Materials Technician Resume Guide

Materials technicians are responsible for inspecting, testing, and analyzing the quality of materials used in manufacturing processes. They conduct tests to determine properties such as strength or stability, inspect raw materials to ensure they meet standards before being sent out for production, and analyze data from test results to recommend changes in product design.

Your expertise in testing and analyzing materials would be an invaluable asset to any laboratory. But employers don’t know how great you are yet, so you need a resume that puts your qualifications on full display.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

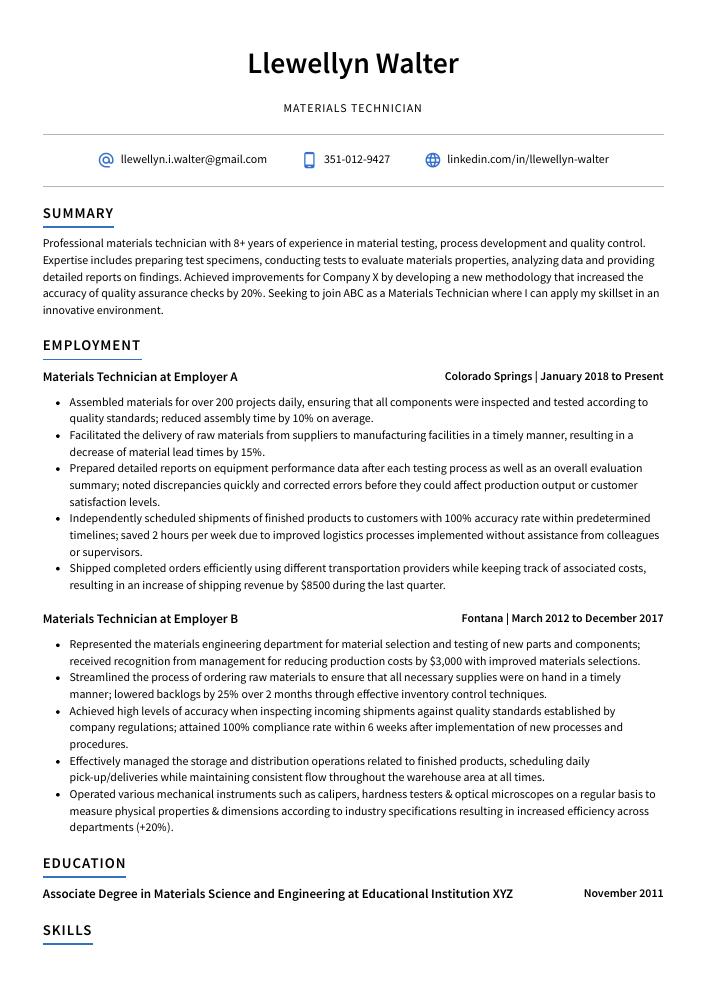

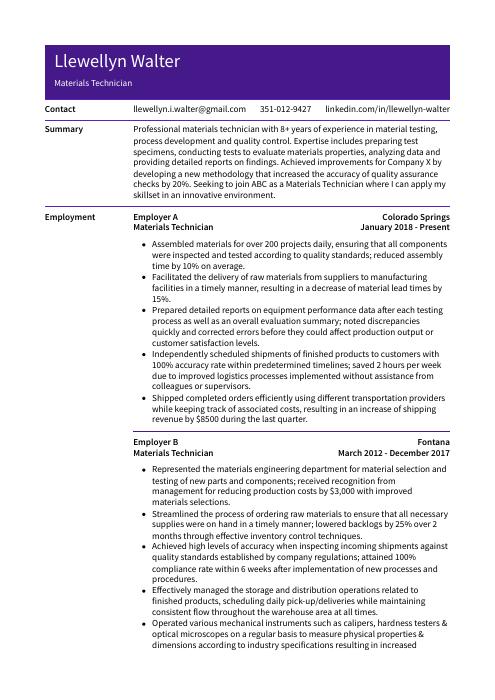

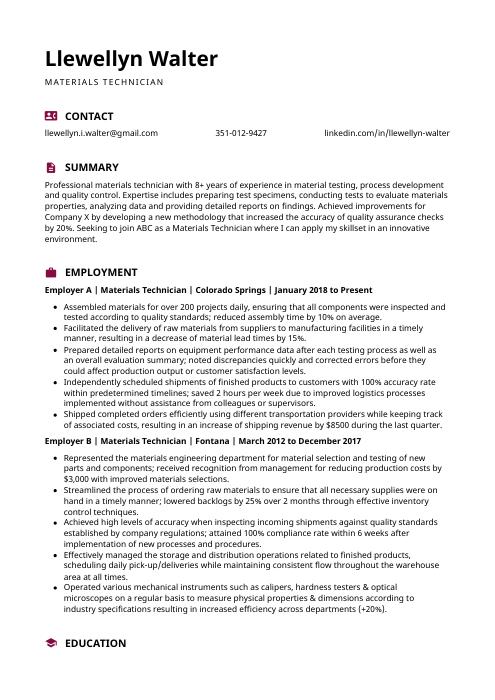

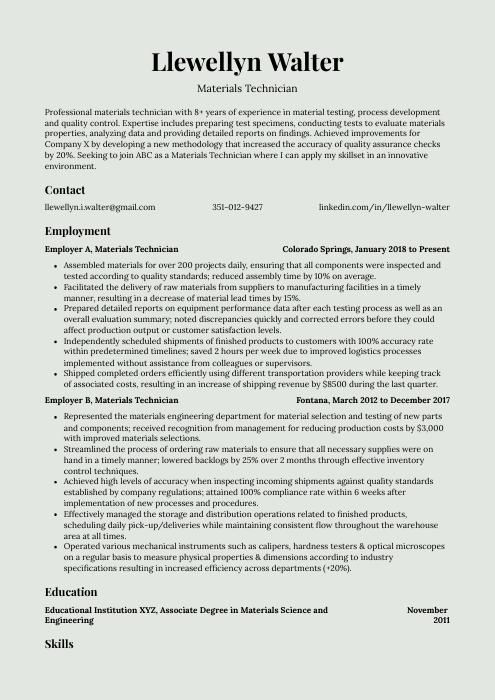

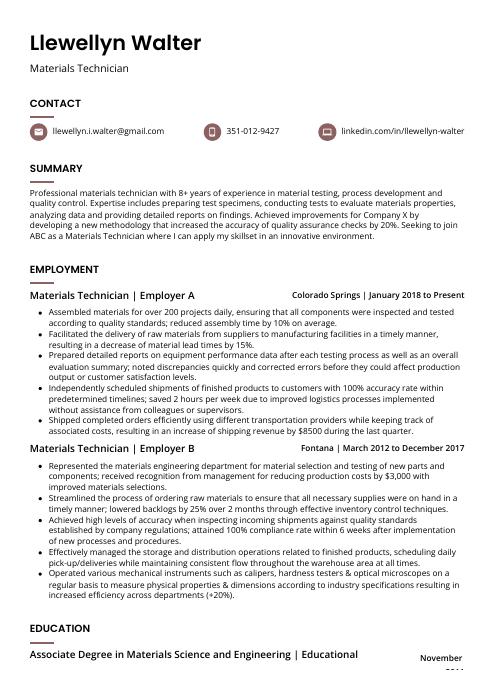

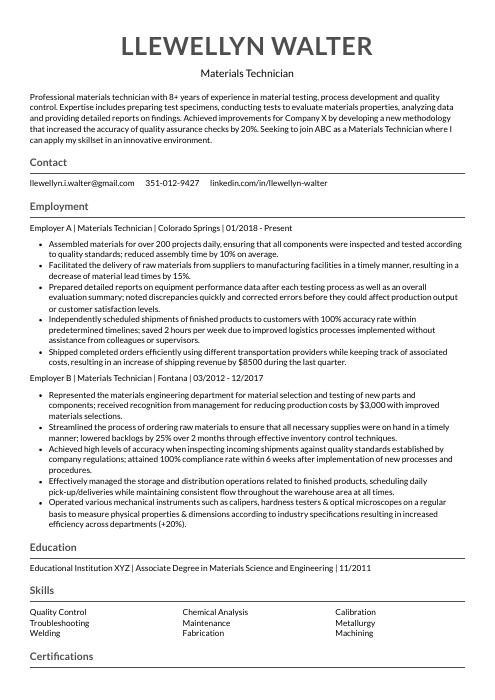

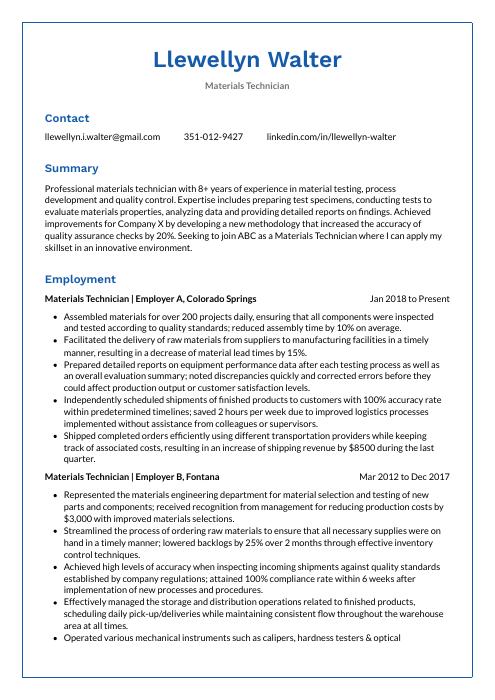

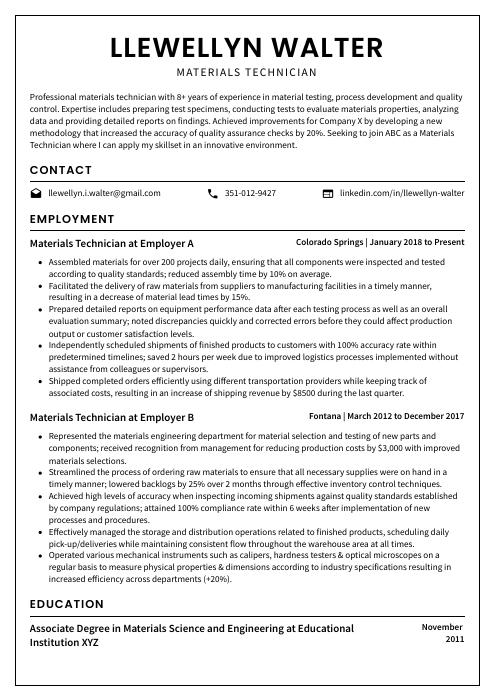

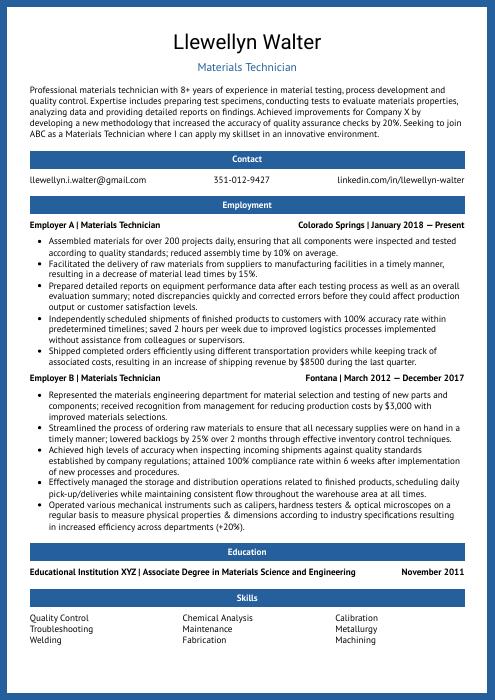

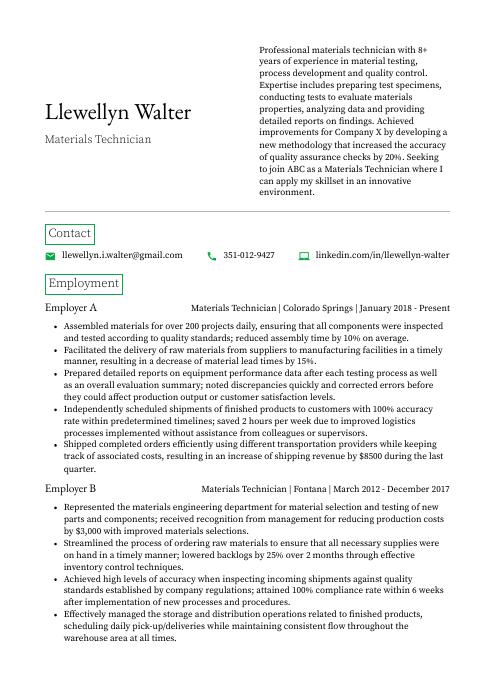

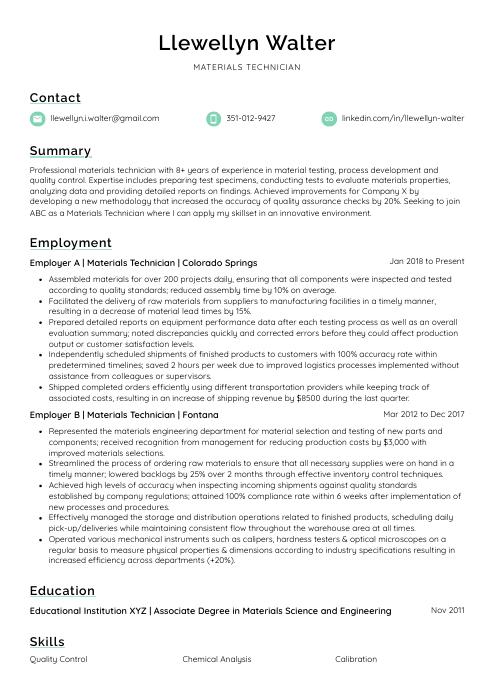

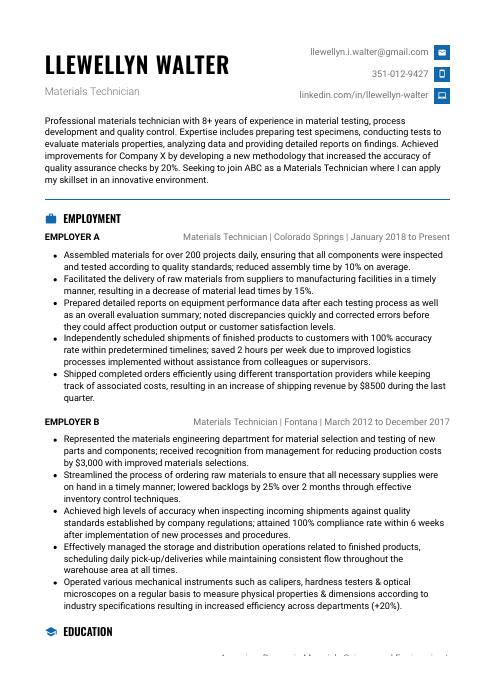

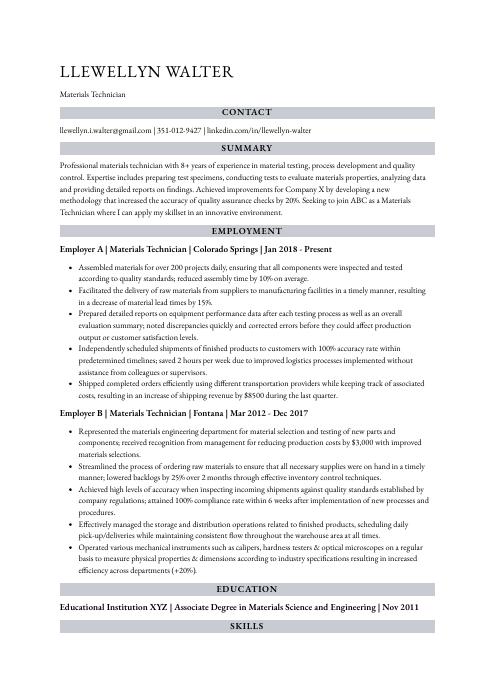

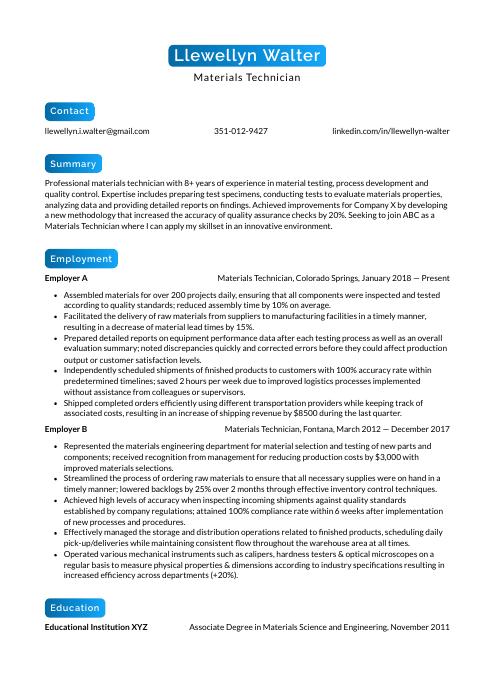

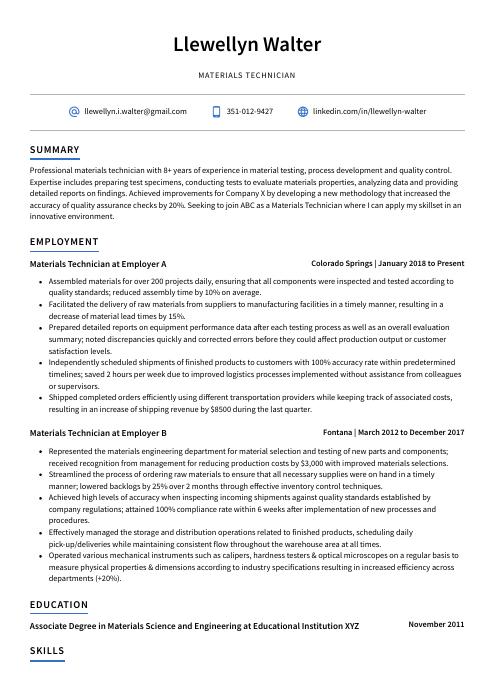

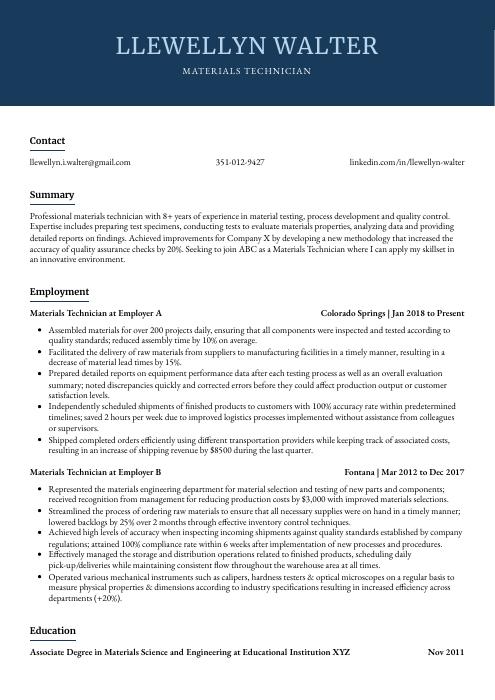

Materials Technician Resume Sample

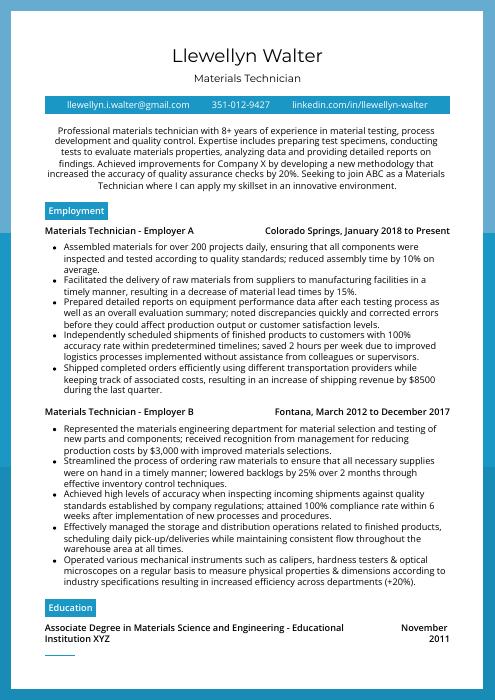

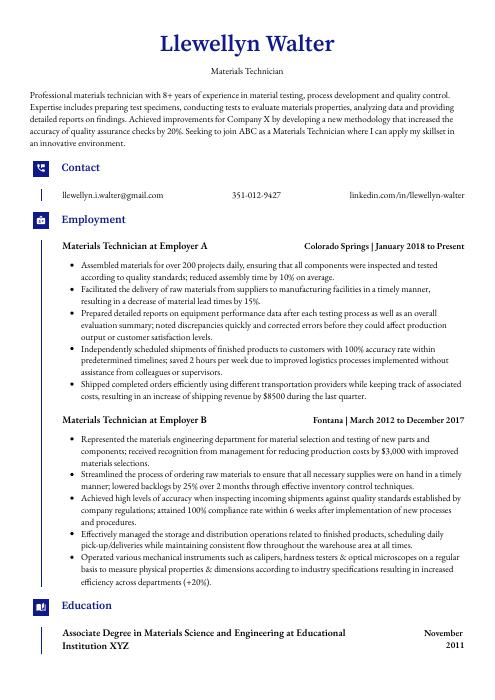

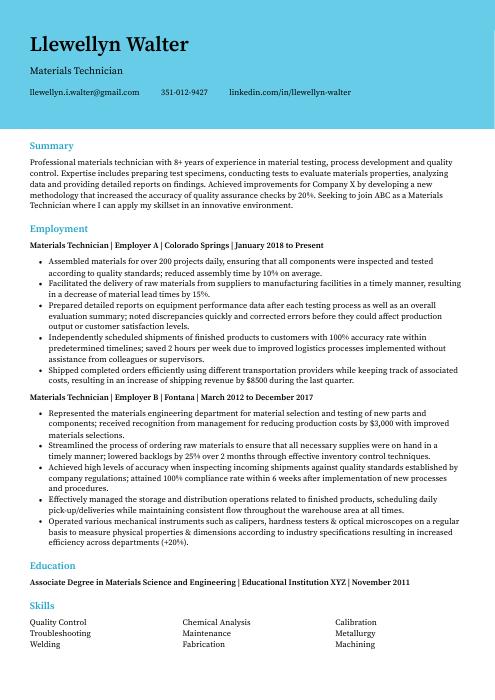

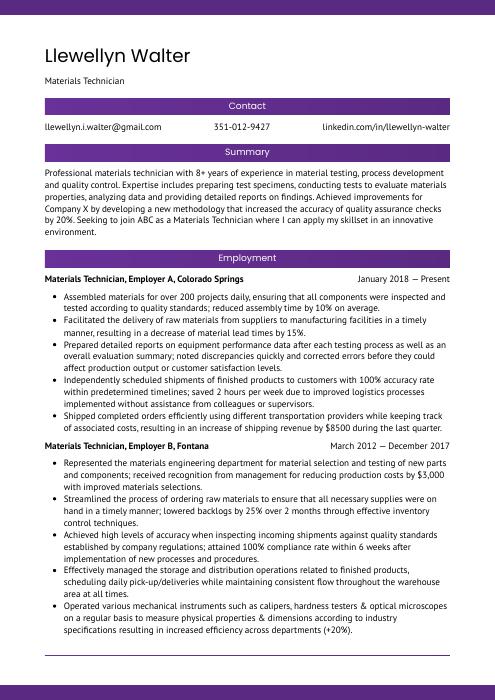

Llewellyn Walter

Materials Technician

[email protected]

351-012-9427

linkedin.com/in/llewellyn-walter

Summary

Professional materials technician with 8+ years of experience in material testing, process development and quality control. Expertise includes preparing test specimens, conducting tests to evaluate materials properties, analyzing data and providing detailed reports on findings. Achieved improvements for Company X by developing a new methodology that increased the accuracy of quality assurance checks by 20%. Seeking to join ABC as a Materials Technician where I can apply my skillset in an innovative environment.

Experience

Materials Technician, Employer A

Colorado Springs, Jan 2018 – Present

- Assembled materials for over 200 projects daily, ensuring that all components were inspected and tested according to quality standards; reduced assembly time by 10% on average.

- Facilitated the delivery of raw materials from suppliers to manufacturing facilities in a timely manner, resulting in a decrease of material lead times by 15%.

- Prepared detailed reports on equipment performance data after each testing process as well as an overall evaluation summary; noted discrepancies quickly and corrected errors before they could affect production output or customer satisfaction levels.

- Independently scheduled shipments of finished products to customers with 100% accuracy rate within predetermined timelines; saved 2 hours per week due to improved logistics processes implemented without assistance from colleagues or supervisors.

- Shipped completed orders efficiently using different transportation providers while keeping track of associated costs, resulting in an increase of shipping revenue by $8500 during the last quarter.

Materials Technician, Employer B

Fontana, Mar 2012 – Dec 2017

- Represented the materials engineering department for material selection and testing of new parts and components; received recognition from management for reducing production costs by $3,000 with improved materials selections.

- Streamlined the process of ordering raw materials to ensure that all necessary supplies were on hand in a timely manner; lowered backlogs by 25% over 2 months through effective inventory control techniques.

- Achieved high levels of accuracy when inspecting incoming shipments against quality standards established by company regulations; attained 100% compliance rate within 6 weeks after implementation of new processes and procedures.

- Effectively managed the storage and distribution operations related to finished products, scheduling daily pick-up/deliveries while maintaining consistent flow throughout the warehouse area at all times.

- Operated various mechanical instruments such as calipers, hardness testers & optical microscopes on a regular basis to measure physical properties & dimensions according to industry specifications resulting in increased efficiency across departments (+20%).

Skills

- Quality Control

- Chemical Analysis

- Calibration

- Troubleshooting

- Maintenance

- Metallurgy

- Welding

- Fabrication

- Machining

Education

Associate Degree in Materials Science and Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Materials Technician (CMT)

American Society for Quality (

May 2017

1. Summary / Objective

Your resume summary/objective is your chance to make a great first impression on the hiring manager. In this section, you should highlight your experience in materials testing and inspection, as well as any certifications or qualifications that demonstrate your expertise. You can also mention any successes you have had in improving production processes or reducing costs for past employers.

Below are some resume summary examples:

Well-rounded materials technician with 3+ years of experience in material handling, quality assurance and inventory management. At XYZ, managed the ordering and distribution process for 20 different materials/supplies while ensuring compliance to all safety standards. Received company-wide recognition for reducing waste by 25% through efficient utilization of resources. Proven ability to work efficiently under pressure while maintaining a high degree of accuracy and attention to detail.

Proficient materials technician with 5+ years of experience in quality control, testing and inspection. Skilled at analyzing material samples using the latest equipment and standards to ensure product safety and reliability. At XYZ Corporation, inspected more than 20000 finished products for compliance prior to shipment. Received numerous accolades from upper management for exceeding all expectations on time-sensitive projects without compromising quality or accuracy.

Enthusiastic and detail-oriented materials technician with 5+ years of experience in material testing, inspecting, and planning. Proven track record for quickly diagnosing problems and providing solutions to difficult issues. On past projects reduced rework by 18% through proactive inspections that identified potential quality concerns before they became major defects. Looking to bring my expertise to ABC Tech as a Materials Technician.

Talented materials technician with 5+ years of experience in the aerospace industry. Experienced in developing and maintaining laboratory test procedures, evaluating materials performance, and creating reports to support product development. Successfully identified a new composite material for aircraft cabin parts that reduced weight by 20%. Recognized as an expert on quality assurance processes and organizational safety regulations.

Dependable materials technician with 10+ years of experience in the manufacturing and materials industries. Experienced at performing quality control inspections, analyzing tests results, identifying defects, troubleshooting material deficiencies and recommending corrective actions to resolve issues. Adept at working collaboratively within a team or independently to achieve project objectives on time and under budget.

Accomplished materials technician with 6+ years of experience in the manufacturing sector. Expertise includes supply chain management, inventory control, and process optimization. At ABC Company, reduced material cost by 16% within a year through careful budgeting and monitoring of resources. Seeking to join XYZ Inc., utilizing my knowledge of materials handling techniques to ensure efficient operations at all times.

Skilled materials technician with 7+ years of experience in the inspection, testing and analysis of raw materials used for production. Proven track record of success in identifying defects, monitoring product quality and providing detailed reports to support decision-making. Looking to join ABC Company as a Materials Technician to help ensure material integrity while reducing costs across the board.

Reliable materials technician with 5+ years of experience in a high-volume manufacturing environment. Skilled at troubleshooting production processes and providing technical support to ensure smooth operations. Seeking to join ABC Factory as the next materials technician where I can apply my expertise in quality assurance, inventory control, and supply chain management.

2. Experience / Employment

For the experience section, you want to provide details on your employment history. This should be written in reverse chronological order, with the most recent role listed first.

Stick primarily to bullet points when writing this section; it makes it easier for the reader to digest what you have said quickly. When talking about what you did and achieved, make sure that each point is detailed and quantifiable if possible.

For example, instead of saying “Tested materials,” you could say, “Performed tensile strength tests on various metals using a hydraulic testing machine according to ASTM standards which resulted in accurate data being collected.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Assembled

- Calibrated

- Operated

- Monitored

- Measured

- Tested

- Analyzed

- Troubleshot

- Adjusted

- Fabricated

- Processed

- Packaged

- Stored

- Shipped

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Presented materials to be tested for various mechanical, chemical and physical properties; conducted over 500 tests in a single year resulting in accurate results with less than 2% error rate.

- Calibrated laboratory equipment such as force gauges, stress analyzers and ultrasonic inspection systems according to manufacturer’s specifications; improved accuracy of testing process by 10%.

- Substantially increased the productivity of materials testing processes by 20%; developed specialized procedures that led to faster data collection without sacrificing quality or safety standards.

- Processed material samples efficiently using advanced computer-aided design (CAD) tools; reduced total processing time from six hours per sample down to four hours on average while increasing precision level by 30%.

- Inspected raw materials for defects prior to use and monitored production outputs following established quality control protocols; detected faulty merchandise before it reached customers at least five times a month, saving the company $1,500 each quarter in losses.

- Troubleshot and repaired over 500 pieces of mechanical equipment, resulting in a 10% increase in production output.

- Fabricated and installed various types of materials such as steel, wood and plastics to build fixtures, cabinets and other structures; saved up to $1,000 per order by using scrap material for certain projects.

- Accurately measured dimensions of parts with calipers & micrometers against engineering drawings for quality control purposes; reduced scrap rate from 0.5% down to 0%.

- Reduced downtime on assembly lines by quickly diagnosing deficiencies in machinery components and performing timely maintenance services; completed repairs within 2 hours or less 90% of the time.

- Spearheaded the implementation of new inventory management system which improved tracking accuracy from 73% up to 95%, allowing better visibility into stock levels across multiple warehouses nationwide.

- Reliably tested and inspected material components using specialized equipment to meet customer standards, improving accuracy by 15% over the last year.

- Utilized technical knowledge of metallurgy, welding & fabrication processes to identify potential design flaws in materials; reduced manufacturing time by 10%.

- Introduced innovative methods for production quality control that increased throughput while reducing waste levels by 20%.

- Optimized inventory management systems with a focus on cost-effectiveness, resulting in a savings of $30K per quarter on raw materials costs.

- Developed comprehensive reports documenting test results and identifying areas for improvement within the production line; decreased defect rate from 5% to 0.8%.

- Developed and tested new materials, formulations and compounds to meet customer needs; increased product strength by 15% while reducing production costs by $7,000.

- Formulated data-driven material specifications based on industry standards and customer requirements; achieved 100% accuracy in all tests conducted over a five month period.

- Monitored incoming raw materials for quality assurance purposes and ensured that they met the required specifications before allowing them into inventory storage; rejected 6 batches of non-compliant products during this process.

- Adjusted existing formulas to improve their performance or extend their shelf life as needed; successfully carried out over 25 such modifications with no significant changes in cost structure or manufacturing timescale.

- Proficiently operated laboratory equipment including spectrometers, mass balances, hardness testers and microscopes to gather detailed physical properties analysis of different materials used in production processes.

- Thoroughly inspected and tested materials for mechanical, chemical, electrical and physical properties; improved quality control processes by 30%, resulting in higher product standards.

- Improved the production capacity of manufacturing plants by 25% through the introduction of innovative material handling strategies utilizing new technologies.

- Structured routine maintenance schedules to ensure that all equipment was operating safely and efficiently; reduced downtime by 15%.

- Mentored a team of 8 technicians on best practices related to proper material analysis techniques with an emphasis on safety awareness; increased productivity levels among staff members by 22%.

- Analyzed raw materials such as steel, aluminum or plastic resins to determine precise composition before processing them into finished products per company specifications; created 2 new test protocols which helped reduce waste during testing procedures by 10%.

- Expedited the delivery of over $25,000 worth of materials and supplies for production projects, reducing out-of-stock situations by 50%.

- Diligently monitored inventory levels to ensure that all necessary components were stocked in the supply room; identified potential shortages before they occurred and averted any production delays.

- Measured temperature, pressure and humidity levels within storage areas on a regular basis to maintain optimal conditions for long term durability; reduced spoilage rate by 20% in one month alone.

- Advised colleagues on proper material handling techniques during manufacturing operations, improving safety performance at the workplace by 30%.

- Assessed product quality through periodic testing of raw materials used in various stages of production; detected inconsistencies early-on which resulted in an overall reduction of customer complaints by 25%.

- Revised procedures for the storage and distribution of materials, resulting in an 18% decrease in operating costs.

- Compiled inventory records detailing over 200 types of raw materials; accurately reported on stock levels across all warehouses weekly.

- Stored and organized a variety of items such as lumber, steel bars and electrical components according to safety standards; improved efficiency by 30%.

- Coordinated with suppliers to replenish stocks when needed while maintaining cost-effective purchasing practices; reduced spending on materials by $1,000 per month at peak times.

- Confidently operated warehouse equipment including forklifts, pallet jacks & hoists to move heavy loads weighing up to 1 tonne during loading/unloading tasks within tight deadlines (+12 hours).

- Packaged and shipped over 500 materials and supplies a month, ensuring that quality-control standards were met and maintained.

- Demonstrated advanced knowledge of material handling processes for the organization; successfully reduced costs associated with shipping errors by 40%.

- Participated in inventory management activities to maintain accurate records on all incoming shipments and outgoing orders; assisted in eliminating wasted time looking for misplaced items by 25%.

- Reorganized parts storage area, allowing easy access to critical tools & machinery components while increasing safety within the warehouse environment.

- Actively monitored stock levels of raw materials used to manufacture products, resulting in an 11% reduction of total spend on these items during the last quarter alone.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with knowledge of the latest safety regulations, while another may be looking for someone who is well-versed in material testing techniques.

As such, you want to tailor the skills section of your resume to each job that you are applying for. This will ensure that applicant tracking systems (which many employers use) can easily detect relevant keywords and pass on your resume to a human reviewer.

Once listed here, it would also be beneficial if you discussed these abilities further in other areas of your resume; this could include talking about them more thoroughly in the summary or experience sections.

Below is a list of common skills & terms:

- CAD/CAM Software

- Calibration

- Chemical Analysis

- Fabrication

- Machining

- Maintenance

- Metallurgy

- Quality Control

- Troubleshooting

- Welding

4. Education

Including an education section on your resume depends on how much experience you have in the materials technician field. If you are just starting out and don’t yet have any work experience, include an education section below your resume objective. However, if you already have a few years of relevant work history to showcase, omitting the education section is perfectly fine.

If an education section is included on your resume, try to mention courses and subjects related to materials technology that demonstrate knowledge applicable for this role.

Associate Degree in Materials Science and Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a given field. They show potential employers that you have taken the time to learn about an industry or skill set, and are committed to staying up-to-date with the latest developments.

Including certifications on your resume can be beneficial when applying for jobs as they prove that you possess certain qualifications which may give you an edge over other applicants. Be sure to list any relevant certifications so hiring managers know what skills and experience you bring to the table.

Certified Materials Technician (CMT)

American Society for Quality (

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Llewellyn Walter, this would be Llewellyn-Walter-resume.pdf or Llewellyn-Walter-resume.docx.

7. Cover Letter

Including a cover letter in your job application is one of the best ways to make a great impression on recruiters. It should provide more detail about who you are, what qualifications and experience you have, and why you believe that makes you an ideal candidate for the role.

Cover letters usually consist of 2 to 4 paragraphs and don’t need to be longer than one page in length. They help employers gain further insight into your skillset beyond what’s stated in your resume, giving them a better understanding of how well-suited you’d be for the position they’re hiring for.

Below is an example cover letter:

Dear Adelbert,

I am writing in response to your job posting for a Materials Technician. With experience working in both manufacturing and construction environments, I have the skills and knowledge to excel in this role.

In my current position as a Materials Technician at [company name], I am responsible for inspecting incoming materials, verifying that they meet quality standards, and documenting any discrepancies. I also maintain detailed records of all material testing results and coordinate with suppliers to resolve any issues. Through my efforts, I have helped reduce material defects by 15%.

In previous roles, I gained experience working with a variety of materials including metals, plastics, composites, and ceramics. My comprehensive understanding ofmaterial properties and behavior has allowed me to identify potential problems early on and propose solutions that improve product quality while minimizing costs.

I am confident that I can be an asset to your team. My attention to detail and ability to work independently will allow me to hit the ground running in this role. Please find attached a copy of my resume for your review; I look forward to speaking with you soon about this opportunity.

Sincerely,

Llewellyn

Materials Technician Resume Templates

Pika

Pika Hoopoe

Hoopoe Saola

Saola Fossa

Fossa Indri

Indri Markhor

Markhor Cormorant

Cormorant Ocelot

Ocelot Quokka

Quokka Lorikeet

Lorikeet Echidna

Echidna Rhea

Rhea Gharial

Gharial Dugong

Dugong Jerboa

Jerboa Numbat

Numbat Kinkajou

Kinkajou Axolotl

Axolotl Bonobo

Bonobo Rezjumei

Rezjumei