Instrumentation Engineer Resume Guide

Instrumentation Engineers design, install and maintain electronic systems used to measure physical conditions such as pressure, flow rate, temperature or level. They use a variety of instruments including transducers, thermocouples and transmitters to ensure that the data being collected is accurate. Additionally they develop control systems which regulate the operations of industrial plants in order to maximize efficiency and safety.

Your engineering experience and expertise make you a perfect fit for any instrumentation role. But employers don’t know who you are yet, so to get their attention, you must create an impressive resume that highlights your qualifications.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

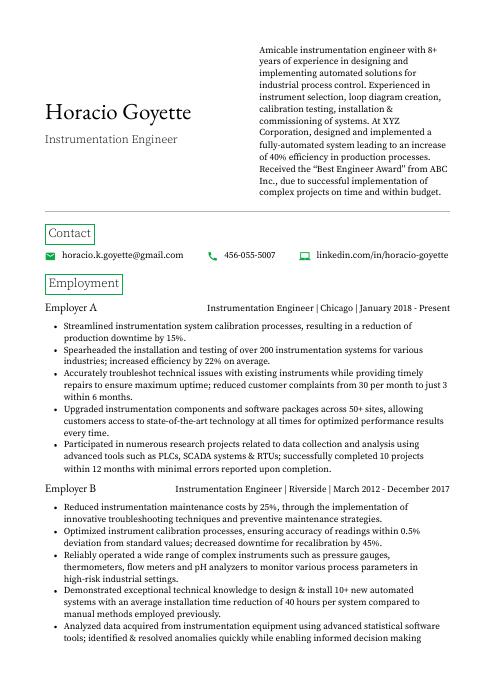

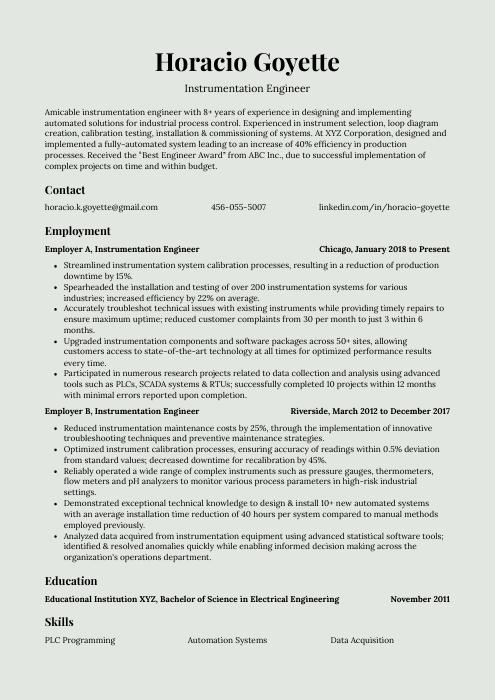

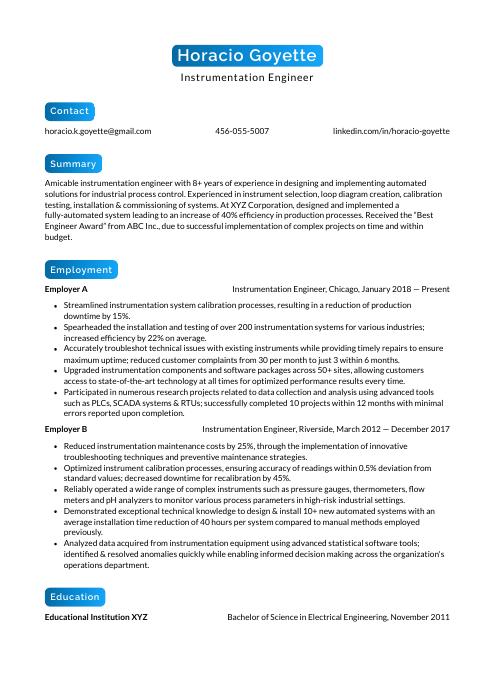

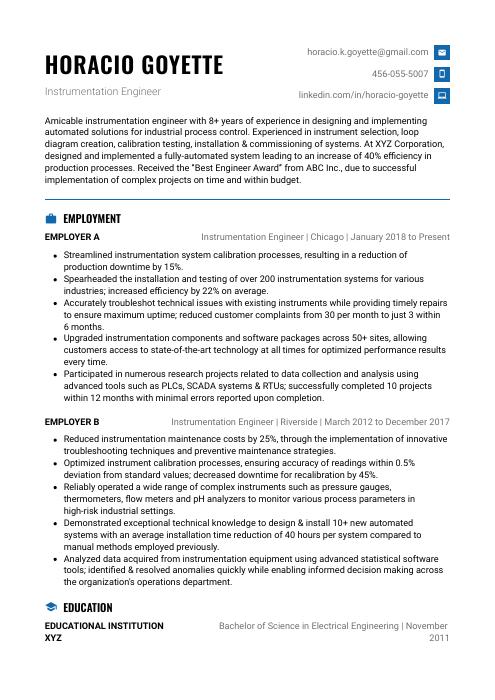

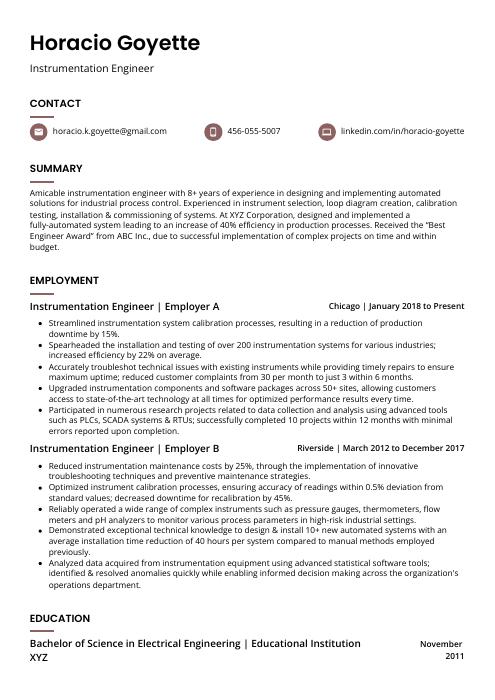

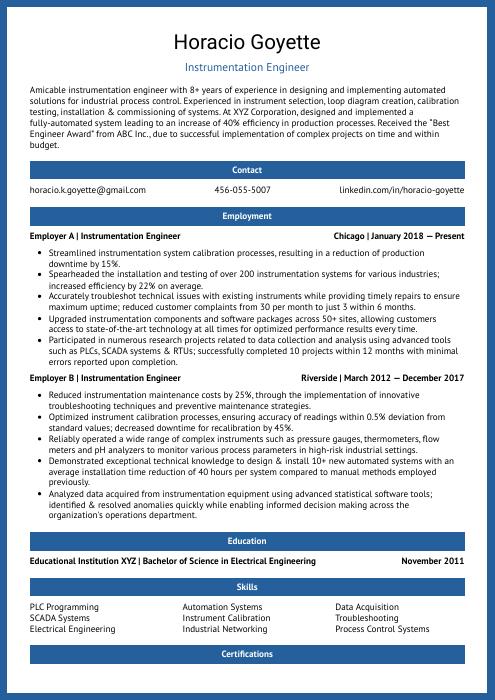

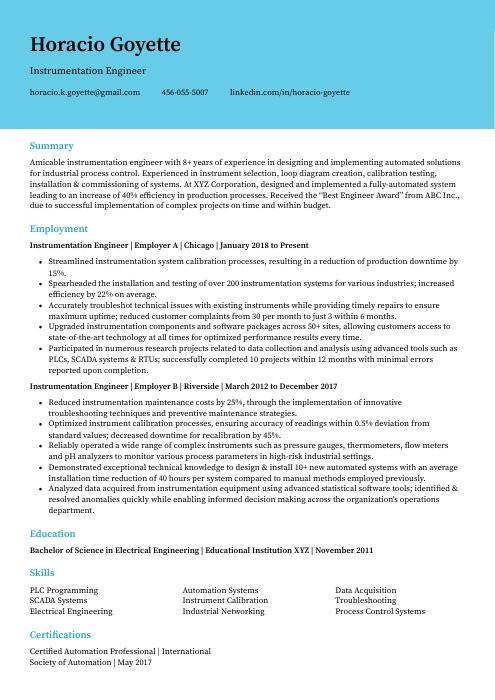

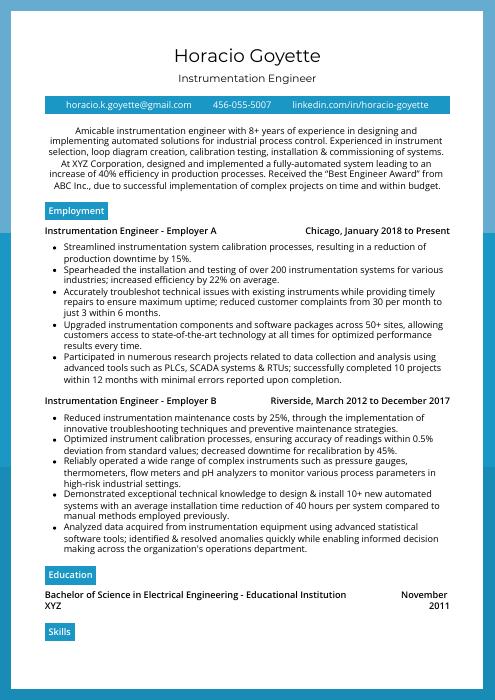

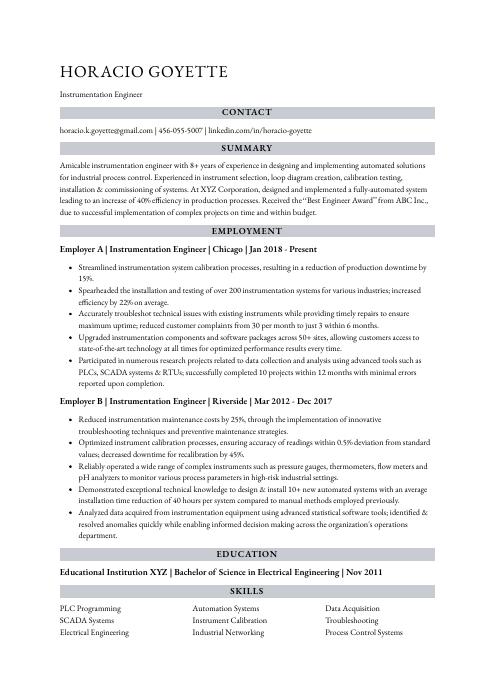

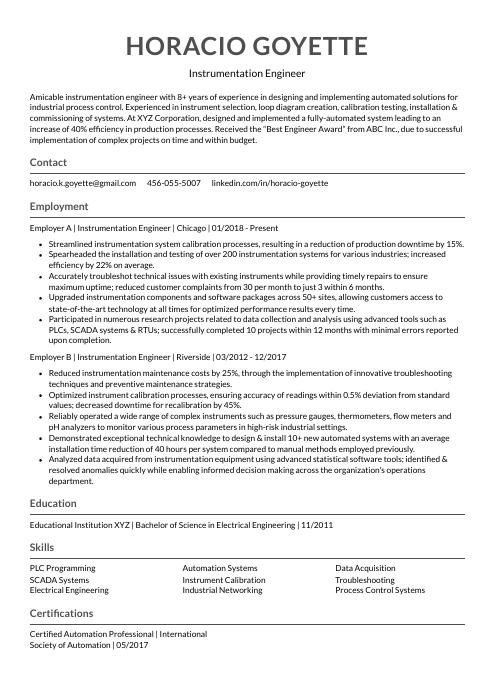

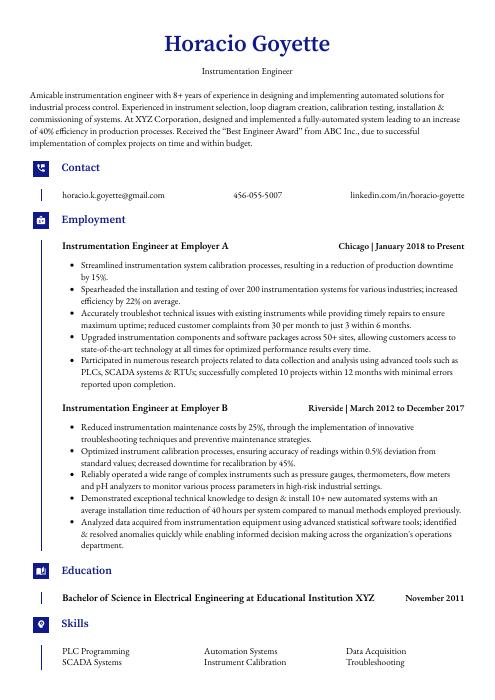

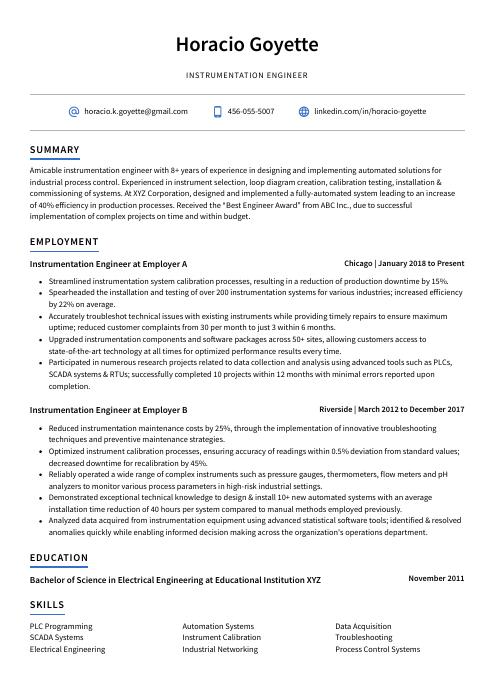

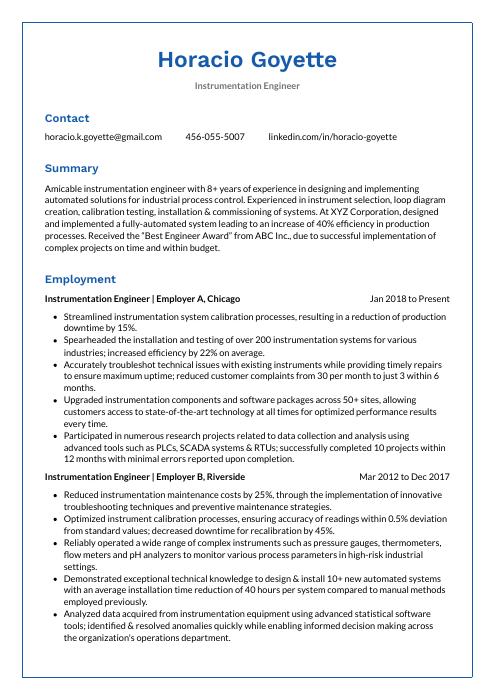

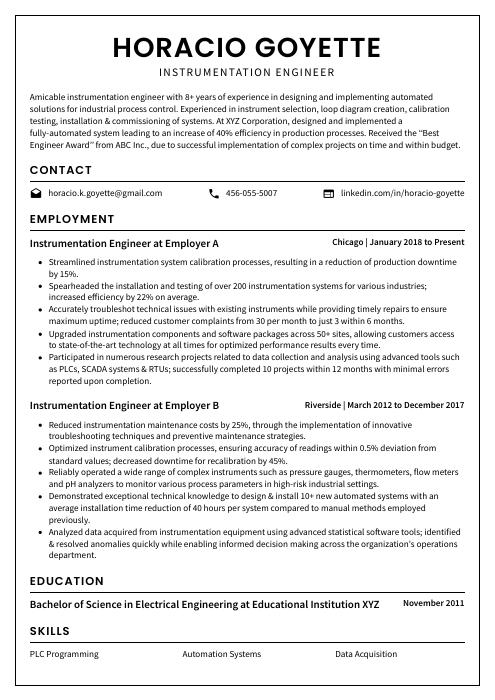

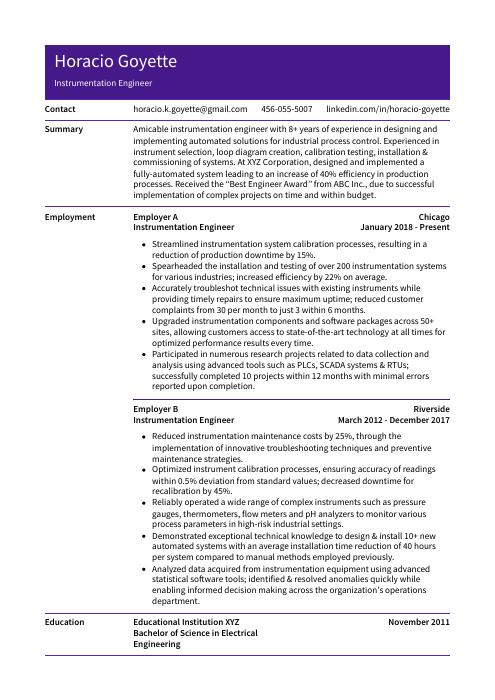

Instrumentation Engineer Resume Sample

Horacio Goyette

Instrumentation Engineer

[email protected]

456-055-5007

linkedin.com/in/horacio-goyette

Summary

Amicable instrumentation engineer with 8+ years of experience in designing and implementing automated solutions for industrial process control. Experienced in instrument selection, loop diagram creation, calibration testing, installation & commissioning of systems. At XYZ Corporation, designed and implemented a fully-automated system leading to an increase of 40% efficiency in production processes. Received the “Best Engineer Award” from ABC Inc., due to successful implementation of complex projects on time and within budget.

Experience

Instrumentation Engineer, Employer A

Chicago, Jan 2018 – Present

- Streamlined instrumentation system calibration processes, resulting in a reduction of production downtime by 15%.

- Spearheaded the installation and testing of over 200 instrumentation systems for various industries; increased efficiency by 22% on average.

- Accurately troubleshot technical issues with existing instruments while providing timely repairs to ensure maximum uptime; reduced customer complaints from 30 per month to just 3 within 6 months.

- Upgraded instrumentation components and software packages across 50+ sites, allowing customers access to state-of-the-art technology at all times for optimized performance results every time.

- Participated in numerous research projects related to data collection and analysis using advanced tools such as PLCs, SCADA systems & RTUs; successfully completed 10 projects within 12 months with minimal errors reported upon completion.

Instrumentation Engineer, Employer B

Riverside, Mar 2012 – Dec 2017

- Reduced instrumentation maintenance costs by 25%, through the implementation of innovative troubleshooting techniques and preventive maintenance strategies.

- Optimized instrument calibration processes, ensuring accuracy of readings within 0.5% deviation from standard values; decreased downtime for recalibration by 45%.

- Reliably operated a wide range of complex instruments such as pressure gauges, thermometers, flow meters and pH analyzers to monitor various process parameters in high-risk industrial settings.

- Demonstrated exceptional technical knowledge to design & install 10+ new automated systems with an average installation time reduction of 40 hours per system compared to manual methods employed previously.

- Analyzed data acquired from instrumentation equipment using advanced statistical software tools; identified & resolved anomalies quickly while enabling informed decision making across the organization’s operations department.

Skills

- PLC Programming

- Automation Systems

- Data Acquisition

- SCADA Systems

- Instrument Calibration

- Troubleshooting

- Electrical Engineering

- Industrial Networking

- Process Control Systems

Education

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Automation Professional

International Society of Automation

May 2017

1. Summary / Objective

The summary or objective at the beginning of your instrumentation engineer resume should be a snapshot of who you are and why you make an excellent candidate for this role. You could mention the types of instruments or systems that you have experience working with, any certifications or awards related to engineering, and how you solved complex technical issues in past roles. This is where you can really shine!

Below are some resume summary examples:

Professional instrumentation engineer with 5+ years of experience in designing, developing and maintaining control systems for industrial process plants. Highly experienced in troubleshooting complex instrumentation issues and delivering optimal solutions to client requirements. At XYZ, successfully designed a new system architecture that improved the plant operations’ efficiency by 30%. Possess excellent technical skills along with strong communication abilities necessary to effectively collaborate on projects.

Passionate Instrumentation Engineer with 7+ years of experience in designing and troubleshooting instrumentation systems. Experienced in developing control strategies, conducting research studies, and optimizing data acquisition processes. Proven track record of successfully integrating new technologies into existing solutions to ensure optimal performance. Looking to utilize my expertise at ABC Company to drive efficiency improvements in their instrumentation system design process.

Detail-oriented instrumentation engineer with 5+ years of experience designing and installing instrumentation systems for industrial applications. Proven track record in overseeing the implementation of advanced control systems that have significantly increased accuracy, reliability, and safety within production environments. Aims to join ABC’s team as an Instrumentation Engineer to utilize my expertise in developing cost-effective solutions for their clients.

Hard-working instrumentation engineer with 7+ years of experience in the oil and gas industry. Strong background in designing, commissioning, troubleshooting and maintaining instrumentation systems for offshore rigs. Experienced at configuring PLCs to ensure accurate data collection from various sources. Proven record of developing cost-effective solutions that increased safety and efficiency onsite while reducing downtime by 40%.

Driven instrumentation engineer with 8+ years of experience in the design, installation, and commissioning of industrial instrument systems. Skilled at troubleshooting complex problems to ensure optimal performance of both new and existing equipment. Seeking a new opportunity as an Instrument Engineer at ABC Engineering where I can utilize my expertise in process control systems to provide innovative solutions for clients.

Seasoned instrumentation engineer with over 15 years of experience designing, installing and maintaining instrumentation systems for high-capacity industrial processes. Expert in the use of various types of instruments such as flow meters, pressure gauges, thermocouples and PLCs to monitor process conditions. Proven ability to identify and resolve problems quickly while remaining compliant with safety regulations.

Talented and results-driven instrumentation engineer with 8+ years of experience in the oil and gas industry. Proven track record of developing, installing, commissioning, testing, and troubleshooting process control systems to ensure optimal efficiency within a facility. Seeking to join ABC Energy Solutions as an Instrumentation Engineer where I can apply my knowledge to improve safety and performance standards.

Determined instrumentation engineer with 5+ years of experience in designing and developing complex instrumentation systems for the oil & gas industry. Seeking to join ABC Company, where expertise will be utilized to improve data collection accuracy, reduce downtime costs and increase overall plant efficiency. Recognized by XYZ Group for creating a cutting-edge system that increased production output by 18%.

2. Experience / Employment

In the experience section, you should list your work history in reverse chronological order. That means the most recent job is listed first.

When writing about what you did in each role, use bullet points to make it easier for the reader to take in the information quickly. You want to provide detail and explain how your actions resulted in quantifiable outcomes.

For example, instead of saying “Developed instrumentation systems,” you could say, “Designed a reliable instrumentation system that monitored pressure levels with an accuracy of +/- 0.2 PSI over a range of -100PSI to +200PSI.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Installed

- Programmed

- Calibrated

- Monitored

- Troubleshot

- Tested

- Commissioned

- Documented

- Analyzed

- Optimized

- Fabricated

- Assembled

- Configured

- Upgraded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Competently designed and developed instrumentation systems for over 25 industrial projects, resulting in a 10% reduction in energy costs.

- Advised clients on the selection of suitable instruments to meet their process requirements, ensuring that all operations were optimized to deliver superior performance outcomes.

- Tested existing instrumentation equipment and software programs for accuracy and reliability; identified system deficiencies which resulted in an improved efficiency level of 20%.

- Improved functionality of automation systems through programming changes by utilizing PLCs (Programmable Logic Controllers), HMIs (Human Machine Interfaces) as well as other computer-based control technologies such as SCADA (Supervisory Control And Data Acquisition).

- Utilized advanced data acquisition techniques like RTUs (Remote Terminal Units) to monitor the operation status of automated devices remotely; this enabled remote monitoring capabilities across multiple sites reducing downtime by 15 hours per month on average.

- Troubleshot over 500 instrumentation system faults, resulting in a 10% increase in operational uptime and an $8,000 reduction in annual maintenance costs.

- Fabricated custom-made instruments for process control applications using advanced mechanical assembly techniques; reduced lead times by 3 days on average.

- Assessed the performance of existing electro-mechanical systems against industry standards to identify areas of improvement; improved accuracy levels by 17%.

- Presented technical reports to management detailing repair and upgrade recommendations for over 15 critical components within instrumentation networks across multiple sites nationwide.

- Successfully implemented real-time data acquisition solutions that increased overall efficiency by 30% while reducing errors due to manual inputting down to 1%.

- Commissioned and tested over 100 instrumentation systems, resulting in an average $15,000 savings per project.

- Documented and maintained up-to-date technical records of all instruments installed, ensuring compliance with regulatory agencies at all times.

- Consistently monitored the performance of existing systems to identify any potential issues or malfunctions; reduced downtime by 30%.

- Assembled a variety of electrical and mechanical components for various instruments; completed tasks within budget while still meeting safety regulations & quality standards each time.

- Calibrated 200+ pieces of equipment onsite using advanced software programs such as LabVIEW and SCADA; improved accuracy levels by 10% compared to manual calibrations alone.

- Installed and configured over 20 complex instrumentation systems and ancillary components with precision, resulting in a 10% increase in productivity.

- Designed automated control programs to monitor and regulate process variables such as temperature, pressure and flow rate; identified potential safety issues beforehand that prevented accidents or malfunctions from occurring during operations.

- Effectively communicated technical information to other personnel for easier comprehension of project requirements; reduced the time required for training new staff by 50%.

- Compiled detailed reports on performance metrics, troubleshooting procedures, calibration methods and maintenance schedules; improved overall system reliability by 15%.

- Facilitated regular meetings between engineering teams to identify areas needing improvement across all projects and allocated resources accordingly; decreased downtime associated with manual adjustments by 25%.

- Actively developed and tested instrumentation systems for 50+ industrial processes, completed the installation of equipment within budget schedules and ensured operational readiness with 95% accuracy.

- Structured implementation plans to monitor prototype testing before full-scale production launch; identified potential issues in advance and resolved them quickly by modifying engineering designs accordingly.

- Monitored process behavior through data acquisition devices (PLCs & RTUs) on a daily basis, ensuring that performance levels met predetermined standards with deviation as low as 3%.

- Revised existing control loops using PID controllers or fuzzy logic techniques to optimize system efficiency at all times; improved energy utilization ratings by 15%.

- Programmed PLCs based on customer specifications for large scale automation projects across multiple industries over the course of 5 years; reduced operating costs by $20,000 per annum on average.

- Achieved a 10% increase in process efficiency by configuring over 200 pieces of instrumentation equipment across various industrial production sites.

- Represented the engineering team on 5 different projects, ensuring that all safety regulations and standard operating procedures were strictly adhered to at all times.

- Coordinated with a team of 15 technicians to develop innovative solutions for complex instrumentation problems; reduced malfunctioning rate from 30% to 3%.

- Proficiently maintained up-to-date calibration records for more than 250 instruments and monitored their performance according to set standards, reducing maintenance costs by $8,000 annually.

- Generated comprehensive test reports detailing findings and recommendations based on manual testing results while troubleshooting sophisticated electronic systems and devices within specified deadlines.

- Prepared and updated over 500 technical documents, specifications and drawings related to instrumentation engineering projects; achieved a cost reduction of 10% in the process.

- Meticulously designed, tested and implemented new control systems for clients within budget constraints while adhering to industry standards such as ISA 18.1 & IEC 61508-3; saved $25K on project costs by optimizing parts procurement procedures.

- Developed 20+ software applications for data acquisition analysis with an average 97% accuracy rate; increased system efficiency by 25%.

- Mentored junior engineers in developing programming skillsets & troubleshooting techniques when working with PLCs and HMIs; reduced development time per task from 3 days to 1 day on average among team members.

- Formulated innovative solutions that addressed complex automation problems arising during testing or commissioning phases resulting in a 30% increase in production throughput across three manufacturing sites worldwide.

- Reorganized instrumentation systems for a chemical plant, resulting in an 18% increase in production efficiency and cost savings of $10,000.

- Introduced innovative solutions to identify issues within the control system and implemented preventive maintenance programs that reduced downtime by 20%.

- Resourcefully designed & developed new instrumentation equipment to meet specific process requirements; improved accuracy levels by +25%.

- Expedited delivery times from suppliers by negotiating contracts with multiple vendors and managed inventory levels of spare parts to ensure uninterrupted operations.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization may be looking for someone with experience in industrial automation while another may require a strong understanding of instrumentation and control systems.

Therefore, you want to tailor the skills section of your resume to each job that you are applying for. This is important because many employers use applicant tracking systems these days, which scan resumes for certain keywords before passing them on to a human.

Once listed here, it would also be beneficial to discuss some of your most relevant skills in more detail elsewhere; this could include the summary or work history sections.

Below is a list of common skills & terms:

- Automation Systems

- Data Acquisition

- Electrical Engineering

- Industrial Networking

- Instrument Calibration

- PLC Programming

- Process Control Systems

- Robotics

- SCADA Systems

- Troubleshooting

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, mention your education below the resume objective section. However, if you have been working as an instrumentation engineer for several years with plenty of accomplishments to showcase, omitting this section is perfectly acceptable.

If including an education section, try to highlight courses or subjects related to the instrumentation engineering role that demonstrate a mastery of relevant skills and knowledge.

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a particular field. They show potential employers that you have taken the time to learn more about the industry, and are committed to staying up-to-date with current trends.

If you have any certifications related to the job for which you are applying, make sure they appear prominently on your resume. This will give hiring managers an indication of how well qualified you are for the position.

Certified Automation Professional

International Society of Automation

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Horacio Goyette, this would be Horacio-Goyette-resume.pdf or Horacio-Goyette-resume.docx.

7. Cover Letter

Cover letters are a great way to make your job application stand out from the rest. They offer you an opportunity to introduce yourself and explain why you would be an ideal candidate for the role.

A cover letter should typically consist of 2-4 paragraphs, separate from your resume or CV. It should provide more detail about who you are as well as highlight any relevant experience that makes you suitable for the position in question. Although they aren’t always required, taking the time to write one will give employers further insight into who you are and what value you can bring their organization.

Below is an example cover letter:

Dear Wanda,

I am writing in response to your advertisement for an Instrumentation Engineer at XYZ Corporation. With my experience in design, development, and implementation of instrumentation systems, I am confident I would make a valuable contribution to your team.

In my current role as Instrumentation Engineer at ABC Company, I work on a variety of projects involving the design and installation of electrical and electronic equipment. I have gained valuable experience in this field that I can bring to your organization, including:

– Designing schematics and layouts for electrical control panels

– Selecting appropriate instruments for specific applications

– Installing and commissioning instrumentation systems

– Troubleshooting issues with existing systems

– Providing support during system maintenance or upgrades

My enclosed resume provides additional details about my skills and accomplishments. I look forward to speaking with you soon about this opportunity.

Sincerely,

Horacio

Instrumentation Engineer Resume Templates

Jerboa

Jerboa Hoopoe

Hoopoe Bonobo

Bonobo Quokka

Quokka Saola

Saola Kinkajou

Kinkajou Echidna

Echidna Fossa

Fossa Ocelot

Ocelot Dugong

Dugong Rhea

Rhea Numbat

Numbat Indri

Indri Gharial

Gharial Axolotl

Axolotl Markhor

Markhor Cormorant

Cormorant Pika

Pika Rezjumei

Rezjumei