Manufacturing Engineer Resume Guide

Manufacturing Engineers are responsible for designing and developing manufacturing processes, as well as overseeing their implementation. They analyze production costs to identify areas of improvement, develop ways to increase efficiency in the factory or plant setting, and ensure that all safety regulations are followed. Additionally, they may design machinery and equipment layouts for new factories or plants.

Your expertise in the manufacturing industry is unparalleled, but potential employers don’t know about you yet. To get their attention and show them what you can do, your resume must be well-crafted and impressive.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

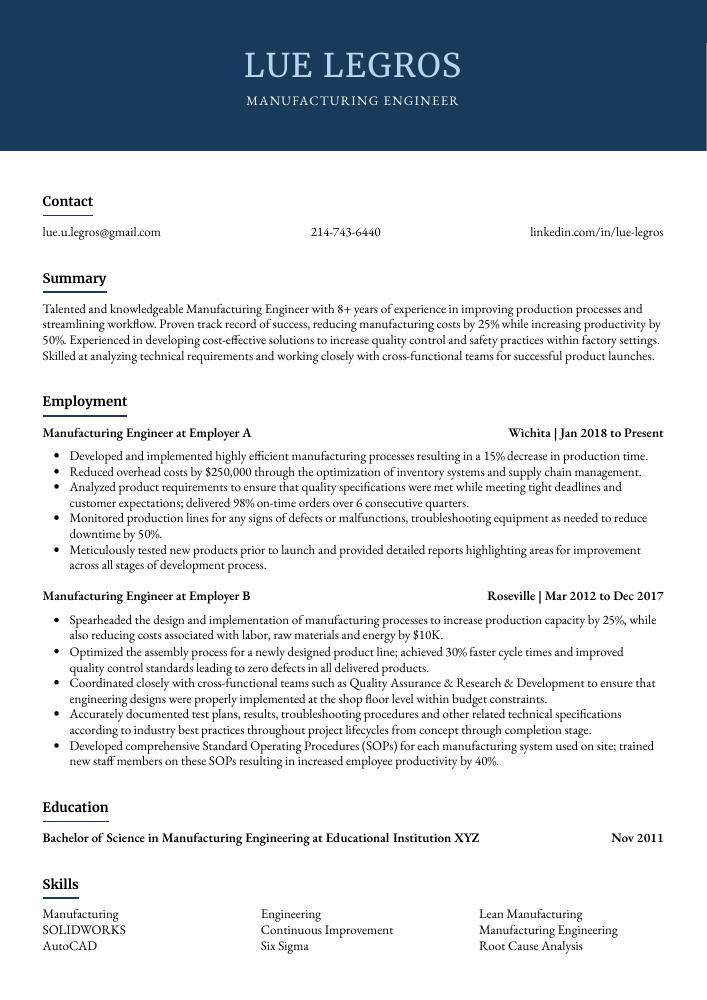

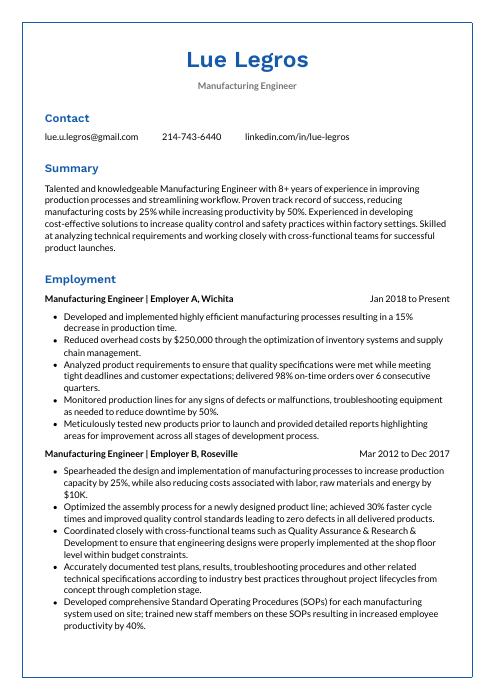

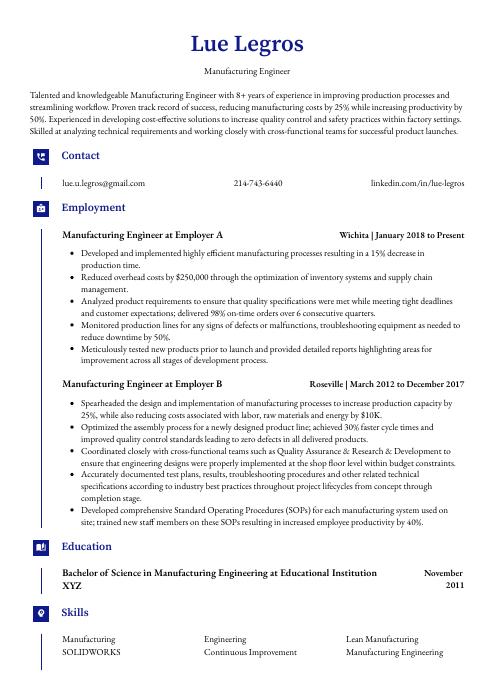

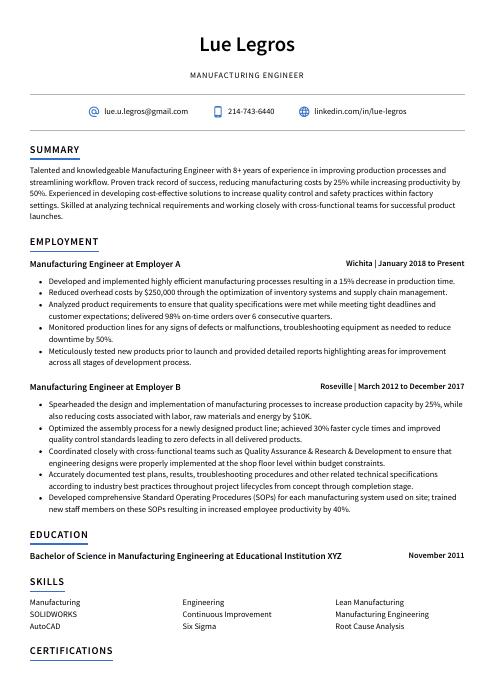

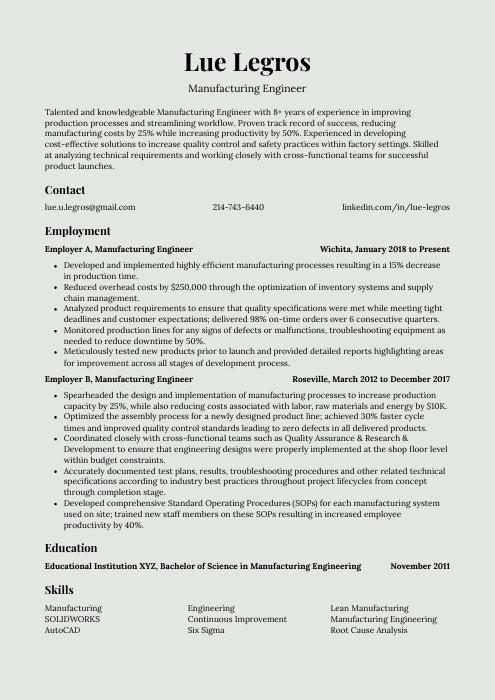

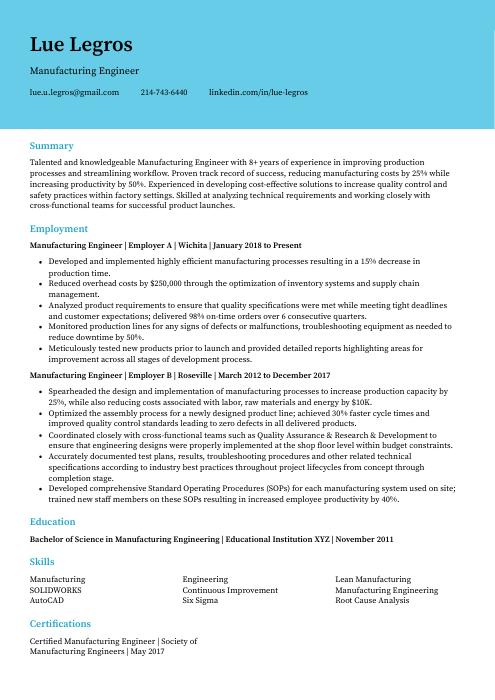

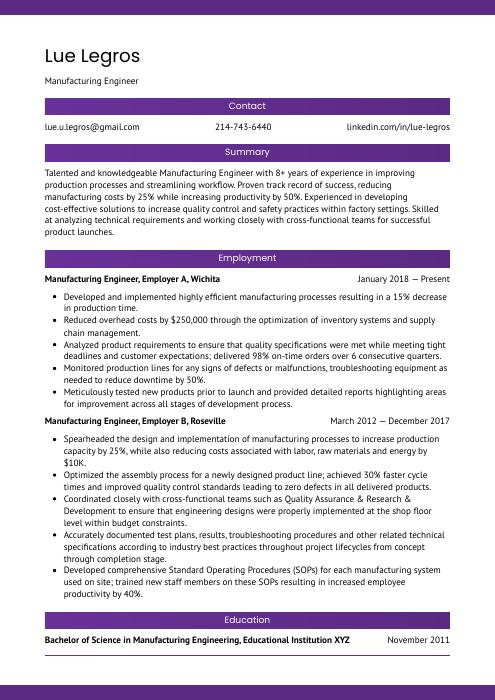

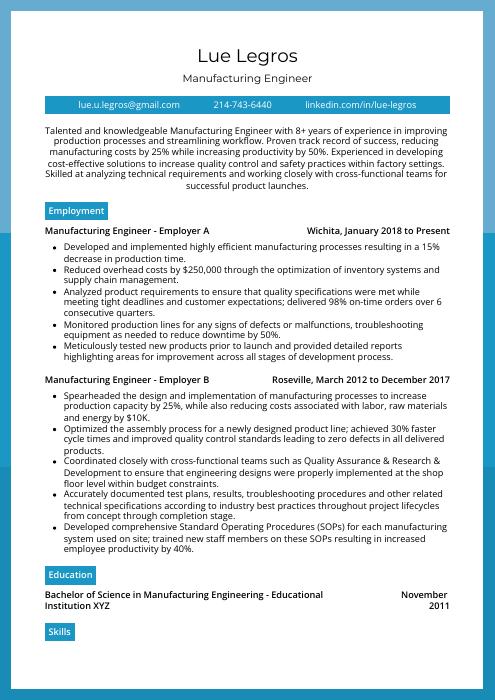

Manufacturing Engineer Resume Sample

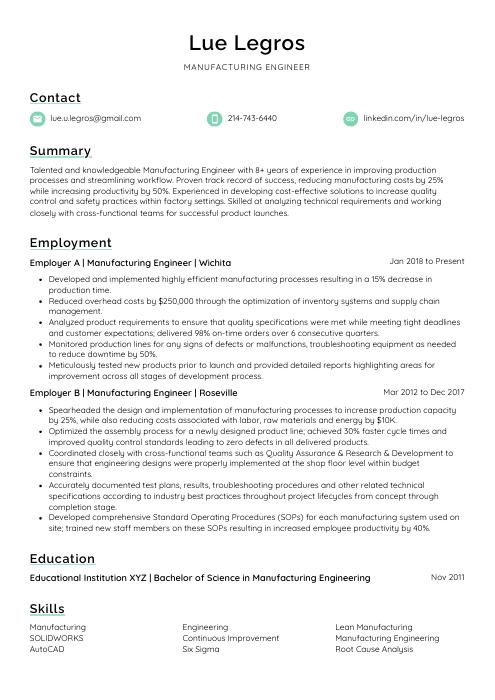

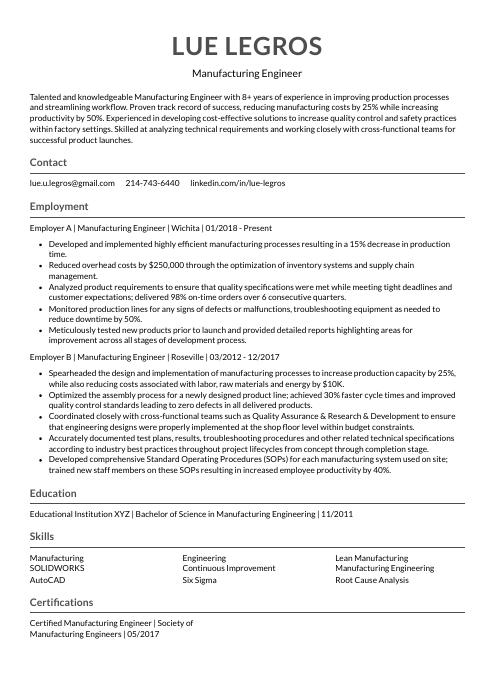

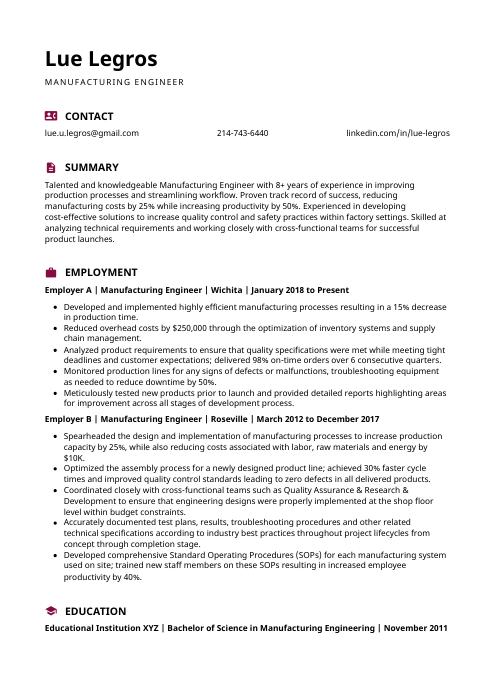

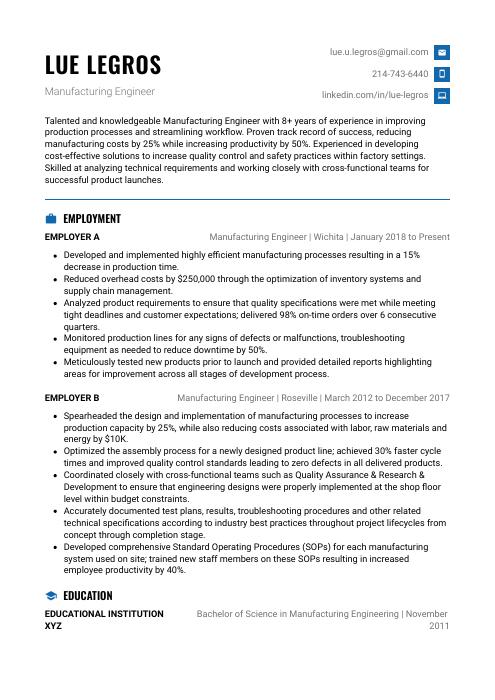

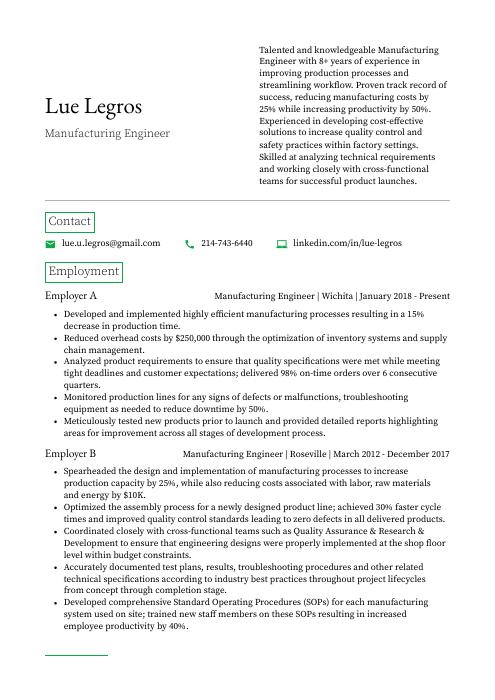

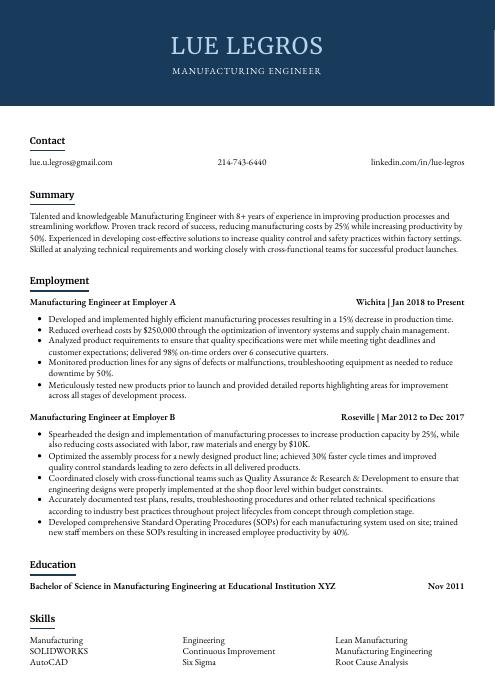

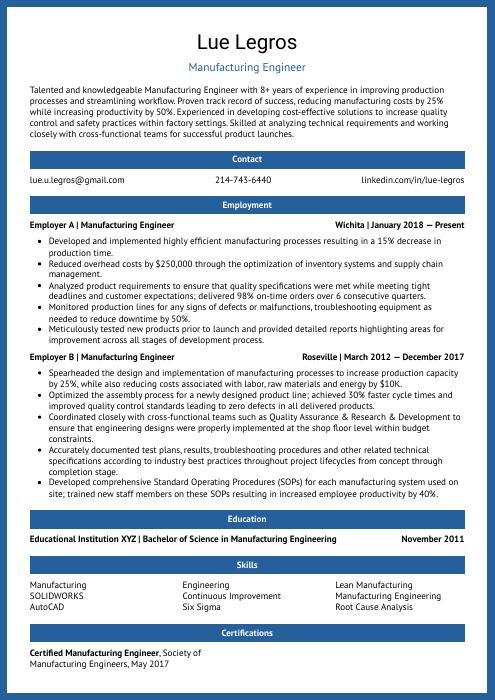

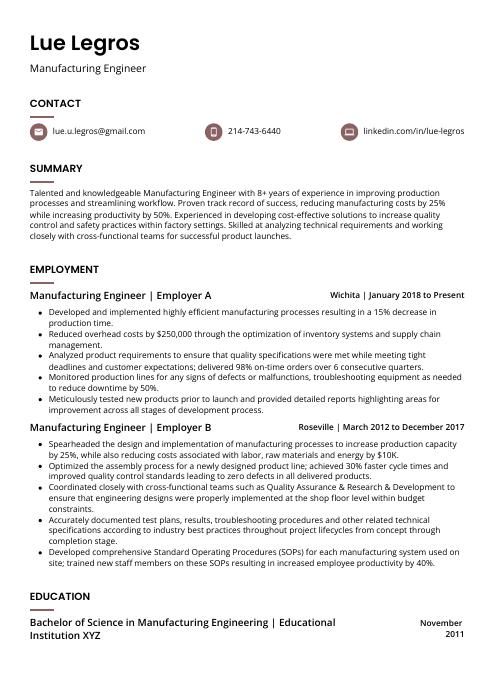

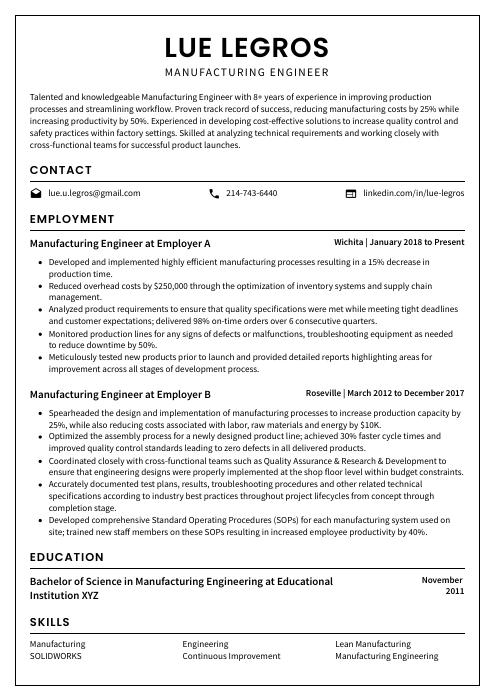

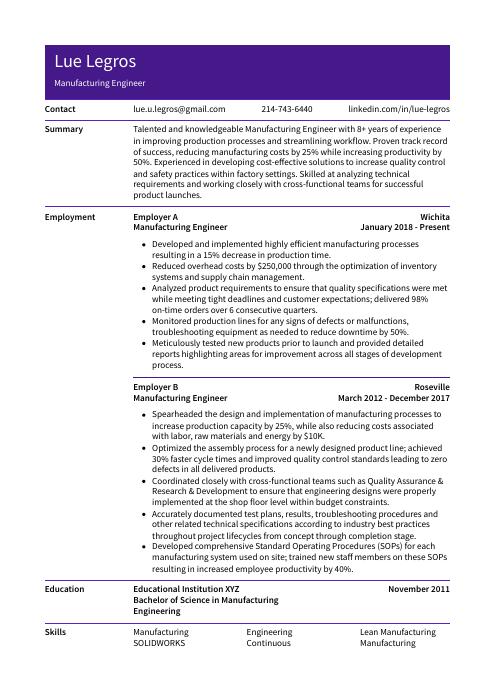

Lue Legros

Manufacturing Engineer

[email protected]

214-743-6440

linkedin.com/in/lue-legros

Summary

Talented and knowledgeable Manufacturing Engineer with 8+ years of experience in improving production processes and streamlining workflow. Proven track record of success, reducing manufacturing costs by 25% while increasing productivity by 50%. Experienced in developing cost-effective solutions to increase quality control and safety practices within factory settings. Skilled at analyzing technical requirements and working closely with cross-functional teams for successful product launches.

Experience

Manufacturing Engineer, Employer A

Wichita, Jan 2018 – Present

- Developed and implemented highly efficient manufacturing processes resulting in a 15% decrease in production time.

- Reduced overhead costs by $250,000 through the optimization of inventory systems and supply chain management.

- Analyzed product requirements to ensure that quality specifications were met while meeting tight deadlines and customer expectations; delivered 98% on-time orders over 6 consecutive quarters.

- Monitored production lines for any signs of defects or malfunctions, troubleshooting equipment as needed to reduce downtime by 50%.

- Meticulously tested new products prior to launch and provided detailed reports highlighting areas for improvement across all stages of development process.

Manufacturing Engineer, Employer B

Roseville, Mar 2012 – Dec 2017

- Spearheaded the design and implementation of manufacturing processes to increase production capacity by 25%, while also reducing costs associated with labor, raw materials and energy by $10K.

- Optimized the assembly process for a newly designed product line; achieved 30% faster cycle times and improved quality control standards leading to zero defects in all delivered products.

- Coordinated closely with cross-functional teams such as Quality Assurance & Research & Development to ensure that engineering designs were properly implemented at the shop floor level within budget constraints.

- Accurately documented test plans, results, troubleshooting procedures and other related technical specifications according to industry best practices throughout project lifecycles from concept through completion stage.

- Developed comprehensive Standard Operating Procedures (SOPs) for each manufacturing system used on site; trained new staff members on these SOPs resulting in increased employee productivity by 40%.

Skills

- Manufacturing

- Engineering

- Lean Manufacturing

- SOLIDWORKS

- Continuous Improvement

- Manufacturing Engineering

- AutoCAD

- Six Sigma

- Root Cause Analysis

Education

Bachelor of Science in Manufacturing Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Manufacturing Engineer

Society of Manufacturing Engineers

May 2017

1. Summary / Objective

Your resume summary should be a brief yet compelling introduction to your professional experience and qualifications as a manufacturing engineer. In this section, you should highlight the most important skills that make you an ideal candidate for the job – such as knowledge of CAD/CAM software, expertise in lean manufacturing principles, or success with streamlining production processes. Additionally, mention any awards or certifications that demonstrate your commitment to excellence in engineering.

Below are some resume summary examples:

Professional Manufacturing Engineer with 8+ years of experience in the automotive industry. Highly skilled at designing, developing and troubleshooting manufacturing processes to ensure cost-effective production operations. Proven track record of optimizing existing designs while creating new ones to reduce costs without compromising quality or safety standards. Specialty areas include CNC programming, CAD/CAM design, Lean Manufacturing principles and Six Sigma process improvement methods.

Hard-working and highly organized manufacturing engineer with 5+ years of experience in the automotive industry. Proven track record of utilizing Lean Six Sigma principles to reduce production costs by 20% and increase throughput capacity by 50%. At XYZ, successfully led the implementation of new processes for cost optimization and waste reduction. Excellent problem-solving skills combined with a deep understanding of CAD/CAM software make me an ideal candidate for this role.

Driven manufacturing engineer with 8+ years of experience in product design, assembly line optimization and process improvement. Skilled in using CAD/CAM software to create detailed drawings for precision parts manufacturing. Proven record of reducing production costs by 19% while improving quality standards at XYZ Manufacturing. Seeking to join ABC’s team as a Senior Engineer where I can use my technical knowledge and expertise to drive successful production outcomes.

Dependable and results-driven manufacturing engineer with 4+ years of experience in the automotive industry. At ABC, successfully integrated a new production line that resulted in an increase of efficiency by 20%. Proven record of developing innovative solutions to reduce costs and improve quality while maintaining safety protocols. Skilled at leading cross-functional teams to achieve challenging project goals on time and within budget.

Detail-oriented manufacturing engineer with 5+ years of experience in product development and cost optimization. Experienced in streamlining processes, identifying improvement opportunities, and driving process efficiencies to reduce costs. Seeking a manufacturing engineering position at ABC Corp where I can utilize my expertise to maximize the efficiency of production operations while ensuring compliance with safety standards.

Seasoned Manufacturing Engineer with over 10 years of experience in the automotive manufacturing industry. Experienced in developing and implementing cost-effective production methods to meet customer demands, while ensuring quality standards are met. Proven track record of improving productivity by 30% and lowering costs by 25%. Skilled at using CAD/CAM software for design optimization and process simulation.

Reliable and detail-oriented manufacturing engineer with 5+ years of experience in the design and optimization of production processes. Adept at quickly identifying problems, implementing solutions, and ensuring quality control standards are met. Recently led a successful project that decreased cost by 10% while increasing efficiency by 15%. Looking to join ABC Manufacturing as part of their engineering team.

Skilled manufacturing engineer with 8+ years of applied experience in cost-effective production and process improvement. Solid record of successfully designing, testing, and implementing new processes to improve efficiency across the board. At ABC Corp., improved throughput by 15% while reducing costs by 25%. Seeking to bring that same level of expertise to an innovative organization like XYZ Inc.

2. Experience / Employment

The work history/experience section should be written in reverse chronological order, with your most recent role listed at the top. Use bullet points to provide details on what you did and the results of your efforts.

For example, instead of saying “Developed manufacturing processes,” you could say, “Created a new production process for automotive components that increased throughput by 20% while reducing costs by 15%. ”.

Be sure to include any technical skills or tools used as well as any certifications or qualifications obtained during this time period.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Optimized

- Fabricated

- Assembled

- Installed

- Monitored

- Troubleshot

- Programmed

- Calibrated

- Inspected

- Tested

- Analyzed

- Improved

- Documented

- Implemented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Independently designed, developed and implemented new manufacturing processes to increase production efficiency by 28%, resulting in a cost reduction of $1.2 million.

- Presented innovative solutions to improve existing machinery designs and assembly processes that saved an additional 7% in production costs over six months.

- Revised company-wide safety protocols related to machine operations, reducing injury incidents by 20%.

- Fabricated prototype components using CNC machining tools for product testing; identified 3 design flaws prior to release which prevented defective products from entering the market.

- Facilitated collaboration between engineering teams as well as other departments such as Quality Control, Purchasing and Logistics; decreased project lead times by 30%.

- Utilized CNC programming software to design and manufacture precision components for machinery, leading to a 6% increase in production output.

- Calibrated machines on the factory floor to ensure parts met exact tolerances; tested over 80 assemblies per shift with no errors reported during quality control inspections.

- Substantially increased efficiency by automating labor-intensive processes from start-up through completion; reduced cycle times by 24%, resulting in higher throughput capacity and better ROI of capital investments.

- Compiled comprehensive reports detailing machine performance data, cost savings initiatives and other metrics related to manufacturing operations; presented these findings at weekly team meetings for further optimization efforts.

- Streamlined assembly line workflows using Lean Manufacturing techniques, eliminating non-value added activities which enabled faster product delivery while maintaining high standards of quality assurance throughout the process.

- Programmed automated production machines to run 24/7, increasing output by 35% and reducing downtime of factory equipment by 20%.

- Thoroughly inspected all manufacturing processes from start to finish for quality assurance; reduced defect rate in final products by 10%.

- Inspected machined components using a variety of measurement tools such as calipers, micrometers and depth gauges; identified defects quickly and repaired them on-site.

- Reorganized the layout of assembly lines with efficient material handling systems that enabled faster processing times while maintaining high standards of safety protocols; decreased lead time per unit produced by 15%.

- Prepared detailed reports outlining process improvements, cost reduction strategies and design modifications based on customer feedback which increased satisfaction ratings among clients by 12%.

- Formulated and executed cost-effective production plans for manufacturing teams, resulting in a 12% reduction of labor costs and an increase in efficiency by 23%.

- Advised executives on the best methods to reduce waste and improve quality assurance; decreased product recalls due to defects by 50%.

- Reliably monitored all automated systems within the facility, ensuring that safety regulations were followed at all times; implemented new process controls which improved output rate by 22%.

- Mentored junior engineers on advanced techniques related to automation processes and maintenance schedules; successfully trained 10 team members over two years.

- Represented company at industry events around the country, showcasing successful products & services while networking with potential partners & clients; generated $500K worth of sales leads from attending conferences throughout 2020 alone.

- Installed and tested 10+ automated production systems, reducing manual labor by 20% and increasing product output from 50 to 75 units per hour.

- Assembled parts for 15 new machines with precision accuracy, ensuring that each system was ready for operation within two weeks of initial delivery.

- Introduced more efficient manufacturing processes which resulted in a 25% reduction in waste materials and an increase in gross profit margins of $10K annually.

- Expedited the assembly process by 30%, while maintaining quality assurance standards; generated cost savings of $5K over the course of six months using lean-manufacturing techniques such as JIT (Just In Time) inventory management practices & Kanban scheduling strategies.

- Consistently met or exceeded deadlines set forth by upper management despite challenging timelines; achieved 95% success rate on all assigned projects during three years as Manufacturing Engineer at ABC Company.

- Troubleshot and resolved manufacturing process and equipment problems, resulting in a 25% increase in production efficiency.

- Improved existing designs of machinery parts to enhance performance and reduce downtime by 30%.

- Structured complex processes for new product introduction, testing protocols & quality assurance checks which resulted in an 87% reduction in lead time on all items produced.

- Implemented innovative automation solutions that increased productivity rates by 45% while simultaneously reducing labor costs by 20%.

- Actively monitored production data to identify areas of potential improvement; developed strategies that drove cost savings of over $25K annually from reduced wastage and energy consumption levels.

- Demonstrated expertise in manufacturing processes, executing tests and analyzing results to identify opportunities for redesigning production equipment and streamlining operations; improved productivity by 20% within 6 months.

- Tested new materials and components for use in the production process, identifying cost savings of $10K per quarter through more efficient sourcing methods.

- Participated actively in design review meetings with cross-functional teams to ensure that product designs meet customer requirements while remaining compliant with applicable codes & standards; consistently met project deadlines ahead of schedule by an average of 4 days each time.

- Designed fixtures, tooling and other components using CAD software such as SolidWorks; generated detailed specifications outlining machining tolerances required when fabricating parts from various metals including steel, aluminum & titanium alloys at a fraction of usual costs associated with manual fabrication techniques used previously.

- Effectively managed inventory levels on a daily basis to minimize stockouts while avoiding overstocking situations which could lead to wastage or obsolescence issues down the line; implemented updated protocols resulting in reduced safety stockholding levels by 30%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require proficiency in CAD software while Organization XYZ may need knowledge of CNC machinery.

It is essential to tailor the skills section of your resume to each job you are applying for because many employers use applicant tracking systems these days, which scan resumes for certain keywords before passing them on to a human.

You should also elaborate on the most important skills in other sections such as the summary or experience section – this will help demonstrate that you have what it takes and make sure that your resume doesn’t get filtered out by an ATS.

Below is a list of common skills & terms:

- 5S

- Aerospace

- AutoCAD

- Autodesk Inventor

- Automation

- Automotive

- CAD

- CATIA

- CNC Programming

- Computer Aided Design

- Continuous Improvement

- Cross Functional Team Leadership

- Data Analysis

- Design for Manufacturing

- Design of Experiments

- Electronics

- Engineering

- Engineering Management

- FMEA

- Finite Element Analysis

- GD&T

- Industrial Engineering

- Kaizen

- Lean Manufacturing

- MATLAB

- Machine Tools

- Machining

- Manufacturing

- Manufacturing Engineering

- Mechanical Engineering

- Minitab

- PTC Creo

- Pro Engineer

- Problem Solving

- Process Engineering

- Process Improvement

- Product Design

- Product Development

- Project Planning

- Root Cause Analysis

- SOLIDWORKS

- SPC

- Six Sigma

- Team Leadership

- Teamwork

- Testing

- Time Management

- Troubleshooting

- Value Stream Mapping

4. Education

Adding an education section to your resume is optional depending on how far along you are in your career. If you just graduated and have no prior job experience, list your education below the resume objective. However, if you’ve been working as a manufacturing engineer for years with plenty of work accomplishments to showcase, omitting an education section might be best.

If including an education section, try to mention courses and subjects related to the manufacturing engineering role that could help demonstrate your qualifications for the position.

Bachelor of Science in Manufacturing Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show that you have taken the time and effort to gain knowledge of the subject matter, as well as prove that you are proficient in it.

If there is an industry-specific certification related to the job you are applying for, make sure to include it on your resume. This will help employers understand how qualified and experienced you are for their position.

Certified Manufacturing Engineer

Society of Manufacturing Engineers

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Lue Legros, this would be Lue-Legros-resume.pdf or Lue-Legros-resume.docx.

7. Cover Letter

Attaching a cover letter to your job application is a great way to make yourself stand out from the competition. It’s an opportunity for you to explain why you’re the right candidate for the role and what makes you unique.

Cover letters are usually made up of 2-4 paragraphs that highlight relevant skills, experiences and qualifications related to the position being applied for. By writing one, it gives recruiters more insight into who you are as a professional and why they should consider hiring you over other applicants.

Below is an example cover letter:

Dear Willow,

I am writing in response to your posting for a Manufacturing Engineer. As an experienced professional with a Bachelor’s degree in Mechanical Engineering and 5+ years of experience working in manufacturing, I am confident I would be a valuable asset to your team.

In my current role at [company name], I am responsible for overseeing the production of parts and components for automotive applications. I have gained extensive knowledge of lean manufacturing principles and have successfully implemented several process improvements that have resulted in increased efficiency and productivity. In addition, I have developed strong problem-solving skills that enable me to quickly identify and resolve issues that arise during production.

I am knowledgeable of various CAD software programs and have experience using them to create models and drawings for new products. My ability to effectively communicate with other engineers, managers, and workers across all levels of the organization has allowed me to successfully manage projects from start to finish.

I believe my skills and experience make me well-qualified for the Manufacturing Engineer position at your company. I look forward to speaking with you soon about this opportunity. Thank you for your time and consideration.

Sincerely,

Lue

Manufacturing Engineer Resume Templates

Markhor

Markhor Gharial

Gharial Axolotl

Axolotl Saola

Saola Dugong

Dugong Jerboa

Jerboa Rhea

Rhea Lorikeet

Lorikeet Indri

Indri Hoopoe

Hoopoe Echidna

Echidna Quokka

Quokka Bonobo

Bonobo Numbat

Numbat Kinkajou

Kinkajou Ocelot

Ocelot Fossa

Fossa Cormorant

Cormorant Pika

Pika Rezjumei

Rezjumei