Mechanical Technician Resume Guide

Mechanical Technicians install, maintain and repair machinery and equipment. They use technical manuals, drawings and specifications to diagnose problems, adjust or replace defective parts and ensure the machines are operating properly. They also conduct tests on motors, engines, pumps and other mechanical systems in order to identify any issues that may arise.

You’re an expert when it comes to maintaining and repairing machines, but employers don’t know about your experience yet. To make them aware of your technical abilities and accomplishments, you must create a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

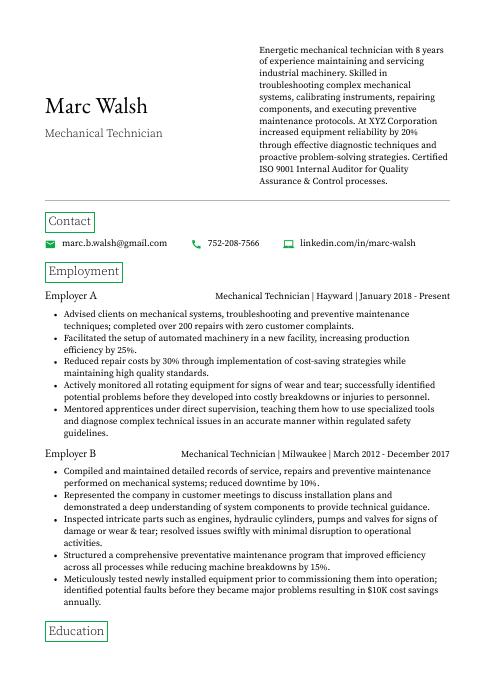

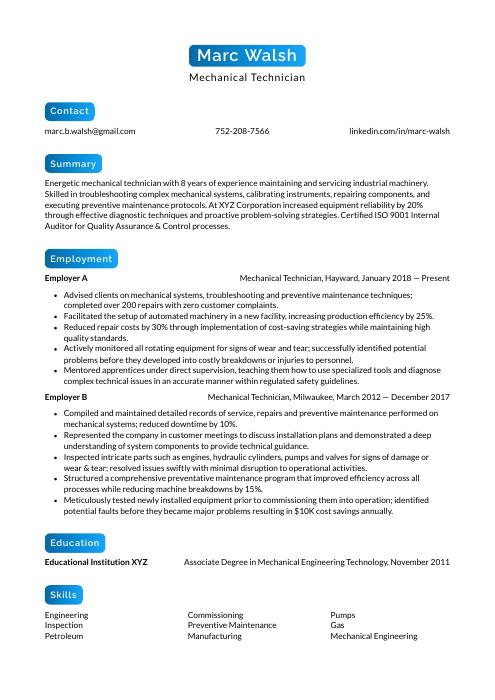

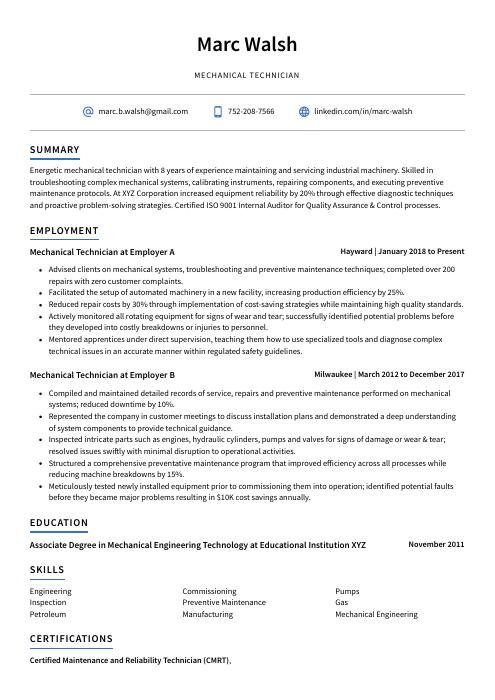

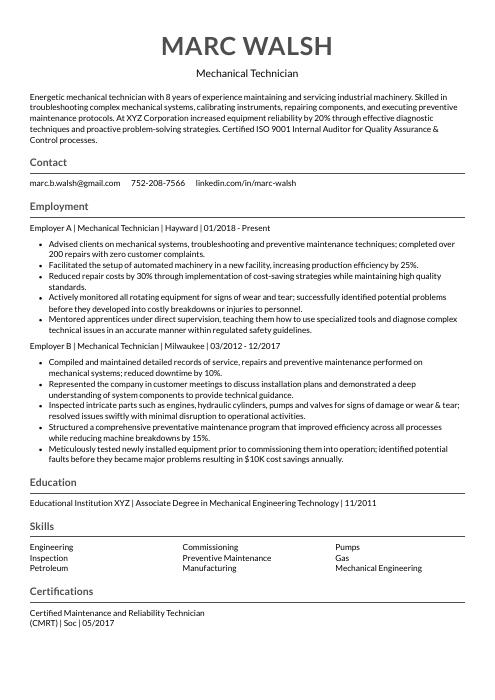

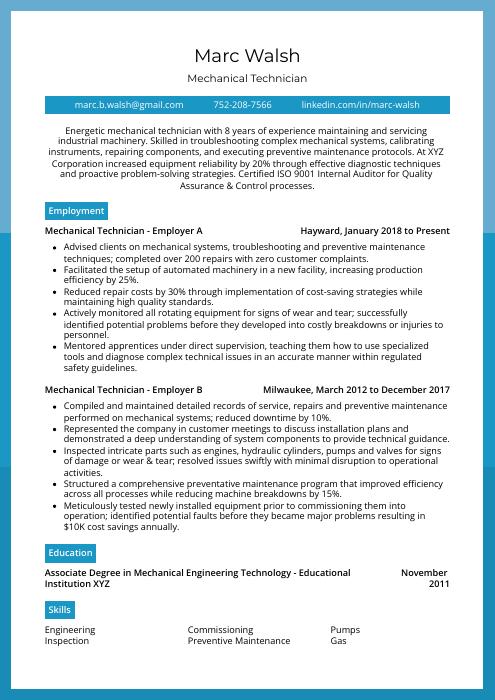

Mechanical Technician Resume Sample

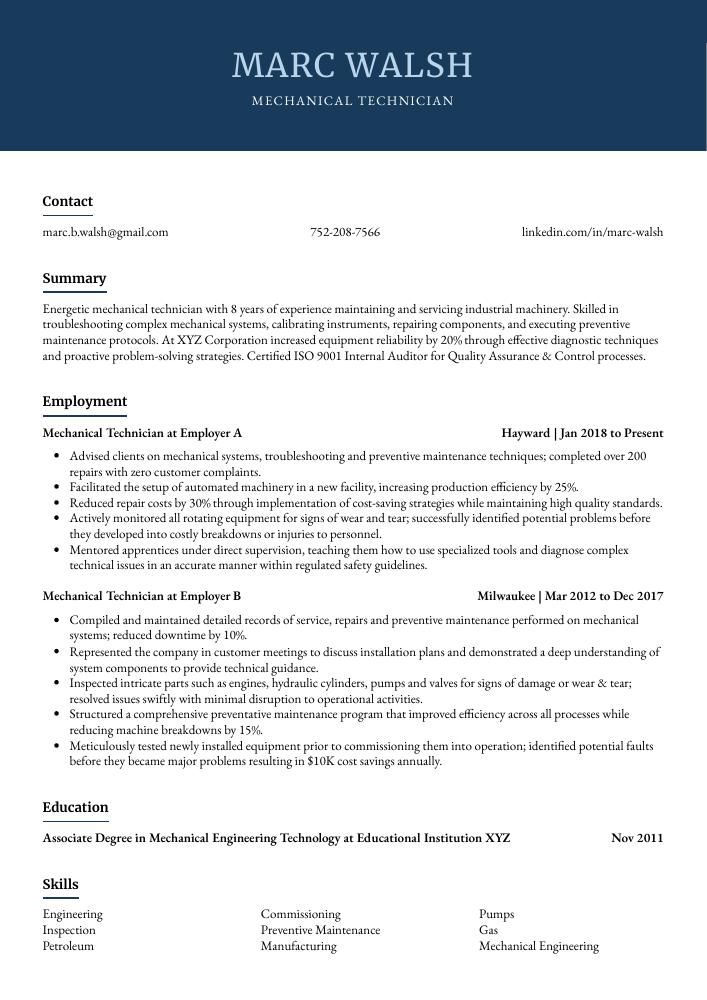

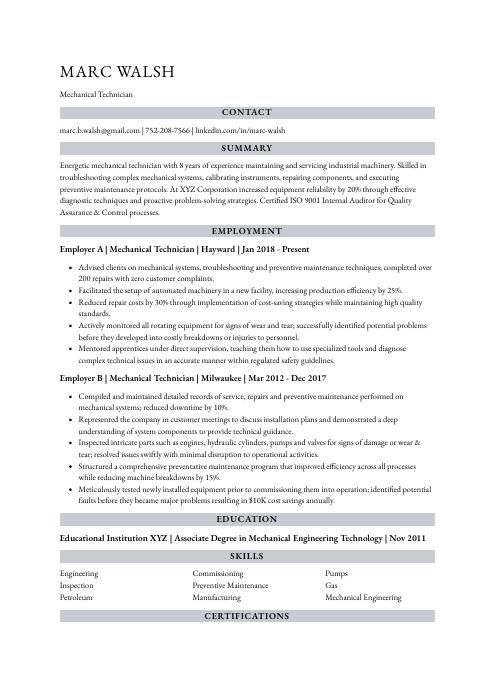

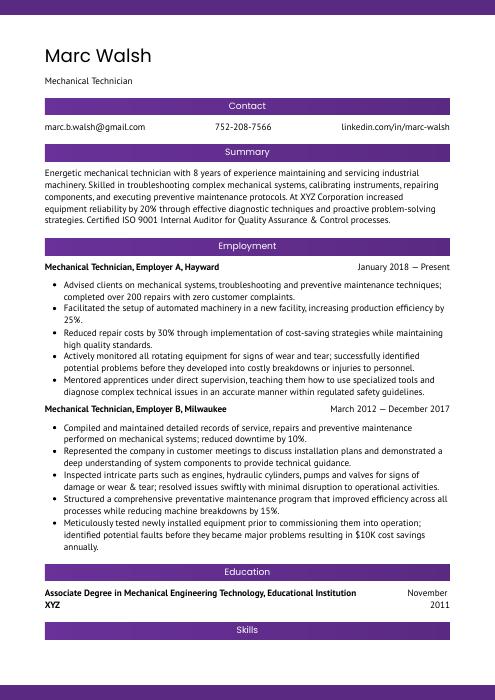

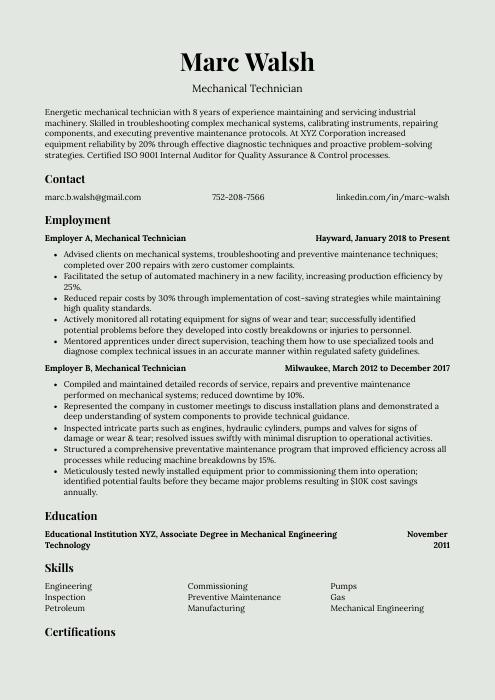

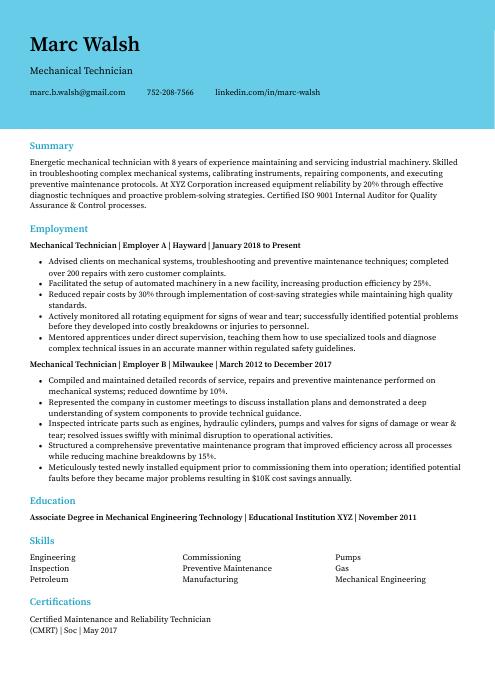

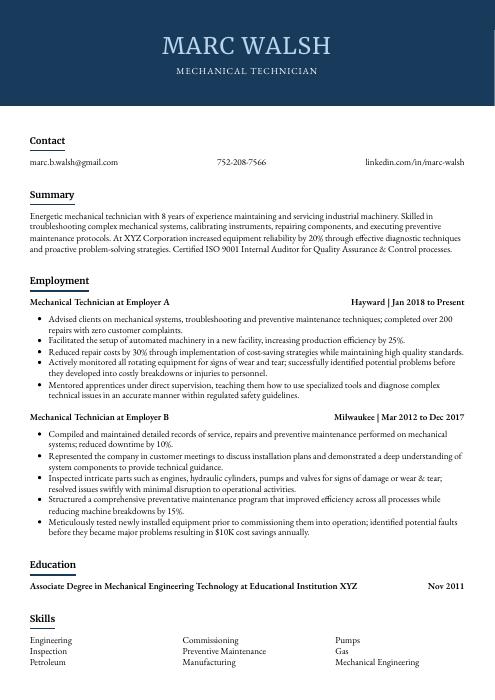

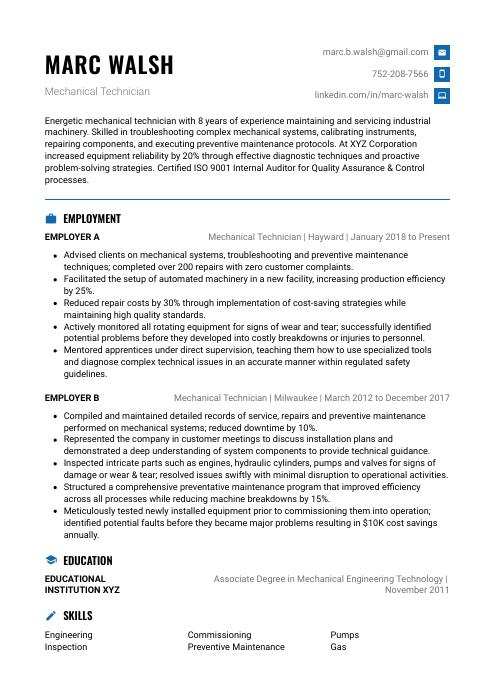

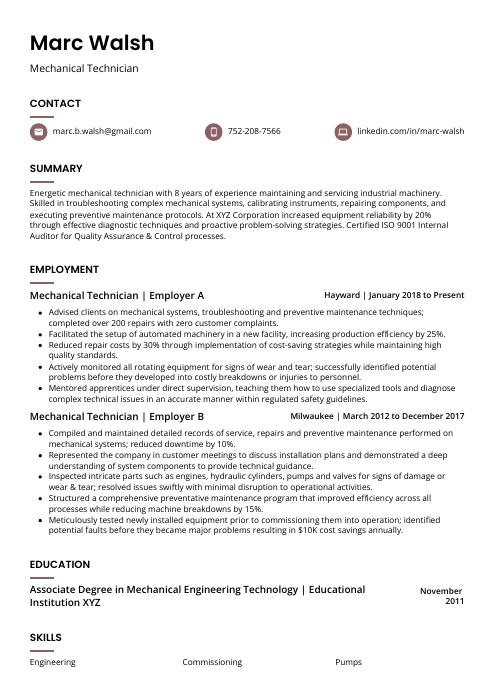

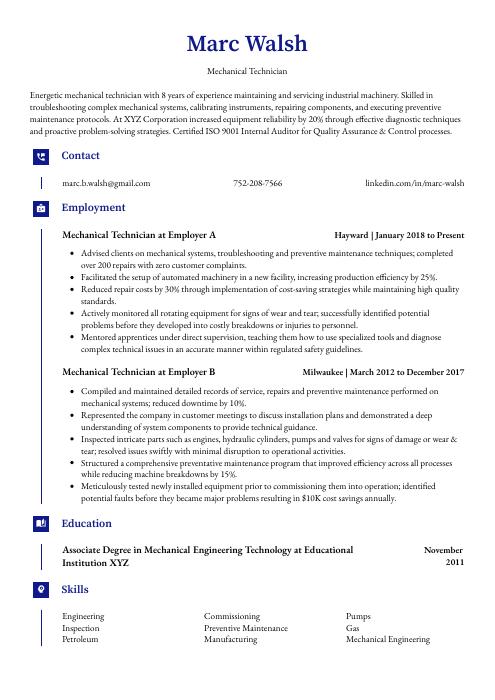

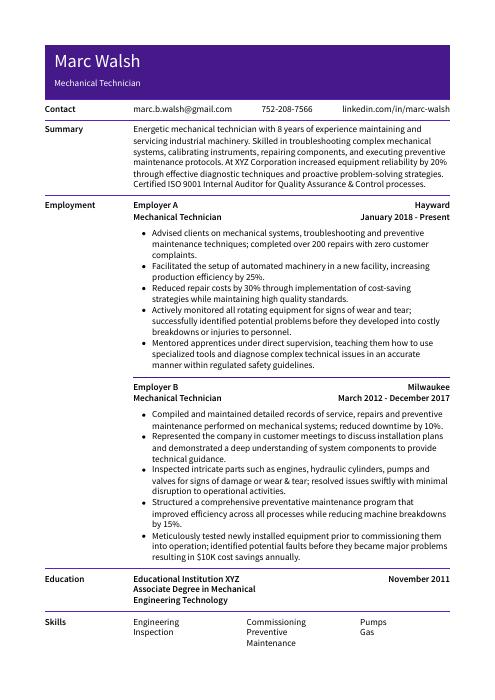

Marc Walsh

Mechanical Technician

[email protected]

752-208-7566

linkedin.com/in/marc-walsh

Summary

Energetic mechanical technician with 8 years of experience maintaining and servicing industrial machinery. Skilled in troubleshooting complex mechanical systems, calibrating instruments, repairing components, and executing preventive maintenance protocols. At XYZ Corporation increased equipment reliability by 20% through effective diagnostic techniques and proactive problem-solving strategies. Certified ISO 9001 Internal Auditor for Quality Assurance & Control processes.

Experience

Mechanical Technician, Employer A

Hayward, Jan 2018 – Present

- Advised clients on mechanical systems, troubleshooting and preventive maintenance techniques; completed over 200 repairs with zero customer complaints.

- Facilitated the setup of automated machinery in a new facility, increasing production efficiency by 25%.

- Reduced repair costs by 30% through implementation of cost-saving strategies while maintaining high quality standards.

- Actively monitored all rotating equipment for signs of wear and tear; successfully identified potential problems before they developed into costly breakdowns or injuries to personnel.

- Mentored apprentices under direct supervision, teaching them how to use specialized tools and diagnose complex technical issues in an accurate manner within regulated safety guidelines.

Mechanical Technician, Employer B

Milwaukee, Mar 2012 – Dec 2017

- Compiled and maintained detailed records of service, repairs and preventive maintenance performed on mechanical systems; reduced downtime by 10%.

- Represented the company in customer meetings to discuss installation plans and demonstrated a deep understanding of system components to provide technical guidance.

- Inspected intricate parts such as engines, hydraulic cylinders, pumps and valves for signs of damage or wear & tear; resolved issues swiftly with minimal disruption to operational activities.

- Structured a comprehensive preventative maintenance program that improved efficiency across all processes while reducing machine breakdowns by 15%.

- Meticulously tested newly installed equipment prior to commissioning them into operation; identified potential faults before they became major problems resulting in $10K cost savings annually.

Skills

- Engineering

- Commissioning

- Pumps

- Inspection

- Preventive Maintenance

- Gas

- Petroleum

- Manufacturing

- Mechanical Engineering

Education

Associate Degree in Mechanical Engineering Technology

Educational Institution XYZ

Nov 2011

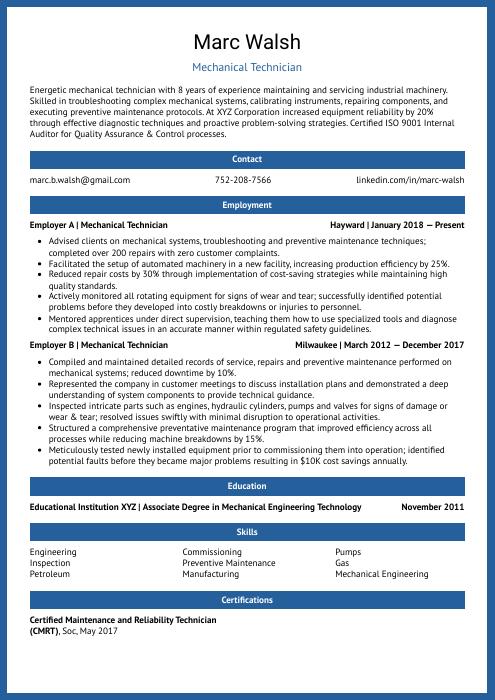

Certifications

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

1. Summary / Objective

The summary/objective at the top of your mechanical technician resume should be a brief, yet powerful statement that captures who you are and why you excel in this field. This is where you can showcase your best qualities; for example, mention any certifications or licenses held, the number of years experience working with different types of machinery and equipment, as well as any special skills such as welding or machining.

Below are some resume summary examples:

Talented mechanical technician with 5+ years of experience in the maintenance and repair of industrial machinery. Possess a knack for troubleshooting complex mechanical problems and installing new systems to improve efficiency. At XYZ, identified an issue that was causing costly downtime and implemented solutions that saved $50K/year. Seeking to use expertise at ABC Corporation to drive innovation while keeping operations running smoothly.

Hard-working, detail-oriented mechanical technician with 8+ years of experience in the field. Demonstrated expertise in troubleshooting and repairing complex machinery, as well as performing preventive maintenance on a variety of motorized equipment systems. At XYZ Corporation, identified an issue that reduced production costs by 25%. Also successful at training and supervising junior technicians for more efficient workflow.

Enthusiastic mechanical technician with 5+ years of experience in the industry. Seeking to leverage my knowledge and expertise in performing maintenance, repairs, and installations on a wide range of mechanical systems at XYZ Corporation. Highly skilled in troubleshooting complex problems using advanced diagnostic tools. Committed to providing quality services within strict deadlines for optimal customer satisfaction.

Reliable and detail-oriented mechanical technician with 7+ years of experience maintaining and operating a variety of production equipment. Seeking to join ABC Tech, utilizing strong problem-solving skills and knowledge in all aspects of installation, maintenance, troubleshooting, repair and safety practices. At XYZ Co., successfully completed over 300 repairs on complex machinery while adhering to tight deadlines.

Determined and experienced Mechanical Technician with 11+ years of experience in the engineering field. Skilled in troubleshooting, repairing and maintaining mechanical systems used in industrial applications. Proven track record at ABC Corporation for reducing downtime by 25% through timely maintenance interventions. Experienced working on a variety of equipment such as pumps, motors, compressors and generators.

Seasoned mechanical technician with 10+ years of experience troubleshooting, repairing, and maintaining a wide range of industrial machinery. Skilled in operating power tools while adhering to safety protocols. Committed to providing effective solutions that reduce downtime and ensure optimal production at ABC Tech. Previously reduced labor costs by 20% on an assembly line project for Company X.

Well-rounded mechanical technician with 5+ years of experience in maintenance and repairs. Seeking to leverage hands-on expertise to join ABC Company as a mechanical technician, where I can apply my knowledge of industrial machinery diagnostics and troubleshooting. At XYZ, identified an improvement opportunity that saved the company $30k annually in labor costs.

Dependable mechanical technician with 8+ years of experience in diagnosing, troubleshooting and repairing various machine components. Adept at working with both manual and automated systems to diagnose problems quickly and accurately. Proven track record of successfully completing projects on time while maintaining the highest safety standards.

2. Experience / Employment

In the experience section, you should provide details on your work history. This section should be written in reverse chronological order, with the most recent job listed first.

When it comes to writing this section, stick primarily to bullet points; this makes the information easier for a reader to take in quickly. When writing each point, try and provide detail about what you did and any results that were obtained as a result of your actions.

For example, instead of saying “Repaired mechanical components,” you could say “Diagnosed problems with various types of machinery using specialized tools such as oscilloscopes and multimeters; repaired malfunctioning parts which resulted in an increase in production efficiency by 15%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Installed

- Operated

- Calibrated

- Troubleshot

- Inspected

- Repaired

- Adjusted

- Fabricated

- Welded

- Programmed

- Tested

- Monitored

- Diagnosed

- Serviced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Formulated and executed preventative maintenance plans on over 100 pieces of mechanical equipment, resulting in a 24% reduction in unplanned downtime.

- Proficiently repaired and troubleshot malfunctions on hydraulic systems, engines, motors and other components to ensure optimal performance of all machinery; reduced total repair time by 30%.

- Repaired faulty wiring harnesses, replaced worn belts & bearings and reassembled parts with precision while adhering to manufacturer instructions within established timelines; successfully completed 70+ repairs per month during peak season.

- Expedited the testing of several new automated machines for production use through quick diagnosis & root cause analysis; identified potential defects before mass scale deployment which saved an estimated $5K-$10K each year from avoidable losses due to defective products entering circulation prematurely or without stringent quality checks being performed first.

- Streamlined the overall machine efficiency process by implementing improved diagnostic methods using modern motion control technology coupled with AI-driven predictive analytics that increased productivity output by 15% across multiple departments simultaneously as well as boosting morale among staff members who could now work smarter rather than harder throughout their shift hours every day.

- Monitored and maintained mechanical equipment performance, resulting in a 15% decrease in breakdowns and unplanned maintenance.

- Revised and updated existing technical documents as part of scheduled preventive maintenance activities; reduced average downtime by 25%.

- Calibrated measuring devices to ensure accuracy of results when inspecting components; improved product quality with fewer rejects or reworks needed.

- Participated in the assembly, installation and testing of new machinery for 3 production lines; completed all tasks within 2 days ahead of schedule.

- Independently troubleshot complex problems using advanced diagnostic tools such as multimeters, oscilloscopes and spectrometers; identified faults quickly to reduce repair time by 40%.

- Diligently diagnosed and repaired over 300 pieces of mechanical equipment with a success rate of 97%, resulting in an average decrease in repair times by 20%.

- Programmed PLCs, servo systems, motor controllers and other electronic control units for various machines; improved production output by 10% due to increased efficiency.

- Tested the performance capacity of newly installed machinery components and provided recommendations on further improvement opportunities that could enhance productivity levels.

- Serviced multiple types of industrial robots such as ABB, KUKA & FANUC based on their specific technical requirements; reduced downtime caused by robot malfunctions from 24 hours to 4 hours per incident.

- Replaced worn-out parts using hand tools while adhering to safety regulations at all times; saved $15,000 in maintenance costs within 6 months through preventive repairs before breakdowns occurred.

- Presented technical solutions to a total of 50+ mechanical systems issues, resulting in improved machine performance and increased production output by 15%.

- Troubleshot complex machinery malfunctions with accuracy and speed; reduced downtime by 30% within the first 6 months of employment.

- Spearheaded multiple preventative maintenance projects; tested and inspected components for signs of wear & tear, replaced faulty parts, lubricated moving mechanisms as required and monitored operations regularly to ensure smooth running at all times.

- Reliably installed new machines according to manufacturer’s instructions using hand tools such as wrenches, screwdrivers etc., resolving any problems that arose quickly before further disruption occurred in the workplace environment.

- Achieved optimal efficiency levels across an array of automated equipment through careful analysis paired with expert-level repairs on hydraulic systems, pneumatic valves & controls etc.; decreased energy consumption costs by 20%.

- Introduced automated systems to increase production efficiency by 45%, resulting in a decrease of costs by $4,500 annually.

- Improved system performance for 10+ machines through preventive maintenance and troubleshooting; decreased breakdowns from 2 per month to 1 every 3 months.

- Utilized engineering skills and knowledge of mechanical components to inspect, diagnose, repair and assemble various equipment according to manufacturer specifications with zero errors or defects reported afterwards.

- Resourcefully devised innovative solutions for complex technical issues that were causing operational delays on the assembly line, thus reducing downtime hours from 8 to 4 weekly on average.

- Operated manual lathes & milling machines effectively while adhering strictly to all safety protocols; successfully handled 60+ projects in the last year without any incidents or accidents reported.

- Fabricated and installed machine parts, assemblies and complete systems to meet production specifications; substantially reduced downtime by 15%.

- Reorganized the plant layout for maximum efficiency; increased speed of assembly lines by 30% while eliminating safety hazards.

- Developed and implemented preventative maintenance plans that improved equipment reliability and longevity; minimized repair costs by 25%.

- Demonstrated strong mechanical aptitude when troubleshooting issues in various machines/equipment; decreased average repair time from 10 hours to 5 hours on complex repairs.

- Substantially boosted productivity with innovative solutions such as automated processes & robotics technology, resulting in an increase of $20K in annual profits for the company.

- Optimized assembly line operations by adjusting, repairing and replacing parts in mechanical systems; reduced downtime by 30%.

- Assembled complex machinery components to precise specifications as per technical drawings provided; improved production efficiency on all projects.

- Welded steel structures of up to 2 tons with a welding torch, meeting industry standards for safety and durability; increased shop productivity by 25%.

- Installed automated equipment at 10+ industrial sites across the province within tight deadlines without compromising quality control measures or health & safety regulations.

- Competently diagnosed malfunctions using various troubleshooting methods such as electrical testing devices and manual inspection techniques, resolving issues in record time (+20% faster than average).

- Prepared and installed mechanical components for new machinery and equipment, resulting in a 40% increase of production output over the last year.

- Assessed and diagnosed malfunctioning parts or systems using specialized testing tools; reduced machine downtime by 25%.

- Coordinated with other technicians to develop maintenance strategies that extended the life of client machines while minimizing repair cost by $7,000 annually.

- Adjusted various settings on motors and engines to ensure proper performance levels were achieved; improved power efficiency ratings by 15% per engine model tested during Q1 quarter this year.

- Confidently handled complex repairs involving hydraulics, pneumatics and electrical systems with minimal guidance from senior staff members; completed all assigned tasks ahead of schedule every month since joining 5 months ago.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might be looking for a technician with experience in HVAC systems, while another might need someone who is knowledgeable about robotics.

It is important to tailor the skills section of your resume to each job you apply for because many employers use applicant tracking systems (ATS) these days. These computer programs scan resumes and filter out those that do not contain certain keywords or phrases related to the role they are trying to fill.

In addition, you can further demonstrate your expertise by elaborating on some of the most relevant skills in other parts of your resume such as the summary or work experience sections.

Below is a list of common skills & terms:

- Air Compressors

- AutoCAD

- Commissioning

- Continuous Improvement

- Energy

- Engineering

- FPSO

- Factory

- Gas

- Gas Turbines

- Hydraulics

- Inspection

- LNG

- Lean Manufacturing

- Machining

- Maintenance

- Maintenance Management

- Maintenance and Repair

- Manufacturing

- Mechanical Engineering

- Mechanics

- Metal Fabrication

- Offshore Drilling

- Offshore Operations

- Oil

- Oil and Gas

- Oil and Gas Industry

- Onshore

- Petrochemical

- Petroleum

- Pipelines

- Piping

- Planned Preventative Maintenance

- Plant Maintenance

- Pneumatics

- Power Generation

- Preventive Maintenance

- Project Engineering

- Project Planning

- Pumps

- Refinery

- Rotating Equipment

- Supervisory Skills

- Team Leadership

- Troubleshooting

- Turbines

- Valves

- Welding

4. Education

Mentioning an education section on your resume will depend on the experience you have in the field. If you are just starting out and lack any professional experience, include a brief mention of your educational background below your resume objective. However, if you have significant work history to showcase then omitting an education section altogether is perfectly acceptable.

If including an education section, make sure to list courses or subjects that are relevant to mechanical technician roles such as mechanics, engineering principles and safety procedures.

Associate Degree in Mechanical Engineering Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have taken the time and effort to gain recognition for your skills, which can give you an edge over other applicants who may not have any certifications.

When applying for jobs, make sure to include any relevant certifications on your resume so hiring managers know that you are qualified and knowledgeable about the position they are looking to fill.

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Marc Walsh, this would be Marc-Walsh-resume.pdf or Marc-Walsh-resume.docx.

7. Cover Letter

Providing a cover letter when applying for a job can be the difference between your application being successful or not. Cover letters are separate from resumes and provide recruiters with more information about you as an individual, allowing them to get a better understanding of who you are and why they should hire you.

Cover letters usually consist of 2-4 paragraphs that explain your qualifications, experience, skillset and any other relevant details that would make you stand out as the ideal candidate for the role. It’s important to note however, whilst cover letters aren’t always required some employers may prefer one included in order to gain further insight into who is applying for their position.

Below is an example cover letter:

Dear Estell,

I am writing in regards to the Mechanical Technician position at your company. As a certified technician with more than 10 years of experience working on mechanical systems, I am confident that I would be a valuable asset to your team.

In my current role as a mechanic at [company name], I work on a variety of machines and equipment, including engines, pumps, and HVAC systems. I have experience troubleshooting issues and performing repairs quickly and efficiently. In addition, I regularly perform preventative maintenance tasks to help reduce the likelihood of future problems.

I have excellent problem-solving skills and always take a proactive approach to my work. For example, when one of our company’s vehicles began having engine trouble, I conducted extensive research until I found the root cause of the issue. By taking this initiative, I was able to save our company time and money by avoiding costly repairs down the road.

I am knowledgeable about OSHA regulations and always prioritize safety when working on projects. My goal is to complete every task correctly the first time so that rework is not necessary. Quality is also important to me; as such, I always take pride in my workmanship no matter how big or small the job may be.

I believe that my skills and experience make me an ideal candidate for this position at your company. If given the opportunity, I will do everything in my power to exceed your expectations while contributing positively to your organization’s success.

Sincerely,

Marc

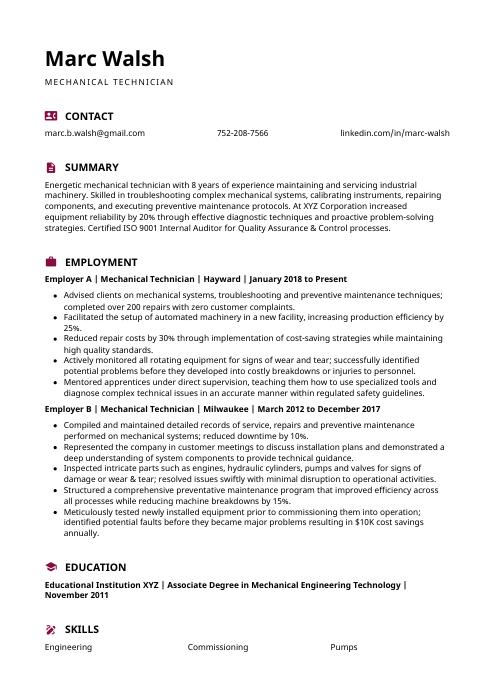

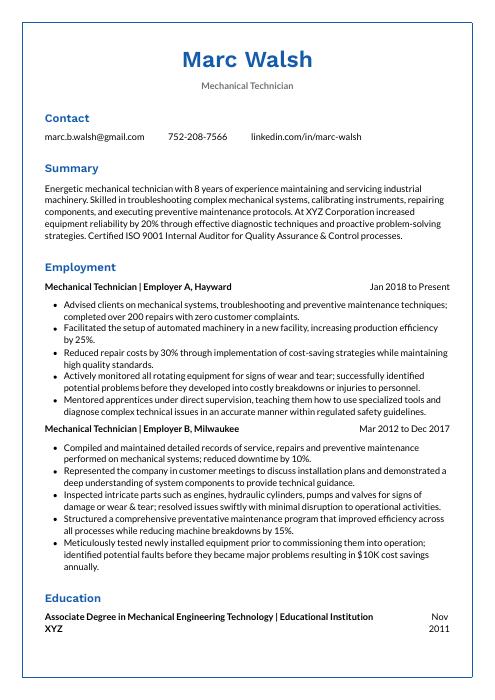

Mechanical Technician Resume Templates

Numbat

Numbat Jerboa

Jerboa Saola

Saola Quokka

Quokka Kinkajou

Kinkajou Axolotl

Axolotl Indri

Indri Rhea

Rhea Hoopoe

Hoopoe Markhor

Markhor Ocelot

Ocelot Dugong

Dugong Bonobo

Bonobo Cormorant

Cormorant Lorikeet

Lorikeet Echidna

Echidna Fossa

Fossa Gharial

Gharial Pika

Pika Rezjumei

Rezjumei