Operations Engineer Resume Guide

Operations Engineers are responsible for ensuring that a company’s operations run smoothly and efficiently. They design, implement, maintain and monitor operational systems to ensure they meet the organization’s needs. They also analyze data to identify trends and opportunities for improvement in order to optimize performance.

You have the experience and know-how to make any operations department run like a well-oiled machine. But potential employers don’t know your name yet, so you must write an impressive resume that highlights all of your abilities.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Operations Engineer Resume Sample

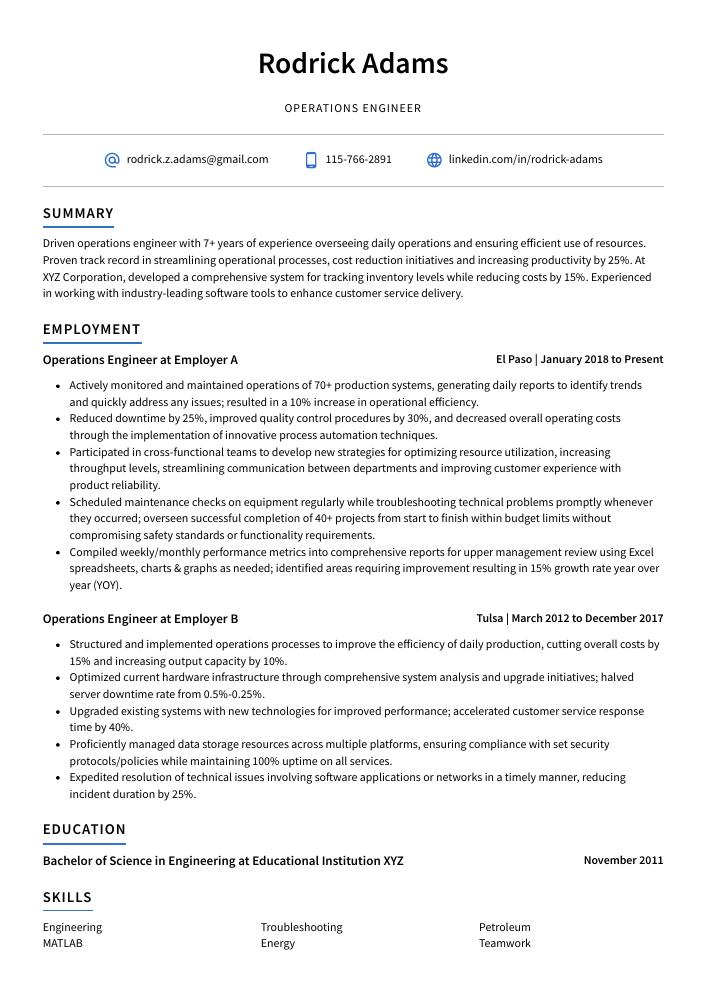

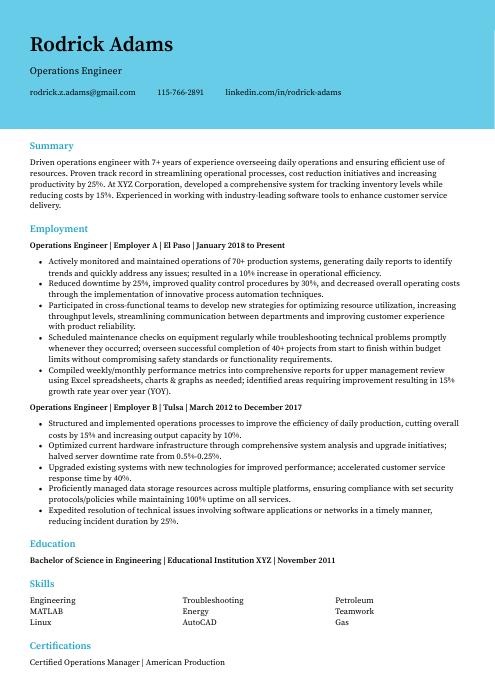

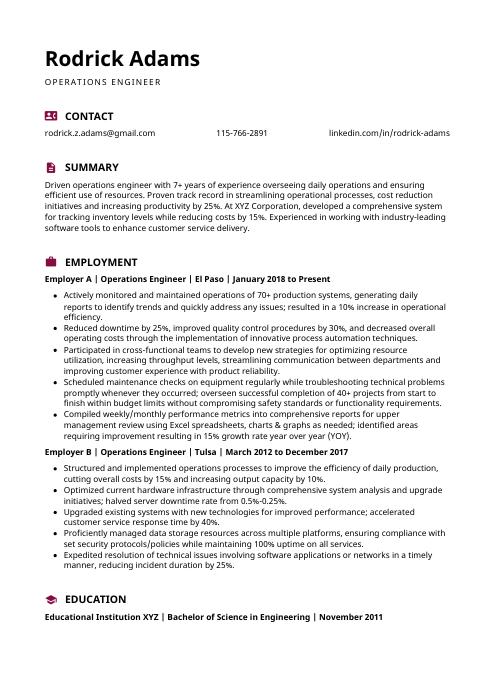

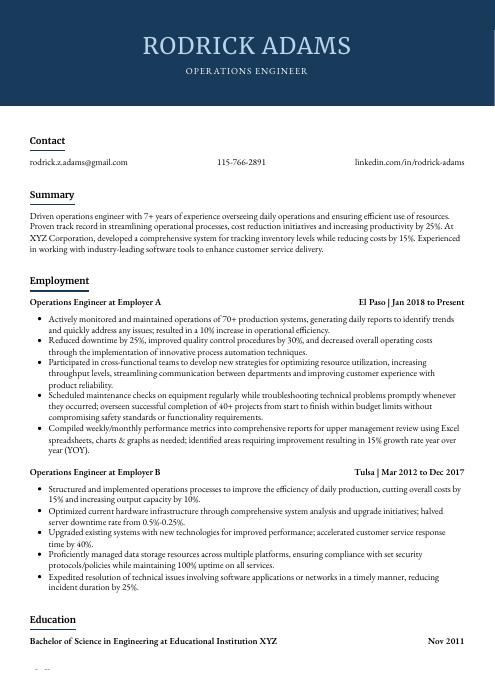

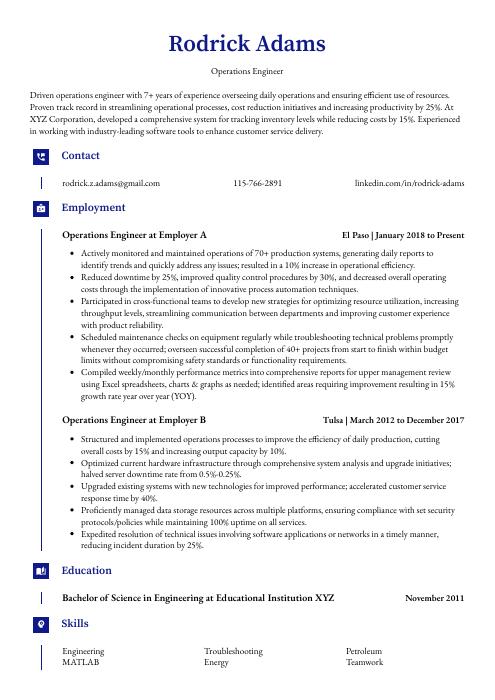

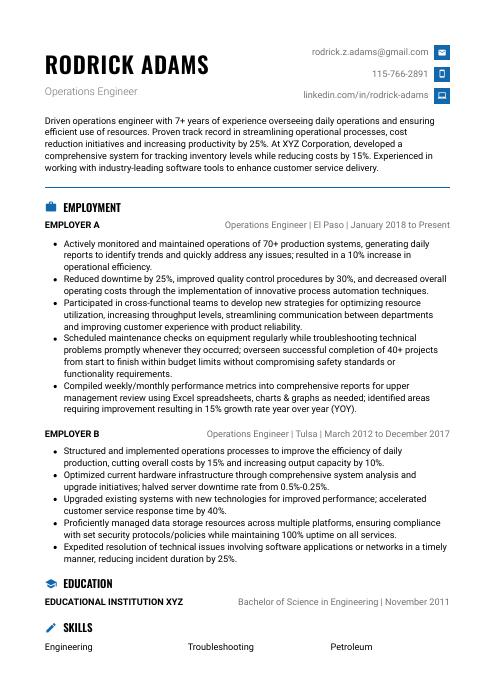

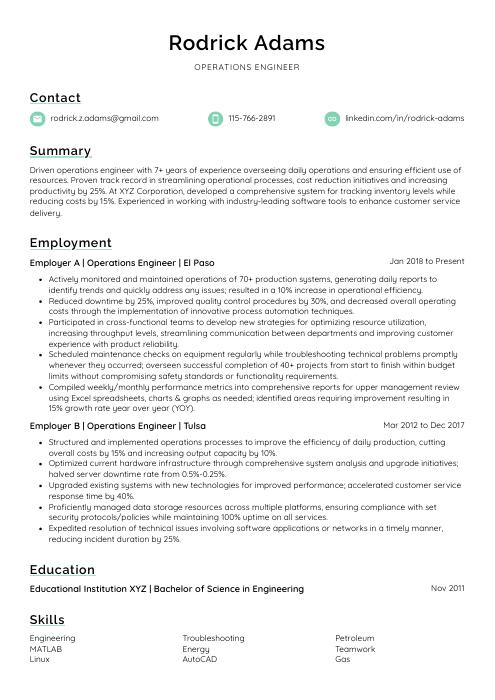

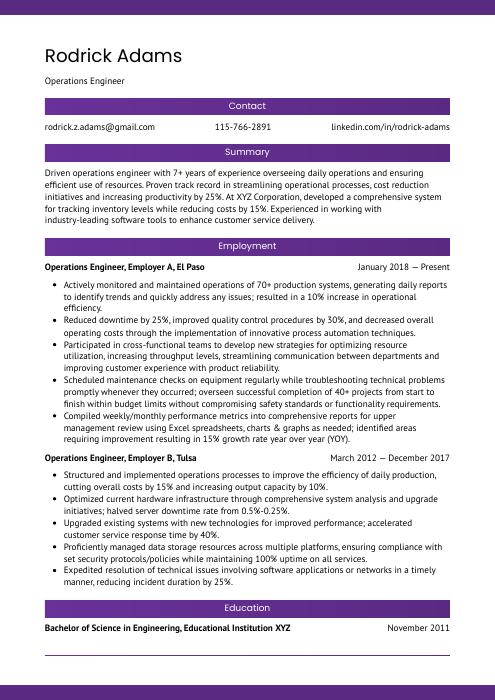

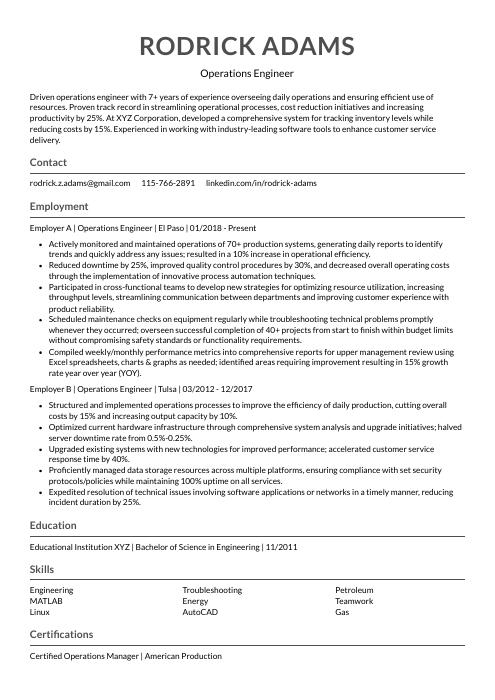

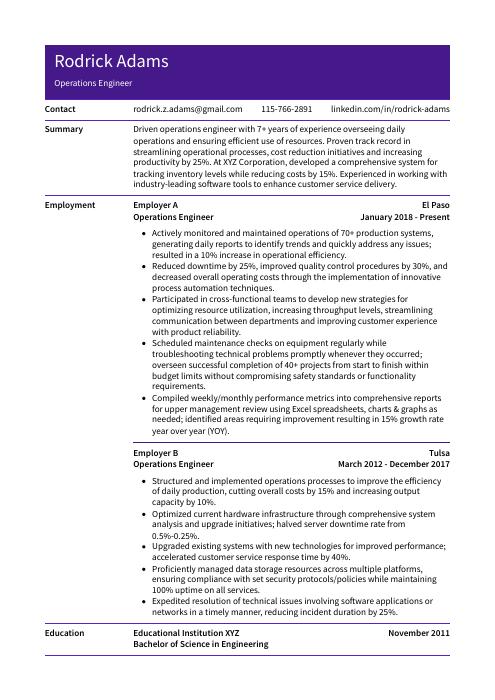

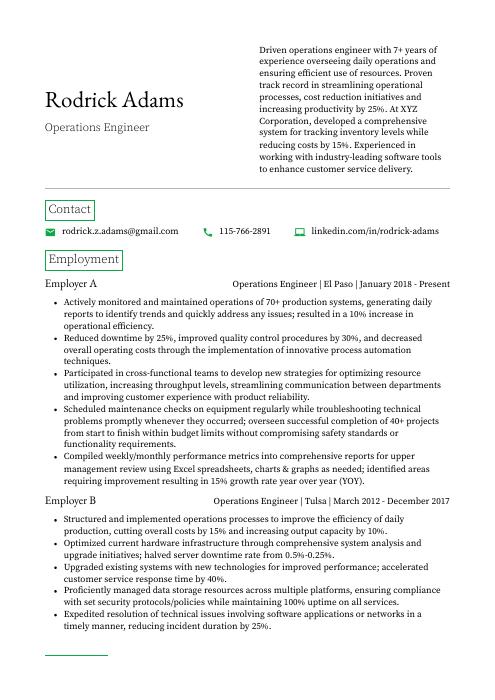

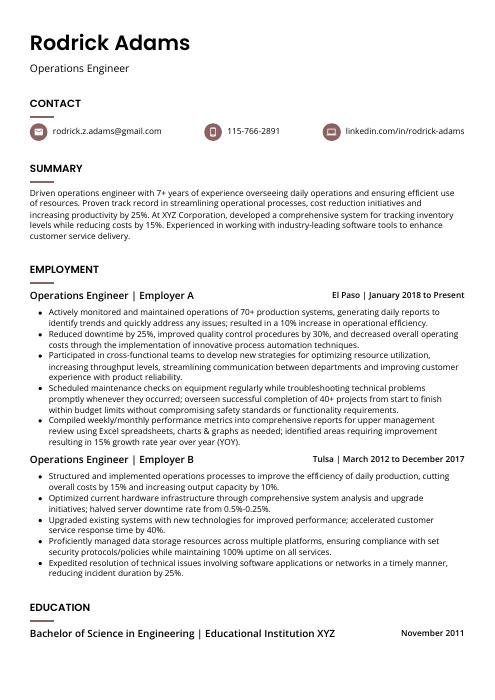

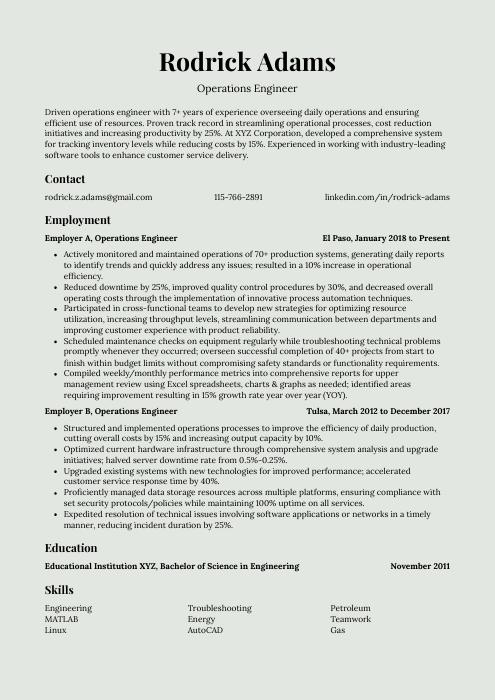

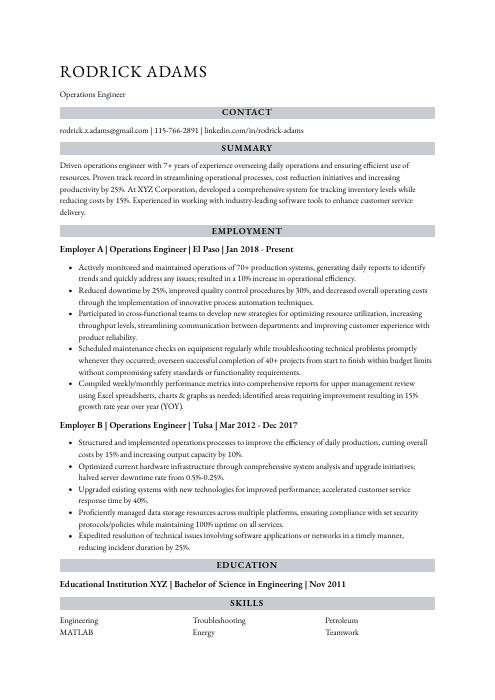

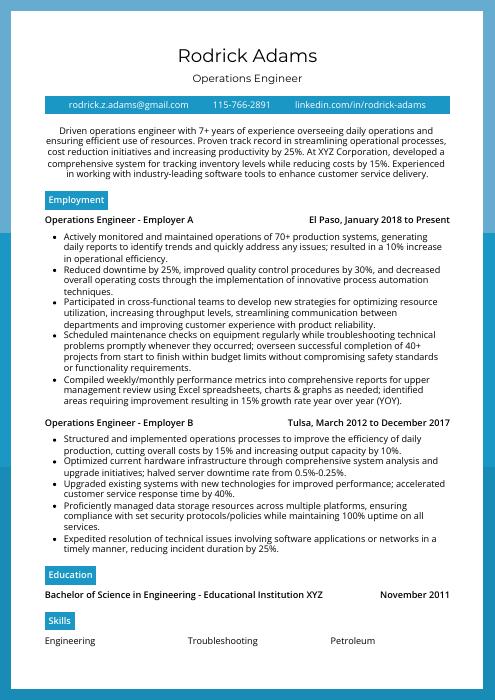

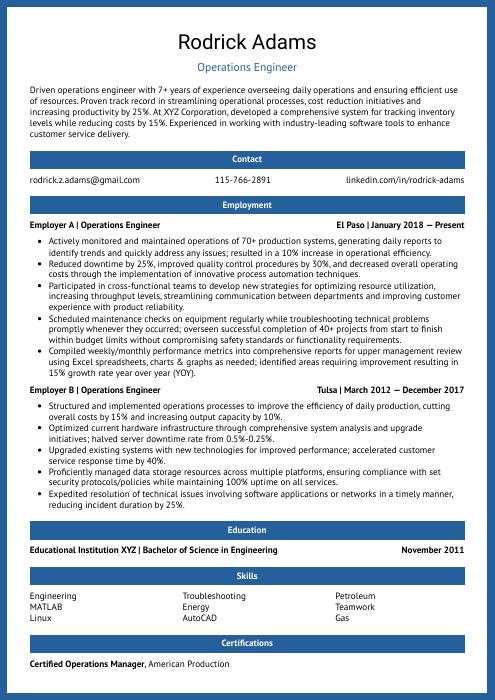

Rodrick Adams

Operations Engineer

[email protected]

115-766-2891

linkedin.com/in/rodrick-adams

Summary

Driven operations engineer with 7+ years of experience overseeing daily operations and ensuring efficient use of resources. Proven track record in streamlining operational processes, cost reduction initiatives and increasing productivity by 25%. At XYZ Corporation, developed a comprehensive system for tracking inventory levels while reducing costs by 15%. Experienced in working with industry-leading software tools to enhance customer service delivery.

Experience

Operations Engineer, Employer A

El Paso, Jan 2018 – Present

- Actively monitored and maintained operations of 70+ production systems, generating daily reports to identify trends and quickly address any issues; resulted in a 10% increase in operational efficiency.

- Reduced downtime by 25%, improved quality control procedures by 30%, and decreased overall operating costs through the implementation of innovative process automation techniques.

- Participated in cross-functional teams to develop new strategies for optimizing resource utilization, increasing throughput levels, streamlining communication between departments and improving customer experience with product reliability.

- Scheduled maintenance checks on equipment regularly while troubleshooting technical problems promptly whenever they occurred; overseen successful completion of 40+ projects from start to finish within budget limits without compromising safety standards or functionality requirements.

- Compiled weekly/monthly performance metrics into comprehensive reports for upper management review using Excel spreadsheets, charts & graphs as needed; identified areas requiring improvement resulting in 15% growth rate year over year (YOY).

Operations Engineer, Employer B

Tulsa, Mar 2012 – Dec 2017

- Structured and implemented operations processes to improve the efficiency of daily production, cutting overall costs by 15% and increasing output capacity by 10%.

- Optimized current hardware infrastructure through comprehensive system analysis and upgrade initiatives; halved server downtime rate from 0.5%-0.25%.

- Upgraded existing systems with new technologies for improved performance; accelerated customer service response time by 40%.

- Proficiently managed data storage resources across multiple platforms, ensuring compliance with set security protocols/policies while maintaining 100% uptime on all services.

- Expedited resolution of technical issues involving software applications or networks in a timely manner, reducing incident duration by 25%.

Skills

- Engineering

- Troubleshooting

- Petroleum

- MATLAB

- Energy

- Teamwork

- Linux

- AutoCAD

- Gas

Education

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Operations Manager

American Production and Inventory Control Society (APICS

May 2017

1. Summary / Objective

A resume summary/objective is an opportunity to showcase your best qualities and experience as an operations engineer. In this section, you can mention the types of systems you have worked on in the past, any certifications or qualifications that make you stand out from other applicants, and how your work has helped streamline processes for businesses. Additionally, it is a good idea to include some information about why you are passionate about working in operations engineering.

Below are some resume summary examples:

Seasoned operations engineer with 8+ years of experience in the software industry. Proven record of developing and deploying sophisticated systems that improve performance, scalability, reliability and cost-effectiveness. Successfully led projects to reduce operating costs by an average of 10% while improving customer satisfaction ratings by 15%. Seeking to join ABC Tech as a Senior Operations Engineer and help them achieve their strategic objectives.

Energetic operations engineer with a passion for problem-solving, process automation, and optimization. Skilled in end-to-end project management, from concept to delivery. Over 5 years of experience troubleshooting and developing solutions for complex technical problems at ABC Company. Experienced in leveraging various technologies across multiple platforms to develop efficient operations processes that reduce costs and improve customer satisfaction.

Proficient operations engineer with 5+ years of experience in the IT industry. Experienced in maintaining and monitoring systems, networks, and databases for multiple clients. At XYZ, managed 10 mission-critical projects simultaneously to ensure maximum efficiency and productivity. Recognized for successfully streamlining operations by implementing automated processes that resulted in a 20% cost reduction over two years.

Detail-oriented operations engineer with 5+ years of experience developing, deploying, and maintaining complex systems. Proven track record of increasing operational efficiency by up to 42%. Skilled in designing cloud-native solutions using Kubernetes and Docker containers. Looking to bring my expertise to ABC Tech’s operations team and help create a secure IT infrastructure that supports scalability.

Committed operations engineer with 5+ years of experience managing and maintaining infrastructure, systems, networks, and databases. Responsible for ensuring uptime and performance standards are met in a timely manner. At ABC Company I designed an automated system that reduced resources by 30%. Seeking to join XYZ team as the lead operations engineer to improve reliability while driving down costs.

Talented operations engineer with 8+ years of experience in the design, implementation and maintenance of systems for large-scale operations. Skilled at developing cost effective solutions to optimize production processes and improve operational efficiency. Experienced project manager adept at coordinating multiple stakeholders across departments to ensure successful delivery on time.

Reliable operations engineer with 10+ years of experience in designing, developing and implementing operational solutions. Skilled at identifying process improvement opportunities to reduce operational costs while improving efficiency. Seeking a position at ABC Company where I can leverage my expertise in project management and technical problem solving to drive successful outcomes.

Amicable operations engineer with 7+ years of experience in managing IT operations, ensuring system reliability and performance optimization. Skilled in developing processes to improve efficiency and productivity while reducing costs. Seeking to leverage demonstrated success in leading projects and teams at ABC Tech for continued growth opportunities within the company.

2. Experience / Employment

For the experience section, you want to list your past jobs in reverse chronological order, with the most recent one at the top.

When talking about what you did for each job, use bullet points and provide as much detail as possible. This allows the reader to quickly digest what you have written and get an idea of how well-versed you are in operations engineering.

For instance, instead of saying “Managed daily operations,” try something like this: “Oversaw day-to-day operations of a 200+ person team; developed processes that reduced downtime by 30% while increasing productivity levels by 40%. ”.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Automated

- Optimized

- Configured

- Troubleshot

- Implemented

- Analyzed

- Resolved

- Investigated

- Streamlined

- Scheduled

- Upgraded

- Documented

- Executed

- Managed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Structured

- Utilized

Below are some example bullet points:

- Represented operations team in cross-functional meetings, providing feedback and insight to help drive process improvement initiatives that have resulted in a 10% reduction of operational costs.

- Prepared detailed reports on equipment performance, analyzing data to identify areas for improvement which led to an 8 hour decrease in production timescales.

- Monitored daily operations activities within the engineering department, ensuring strict adherence to all safety regulations while meeting tight deadlines; successfully implemented 15 new procedures over 2 months without any incidents or accidents occurring.

- Reorganized warehouse storage systems with careful consideration taken towards optimizing space utilization; achieved 20% increase in capacity with minimal investment costs incurred (less than $1k).

- Reliably maintained up-to-date documentation for all projects handled by engineering teams including design specifications, test results & compliance records – resulting in 35% faster project delivery times compared to industry standards.

- Independently managed all operations activities for a large engineering firm, optimizing production line processes and maintaining equipment to reduce downtime by 30%.

- Demonstrated expertise in coordinating maintenance of mechanical, electrical and hydraulic systems; successfully completed 100+ preventative maintenance checklists within budgeted timeframes.

- Assessed manufacturing capacity needs on a daily basis to ensure maximum efficiency without compromising product quality standards; reduced costs by 15% through process re-engineering initiatives.

- Achieved full compliance with applicable safety regulations after introducing new safety protocols across the facility; improved overall employee engagement scores by 40%.

- Troubleshot complex operating issues related to assembly lines, robotics and other automated machinery components based on technical knowledge acquired over 8 years of experience in the field.

- Introduced cost-saving measures which reduced operational expenses by 17% while maintaining optimal efficiency.

- Executed daily tasks of overseeing production operations and ensuring machines were running with maximum output; increased productivity by 25%.

- Utilized statistical process control to monitor performance, identify non-conformance areas, and implement corrective actions for quality improvement in line with ISO 9001 standards.

- Implemented automated system upgrades that improved accuracy and reliability of equipment used in the manufacturing process; achieved a 99% on time delivery rate in all orders placed within 1 month period.

- Efficiently managed a team of technicians responsible for troubleshooting technical issues related to machinery breakdowns, leading to an 85% reduction in unplanned downtime costs over 3 months.

- Resolved 200+ operational issues within 24 hours, improving system uptime by 32% and reducing customer complaints by 50%.

- Mentored a team of 5 junior engineers in troubleshooting hardware/software problems and developing best practices for preventive maintenance; improved overall employee satisfaction rates by 16%.

- Developed comprehensive operations procedure manuals detailing the correct steps to be taken when resolving complex technical issues, resulting in an 11% decrease in repair time.

- Spearheaded projects to upgrade outdated systems with state-of-the-art technology solutions, ensuring that all security protocols were met while maintaining budget constraints (+$20K savings).

- Confidently handled escalated customer concerns and provided timely resolutions using strong problem solving skills; reduced call transfers and wait times by 25%.

- Documented operational procedures and standards for a fleet of over 500 vehicles, creating an accessible database which increased efficiency by 25%.

- Advised senior management on the design of new control systems to optimize workflow in operations, resulting in 40% cost savings for the company.

- Improved operational processes using Lean Six Sigma methodology; reduced production time from 8 hours down to 4 hours per unit with no additional costs incurred.

- Accurately monitored equipment performance levels and identified potential issues before they escalated into major problems, minimizing downtime by 35%.

- Coordinated teams of up to 15 personnel during daily maintenance activities; completed all tasks within schedule parameters while ensuring safety regulations were always met or exceeded.

- Effectively managed the operations of a large-scale manufacturing facility, leading to an increase in efficiency by 20% and cost savings of $30,000 over six months.

- Configured automated assembly lines for quicker production turnaround time while ensuring compliance with safety regulations; reduced downtime by 35%.

- Presented monthly reports on operational performance metrics to senior management team and made suggestions for improvement based on data analysis; implemented changes that resulted in 15% productivity gains in subsequent weeks.

- Investigated problems within existing systems and identified root causes using advanced diagnostic tools; resolved issues within 6 hours on average, slashing system breakdowns by 40%.

- Revised processes for improved quality control standards and oversaw the development of new procedures when necessary; achieved 100% product accuracy rate during routine audits over two consecutive quarters.

- Automated production processes to increase efficiency by 30%, resulting in a 20% reduction in operational costs.

- Streamlined workflow and developed new procedures for the successful launch of 3 new products into the market, increasing sales revenue by $5 million annually.

- Facilitated daily meetings with production staff and management teams to identify areas needing improvement; implemented changes that reduced downtime hours from 6 per week to an average of 2 hours per month.

- Managed 15+ personnel across multiple shifts while overseeing operations activities such as inventory control, quality assurance and material handling; improved overall productivity levels by 25%.

- Competently tracked project progress using various software tools including MS Project & Tableau Dashboards; provided regular updates on milestones achieved & challenges encountered during implementation phases.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might require a candidate to be proficient in the use of AWS, while another might prioritize knowledge in Azure.

It is important to tailor your skills section accordingly because many companies now employ applicant tracking systems (ATS) which are computer programs that scan resumes for certain keywords before passing them on to human recruiters.

In addition, you can further elaborate on the most relevant qualifications by discussing them more thoroughly elsewhere – such as in the summary or experience sections.

Below is a list of common skills & terms:

- Active Directory

- AutoCAD

- C++

- Continuous Improvement

- Data Analysis

- Drilling

- Energy

- Energy Industry

- Engineering

- Gas

- HTML

- Java

- Lean Manufacturing

- Linux

- MATLAB

- Manufacturing

- Mechanical Engineering

- Network Administration

- Networking

- Oil and Gas

- Oilfield

- Onshore

- Operations Management

- Petroleum

- Petroleum Engineering

- Process Engineering

- Process Improvement

- Project Engineering

- Project Planning

- Python

- SOLIDWORKS

- SQL

- Servers

- System Administration

- Team Leadership

- Teamwork

- Technical Support

- Time Management

- Troubleshooting

- Unix

- Upstream

- VMware

- Windows

- Windows Server

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you recently graduated and have no prior experience, include the education section below your resume objective. However, if you have plenty of work experience that is relevant to the operations engineer role, an education section might not be necessary at all.

If including it is desired or required by a job application, try to list courses and subjects related to the operations engineering field that could give employers insight into why they should hire you for this position.

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a given field. They show potential employers that you have taken the time and effort to gain knowledge of certain topics, as well as prove that you are committed to staying up-to-date with industry trends.

Including certifications on your resume is an effective way of showing hiring managers that you possess the necessary skills for the job at hand. Be sure to list any relevant certifications so they can be easily identified by recruiters when reviewing applications.

Certified Operations Manager

American Production and Inventory Control Society (APICS

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Rodrick Adams, this would be Rodrick-Adams-resume.pdf or Rodrick-Adams-resume.docx.

7. Cover Letter

Writing a cover letter is an important part of any job application process. It is a document that should accompany your resume and provide more detail about who you are, why you’re interested in the role and how your skills make you a great fit for it.

A cover letter usually consists of 2 to 4 paragraphs and provides recruiters with valuable insights into what makes you unique as a professional. Whilst cover letters aren’t always required, having one can give you an edge over other applicants competing for the same position.

Below is an example cover letter:

Dear Alivia,

I am writing to apply for the Operations Engineer position at XYZ Corporation. As a certified Six Sigma Green Belt and experienced operations engineer, I am confident I will be an asset to your organization.

In my current role as an operations engineer at ABC Corporation, I lead a team of 12 engineers responsible for improving manufacturing processes and developing new product designs. In this role, I have utilized my expertise in Six Sigma methodology to streamline production processes and reduce waste, resulting in cost savings of more than $1 million over the past two years. Additionally, I have led successful projects to develop new products from concept to launch, including managing all aspects of design, prototyping, testing, and mass production.

I am confident that my skills and experience will enable me to contribute immediately to the success of XYZ Corporation. I look forward to discussing how I can add value to your organization during an interview at your earliest convenience. Thank you for your time and consideration.

Sincerely,

Rodrick

Operations Engineer Resume Templates

Dugong

Dugong Kinkajou

Kinkajou Markhor

Markhor Hoopoe

Hoopoe Bonobo

Bonobo Gharial

Gharial Echidna

Echidna Lorikeet

Lorikeet Jerboa

Jerboa Indri

Indri Pika

Pika Quokka

Quokka Fossa

Fossa Cormorant

Cormorant Axolotl

Axolotl Saola

Saola Numbat

Numbat Rhea

Rhea Ocelot

Ocelot Rezjumei

Rezjumei