Metrology Technician Resume Guide

Metrology Technicians are responsible for ensuring precision and accuracy in the measurement of physical objects. They use a variety of tools including calipers, micrometers and optical comparators to take precise measurements that can then be used to check production components or calibrate instruments.

Your technical skills and precision measurements are invaluable to any metrology laboratory. But employers don’t know who you are yet, so it’s up to you to create a resume that stands out from the competition and showcases your unique expertise in this field.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

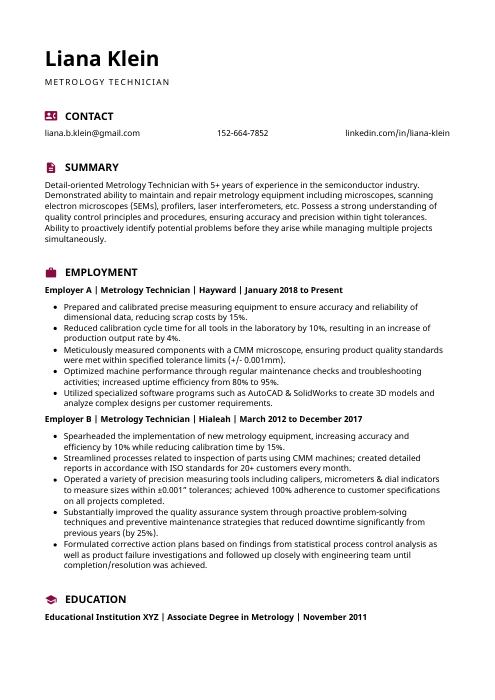

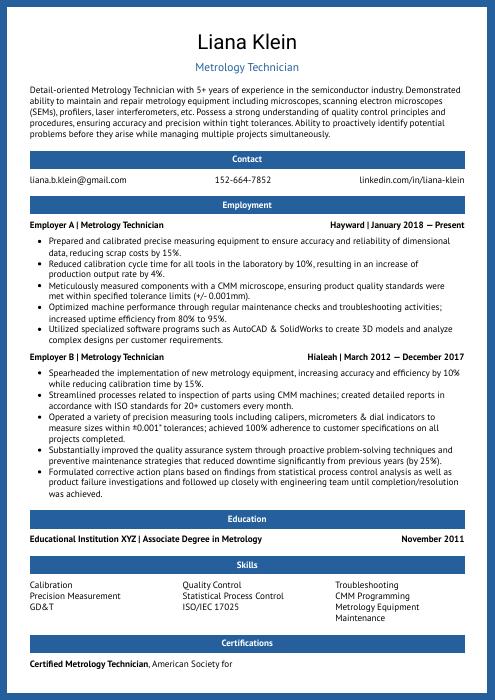

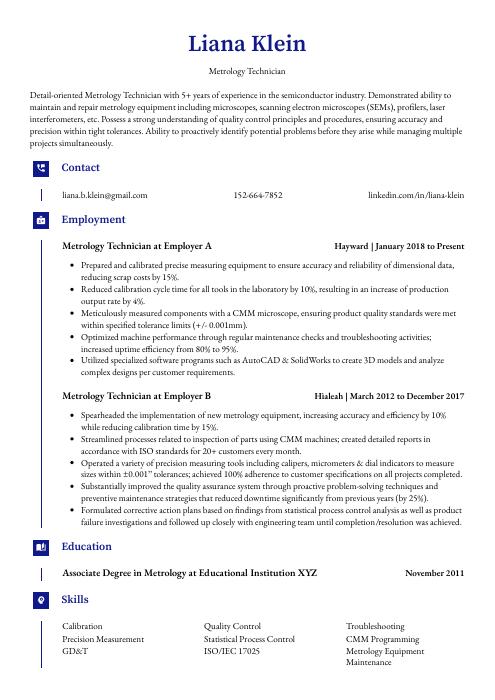

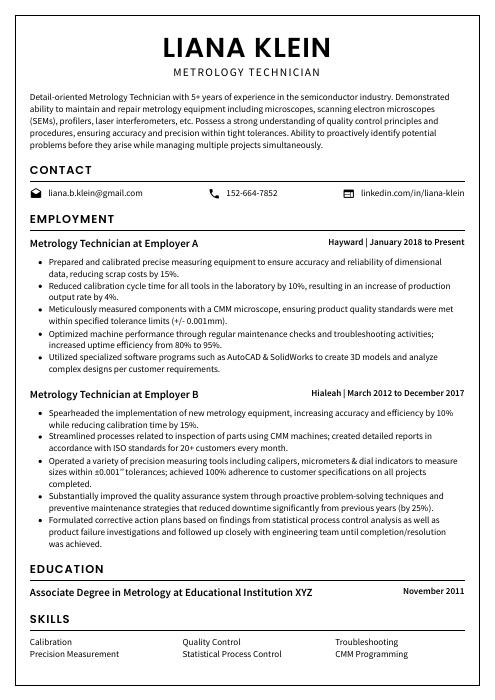

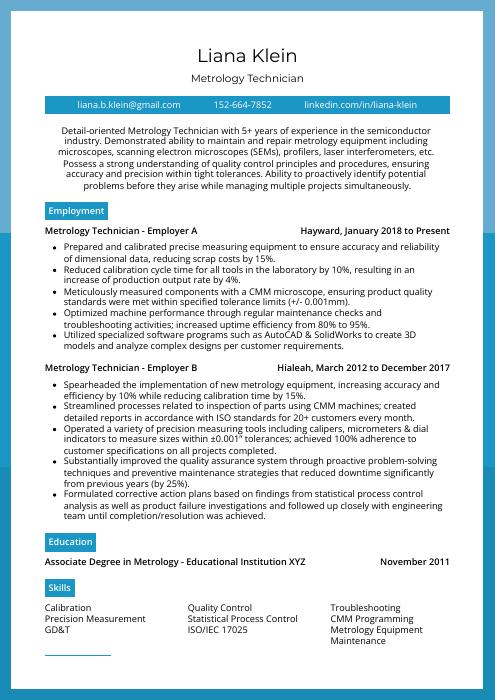

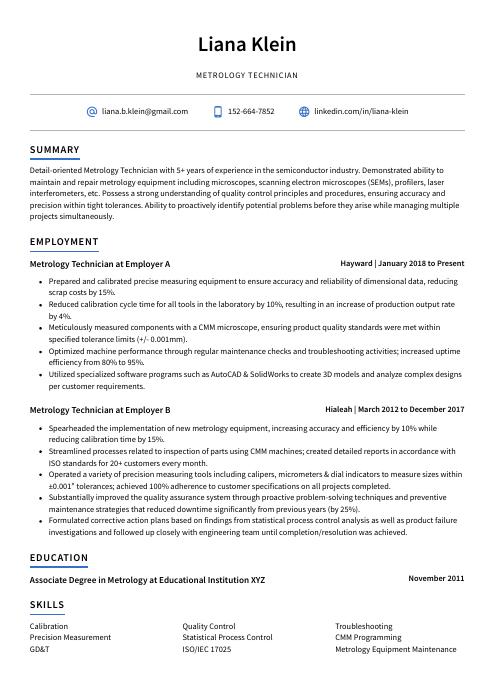

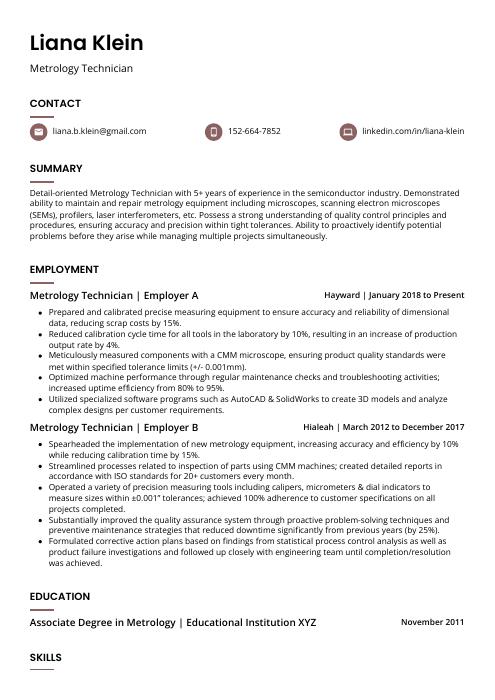

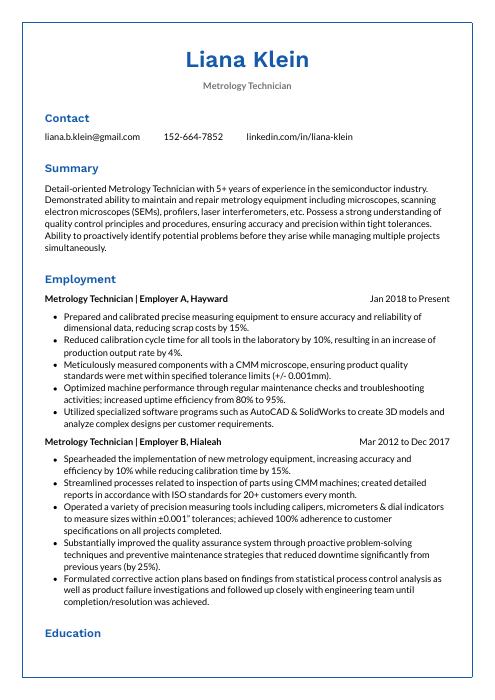

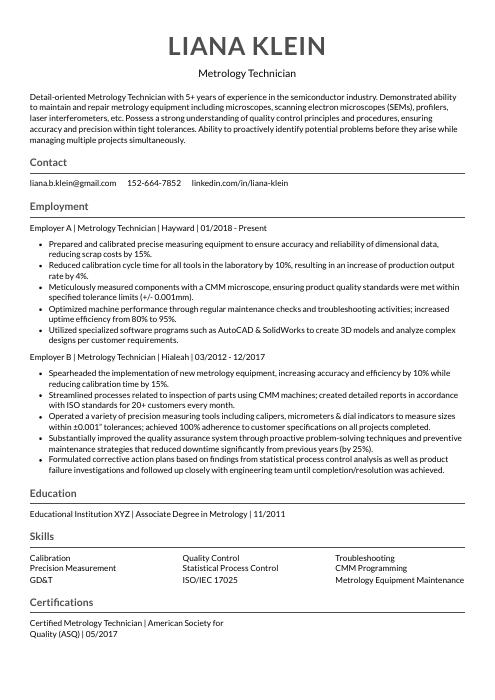

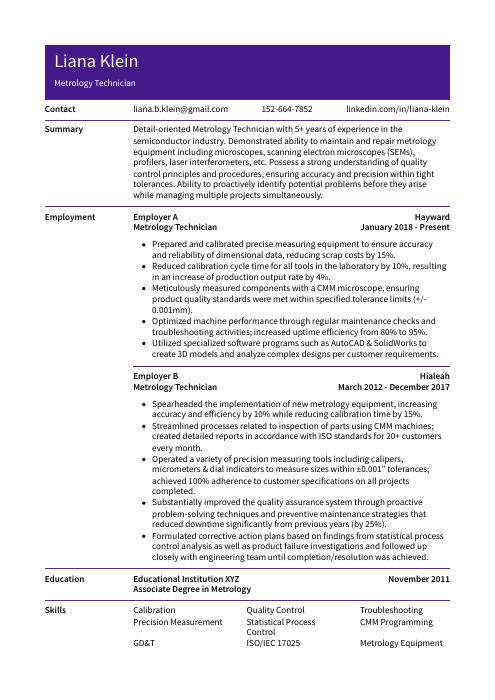

Metrology Technician Resume Sample

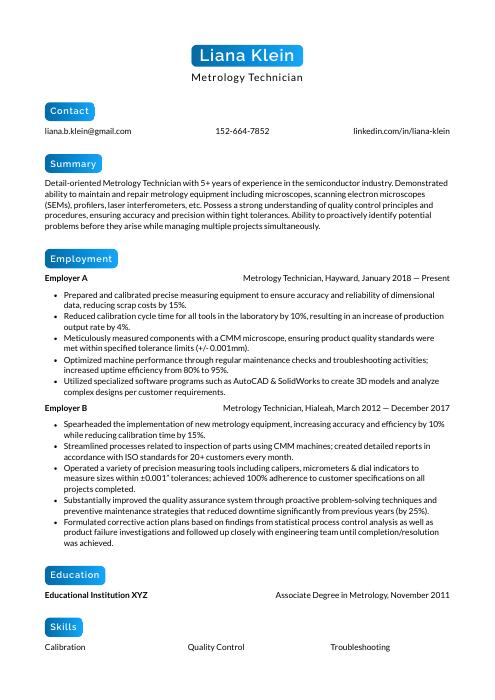

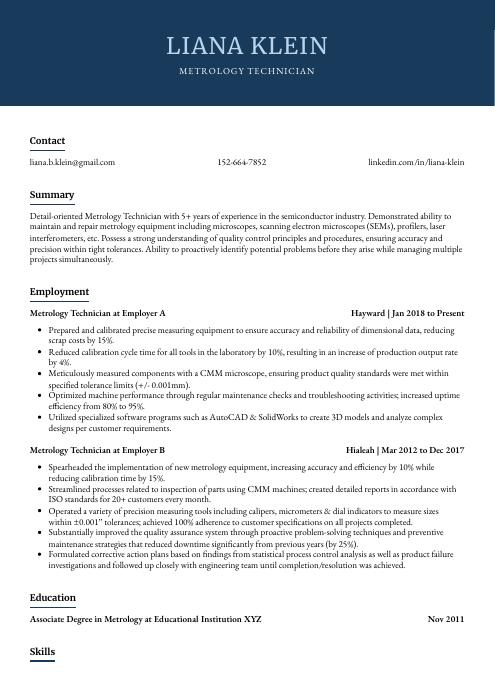

Liana Klein

Metrology Technician

[email protected]

152-664-7852

linkedin.com/in/liana-klein

Summary

Detail-oriented Metrology Technician with 5+ years of experience in the semiconductor industry. Demonstrated ability to maintain and repair metrology equipment including microscopes, scanning electron microscopes (SEMs), profilers, laser interferometers, etc. Possess a strong understanding of quality control principles and procedures, ensuring accuracy and precision within tight tolerances. Ability to proactively identify potential problems before they arise while managing multiple projects simultaneously.

Experience

Metrology Technician, Employer A

Hayward, Jan 2018 – Present

- Prepared and calibrated precise measuring equipment to ensure accuracy and reliability of dimensional data, reducing scrap costs by 15%.

- Reduced calibration cycle time for all tools in the laboratory by 10%, resulting in an increase of production output rate by 4%.

- Meticulously measured components with a CMM microscope, ensuring product quality standards were met within specified tolerance limits (+/- 0.001mm).

- Optimized machine performance through regular maintenance checks and troubleshooting activities; increased uptime efficiency from 80% to 95%.

- Utilized specialized software programs such as AutoCAD & SolidWorks to create 3D models and analyze complex designs per customer requirements.

Metrology Technician, Employer B

Hialeah, Mar 2012 – Dec 2017

- Spearheaded the implementation of new metrology equipment, increasing accuracy and efficiency by 10% while reducing calibration time by 15%.

- Streamlined processes related to inspection of parts using CMM machines; created detailed reports in accordance with ISO standards for 20+ customers every month.

- Operated a variety of precision measuring tools including calipers, micrometers & dial indicators to measure sizes within ±0.001” tolerances; achieved 100% adherence to customer specifications on all projects completed.

- Substantially improved the quality assurance system through proactive problem-solving techniques and preventive maintenance strategies that reduced downtime significantly from previous years (by 25%).

- Formulated corrective action plans based on findings from statistical process control analysis as well as product failure investigations and followed up closely with engineering team until completion/resolution was achieved.

Skills

- Calibration

- Quality Control

- Troubleshooting

- Precision Measurement

- Statistical Process Control

- CMM Programming

- GD&T

- ISO/IEC 17025

- Metrology Equipment Maintenance

Education

Associate Degree in Metrology

Educational Institution XYZ

Nov 2011

Certifications

Certified Metrology Technician

American Society for Quality (ASQ)

May 2017

1. Summary / Objective

Your resume summary should be a concise overview of your experience and qualifications as a metrology technician. Include any certifications you have, such as ISO 9001 or ASQ Certified Quality Technician (CQT). Mention the types of instruments you are familiar with, like calipers, micrometers, optical comparators and coordinate measuring machines. You can also highlight how many years of experience you have in this field and any special projects that demonstrate your expertise.

Below are some resume summary examples:

Enthusiastic metrology technician with 5+ years of experience in the medical device industry. Skilled in using and maintaining a wide range of precision measuring instruments and tools to ensure product accuracy for clients. Adept at providing detailed reports, troubleshooting issues, and collaborating with other departments on quality control initiatives. Seeking an opportunity to use my expertise at ABC Medical Devices to improve customer satisfaction.

Skilled metrology technician with 10+ years of experience in the measurement and calibration industry. At XYZ, managed a team of three technicians that were responsible for calibrating hundreds of instruments each month. Experienced in using CMM, laser trackers, roundness testers, and other measuring equipment to ensure accuracy and precision. Committed to providing quality products while maintaining safety standards at all times.

Reliable metrology technician with 4+ years of experience in inspecting, measuring and testing products using optical comparators, calipers, micrometers and other precision instruments. Seeking to utilize my skills to provide accurate results for XYZ Company. At ABC Corporation I successfully diagnosed over 30 pieces of equipment that were not working properly; saving the company time and money by ensuring proper functioning.

Talented and experienced metrology technician with a proven track record of success in the field. Extensive experience working with high-precision measuring instruments and tools, analyzing data, troubleshooting equipment issues, and performing quality assurance tests on manufactured parts. At XYZ Corporation reduced scrap rate by 8% through careful analysis of machining tolerances to improve production efficiencies.

Hard-working metrology technician with 4+ years of experience performing inspections, calibrations and measurements for a wide variety of mechanical instruments. Ability to read complex blueprints and schematics. Seeking the opportunity to join ABC Company as an entry-level metrology technician where I can apply my knowledge in precision measurement technologies to provide excellent customer service.

Proficient metrology technician with 5+ years of experience in precision measuring and fabrication. Skilled in leading teams, setting up machinery, performing quality control inspections, and identifying defects to ensure optimal performance. Seeking a position at ABC Technologies where I can leverage my knowledge and skillset to help develop top-of-the-line products for customers around the world.

Accomplished metrology technician with 5+ years of experience in inspection, testing, and calibration processes. Skilled at using a variety of metrology instruments to perform quality checks on components used in various industries. Highly motivated to join ABC Corp as a metrologist and help ensure that the highest standards are maintained when producing products for customers.

Professional metrology technician with 5+ years of experience in calibration and repair of precision measuring instruments. Skilled at performing tests, inspections, and repairs using a variety of tools such as calipers, micrometers, and optical comparators. Seeking to join ABC Company’s team to provide quality assurance services for its highly precise production processes.

2. Experience / Employment

In the experience/employment/work history section, you should list your past roles in reverse chronological order, starting with the most recent.

When writing about what you did in each role, use bullet points to make it easier for the reader to digest. You also want to include detail and quantify results where possible. For example, instead of saying “Performed calibration tests,” say something like “Conducted accuracy testing on precision measuring instruments using a variety of methods such as laser interferometry; achieved an average accuracy rate of 99%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Calibrated

- Inspected

- Analyzed

- Measured

- Adjusted

- Tested

- Monitored

- Troubleshot

- Documented

- Operated

- Programmed

- Repaired

- Aligned

- Certified

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Certified in metrology practices, successfully calibrating and measuring a variety of instruments over the course of 5 years; reduced calibration time by 10% on average.

- Demonstrated knowledge in precision measurement devices such as micrometers, calipers & optical comparators to evaluate parts for quality assurance purposes and ensure that tolerances were maintained at all times.

- Revised standard operating procedures (SOPs) to improve operational efficiency within the metrology department; implemented new inspection processes that resulted in an 8% cost reduction across all production lines.

- Adjusted settings or repairs on defective equipment while following safety rules and guidelines established by governing bodies; identified faulty components before they caused further damage/downtime, decreasing repair costs by $1,200 annually.

- Proficiently used computer software programs such as Microsoft Excel and SPC analysis tools to analyze data collected during testing activities and create detailed reports for review by management team members.

- Diligently performed metrology tests to validate accuracy of components, increasing test accuracy by 10% and reducing customer complaints by 20%.

- Improved calibration processes for a variety of instruments including electronic scales, thermometers and ultrasonic measurement machines; reduced downtime waiting for calibrations from 48 hours to 24 hours.

- Aligned measuring devices with best practice methods in order to ensure accurate readings were taken every time; decreased data collecting errors by 15%.

- Introduced new software programs that enabled the automation of quality control processes, saving over 400 man-hours per year on manual testing labor costs.

- Reorganized existing laboratory protocols into an efficient system which minimized waste materials while ensuring compliance with regulations; increased productivity levels by 25%.

- Confidently operated a variety of precision measuring instruments and equipment to measure, verify, analyze and correct dimensional tolerances; reduced inspection time by 15%.

- Coordinated with the Quality Control team to ensure that all mechanical components were manufactured according to customer specifications; tracked quality metrics weekly for continuous improvement.

- Monitored production operations using statistical process control (SPC) methods and identified potential errors or discrepancies before they occurred on over 100 components per day.

- Facilitated calibration tasks for both in-house and external metrology machines as needed, resulting in improved accuracy levels by 10%.

- Programmed CMM software such as Metrolog XG & PC DMIS Pro Gage Suite effectively to create 3D models of parts/assemblies while adhering to ISO 9001:2015 standards at all times.

- Achieved a 95% success rate in calibration of metrology lab equipment, which included 14 pieces of dimensional and mechanical measurement devices.

- Compiled over 500 inspection results for quality control processes using precision measuring instruments; reduced scrap expenses by 15%.

- Represented the Metrology Department at 10+ technical meetings, presenting accurate data collected from gauges and other testing tools to senior management.

- Mentored 2 junior technicians on proper use of various laboratory instruments such as calipers, micrometers & optical comparators; trained employees increased their skillset by 40%.

- Independently managed the maintenance program for all 35 metrology machines; completed repairs within 24 hours with minimal downtime and no complaint record reported in 4 years.

- Analyzed the accuracy of measuring instruments and tools to ensure that all production measurements were within acceptable tolerance levels; reduced measurement errors by 18%.

- Advised engineers on the best methods for inspecting, testing and calibrating precision machinery parts in accordance with industry standards; facilitated smoother product quality control processes.

- Expedited process times through proactive maintenance work on gauges, calipers, micrometers and other metrology equipment used in manufacturing plants; improved efficiency by 10% across the board.

- Calibrated over 300 digital measuring devices per month using advanced calibration software programs such as MetCal & GageSuite; minimized instances of faulty readings or miscalculations during inspections by 25%.

- Actively monitored company-wide compliance with ISO 9001/9002 requirements related to metrological practices while providing technical support to operations personnel when necessary.

- Utilized various metrology measuring tools and techniques such as calipers, micrometers, surface plate inspection and 3D laser scanning to measure components for accuracy.

- Tested over 500 parts per week with a 0.002% defect rate, exceeding quality assurance standards; saved $10,000 in production costs by fixing errors before they reached the assembly line.

- Inspected complex dimensions using advanced equipment like CMMs to ensure that features remained within tolerance parameters; reduced scrap rates by 25%.

- Developed custom programs on metrology software platforms including PC DMIS & Calypso to automate measurements and reduce manual labor time by 15 hours each month.

- Resourcefully identified areas of improvement through data analysis and collaborated with engineers/designers to create solutions which improved product performance by 10%.

- Participated in the maintenance and calibration of precision measuring instruments to ensure accuracy in readings, achieving a 30% reduction in defective parts over 2 years.

- Structured inspection procedures for incoming components and materials, developed process control plans, documented results and created preventive action plans when necessary.

- Presented quality reports on product performance & reliability to other departments such as engineering; identified root causes of issues affecting production outputs & suggested solutions that increased throughput by 10%.

- Thoroughly inspected mechanical assemblies for compliance with established standards using digital calipers, micrometers, height gauges and optical comparators; improved first-pass yield rate from 80% to 95%.

- Troubleshot failures quickly by diagnosing equipment malfunctions through visual inspections or testing devices; repaired errors before they affected production timescales resulting in at least 500 hours saved annually.

- Repaired, calibrated and maintained over 3,000 pieces of metrology equipment with a 98% success rate; reduced downtime in the calibration lab by 24 hours per month.

- Competently operated optical measurement systems and specialized tools such as micrometers, calipers and thread gauges to ensure accuracy of all measurements taken.

- Documented inspection results on reports using precision measuring instruments while adhering to industry standards; improved product quality levels by 15%.

- Assessed test data to identify any potential process or product issues before they occurred; decreased customer complaints related to inaccurate measurements by 25%.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for someone with experience in electrical metrology and another seeking a technician who is proficient with optical metrology.

Therefore, you want to tailor the skills section of your resume to each job that you are applying for. This will help ensure that any applicant tracking systems used by employers will recognize your qualifications as being relevant to their particular position.

You can further emphasize these skills by discussing them in more detail elsewhere on your resume; such as within the summary or work history sections.

Below is a list of common skills & terms:

- CMM Programming

- Calibration

- Data Analysis and Reporting

- GD&T

- ISO/IEC 17025

- Metrology Equipment Maintenance

- Precision Measurement

- Quality Control

- Statistical Process Control

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your educational qualifications below the resume objective. However, if you have been working as a metrology technician for several years with plenty of responsibilities to showcase, omitting the education section is perfectly acceptable.

If an education section is included, try to list courses related to metrology that demonstrate knowledge and skills applicable to this role.

Associate Degree in Metrology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the knowledge and skills necessary for a particular job. They are also an indication of your commitment to professional development, as they require dedication and hard work in order to obtain them.

Including certifications on your resume can be beneficial when applying for jobs, especially if those certifications are relevant or required by the position you’re seeking. Make sure to list any applicable certifications clearly so hiring managers can easily identify them.

Certified Metrology Technician

American Society for Quality (ASQ)

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Liana Klein, this would be Liana-Klein-resume.pdf or Liana-Klein-resume.docx.

7. Cover Letter

Writing a cover letter can be a great way to showcase your skills and experiences in an effective yet concise manner. It is typically two or three paragraphs long and should serve as an introduction to you, the job seeker.

Cover letters allow employers to gain insight into who you are beyond what can be seen on paper. They help bridge the gap between your resume and provide recruiters with more information about why they should consider you for the role.

Below is an example cover letter:

Dear Ron,

I am writing to apply for the position of Metrology Technician at XYZ Company. I am a recent graduate of ABC Technical Institute with an Associate’s degree in precision measurement technology. I have experience working in a metrology lab and am familiar with a variety of measuring instruments.

In my previous role, I was responsible for calibrating and repairing measuring instruments. I also performed audits of the lab to ensure compliance with ISO/IEC 17025 standards. My attention to detail and ability to follow procedures ensured that all measurements were accurate and within tolerance levels.

I am excited to bring my skills and knowledge to XYZ Company as your next Metrology Technician. In this role, I will be responsible for maintaining the quality of your products by ensuring that all measurements are precise and meet customer specifications. My experience in calibration, repair, and auditing will be valuable in this position, and I am confident that I can make a positive contribution to your team.

Thank you for your time and consideration; I look forward to speaking with you soon about this opportunity.

Sincerely,

Liana

Metrology Technician Resume Templates

Lorikeet

Lorikeet Saola

Saola Echidna

Echidna Kinkajou

Kinkajou Bonobo

Bonobo Dugong

Dugong Quokka

Quokka Hoopoe

Hoopoe Ocelot

Ocelot Numbat

Numbat Jerboa

Jerboa Gharial

Gharial Cormorant

Cormorant Rhea

Rhea Axolotl

Axolotl Fossa

Fossa Markhor

Markhor Indri

Indri Pika

Pika Rezjumei

Rezjumei