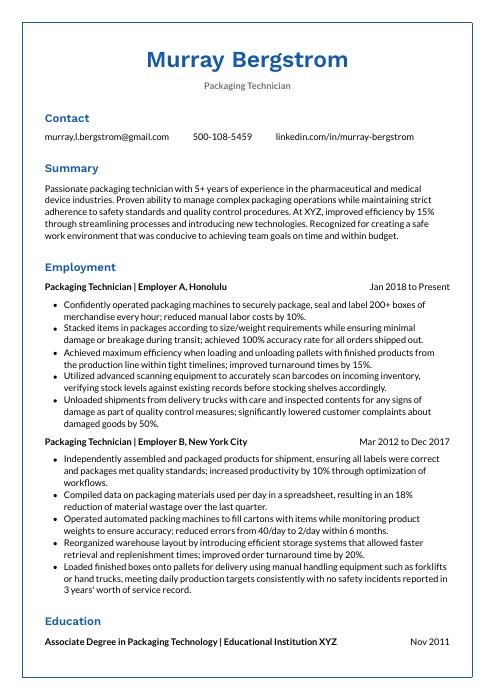

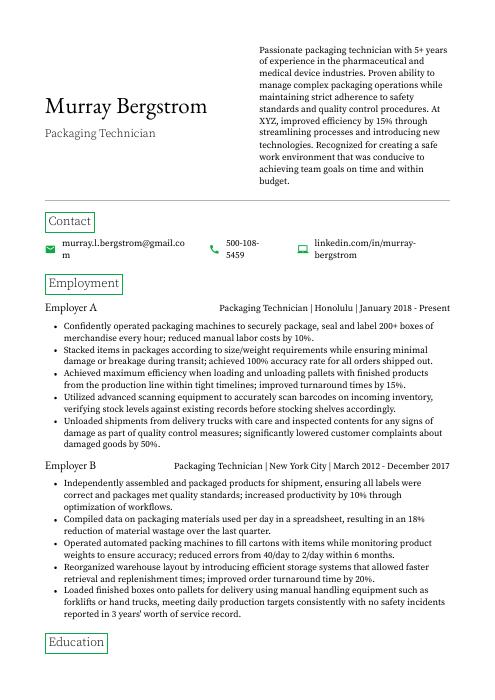

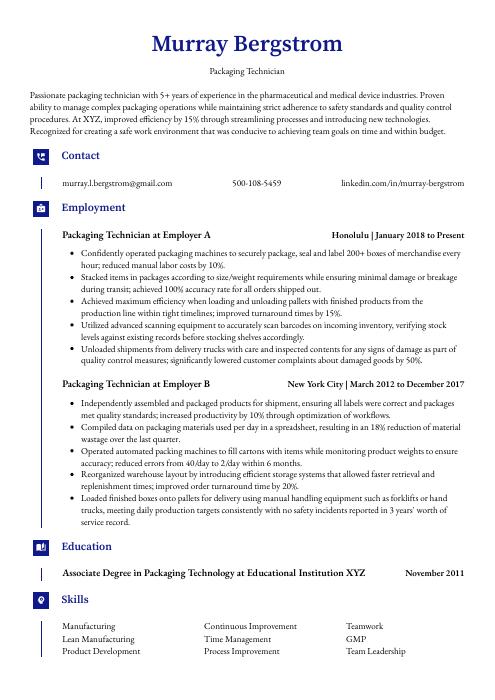

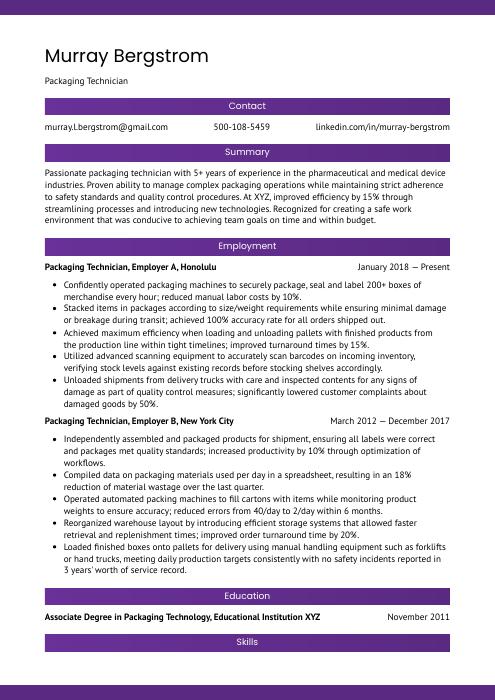

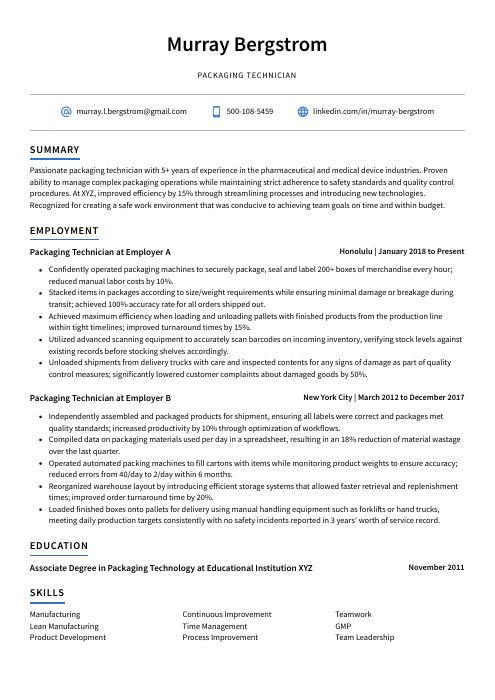

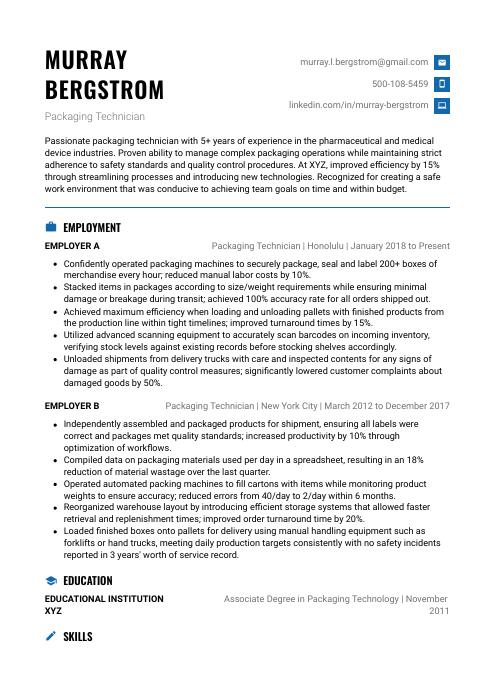

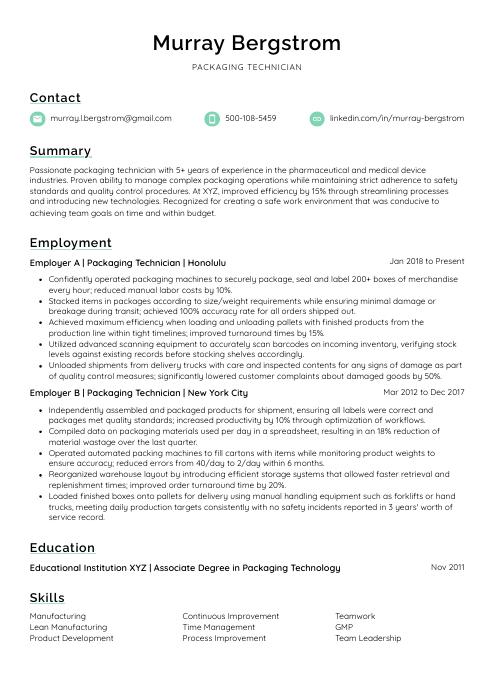

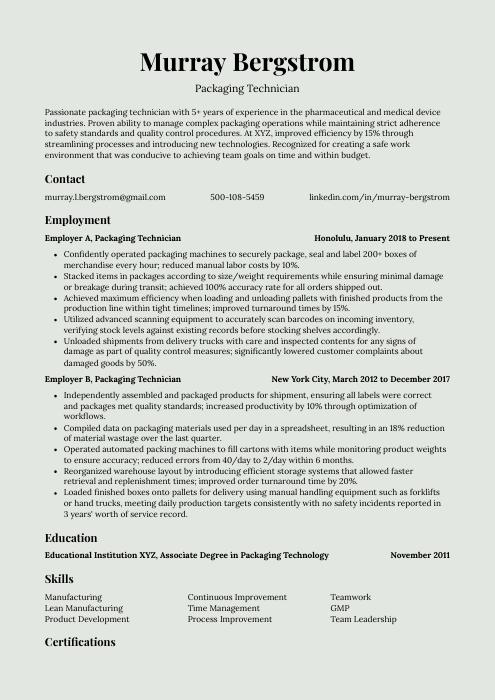

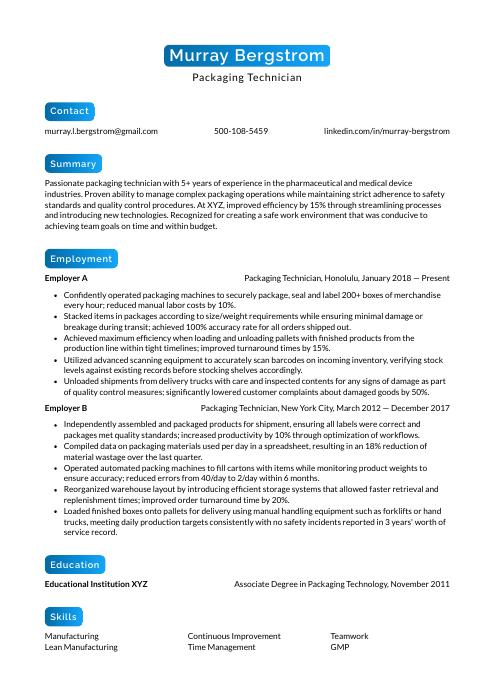

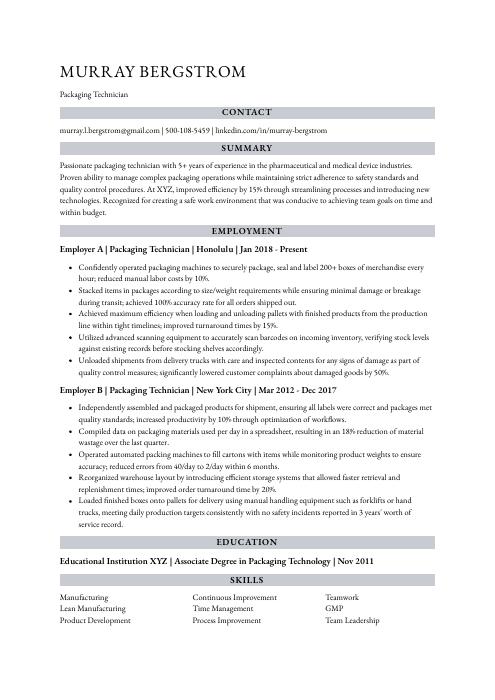

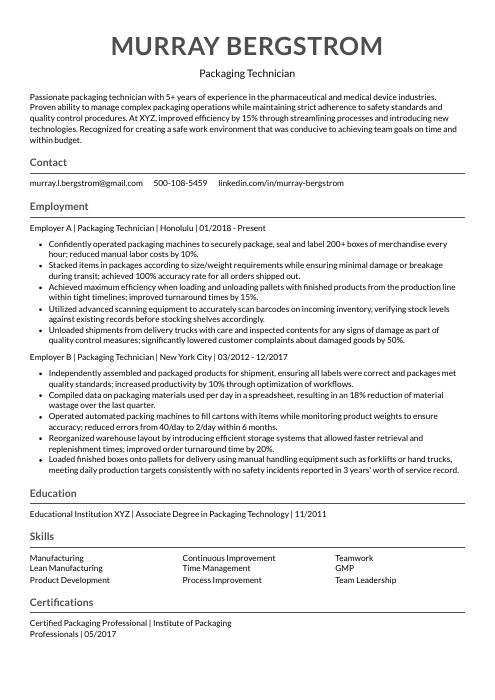

Murray Bergstrom

Packaging Technician

[email protected]

500-108-5459

linkedin.com/in/murray-bergstrom

Summary

Passionate packaging technician with 5+ years of experience in the pharmaceutical and medical device industries. Proven ability to manage complex packaging operations while maintaining strict adherence to safety standards and quality control procedures. At XYZ, improved efficiency by 15% through streamlining processes and introducing new technologies. Recognized for creating a safe work environment that was conducive to achieving team goals on time and within budget.

Experience

Packaging Technician, Employer A

Honolulu, Jan 2018 – Present

- Confidently operated packaging machines to securely package, seal and label 200+ boxes of merchandise every hour; reduced manual labor costs by 10%.

- Stacked items in packages according to size/weight requirements while ensuring minimal damage or breakage during transit; achieved 100% accuracy rate for all orders shipped out.

- Achieved maximum efficiency when loading and unloading pallets with finished products from the production line within tight timelines; improved turnaround times by 15%.

- Utilized advanced scanning equipment to accurately scan barcodes on incoming inventory, verifying stock levels against existing records before stocking shelves accordingly.

- Unloaded shipments from delivery trucks with care and inspected contents for any signs of damage as part of quality control measures; significantly lowered customer complaints about damaged goods by 50%.

Packaging Technician, Employer B

New York City, Mar 2012 – Dec 2017

- Independently assembled and packaged products for shipment, ensuring all labels were correct and packages met quality standards; increased productivity by 10% through optimization of workflows.

- Compiled data on packaging materials used per day in a spreadsheet, resulting in an 18% reduction of material wastage over the last quarter.

- Operated automated packing machines to fill cartons with items while monitoring product weights to ensure accuracy; reduced errors from 40/day to 2/day within 6 months.

- Reorganized warehouse layout by introducing efficient storage systems that allowed faster retrieval and replenishment times; improved order turnaround time by 20%.

- Loaded finished boxes onto pallets for delivery using manual handling equipment such as forklifts or hand trucks, meeting daily production targets consistently with no safety incidents reported in 3 years’ worth of service record.

Skills

- Manufacturing

- Continuous Improvement

- Teamwork

- Lean Manufacturing

- Time Management

- GMP

- Product Development

- Process Improvement

- Team Leadership

Education

Associate Degree in Packaging Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Packaging Professional

Institute of Packaging Professionals

May 2017

1. Summary / Objective

Your resume summary should be a brief but powerful statement that captures the essence of your experience and qualifications as a packaging technician. Include details such as how many years you have been in the industry, any certifications or awards you may have received, and notable accomplishments from past roles. Additionally, mention any specialized skills related to packaging technology that set you apart from other candidates.

Below are some resume summary examples:

Diligent packaging technician with 5+ years of experience in packaging and labeling products for shipping. At XYZ, developed automated processes to streamline the packing process while ensuring accuracy and efficiency. Experienced in quality control procedures, palletizing/wrapping goods, verifying product data against orders and maintaining complete records of shipments. Trained 10 new employees on safety protocols and proper use of equipment.

Driven packaging technician with 8+ years of experience in a fast-paced production facility. At ABC, increased throughput by 25% through the implementation of process improvements and streamlined packaging techniques. Skilled at ensuring product quality standards are met while meeting tight deadlines on time or ahead of schedule. Looking to join XYZ’s team as a packaging technician to help meet customer demands and grow the business further.

Professional packaging technician with 10+ years of experience in the food and beverage industry. Experienced in managing multiple packaging lines while ensuring quality standards are met. Skilled at working with automated equipment and troubleshooting any issues that arise quickly and efficiently. Committed to providing excellent customer service, maintaining a safe work environment, and achieving deadlines on time or ahead of schedule.

Energetic packaging technician with six years of experience in product packaging and quality assurance. At XYZ, designed innovative solutions for packaging products to ensure safe delivery during transit. Responsible for the inspection of 10 million packages per month and identified areas for improvement to reduce defects by 20%. Received multiple awards from management for excellence in problem-solving techniques.

Hard-working packaging technician with 3+ years of experience in a fast-paced production environment. Experienced in packaging and labeling products, ensuring quality control standards are met. Skilled at using machinery to package goods efficiently and accurately according to specifications. Seeking an opportunity at ABC Industries where I can utilize my skills and knowledge for the benefit of the organization.

Skilled packaging technician with 5+ years of experience in the medical device industry. Experienced in managing and organizing inventory, inspecting and testing products for quality control, and packing finished goods according to strict safety protocols. Looking to join ABC Medical Devices as a packaging technician where I can utilize my skillset to support their production process.

Enthusiastic packaging technician with 5+ years of experience in the manufacturing and production industry. Skilled at efficiently packaging products for distribution, operating automated machinery, maintaining a safe working environment, and adhering to company protocols. Aiming to use these skills to take on new challenges as part of ABC’s team.

Accomplished packaging technician with 7+ years of experience in the pharmaceutical industry. Skilled at troubleshooting, process optimization and quality control for production line operations. Seeking to join ABC Pharma as a Packaging Technician where I can use my knowledge and expertise to ensure timely delivery of high-quality products.

2. Experience / Employment

The employment (or experience) section is where you talk about your work history. It should be written in reverse chronological order, meaning the most recent job is listed first.

Stick to bullet points primarily when writing this section; doing so makes it easier for the reader to take in what you have to say quickly. When stating what you did, provide detail and explain any quantifiable results that were obtained from your efforts.

For example, instead of saying “Packaged products,” you could say, “Package finished goods into boxes with an average speed of 100 items per hour while ensuring accuracy and quality control.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Packaged

- Labeled

- Inspected

- Sealed

- Shipped

- Loaded

- Unloaded

- Monitored

- Operated

- Adjusted

- Wrapped

- Stacked

- Weighed

- Recorded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Participated in the packing of 200+ products per day, ensuring that company standards and customer expectations were met while efficiently meeting production goals.

- Competently operated a variety of packaging machines to assemble boxes, wrap materials and seal packages; reduced product damage rate by 10%.

- Introduced cost-saving measures in the packaging process which resulted in an average savings of $1,500 monthly for the organization.

- Inspected finished items on assembly lines to identify potential problems or defects before they reached customers; improved quality control ratings from 79% to 95%.

- Optimized workflow processes through reorganization efforts at each station along the assembly line resulting in a 20% increase in productivity within two weeks following implementation.

- Mentored and trained 3 new packaging technicians per month in line with safety regulations and quality assurance standards, resulting in a 25% improvement of production output.

- Shipped over 10,000 packages daily per customers’ specifications while adhering to strict deadlines; reduced error rate from 5% to 0.3%.

- Reduced costly downtime by consistently monitoring the performance of machinery used for product packing during shifts and proactively identified potential issues well before they occurred.

- Recorded all data associated with each shipment – weight & size, delivery date & time etc – into an automated system for accurate tracking purposes; achieved 100% accuracy in data entry within 4 months on the job.

- Thoroughly inspected every item packed prior to shipping them out using highly sensitive testing equipment; improved overall customer satisfaction ratings by 12%.

- Represented company in packaging and labeling meetings with FDA officials, ensuring compliance with all applicable laws; reduced product recalls by 20%.

- Prepared high-quality boxes for shipping of products to over 50 countries around the world on a daily basis, decreasing delivery time by 10 hours compared to previous year.

- Spearheaded process development projects that improved safety measures when packing fragile items such as glass bottles or delicate electronics; decreased breakage rate from 5% to 0%.

- Improved overall efficiency of package assembly line through careful analysis of workflow and introduction of new automated equipment which boosted output levels by 30%.

- Accurately measured weight and dimensions according to customer specifications before sealing packages using specialized machinery; enabled 100+ successful deliveries every month without any delays or errors.

- Proficiently weighed, monitored and packaged an average of 80 boxes per hour while adhering to strict quality assurance protocols; reduced packaging time by 20% in the last quarter.

- Labeled each box with product details and shipping information as required, ensuring accuracy of records at all times; minimized mislabeled items down to only 2%.

- Monitored temperature levels during the packing process and stored merchandise according to warehouse safety standards; lowered spoilage rate from 5% to 1%.

- Sealed packages securely using shrink-wrap machines or tape before delivering them safely on schedule via truck or van routes; eliminated late deliveries for over 90 customers in the past year alone.

- Assisted production workers with loading boxed goods onto pallets for storage or shipment purposes, helping increase daily output by 25%.

- Meticulously packaged and labeled customer orders for shipment, ensuring that shipping deadlines were met in 98% of cases.

- Demonstrated expertise in using automated packaging machinery to prepare products with speed and accuracy; increased production efficiency by 25%.

- Presented finished packages to quality assurance team members as per company protocols while maintaining a high level of safety at all times.

- Facilitated the storage of packaged items according to government mandated regulations, reducing inventory damage incidents by 42%.

- Assisted other technicians with packing tasks during peak seasons and ensured compliance with industry standards at all times.

- Wrapped and packaged product items with shrink-wrap, cartons and other materials to meet customer specifications; increased packaging efficiency by 30%.

- Formulated packing plans according to the size, shape and weight of products while ensuring maximum protection during transit; reduced damaged goods returned from customers by 10%.

- Effectively managed inventory levels of packaging material such as bubble wrap, tape and labels; decreased stock wastage rate by 20%.

- Assessed machine performance regularly in order to maintain optimal throughput speed throughout production processes.

- Advised cross-functional teams on cost reduction initiatives related to shipping costs and packaging materials usage; saved $2,000 per month for the company through improved workflow optimization techniques.

- Coordinated the packaging of over 200 items per hour, including labeling and sealing products for shipment; increased productivity levels by 20%.

- Streamlined the assembly line process to ensure that orders were accurately filled with minimal errors; reduced product damage incidents from 10% to 0.5% in 12 months.

- Assembled boxes and prepared packages according to customer requirements while adhering strictly to all safety regulations at all times.

- Developed efficient inventory control measures which enabled better tracking of materials needed for packaging operations; saved $500 a month on excess material costs alone.

- Reliably monitored equipment performance during production runs, performing minor repairs when required and keeping downtime occurrences below 5%.

- Structured and adjusted production and packaging lines to meet daily demands, resulting in an average increase of 10% productivity per shift.

- Resourcefully troubleshot machinery malfunctions by identifying the cause and implementing corrective actions that minimized downtime by 25%.

- Revised existing processes to improve efficiency and reduce costs; saved $7000 on material expenses over 6 months.

- Collaborated with quality control team members to inspect all incoming materials for defects before packing or shipping out; reduced customer complaints related to damaged goods by 15%.

- Expedited product shipments while consistently meeting customer delivery deadlines, achieving a 95% on-time performance rate within 12 months.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one might be looking for someone who is comfortable with machine operation and the other may require experience in quality control.

It is essential to tailor your skills section of your resume according to each job that you are applying for, as many employers use applicant tracking systems these days which scan resumes for certain keywords before passing them on to a human recruiter.

In addition to listing relevant skills here, it can also be beneficial to discuss some of the most important ones in more detail elsewhere in your resume – such as within the summary or experience sections.

Below is a list of common skills & terms:

- 5S

- Communication

- Continuous Improvement

- Cross Functional Team Leadership

- Data Entry

- Forklift Operation

- GMP

- Lean Manufacturing

- Manufacturing

- Packaging

- Pharmaceutical Industry

- Process Improvement

- Product Development

- Quality Assurance

- SAP

- SOP

- Six Sigma

- Supply Chain

- Team Leadership

- Teamwork

- Time Management

- Troubleshooting

- Validation

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, list your education below the resume objective. However, if you already have plenty of work experience to showcase, it might be better to omit the education section altogether.

If an education section is included, try mentioning courses or subjects related to packaging technology that can help demonstrate why you’re a good fit for this role.

Associate Degree in Packaging Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have been tested and certified in a particular field. They show that you are knowledgeable, experienced, and proficient in the skills required for the job.

Including certifications on your resume can be beneficial when applying for positions where specific qualifications or knowledge is necessary. It will also demonstrate to hiring managers that you take professional development seriously and have kept up with industry trends over time.

Certified Packaging Professional

Institute of Packaging Professionals

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Murray Bergstrom, this would be Murray-Bergstrom-resume.pdf or Murray-Bergstrom-resume.docx.

7. Cover Letter

Providing a cover letter is a great way to demonstrate your interest in the role and help you stand out from other applicants. It should be made up of 2 to 4 paragraphs that express why you are right for this particular job.

Cover letters give recruiters more insight into who you are as a professional, so take the time needed to craft an effective one. Even if it’s not required by the company, writing one can make all the difference in getting noticed and landing interviews!

Below is an example cover letter:

Dear Jordi,

I am writing in response to your ad for a Packaging Technician. With my experience in packaging and assembly line work, I feel confident I would be a valuable asset to your team.

In my current position as a Packaging Technician at [company name], I am responsible for packing products according to specifications and ensuring that the products are not damaged during shipping. I have also worked on the assembly line, where I was responsible for inspecting products and packaging them according to customer specifications. In both positions, I have consistently met or exceeded production goals while maintaining high standards of quality control.

I am reliable and detail-oriented, with excellent problem-solving skills. My ability to work well under pressure has helped me thrive in fast-paced environments like those found in manufacturing and packaging facilities. In addition, my positive attitude and strong work ethic have allowed me to build good relationships with fellow employees and customers alike.

If given the opportunity, I would be proud to put my skills and experience to work for your company as a Packaging Technician. Thank you for your time; I look forward to hearing from you soon.

Sincerely,

Murray

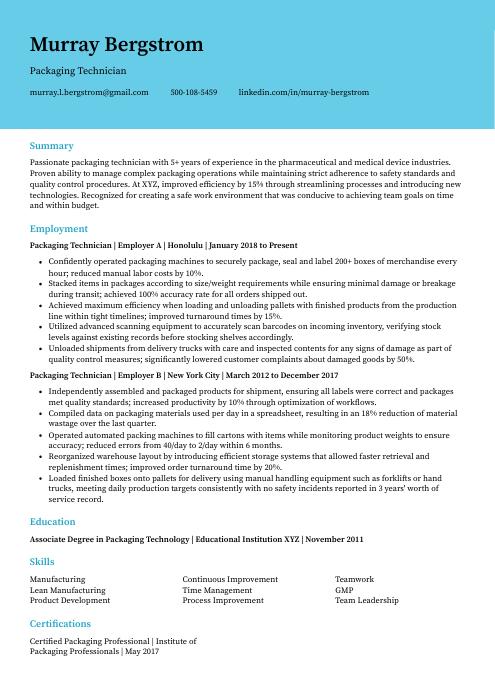

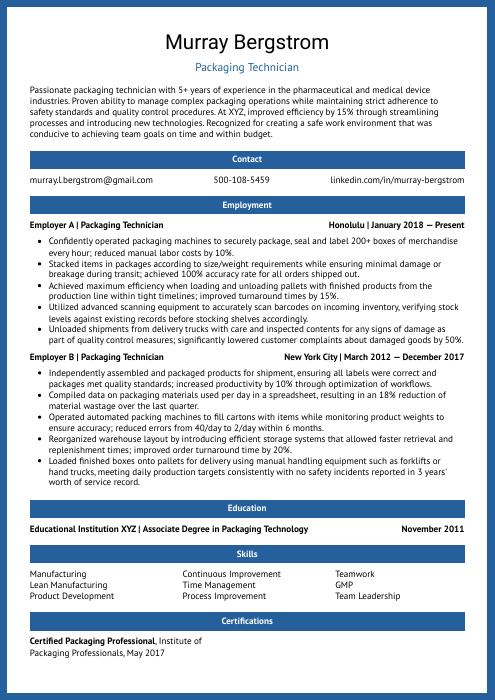

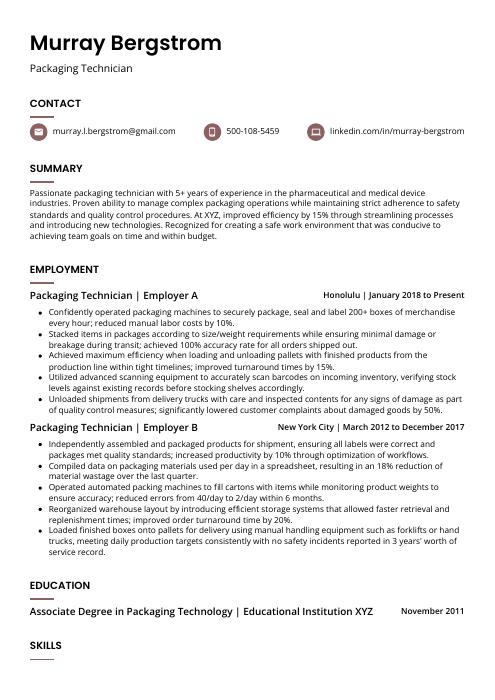

Packaging Technician Resume Templates

Dugong

Dugong Ocelot

Ocelot Fossa

Fossa Pika

Pika Cormorant

Cormorant Bonobo

Bonobo Markhor

Markhor Quokka

Quokka Gharial

Gharial Hoopoe

Hoopoe Rhea

Rhea Jerboa

Jerboa Axolotl

Axolotl Echidna

Echidna Lorikeet

Lorikeet Saola

Saola Kinkajou

Kinkajou Numbat

Numbat Indri

Indri Rezjumei

Rezjumei