Metallurgical Technician Resume Guide

Metallurgical Technicians are responsible for the analysis and testing of metal samples, as well as providing support to engineers in their research. They use a variety of methods such as heat treatment, chemical composition analysis, mechanical tests and microscopic examination to evaluate metals and alloys.

You have a natural knack for metalwork and welding, but hiring managers don’t know about your expertise. To get them to take notice of you, you must create a resume that stands out from the competition.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

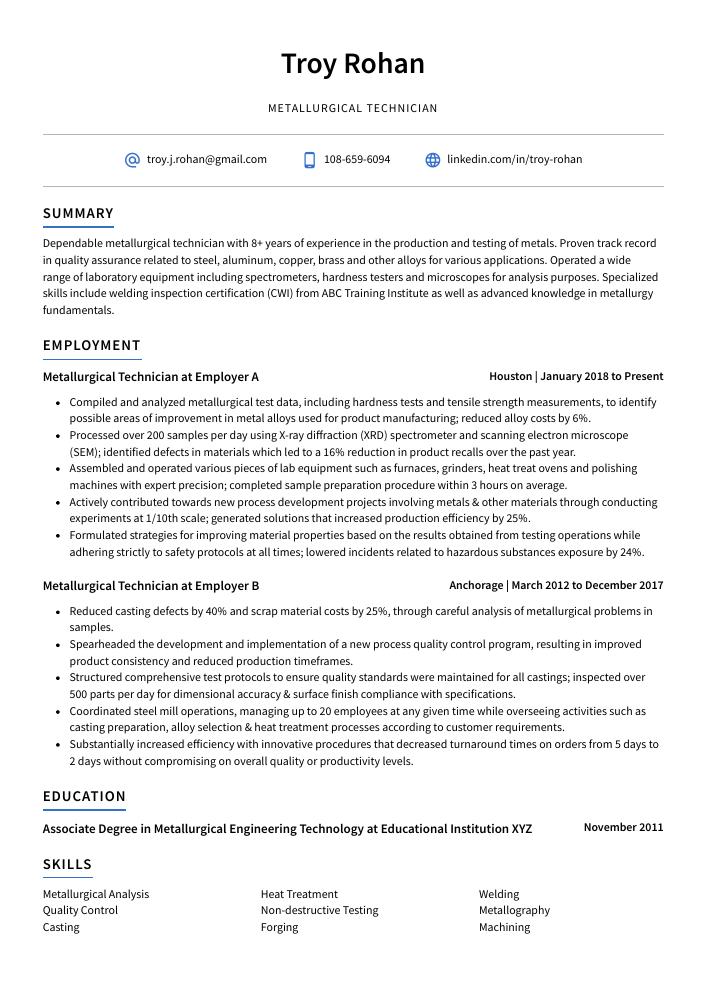

Metallurgical Technician Resume Sample

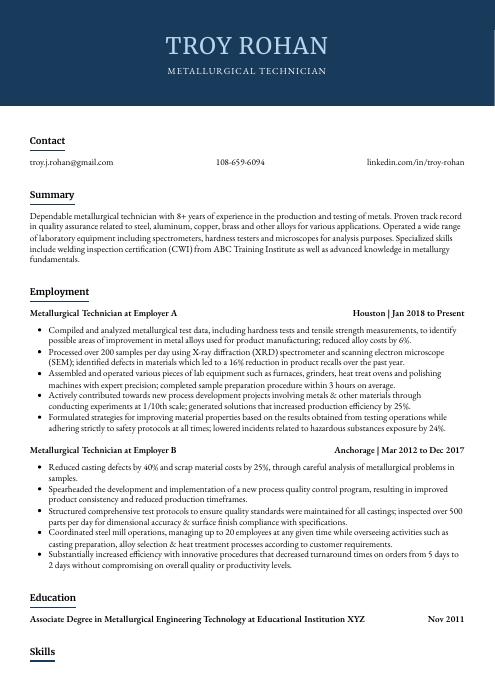

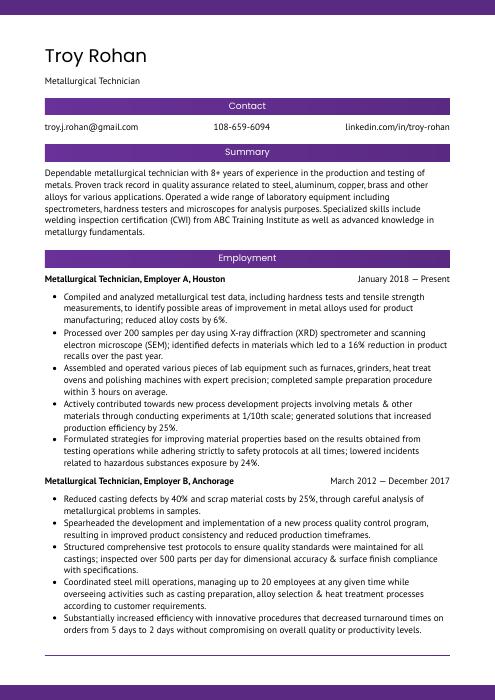

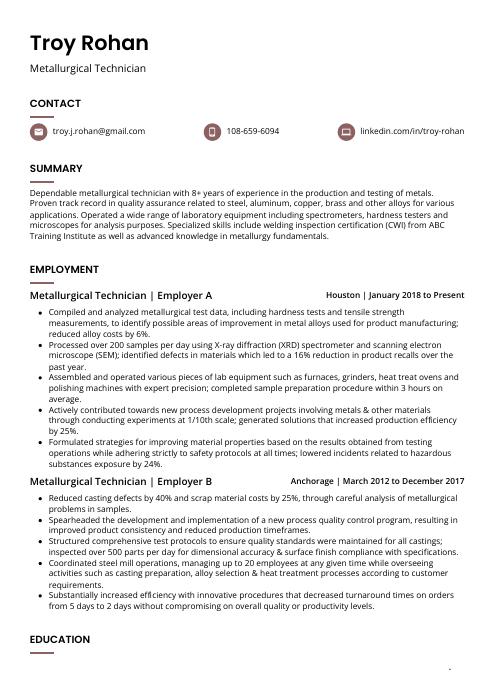

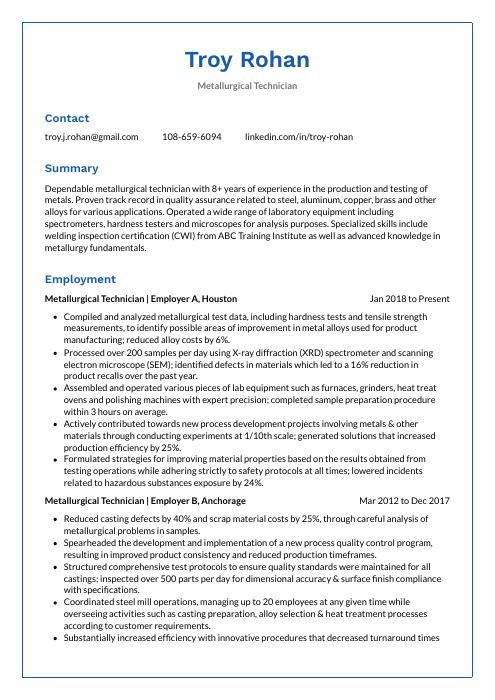

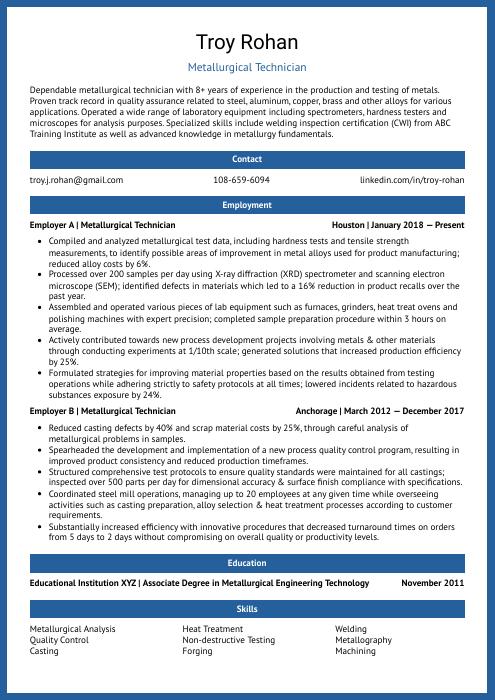

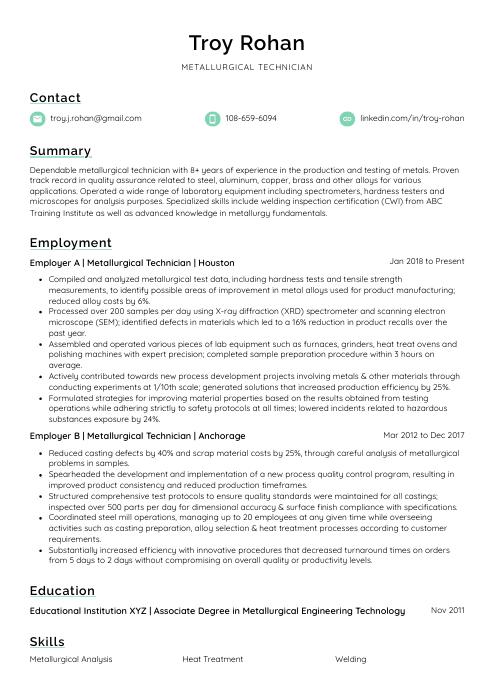

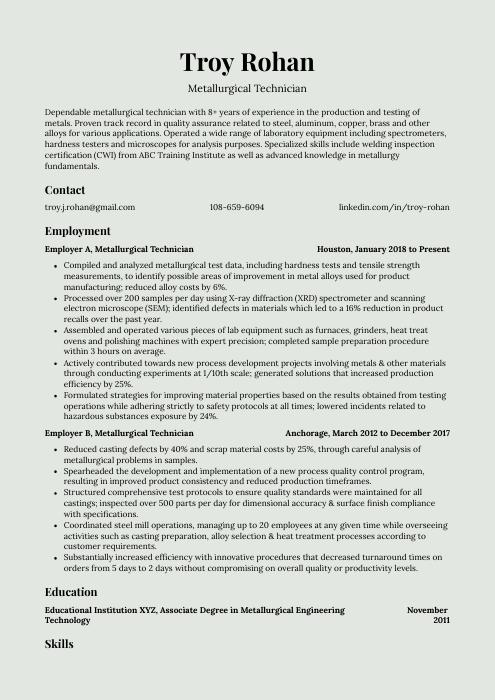

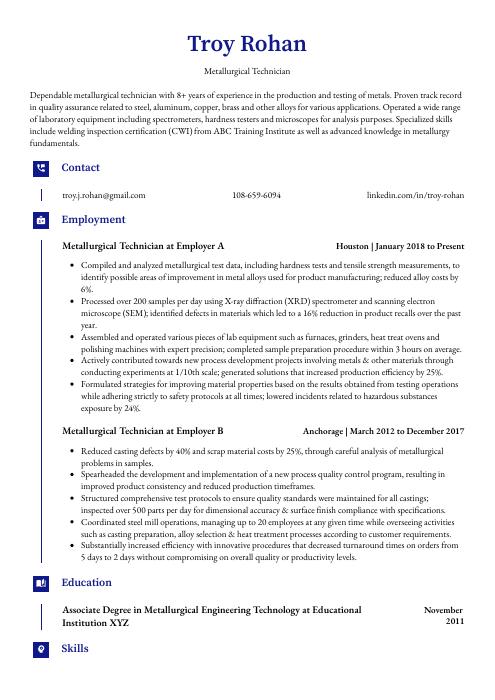

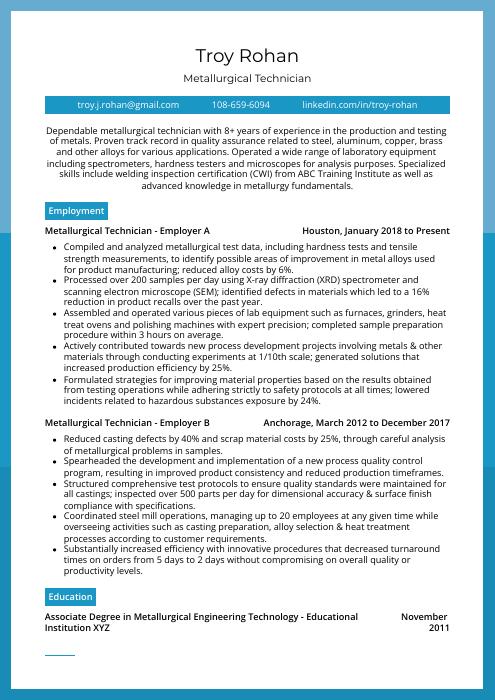

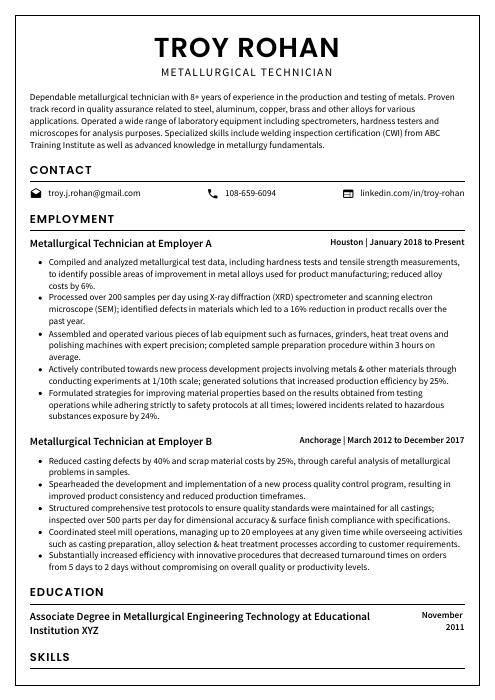

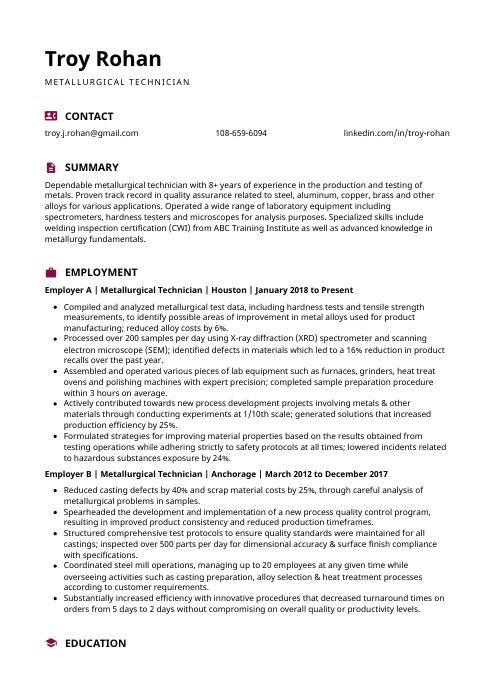

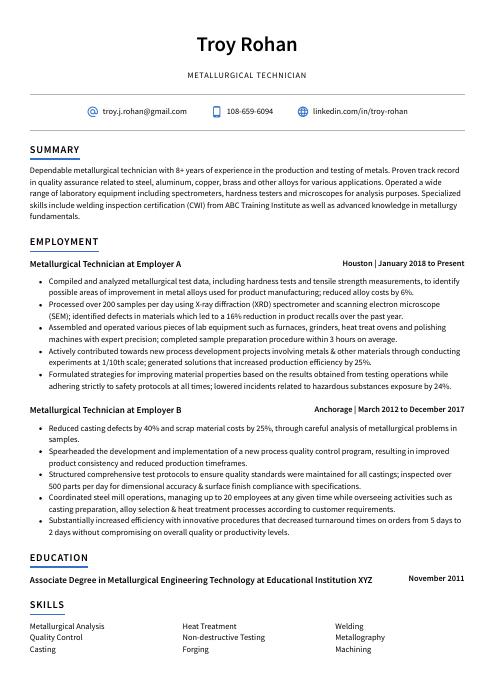

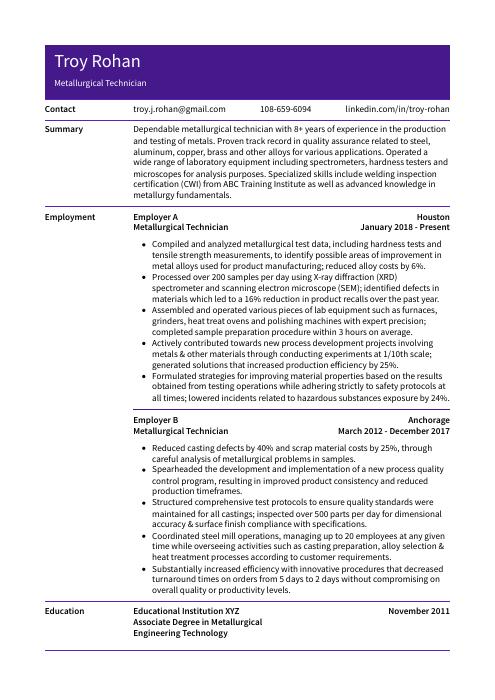

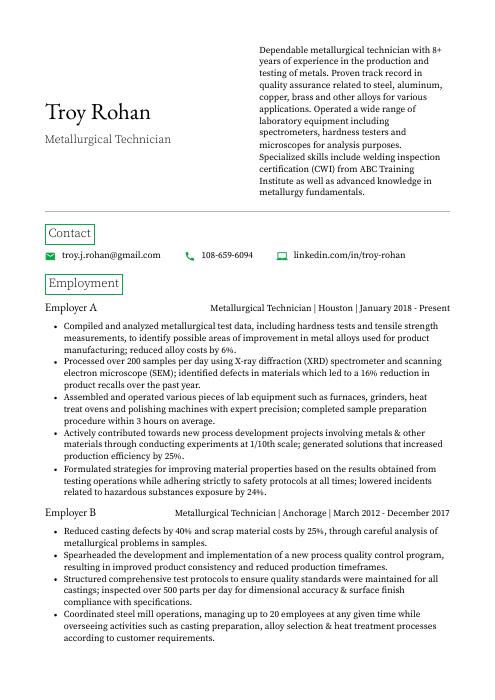

Troy Rohan

Metallurgical Technician

[email protected]

108-659-6094

linkedin.com/in/troy-rohan

Summary

Dependable metallurgical technician with 8+ years of experience in the production and testing of metals. Proven track record in quality assurance related to steel, aluminum, copper, brass and other alloys for various applications. Operated a wide range of laboratory equipment including spectrometers, hardness testers and microscopes for analysis purposes. Specialized skills include welding inspection certification (CWI) from ABC Training Institute as well as advanced knowledge in metallurgy fundamentals.

Experience

Metallurgical Technician, Employer A

Houston, Jan 2018 – Present

- Compiled and analyzed metallurgical test data, including hardness tests and tensile strength measurements, to identify possible areas of improvement in metal alloys used for product manufacturing; reduced alloy costs by 6%.

- Processed over 200 samples per day using X-ray diffraction (XRD) spectrometer and scanning electron microscope (SEM); identified defects in materials which led to a 16% reduction in product recalls over the past year.

- Assembled and operated various pieces of lab equipment such as furnaces, grinders, heat treat ovens and polishing machines with expert precision; completed sample preparation procedure within 3 hours on average.

- Actively contributed towards new process development projects involving metals & other materials through conducting experiments at 1/10th scale; generated solutions that increased production efficiency by 25%.

- Formulated strategies for improving material properties based on the results obtained from testing operations while adhering strictly to safety protocols at all times; lowered incidents related to hazardous substances exposure by 24%.

Metallurgical Technician, Employer B

Anchorage, Mar 2012 – Dec 2017

- Reduced casting defects by 40% and scrap material costs by 25%, through careful analysis of metallurgical problems in samples.

- Spearheaded the development and implementation of a new process quality control program, resulting in improved product consistency and reduced production timeframes.

- Structured comprehensive test protocols to ensure quality standards were maintained for all castings; inspected over 500 parts per day for dimensional accuracy & surface finish compliance with specifications.

- Coordinated steel mill operations, managing up to 20 employees at any given time while overseeing activities such as casting preparation, alloy selection & heat treatment processes according to customer requirements.

- Substantially increased efficiency with innovative procedures that decreased turnaround times on orders from 5 days to 2 days without compromising on overall quality or productivity levels.

Skills

- Metallurgical Analysis

- Heat Treatment

- Welding

- Quality Control

- Non-destructive Testing

- Metallography

- Casting

- Forging

- Machining

Education

Associate Degree in Metallurgical Engineering Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Metallurgical Technician (CMT)

American Society for N

May 2017

1. Summary / Objective

Your resume summary should be a brief introduction to your metallurgical technician experience and qualifications. It should provide the employer with an overview of why you are the ideal candidate for the job. For example, you could mention that you have extensive knowledge of metalworking processes, such as welding and casting; that you have successfully completed projects involving complex materials; or that your attention to detail has resulted in consistently high-quality results.

Below are some resume summary examples:

Driven metallurgical technician with over 5 years of experience in metallurgy and welding processes. Experienced in performing a variety of tests to measure mechanical properties, including tensile strength, hardness testing, fatigue life determination and other complex procedures. Proven track record for ensuring quality control standards are maintained at all stages of production process. Dedicated to providing high-quality services that meet customer needs while maintaining cost efficiency goals.

Passionate metallurgical technician with 5+ years of experience in product development and testing. Proven track record of developing cost-effective, high quality products that exceed customer expectations. Experienced in analyzing data to provide valuable insights into materials properties and performance characteristics. Expertise includes metallography, corrosion analysis, failure analysis, heat treatment process optimization and XRD/XRF sample preparation & data collection.

Proficient Metallurgical Technician with 5+ years of experience in metallurgy laboratory operations and testing. Skilled at performing tests on metal samples, analyzing results, and providing detailed reports to meet customer requirements. Experienced in the use of a variety of lab equipment including microscopes and spectrometers. Demonstrated ability to work accurately under pressure within tight deadlines while maintaining high safety standards.

Diligent metallurgical technician with 8+ years of experience in laboratory and manufacturing environments. Experienced in metallography, failure analysis, welding technology, non-destructive testing (NDT), and X-ray diffraction. Seeking to join ABC as Metallurgical Technician to utilize expertise in performing chemical tests on metals for quality assurance purposes. Key achievements include doubling the production rate while reducing scrap by 15%.

Reliable metallurgical technician with 8 years of experience in the field. Expertise in metallurgy and a proven track record of successfully executing projects from start to finish. Experienced in conducting tests, analyzing data, and performing maintenance on equipment for various metalworking applications. Committed to providing high-quality service that meets customer requirements within budget constraints.

Well-rounded metallurgical technician with 5+ years of experience conducting complex chemical and physical tests on metals. Proficient in the use of a variety of laboratory equipment, including X-ray diffractometers and optical microscopes. Proven track record for providing accurate test results that have enabled clients to optimize their production process while improving product quality at ABC Company.

Skilled metallurgical technician with 5+ years of hands-on experience in the metal fabrication industry. Demonstrated expertise in testing and analyzing metals for quality control purposes using a variety of techniques, including XRF spectroscopy, hardness tester methods, and grain size analysis. Seeking to join ABC Technologies to ensure product excellence through rigorous laboratory tests.

Committed metallurgical technician with 6+ years of experience in heat treatment, welding, fabrication and inspection. Adept at performing complex testing methods to ensure production standards are met while upholding safety protocols. Looking to join ABC Manufacturing as a Metallurgical Technician and leverage my expertise to help boost operational efficiency within the organization.

2. Experience / Employment

The employment (or experience) section is where you talk about your work history. This should be written in reverse chronological order, which means the most recent job is listed first.

When writing this section, stick to bullet points; doing so makes it easier for the reader to quickly digest what you want to say. When providing details on each role, explain what tasks were completed and any results achieved (if applicable).

For example, instead of saying “Performed metallurgical tests,” you could say: “Conducted hardness testing on metals using Rockwell C-scale equipment and analyzed data with statistical methods.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Analyzed

- Operated

- Fabricated

- Measured

- Calibrated

- Welded

- Assembled

- Tested

- Troubleshot

- Monitored

- Processed

- Formulated

- Refined

- Sampled

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Utilized X-ray fluorescence, optical microscopy and other analytical methods to analyze microstructures of steel samples; identified 4 new alloys that are more resistant to corrosion and oxidation.

- Sampled over 300 metal specimens every month for testing purposes, ensuring quality control standards were met with a 99% accuracy rate.

- Consistently monitored the properties of metals such as hardness, tensile strength & ductility during heat treatment processes; improved production time by 30%.

- Streamlined sample preparation techniques to reduce errors in laboratory tests & experiments; decreased turnaround times from 20 hours down to 12 hours per specimen on average.

- Troubleshot mechanical issues within fabrication machinery used for cutting/forming/welding operations; saved an estimated $12,000 in equipment repairs last year alone due to early detection efforts.

- Revised quality control protocols and processes for metallurgical laboratory testing, resulting in a 10% improvement of product safety standards.

- Represented the company at trade shows, conferences and industry events to promote their products; successfully secured 2 new accounts through strategic networking efforts.

- Calibrated complex machinery used in metal fabrication processes on a regular basis to ensure quality assurance standards were exceeded by 50%.

- Mentored junior technicians in techniques related to welding inspection, heat treatment analysis and non-destructive testing; trained 5+ employees over the course of 3 years with 100% positive feedback from superiors.

- Successfully completed 6 large scale projects involving materials such as steel alloys, aluminum composites & titanium within tight deadlines while maintaining high levels of accuracy throughout each process stage.

- Tested the mechanical and chemical properties of metallic materials such as steel, aluminum, copper and titanium according to industry standards; successfully identified structural weaknesses in 15% of samples.

- Presented data from metallurgical tests clearly in formal reports and analyzed the results accurately to inform decisions by production managers; reduced process development time by 30%.

- Reliably operated specialized laboratory equipment including spectrometers, hardness testers and X-ray diffraction devices with minimum supervision for up to 8 hours per day.

- Assessed quality control processes throughout all stages of metal fabrication operations and suggested alternative solutions that improved product reliability by 22%.

- Operated a variety of machining tools including lathes, grinders & drill presses in order to cut raw metals into precise shapes before heat treatment processes were conducted on them.

- Welded and joined metal components for over 500 industrial and automotive parts in the last year, reducing welding time by 30% on average.

- Developed metallurgical tests to determine properties of metals such as hardness, ductility and corrosion resistance; improved testing accuracy by 15%.

- Improved existing steel alloys using heat treatment processes including annealing, tempering and solution treating; raised overall product strength by 25%.

- Resourcefully solved assembly issues onsite utilizing advanced welding techniques that minimized any production delays or costs associated with them.

- Achieved corporate goals within budget limits while ensuring customer satisfaction through delivery of high quality products according to specifications every month.

- Advised metallurgical engineering teams on the most efficient ways to fabricate, form and heat-treat metals; reduced fabrication time by 20% and material costs by $2,000 in the last quarter.

- Accurately inspected all machinery parts prior to assembly using gauges, calipers and other measuring tools; identified potential safety issues early on that would have caused $10,000 worth of damage if gone undetected.

- Demonstrated expertise in welding techniques such as TIG & MIG when working with aluminum sheets for automotive components; completed 75+ welds per day with zero defects or inconsistencies reported from clients.

- Optimized operational processes at the plant facility by introducing new technologies such as robotic arms into production line activities; increased output rate from 400 units/hour to 500 units/hour within a month’s period after implementation.

- Introduced quality control methods throughout various stages of metal production including casting, rolling & forging processes; improved product reliability ratings up 15%.

- Inspected and tested metal samples to ensure compliance with specified quality standards; reduced product defects by 98%.

- Participated in the design, fabrication and installation of metallurgical machinery for aerospace, automotive and medical industries; improved production cycle time by 15 hours per project.

- Fabricated components using precision welding techniques such as MIG/TIG/Arc welding; achieved an average welding speed of 20 inches per minute without compromising on safety measures or accuracy levels.

- Competently operated various specialized equipment like microscopes, spectrometers and X-ray machines to conduct advanced testing procedures on metals & alloys; identified flaws within 4 minutes per sample compared to 6 minutes industry standard rate.

- Monitored every stage of the manufacturing process from raw material selection through final assembly process while adhering strictly to industrial protocols regarding temperature control, stress & strain tests etc.; decreased scrap rates by 22%.

- Prepared and analyzed metal samples to determine chemical & physical properties, reduced scrap material rate by 10% through improved process control.

- Facilitated heat treatment processes on various alloys and tested treated parts for hardness, ductility, strength and corrosion resistance; increased production efficiency by 20%.

- Confidently operated furnace equipment in accordance with safety guidelines while using temperature controls to monitor the progress of metallurgical projects; completed projects an average of two weeks ahead of schedule.

- Refined metallurgical techniques used in sample preparation as well as processing methods based on customer requirements; decreased customer complaints by 15%.

- Measured precise amounts of alloy elements according to specifications before combining them into a molten pool for casting operations; saved up to $500 per month due to fewer re-casting errors from inaccurate measurements.

- Efficiently analyzed metal samples using X-ray diffraction and optical microscopes to determine metallurgical composition, structure and mechanical properties; decreased testing time by 15%.

- Reorganized the laboratory space in order to create a more efficient workflow which included introducing new procedures for sample preparation and data analysis, resulting in 20% accuracy increase.

- Expedited the turnaround times of various tests such as hardness, tensile strength, corrosion resistance & fatigue limit evaluation by 25% through streamlining processes & increasing efficiency with automated systems.

- Performed extensive research on experimental alloys to identify suitable materials for manufacturing components used in aerospace industry; reduced costs associated with material selection process by $5K annually.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for a metallurgical technician with expertise in welding and Organization XYZ may require knowledge of machining.

It is important to tailor the skills section of your resume to each job that you apply for as many employers use applicant tracking systems (computer programs) which scan resumes for certain keywords before passing them on to a human.

In addition, it is also beneficial to discuss these skills further in other sections such as the summary or experience section. This will help demonstrate how they have been applied in previous roles and why you are an ideal candidate for this particular position.

Below is a list of common skills & terms:

- Casting

- Corrosion Protection

- Forging

- Heat Treatment

- Machining

- Metallography

- Metallurgical Analysis

- Non-destructive Testing

- Quality Control

- Welding

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it’s important to mention your educational background below the objective statement. However, if you have been working as a metallurgical technician for years with plenty of accomplishments to showcase, omitting the education section is perfectly fine.

If an education section is included, try to mention courses or subjects related specifically to metallurgy that may be relevant for this job role.

Associate Degree in Metallurgical Engineering Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to show potential employers that you have the knowledge and skills necessary for the job. It is important to include any relevant certifications on your resume, as it can help demonstrate your expertise in a particular field or skill set.

If you are applying for a position that requires specific certification, make sure to highlight this information prominently on your resume so hiring managers will be aware of it right away.

Certified Metallurgical Technician (CMT)

American Society for N

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Troy Rohan, this would be Troy-Rohan-resume.pdf or Troy-Rohan-resume.docx.

7. Cover Letter

Writing a cover letter is a great way to make yourself stand out from other job applicants. This document, usually consisting of 2-4 paragraphs, is designed to give the hiring manager more insight into who you are and how your skills may be beneficial for the company.

Cover letters also provide an opportunity for you to explain why you believe that you’re the perfect fit for this role in particular. Whilst not all jobs require one, having a well-crafted cover letter can help boost your chances of getting hired significantly!

Below is an example cover letter:

Dear Omer,

I am writing to apply for the Metallurgical Technician position at XYZ Corporation. With my experience in conducting metallurgical testing and analysis, as well as my strong communication and problem-solving skills, I am confident that I would be a valuable asset to your team.

In my current role at ABC Company, I conduct metallurgical testing on metals and alloys to determine their physical and chemical properties. I also prepare metal samples for microstructural examination, perform hardness tests, and document all test results. In addition to these duties, I often provide recommendations on process improvements based on my findings. My excellent communication skills have allowed me to effectively collaborate with engineers and other technicians in order to troubleshoot issues and develop solutions.

Through my work experience, I have developed a strong understanding of the principles of metallurgy and how they can be applied in industrial settings. My attention to detail ensures that all tests are conducted accurately, while my analytical skills allow me to interpret data correctly and make sound recommendations. I am confident that I could use my knowledge and skills to benefit your company if given the opportunity.

Thank you for your time & consideration; please do not hesitate to contact me if you have any questions or require further information about my qualifications.

Sincerely,

Troy

Metallurgical Technician Resume Templates

Dugong

Dugong Numbat

Numbat Indri

Indri Bonobo

Bonobo Jerboa

Jerboa Fossa

Fossa Markhor

Markhor Ocelot

Ocelot Echidna

Echidna Lorikeet

Lorikeet Saola

Saola Gharial

Gharial Rhea

Rhea Cormorant

Cormorant Hoopoe

Hoopoe Axolotl

Axolotl Pika

Pika Quokka

Quokka Kinkajou

Kinkajou Rezjumei

Rezjumei