Metrology Engineer Resume Guide

Metrology Engineers are responsible for ensuring the accuracy of measurements in a variety of industries. They use their knowledge and expertise to develop, maintain, calibrate and troubleshoot measuring instruments such as calipers, micrometers and other tools used to measure length, angle or surface finish. Additionally, they analyze data collected from these instruments to ensure quality control standards are met.

You have the expertise to design and implement precision measuring instruments, yet employers don’t know who you are. To make them aware of your qualifications, put together a resume that highlights your experience in metrology engineering.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

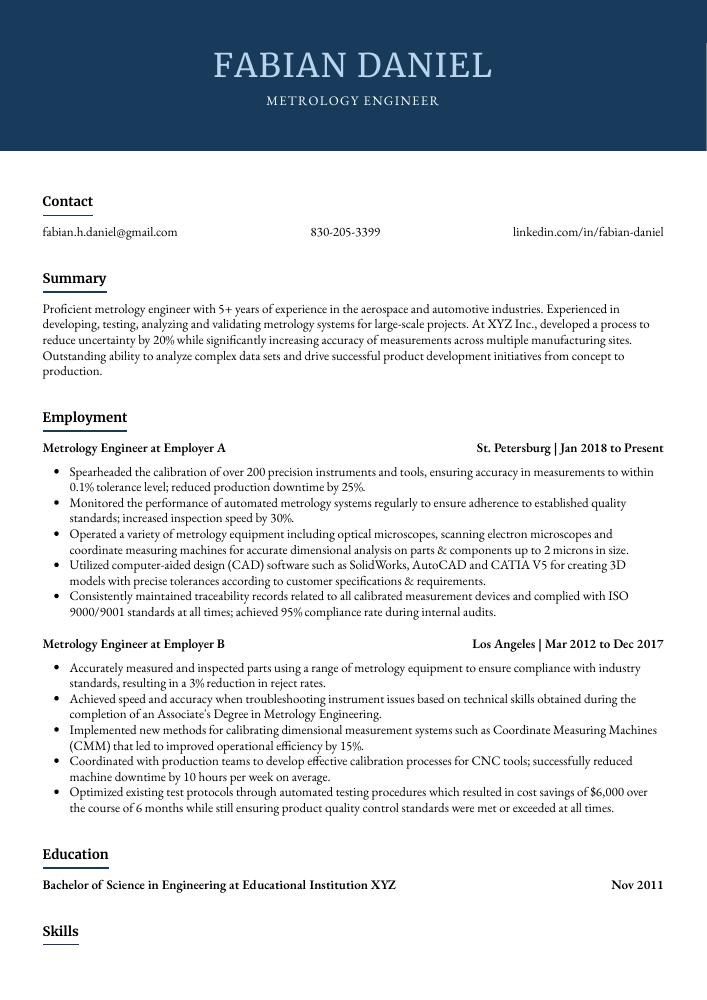

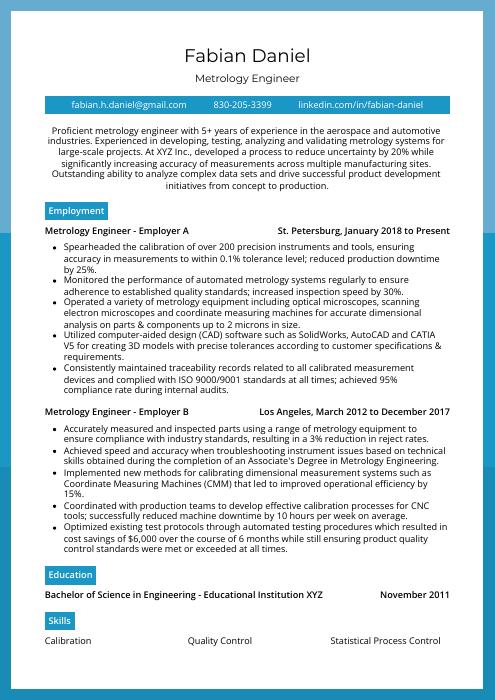

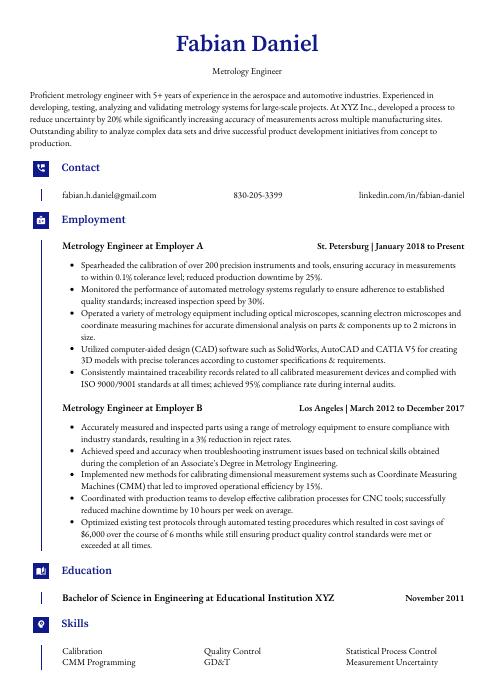

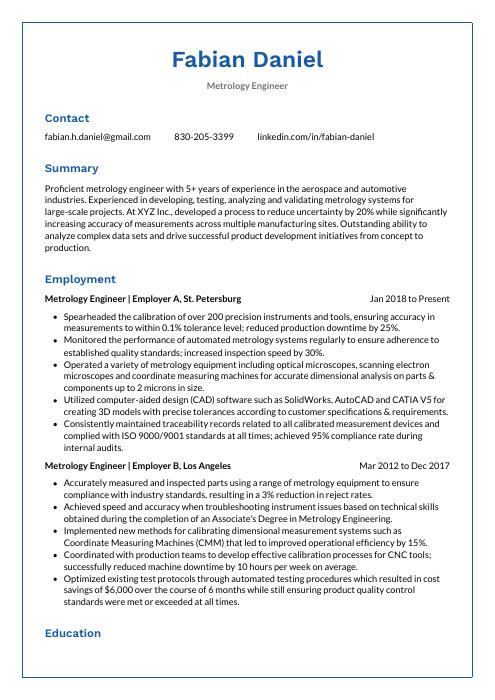

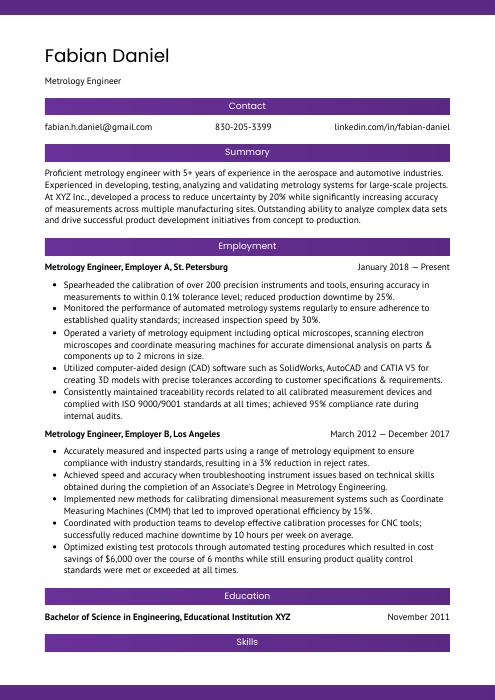

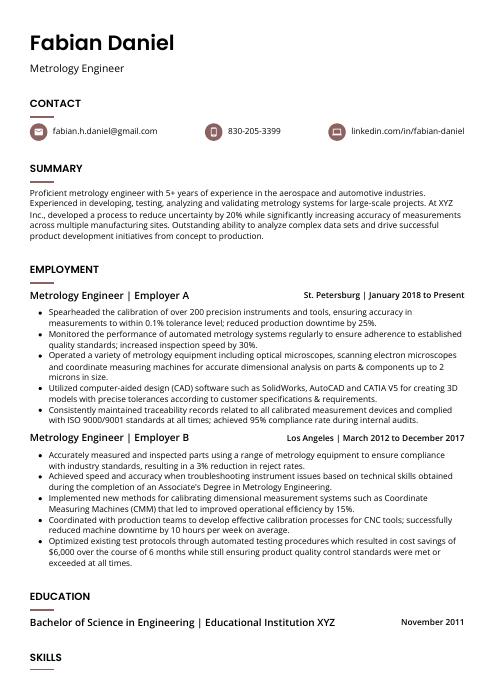

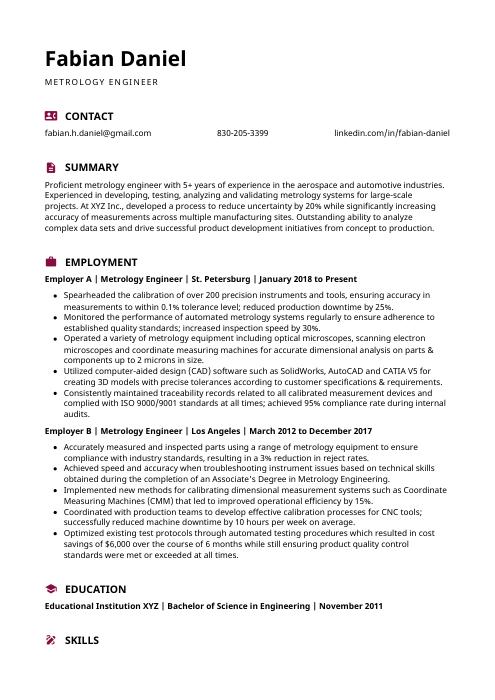

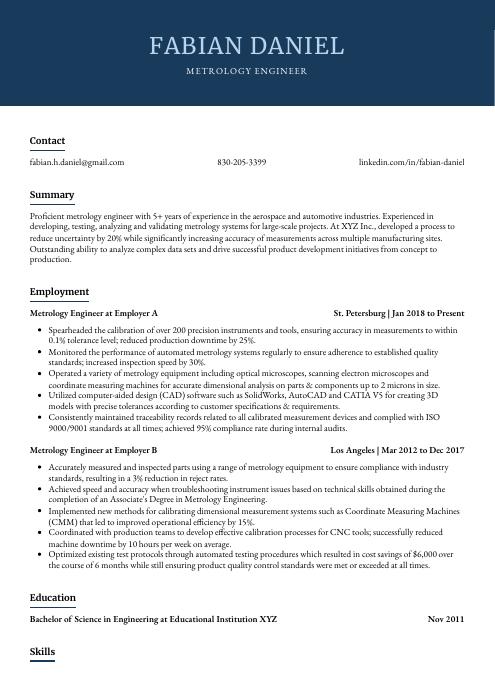

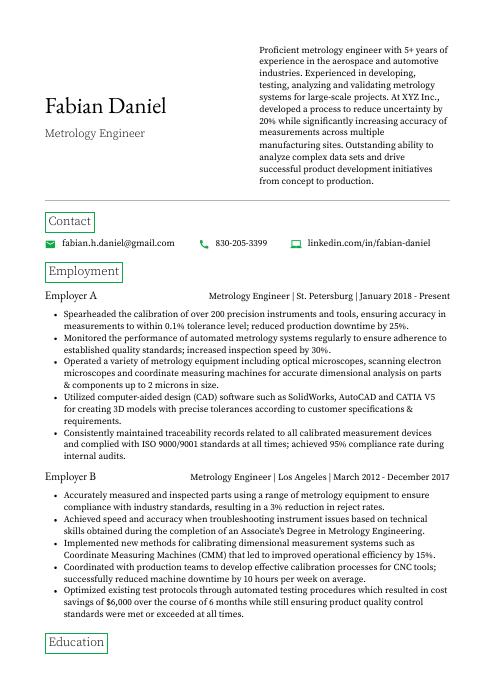

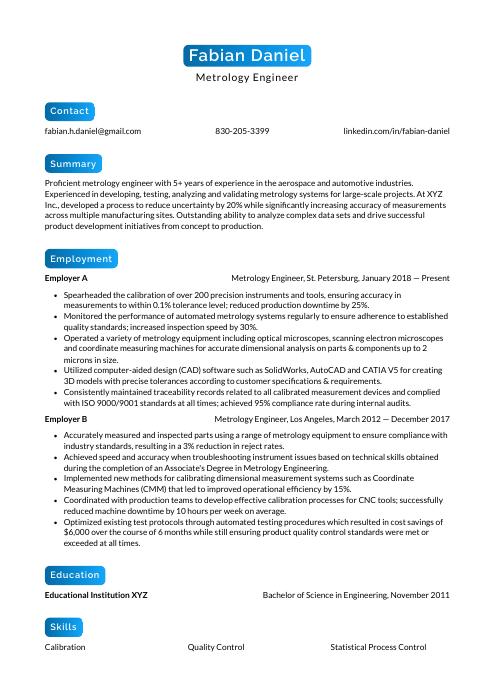

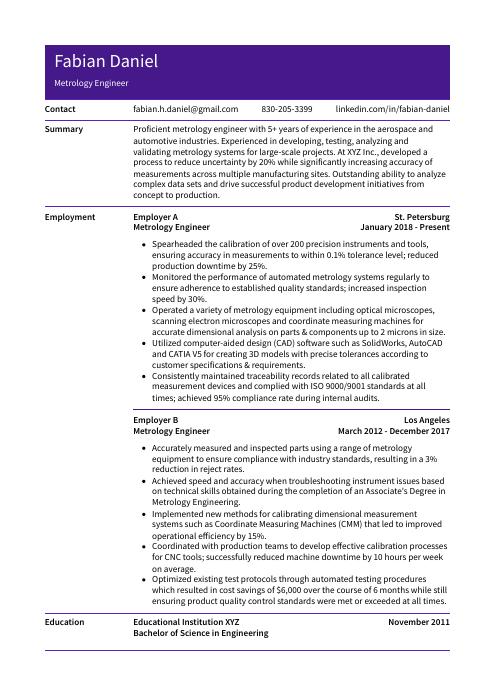

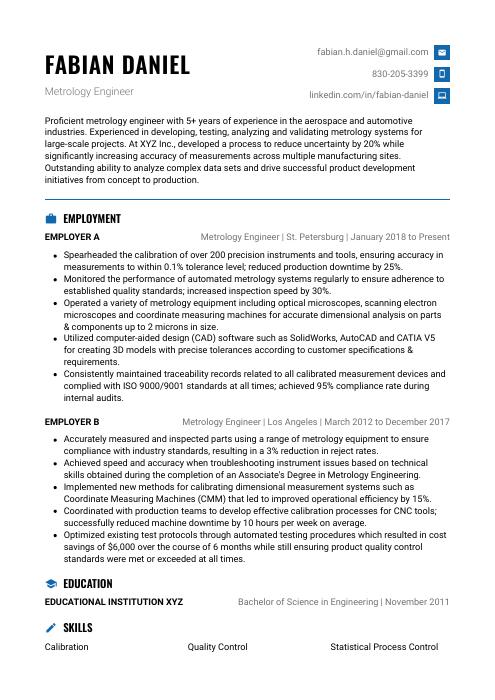

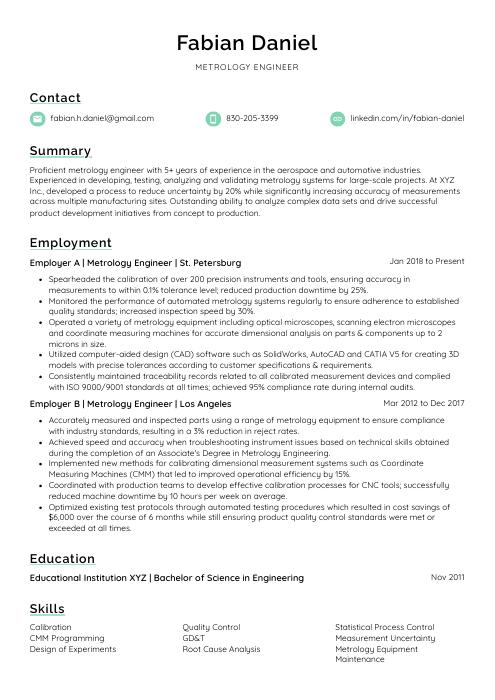

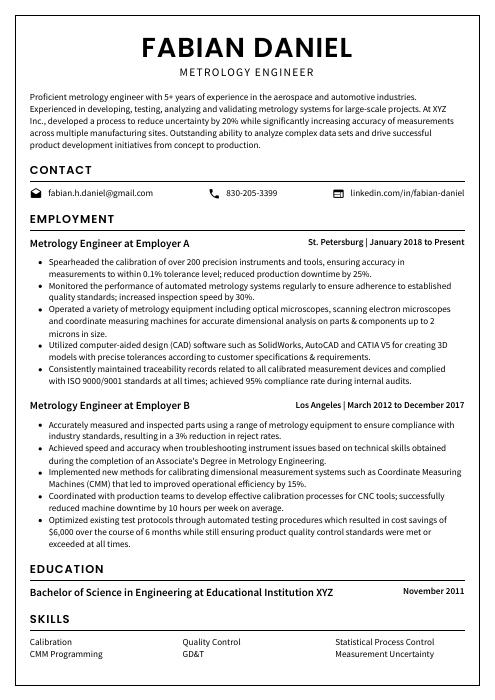

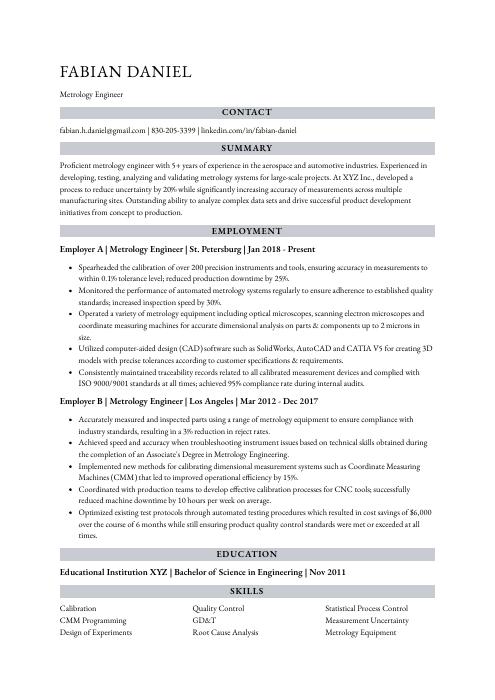

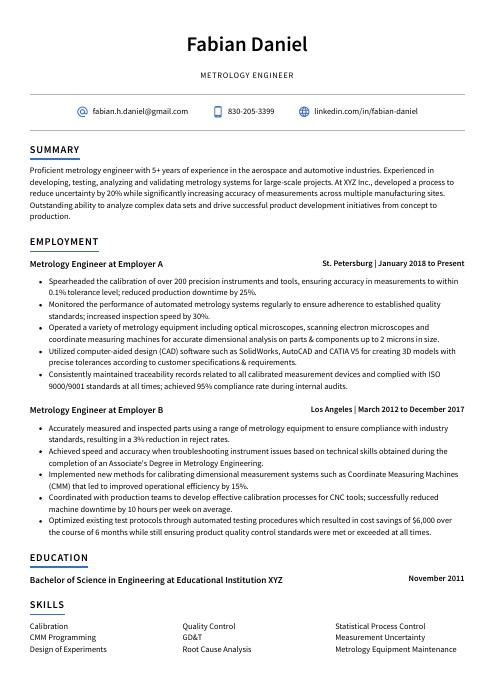

Metrology Engineer Resume Sample

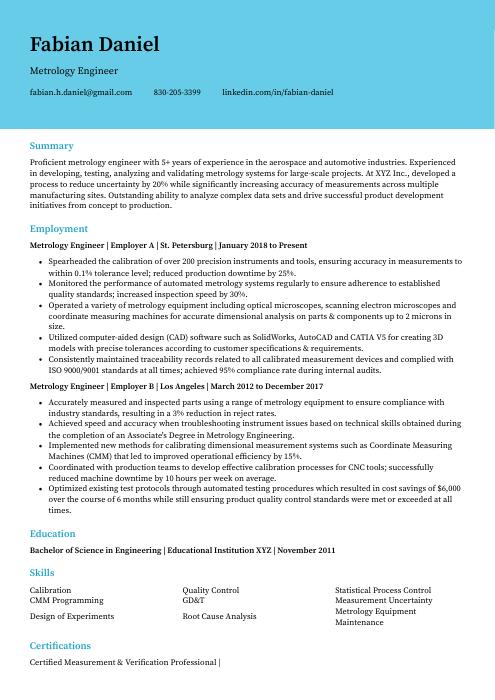

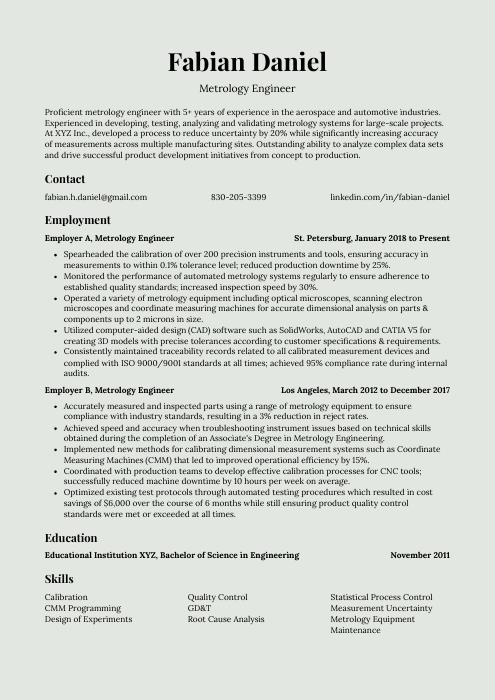

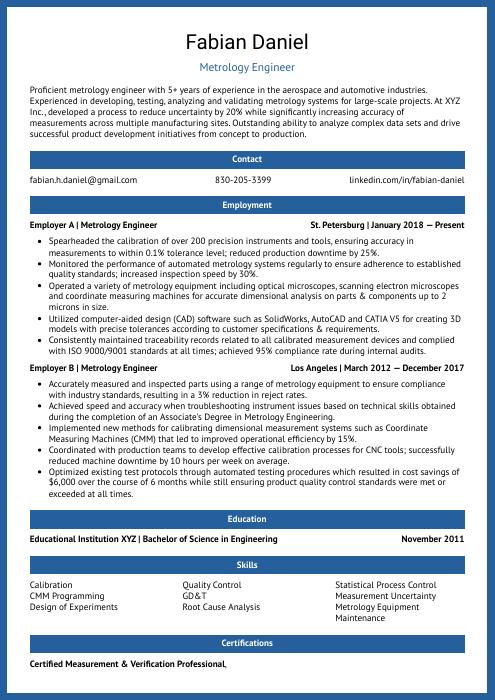

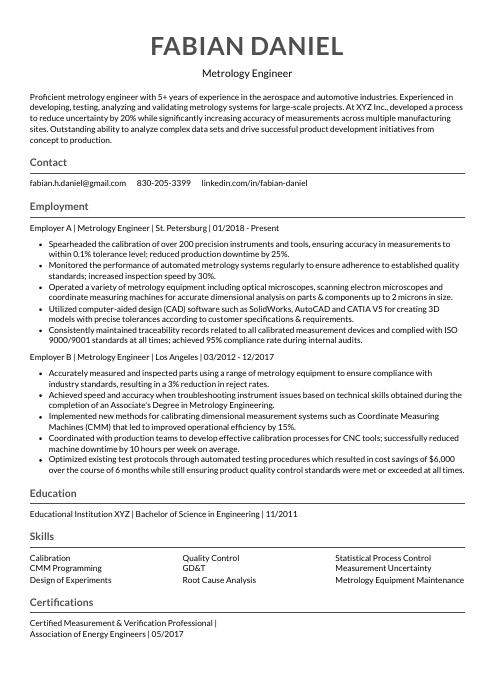

Fabian Daniel

Metrology Engineer

fabian.h.daniel@gmail.com

830-205-3399

linkedin.com/in/fabian-daniel

Summary

Proficient metrology engineer with 5+ years of experience in the aerospace and automotive industries. Experienced in developing, testing, analyzing and validating metrology systems for large-scale projects. At XYZ Inc., developed a process to reduce uncertainty by 20% while significantly increasing accuracy of measurements across multiple manufacturing sites. Outstanding ability to analyze complex data sets and drive successful product development initiatives from concept to production.

Experience

Metrology Engineer, Employer A

St. Petersburg, Jan 2018 – Present

- Spearheaded the calibration of over 200 precision instruments and tools, ensuring accuracy in measurements to within 0.1% tolerance level; reduced production downtime by 25%.

- Monitored the performance of automated metrology systems regularly to ensure adherence to established quality standards; increased inspection speed by 30%.

- Operated a variety of metrology equipment including optical microscopes, scanning electron microscopes and coordinate measuring machines for accurate dimensional analysis on parts & components up to 2 microns in size.

- Utilized computer-aided design (CAD) software such as SolidWorks, AutoCAD and CATIA V5 for creating 3D models with precise tolerances according to customer specifications & requirements.

- Consistently maintained traceability records related to all calibrated measurement devices and complied with ISO 9000/9001 standards at all times; achieved 95% compliance rate during internal audits.

Metrology Engineer, Employer B

Los Angeles, Mar 2012 – Dec 2017

- Accurately measured and inspected parts using a range of metrology equipment to ensure compliance with industry standards, resulting in a 3% reduction in reject rates.

- Achieved speed and accuracy when troubleshooting instrument issues based on technical skills obtained during the completion of an Associate’s Degree in Metrology Engineering.

- Implemented new methods for calibrating dimensional measurement systems such as Coordinate Measuring Machines (CMM) that led to improved operational efficiency by 15%.

- Coordinated with production teams to develop effective calibration processes for CNC tools; successfully reduced machine downtime by 10 hours per week on average.

- Optimized existing test protocols through automated testing procedures which resulted in cost savings of $6,000 over the course of 6 months while still ensuring product quality control standards were met or exceeded at all times.

Skills

- Calibration

- Quality Control

- Statistical Process Control

- CMM Programming

- GD&T

- Measurement Uncertainty

- Design of Experiments

- Root Cause Analysis

- Metrology Equipment Maintenance

Education

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Measurement & Verification Professional

Association of Energy Engineers

May 2017

1. Summary / Objective

The summary or objective at the beginning of your metrology engineer resume should provide a snapshot of who you are and why you’re an ideal candidate for the job. In this section, be sure to highlight any relevant experience or certifications that make you stand out from other applicants. You could also mention how many years of experience in metrology engineering you have, what types of instruments/software tools you are proficient with, and any awards or recognition received for your work.

Below are some resume summary examples:

Accomplished metrology engineer with more than 10 years of experience in precision measurement and quality control. Skilled at developing custom metrology solutions, calibrating complex equipment, and troubleshooting technical issues. At XYZ, reduced calibration turnaround time by 20% through the implementation of an automated system for measuring accuracy and repeatability. Received outstanding reviews from supervisors for demonstrating excellence in all aspects of engineering work.

Talented metrology engineer with 10+ years of experience in the technology and engineering industry. Expertise in calibrating, maintaining, and troubleshooting instruments used for testing, measuring, and analyzing production processes. Skilled at developing innovative solutions to improve metrics accuracy while meeting customer specifications. Consistently awarded for excellence in operational efficiency improvements resulting from new metrology techniques introduced by me.

Committed metrology engineer with 4+ years of experience in the aerospace and defense industry. Skilled at developing, improving, and implementing metrology processes to ensure quality control for production parts. At XYZ Corporation, developed a new laser scanning procedure that reduced inspection time by 60%. Recognized as an outstanding employee after saving the company $50K through process optimization initiatives.

Well-rounded metrology engineer with 10+ years of experience in the field, as well as knowledge and expertise in a variety of metrology tools. Diverse background includes designing high-precision measuring systems for manufacturing processes, developing calibration standards, and troubleshooting issues. Seeking to join ABC Company to utilize my skillset towards optimizing product quality control solutions.

Diligent metrology engineer with 8+ years of experience designing, calibrating and testing a variety of sophisticated measurement instruments. Seeking to join ABC Tech where I can use my expertise in metrology to ensure accuracy and repeatability on products within its global reach. In previous roles, improved calibration times by 22% while maintaining the highest quality standards for all measurements.

Determined metrology engineer with a track record of success in the development, design and implementation of complex metrologic processes. 8+ years of experience leading projects from conception to completion while working within prescribed timeframes and budgets. At XYZ Corporation, developed an innovative method for accurately measuring small parts which resulted in increased efficiency by 20%.

Enthusiastic metrology engineer with 5+ years of experience in precision measurement and instrumentation. Skilled in metrology principles, laser interferometry, 3D optical profiling systems, and statistical process control (SPC). Technology-savvy professional seeking to join ABC’s team to create world-class visual inspection solutions for the company’s diverse customer base.

Energetic metrology engineer with 8+ years of experience developing, deploying and managing metrology operations. Proven track record of streamlining processes to ensure accuracy, reliability, and efficiency in all metrological measurements. Seeking a role at ABC Tech to apply expertise in systems optimization for consistent results across multiple industries.

2. Experience / Employment

In the experience section, you should provide details on your employment history. This section should be written in reverse chronological order, meaning the most recent job is listed first.

When talking about what you did at each role, stick to bullet points as much as possible. Doing so makes it easier for the reader to take in all of the information quickly and accurately. You want to think carefully when writing out these bullet points; instead of saying “Calibrated instruments,” explain exactly how you calibrated them and any results that were achieved from doing so.

For example, instead of just saying “Calibrated instruments,” say something like “Performed calibrations on a variety of metrology equipment using both manual and automated techniques resulting in an average accuracy rate improvement by 8%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Calibrated

- Measured

- Analyzed

- Inspected

- Tested

- Programmed

- Documented

- Troubleshot

- Operated

- Designed

- Monitored

- Improved

- Implemented

- Developed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Calibrated and maintained a wide range of precision measuring instruments, including optical comparators, coordinate measurement machines and micrometers; reduced downtime by 25% over the course of 3 months.

- Efficiently inspected mechanical components to determine conformance with customer specifications using CMM software programs such as PC-DMIS and Verisurf; improved accuracy in measurements up to 0.0005” tolerance level on all parts examined.

- Improved existing metrology processes through regular analysis of equipment performance data and generated comprehensive reports for continuous improvement initiatives which were implemented across several departments within the organization.

- Represented the company at various industry events & conferences related to metrology engineering topics, demonstrating deep knowledge on current trends in quality assurance practices while networking with peers from different industries worldwide.

- Troubleshot technical issues related to automated inspection systems (AOI) used for product testing & evaluation purposes, resulting in increased machine uptime by 40%.

- Measured, inspected and tested over 300+ components using precision metrology instruments such as calipers, micrometers, optical comparators and coordinate measuring machines (CMMs), resulting in a 20% decrease of production errors.

- Streamlined inspection processes by developing automated data acquisition programs for CMM machines to reduce cycle time by 25%.

- Independently wrote reports for all measurement results with precise accuracy; ensured that products were constructed according to customer requirements and quality standards before releasing them into the market.

- Assisted Quality Control department with calibration activities on a periodic basis; achieved 100% compliance rate within the designated timeline following ISO 9001 guidelines consistently throughout employment tenure at company XYZ.

- Facilitated continuous improvement initiatives which resulted in reducing scrap costs due to defect prevention measures by 10%.

- Reduced the time spent on calibrating pressure, temperature and voltage related instruments by 35%, through the introduction of automated calibration processes.

- Revised existing metrology specifications to ensure compliance with industry standards; conducted regular reviews while supervising team of 3 technicians in a lab environment.

- Confidently operated advanced measuring equipment such as coordinate measurement machines (CMM) and surface roughness testers to measure mechanical components for accuracy and quality assurance purposes.

- Introduced new methods to monitor instrument performance over long-term periods, resulting in an increase of uptime from 80% to 95%.

- Reorganized the inventory system within the laboratory, leading to improved efficiency which reduced turnaround times by 20%.

- Developed and implemented calibration plans and procedures for over 200 metrology instruments, ensuring accuracy of all readings to within 0.05%.

- Documented test results in accordance with ISO/IEC 17025 requirements; successfully reduced errors by up to 15% across a range of measurement processes.

- Compiled detailed reports summarizing findings from various types of tests including dimensional analysis, force & torque measurements and pressure gauge calibrations; saved 2 hours per report on average due to improved data processing techniques.

- Tested a variety of precision measuring devices such as calipers, micrometers, gauges and scales according to customer specifications while adhering strictly to industry standards; completed 500+ inspections with zero discrepancies in the last 12 months alone.

- Reliably maintained an inventory database comprising 10K+ items used for testing purposes; decreased cost overruns associated with unnecessary purchases by 20%.

- Analyzed and calibrated a range of measuring instruments, such as calipers and micrometers, to ensure accuracy and precision in the measurement of parts; reduced calibration errors by 12%.

- Competently utilized statistical process control (SPC) methods on various manufacturing processes resulting in an increase in product quality by 11%.

- Demonstrated excellent problem-solving abilities when troubleshooting metrology systems; identified faults within minutes and fixed them for 30+ machines daily.

- Assessed supplier equipment for conformance to ISO/IEC 17025 standards with 0% nonconformities reported over a period of 6 months.

- Programmed automated inspection processes into CMM software programs to reduce manual data entry time from 10 hours per day to 2 hours per day on average while maintaining accuracy levels above 95%.

- Diligently conducted over 200 dimensional, mechanical and optical tests on parts to ensure accuracy of measurements in accordance with applicable industry standards; successfully reduced product defects by 25%.

- Prepared comprehensive calibration reports for various instruments used in metrology operations and identified areas for improvement based on results obtained from tests.

- Structured quality control activities according to client specifications while maintaining a high level of precision; achieved 99% compliance rate during internal audits.

- Formulated detailed maintenance schedules for laboratory equipment such as calipers, micrometers and other measuring tools to optimize performance levels across all systems.

- Advised management team on the selection of appropriate measurement techniques depending upon the nature of components being tested; improved productivity by 30%.

- Thoroughly inspected, tested and calibrated measuring instruments to ensure accuracy in accordance with ISO standards; reduced measurement errors by 25%.

- Mentored 3 junior engineers on the use of precision measurements equipment, thereby increasing their productivity by 50% within 6 months.

- Presented a detailed analysis report on existing metrology processes at company conferences and proposed solutions that led to a 15% reduction in costs over 12 months.

- Participated actively in 5 design reviews for new products, providing valuable feedback that improved product quality and allowed for cost savings of $20K+.

- Designed innovative solutions using C# programming language which enhanced data acquisition speed by 30%, allowing metrics to be collected faster than ever before.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require a metrology engineer with experience in optical inspection, and Organization XYZ may need someone knowledgeable about dimensional measurement.

It is essential to tailor the skills section of your resume for each job you apply for because many employers use applicant tracking systems these days, which are computer programs that scan resumes for certain keywords before passing them on to a human.

In addition to listing relevant skills here, it’s also important to discuss them further in other sections of your resume – such as the summary or experience section.

Below is a list of common skills & terms:

- CMM Programming

- Calibration

- Design of Experiments

- GD&T

- ISO/IEC 17025 Compliance

- Measurement Uncertainty

- Metrology Equipment Maintenance

- Quality Control

- Root Cause Analysis

- Statistical Process Control

4. Education

Mentioning your education on a metrology engineer resume will depend on your experience level. If you are just starting out and have no prior work experience, include an education section below your resume objective. However, if you have been working in the field for years and want to showcase that instead of any academic achievements, then leaving out this section is fine too.

If you decide to include an education section, try to mention courses or subjects related to the job as a metrology engineer that demonstrate your expertise in this area.

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field and can be the deciding factor for potential employers. Include any certifications you have obtained that are relevant to the job you’re applying for, as this will show that you are well-versed in the necessary skillset.

It is also beneficial to include any professional development courses or seminars that you have taken part in, as these can give hiring managers an insight into how up-to-date your knowledge of industry trends is.

Certified Measurement & Verification Professional

Association of Energy Engineers

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Fabian Daniel, this would be Fabian-Daniel-resume.pdf or Fabian-Daniel-resume.docx.

7. Cover Letter

Including a cover letter in your job application is a great way to make an impression on the hiring manager. Not only does it provide them with more information about who you are and why you’re interested in the role, but it also allows you to demonstrate how well-suited you are for the position.

Cover letters should be made up of 2 to 4 paragraphs that expand upon what’s already stated in your resume. They should include details such as relevant skills or experience, accomplishments and any other unique qualities that set yourself apart from other applicants.

Below is an example cover letter:

Dear Bria,

I am writing in response to your job posting for a Metrology Engineer. With extensive experience working in the metrology field and a strong background in engineering, I am confident that I would be a valuable asset to your team.

In my current role as Metrology Engineer at [company name], I oversee all aspects of calibration and measurement for our products. This includes developing calibration procedures, conducting measurements, and analyzing data to ensure accuracy. I have also led several projects to improve our calibration process, including implementing new software to streamline data collection and analysis.

My experience has given me a deep understanding of metrology principles and how they can be applied in an industrial setting. I am also familiar with various types of measuring equipment and how to use them properly. In addition, my engineering skills allow me to develop creative solutions to complex problems.

I believe that my skills and experience make me an ideal candidate for the Metrology Engineer position at your company. I look forward to discussing this opportunity further with you soon.

Sincerely,

Fabian

Metrology Engineer Resume Templates

Rhea

Rhea Gharial

Gharial Markhor

Markhor Dugong

Dugong Saola

Saola Ocelot

Ocelot Indri

Indri Jerboa

Jerboa Fossa

Fossa Hoopoe

Hoopoe Bonobo

Bonobo Quokka

Quokka Kinkajou

Kinkajou Pika

Pika Echidna

Echidna Lorikeet

Lorikeet Cormorant

Cormorant Numbat

Numbat Axolotl

Axolotl Rezjumei

Rezjumei