Metallurgical Engineer Resume Guide

Metallurgical Engineers design, develop, and evaluate the processes that are used to extract metals from ores. They also work with other engineers to create alloys for use in a variety of applications. Additionally, Metallurgical Engineers test materials for their strength and durability as well as analyze failure modes of components made from metal or metal alloys.

Metallurgy is your forte, and you could be a valuable asset to any engineering firm. However, employers won’t know who you are unless you can prove it with a well-crafted resume that highlights all of your accomplishments.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

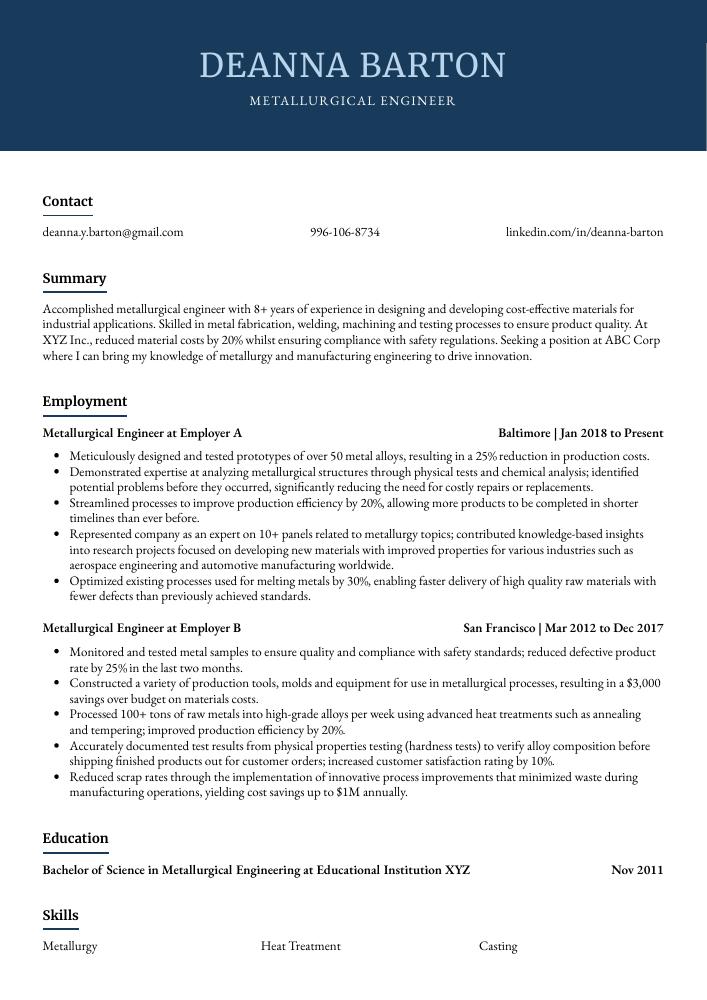

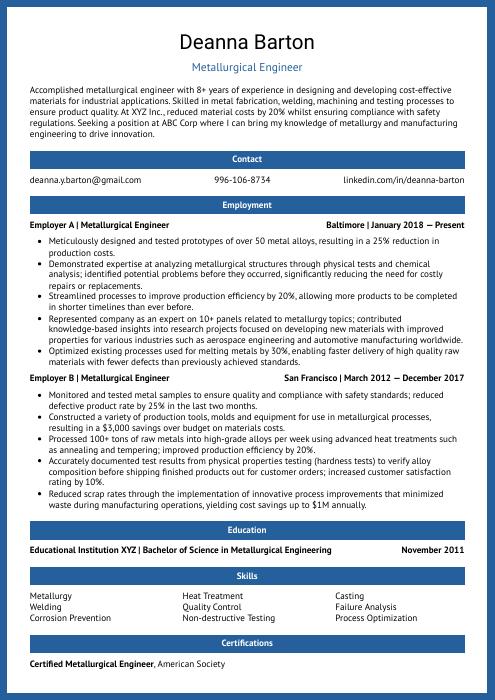

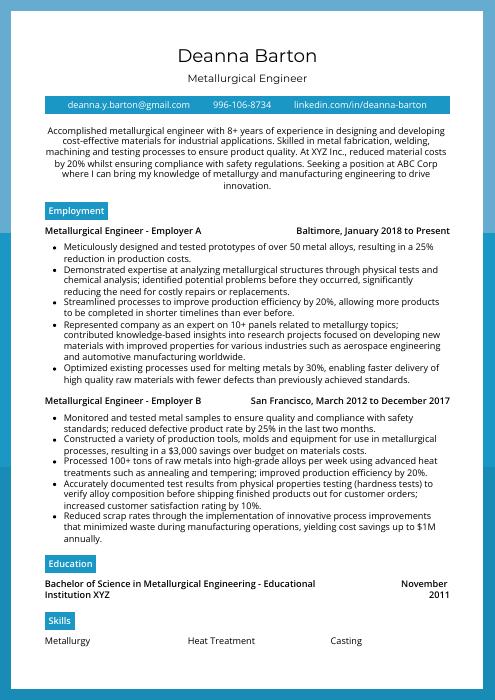

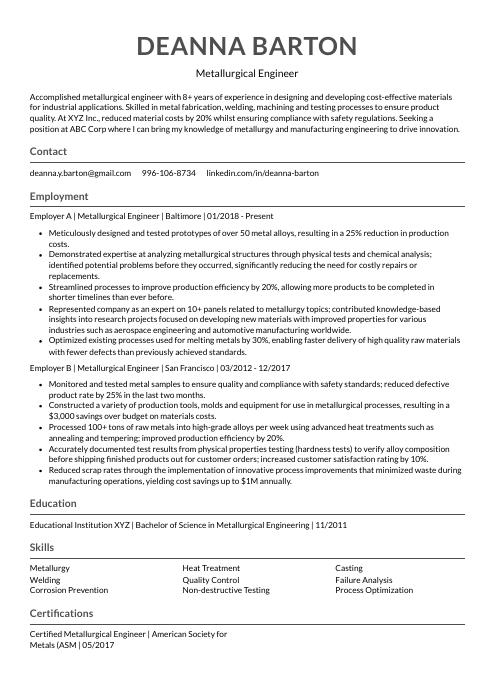

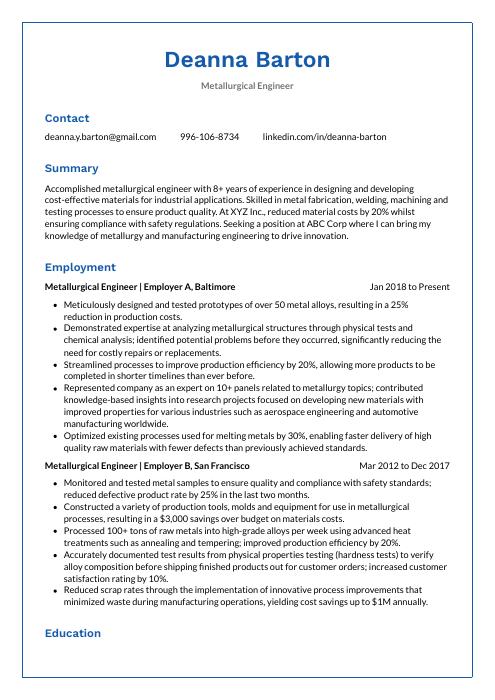

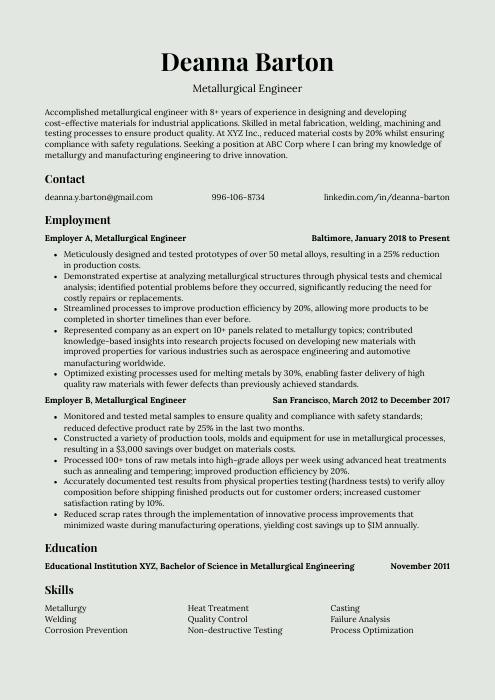

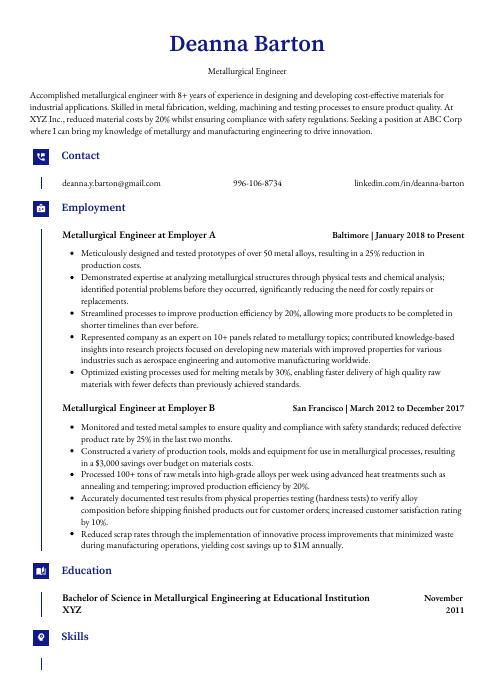

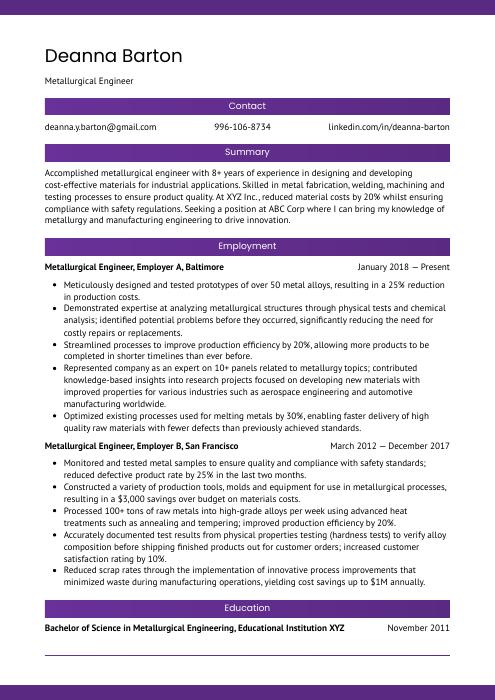

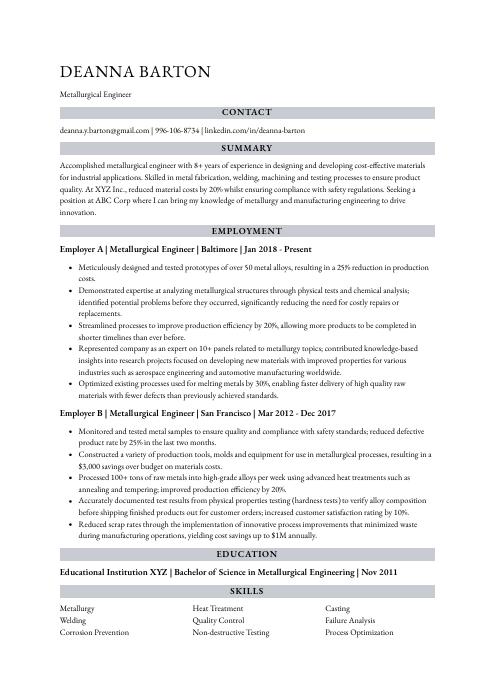

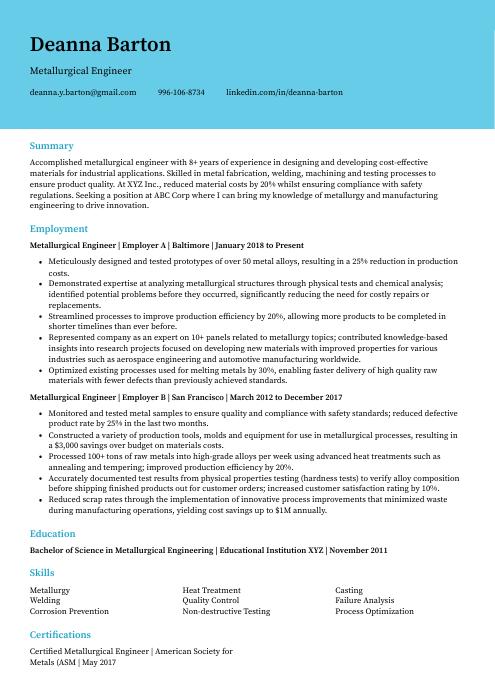

Metallurgical Engineer Resume Sample

Deanna Barton

Metallurgical Engineer

[email protected]

996-106-8734

linkedin.com/in/deanna-barton

Summary

Accomplished metallurgical engineer with 8+ years of experience in designing and developing cost-effective materials for industrial applications. Skilled in metal fabrication, welding, machining and testing processes to ensure product quality. At XYZ Inc., reduced material costs by 20% whilst ensuring compliance with safety regulations. Seeking a position at ABC Corp where I can bring my knowledge of metallurgy and manufacturing engineering to drive innovation.

Experience

Metallurgical Engineer, Employer A

Baltimore, Jan 2018 – Present

- Meticulously designed and tested prototypes of over 50 metal alloys, resulting in a 25% reduction in production costs.

- Demonstrated expertise at analyzing metallurgical structures through physical tests and chemical analysis; identified potential problems before they occurred, significantly reducing the need for costly repairs or replacements.

- Streamlined processes to improve production efficiency by 20%, allowing more products to be completed in shorter timelines than ever before.

- Represented company as an expert on 10+ panels related to metallurgy topics; contributed knowledge-based insights into research projects focused on developing new materials with improved properties for various industries such as aerospace engineering and automotive manufacturing worldwide.

- Optimized existing processes used for melting metals by 30%, enabling faster delivery of high quality raw materials with fewer defects than previously achieved standards.

Metallurgical Engineer, Employer B

San Francisco, Mar 2012 – Dec 2017

- Monitored and tested metal samples to ensure quality and compliance with safety standards; reduced defective product rate by 25% in the last two months.

- Constructed a variety of production tools, molds and equipment for use in metallurgical processes, resulting in a $3,000 savings over budget on materials costs.

- Processed 100+ tons of raw metals into high-grade alloys per week using advanced heat treatments such as annealing and tempering; improved production efficiency by 20%.

- Accurately documented test results from physical properties testing (hardness tests) to verify alloy composition before shipping finished products out for customer orders; increased customer satisfaction rating by 10%.

- Reduced scrap rates through the implementation of innovative process improvements that minimized waste during manufacturing operations, yielding cost savings up to $1M annually.

Skills

- Metallurgy

- Heat Treatment

- Casting

- Welding

- Quality Control

- Failure Analysis

- Corrosion Prevention

- Non-destructive Testing

- Process Optimization

Education

Bachelor of Science in Metallurgical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Metallurgical Engineer

American Society for Metals (ASM

May 2017

1. Summary / Objective

The summary or objective at the beginning of your metallurgical engineer resume should provide a snapshot of who you are and why you excel in this field. This is where you can highlight your best qualities; for example, mention the advanced materials testing techniques you have experience with, any awards or certifications related to metallurgy that you possess, and how many successful projects involving metal components that you have completed.

Below are some resume summary examples:

Talented metallurgical engineer with 10+ years of experience in the design, development and implementation of metallurgical processes. Skilled at optimizing existing processes to improve efficiency while reducing costs. Proven record of success developing new materials for use in medical devices and aerospace products, resulting in an estimated savings of $1 million. Seeking a position at ABC Technologies where I can put my knowledge and expertise to work.

Seasoned metallurgical engineer with 10+ years of experience in the development and implementation of complex metallurgy processes. Adept at overseeing production teams, developing cost-effective solutions to optimize efficiency, and analyzing data for process improvements. Seeking an opportunity to use my expertise as a Metallurgical Engineer at ABC Corp., driving innovation in metal refining operations and technologies.

Detail-oriented metallurgical engineer with a proven track record of successful projects in the development, optimization, and implementation of metallurgic processes for metals manufacturing. Expertise includes corrosion control strategies, alloy selection analysis, welding procedures/techniques development, and quality assurance program design. Experienced in working on large-scale projects from concept to completion.

Driven metallurgical engineer with 8+ years of experience in metalworking, manufacturing and process engineering. Expertise includes quality control and assurance processes, materials characterization testing, failure analysis investigations and developing cost-effective production solutions. At XYZ Corporation developed a new metallurgical alloy for the aerospace industry that resulted in improved efficiency by 40%.

Passionate and knowledgeable metallurgical engineer with 8+ years of experience in product development, testing, and process optimization for the aerospace industry. Skilled at analyzing data to identify trends and develop solutions that reduce costs while improving performance. At XYZ Corporation, developed a new alloy formulation resulting in an 18% increase in strength compared to the previous standard material.

Skilled metallurgical engineer with 5+ years of experience in the development, selection and evaluation of materials for a wide variety of applications. Demonstrated ability to identify process improvements that reduce costs by 24% while improving material properties by 15%. Seeking to leverage expertise and innovative problem-solving skills at ABC Corp., where I can make an impact on product design processes.

Committed metallurgical engineer with 8+ years of experience in research, design and development. Specializes in the use of metals to create resilient products that meet customer expectations. At XYZ, increased product durability by 20% through extensive testing and analysis. Skilled at creating cost-effective solutions to reduce manufacturing costs while maintaining quality standards.

Hard-working metallurgical engineer with 8+ years of experience in production, fabrication and research. Proven track record of providing innovative solutions to complex problems related to metal materials. Seeking a role at ABC Technology where I can apply my knowledge and skills towards developing sustainable products that are cost-effective and safe for the environment.

2. Experience / Employment

For the experience section, you should provide details on your employment history. It should be written in reverse chronological order, with the most recent role listed first.

When writing about what you did for each job, stick to bullet points; this makes it easier for the reader to take in all of the information quickly and efficiently. When describing your duties or accomplishments, make sure to include quantifiable results when possible.

For example, instead of saying “Developed new processes,” you could say “Researched and developed a process that reduced production time by 25%, resulting in an increase of revenue by $50K per month.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Analyzed

- Fabricated

- Inspected

- Operated

- Constructed

- Installed

- Monitored

- Researched

- Processed

- Formulated

- Assessed

- Improved

- Developed

- Tested

Other general verbs you can use are:

- Achieved

- Advised

- Compiled

- Coordinated

- Demonstrated

- Expedited

- Facilitated

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Assessed the mechanical and metallurgical properties of metals and alloys using advanced testing methods; reduced scrap metal rate by 25%.

- Participated in the design, development, implementation and optimization of various industrial processes related to steel production; increased output efficiency by 30% over a 3-month period.

- Facilitated technical discussions between engineers, suppliers and representatives from other departments such as procurement & logistics; reduced downtime due to component shortages by 70%.

- Reliably troubleshooted long-term welding issues for clients with laser beam techniques across 10+ projects within tight deadlines while maintaining quality standards at 95% or higher.

- Mentored 5 junior engineers in problem solving skills through practical tasks on the shop floor environment resulting in positive feedback from supervisors concerning their performance improvement.

- Coordinated the production of metallurgical components, ensuring that all safety protocols were observed and deadlines were met; increased efficiency by 15% in the last quarter.

- Successfully designed and developed 10+ new models of metal-based products to meet customer specifications with a 99% success rate on the first attempt.

- Optimized existing manufacturing processes by introducing automated systems; decreased energy consumption costs by $7000 per month while improving product quality up to 85%.

- Installed special laboratory equipment for research & development purposes, including furnaces, spectrometers and microscopes within budgeted timelines without any technical glitches or delays.

- Spearheaded teams of 25+ subordinate engineers for various projects such as developing heat treatments for metals, conducting tests on raw materials & finished products and creating cost effective solutions for clients’ needs.

- Introduced new techniques to enhance the strength, durability and lifespan of metal products; increased production efficiency by 23%.

- Reorganized and optimized existing metallurgical processes, resulting in a 15% reduction in scrap rate while maintaining quality standards.

- Effectively designed alloy compositions for various industrial applications with complete adherence to safety regulations; improved heat-treating flux properties by 20%.

- Utilized tools such as XRF spectrometers, optical microscopes & DSC instruments to analyze and identify metallic components & assess their mechanical properties per customer requirements.

- Prepared technical reports detailing test results from analysis of metals used in automotive engines, medical implants & aerospace parts; saved 100+ hours annually on research time compared to previous methods.

- Tested metallurgic properties of various metals and alloys, including tensile strength, ductility/brittleness, fatigue resistance and corrosion tolerance; improved product quality by 35% through comprehensive analysis.

- Operated a range of furnaces to melt ore samples for further chemical testing in accordance with safety protocols; reduced energy consumption costs by $4K per month due to optimized furnace settings.

- Competently employed X-ray diffraction techniques & electron microscopy to identify microstructural changes in materials during heat treatments and mechanical processing cycles.

- Structured research activities based on organizational goals while developing new processes for metal alloy production; designed 5+ prototype units that passed stringent quality standards tests with flying colors within budgeted time frames.

- Presented findings from lab studies at national scientific conferences twice a year, developed 3 publications on metallurgical engineering topics that have been accepted into top tier journals so far this year.

- Formulated innovative process improvements to reduce costs and scrap rates by 20%, resulting in increased efficiency across all production lines.

- Revised existing testing methods for metal properties, leading to a reduction of material wastage by 15%.

- Advised senior management on the best type of alloy materials to use for specific projects, which resulted in a cost savings of $25K over two years.

- Improved metallurgical processes through the introduction of new technologies and techniques, increasing output quality and consistency by 35%.

- Efficiently managed a team responsible for designing & producing prototype components while ensuring adherence with safety standards; completed project within allocated budget & timeline parameters set out at start date.

- Analyzed metallurgical test data, and developed/implemented strategies to improve the quality of metal castings; increased strength of aluminum components by 23%.

- Fabricated custom tooling for casting processes and machined metals into desired shapes with a CNC mill, ensuring that products met customer specifications.

- Achieved cost savings of $12K in the last quarter through optimized production techniques such as welding automation & computer-aided design (CAD).

- Resourcefully modified existing molds and dies to create complex parts within tight deadlines; reduced lead time by 50% on average while maintaining high standards of safety/quality assurance measures.

- Expedited product delivery schedules by quickly troubleshooting technical issues related to alloy selection & heat treatment methods during production runs.

- Compiled comprehensive reports on the metallurgical and thermodynamic properties of various alloys, resulting in a 10% reduction in production costs.

- Inspected metals for defects to ensure compliance with quality standards; identified 6 major flaws which were corrected within 2 weeks, leading to improved product reliability.

- Developed innovative processes that enabled the rapid assembly of complex metal components; reduced production time by 50 hours per month without sacrificing quality assurance protocols.

- Researched new methods for welding metals together using advanced machinery and software; increased weld strength by 25%, consequently reducing repair costs significantly over an 8-month period.

- Substantially enhanced industrial safety parameters at 3 manufacturing plants through regular maintenance checks on tools & equipment used during fabrication tasks; decreased accidents caused by faulty machines/tools by 35%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for someone with experience in metallurgical testing and Organization XYZ may require expertise in metal forming.

It is essential to keep this in mind because of the applicant tracking systems utilized by many companies. Their role is to analyze resumes for certain characteristics (such as specific keywords), filtering out the ones they deem not to be a high-quality match for that particular job.

In addition, you should also elaborate on your skillset by discussing it further within other resume sections, such as an objective statement or summary section. This allows employers to gain a better understanding of how these skills can benefit them if you are hired into their organization.

Below is a list of common skills & terms:

- Casting

- Corrosion Prevention

- Failure Analysis

- Heat Treatment

- Materials Selection

- Metallurgy

- Non-destructive Testing

- Process Optimization

- Quality Control

- Welding

4. Education

Mentioning an education section on your resume will depend on how far you are in your career. If you just graduated and have no prior experience, include the education section below your resume objective. However, if you have been working as a metallurgical engineer for years with plenty of work to showcase, omitting an education section is perfectly fine.

If including an education section, try to mention courses and subjects related to metallurgy that may be relevant to the job role you are applying for.

Bachelor of Science in Metallurgical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the necessary skills and knowledge for a particular job. It is important to include any certifications relevant to the position on your resume, as it will demonstrate your commitment to professional development in the field.

Including certifications also shows that you are up-to-date with industry trends and standards, which can be an attractive quality for hiring managers looking for qualified candidates.

Certified Metallurgical Engineer

American Society for Metals (ASM

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Deanna Barton, this would be Deanna-Barton-resume.pdf or Deanna-Barton-resume.docx.

7. Cover Letter

Writing a cover letter is a great way to make your job application stand out from the rest. It’s an opportunity to introduce yourself, explain why you’re interested in the role and demonstrate how your skills and experience can add value to the company.

Cover letters are usually made up of 2-4 paragraphs that sit separate from your resume. They should be tailored for each individual job application so they reflect what makes you a suitable candidate for that particular position. Although cover letters aren’t always required, submitting one is highly recommended as it allows recruiters to get a better understanding of who you are as an applicant.

Below is an example cover letter:

Dear Moshe,

I am writing to apply for the Metallurgical Engineer position at XYZ Corporation. As a highly skilled and experienced engineer with extensive experience in metallurgy, I am confident I will make a valuable contribution to your organization.

In my current role as Metallurgical Engineer at ABC Corporation, I am responsible for overseeing all aspects of metallurgical operations, from product development and research to quality control and production. I have a proven track record of success in this area, having developed several new alloy compositions that have been successfully commercialized. In addition, I have also played a key role in improving production efficiency by streamlining process flow and introducing new technologies.

I am knowledgeable in all areas of metallurgy and have a strong understanding of both ferrous and non-ferrous metals. My analytical skills are superb, allowing me to quickly identify problems and develop effective solutions. In addition, I possess excellent communication and interpersonal skills that enable me to work effectively with people at all levels within an organization.

I would welcome the opportunity to bring my knowledge and expertise to your company and contribute to its continued success. Please find attached my resume for your review; if you have any questions or require any further information, do not hesitate to contact me at [phone number] or [email address]. Thank you for your time & consideration; I look forward hearing from you soon!

Sincerely,

Deanna

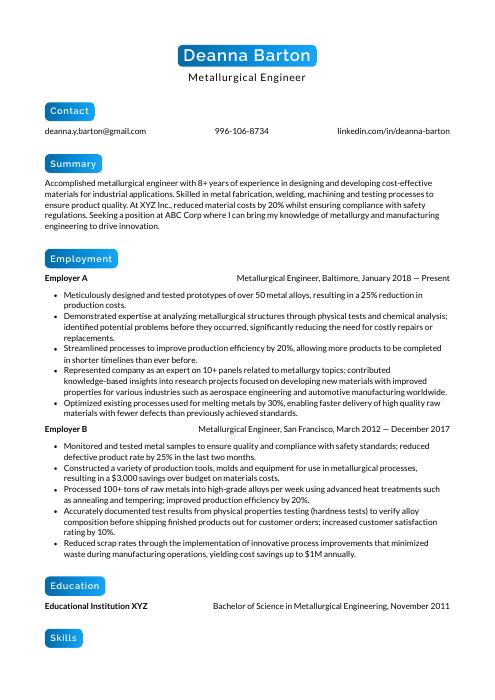

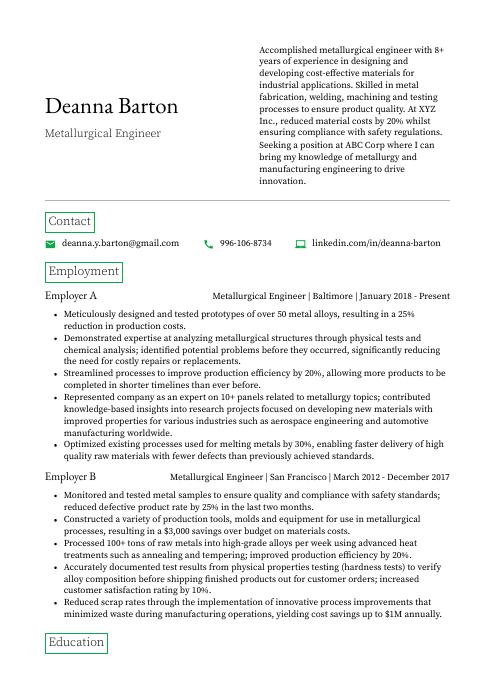

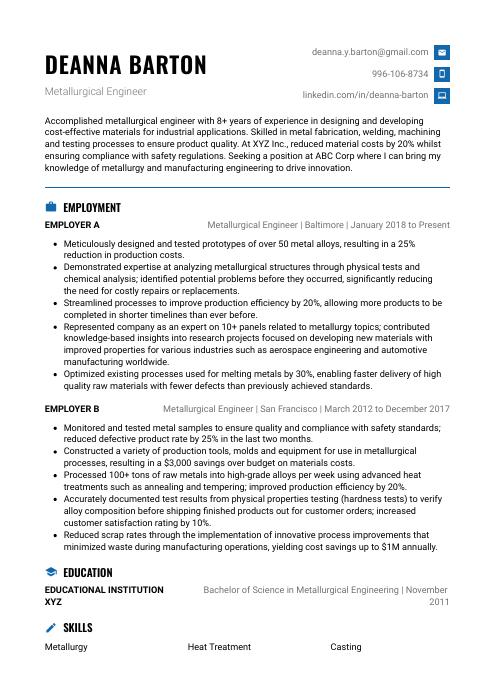

Metallurgical Engineer Resume Templates

Kinkajou

Kinkajou Quokka

Quokka Echidna

Echidna Ocelot

Ocelot Rhea

Rhea Indri

Indri Markhor

Markhor Saola

Saola Gharial

Gharial Cormorant

Cormorant Pika

Pika Hoopoe

Hoopoe Lorikeet

Lorikeet Axolotl

Axolotl Bonobo

Bonobo Jerboa

Jerboa Numbat

Numbat Dugong

Dugong Fossa

Fossa Rezjumei

Rezjumei