Installation Engineer Resume Guide

Installation engineers install, maintain and repair a variety of technical equipment. They are responsible for ensuring that all components of the system are working properly, as well as troubleshooting any issues that arise during installation or operation. Additionally, they often provide training to users on how to use the installed systems correctly.

You have the technical know-how and experience to make installations go smoothly, but hiring managers don’t yet know of your expertise. To get them aware of your qualifications, you must write a well-crafted resume that highlights your talents.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Installation Engineer Resume Sample

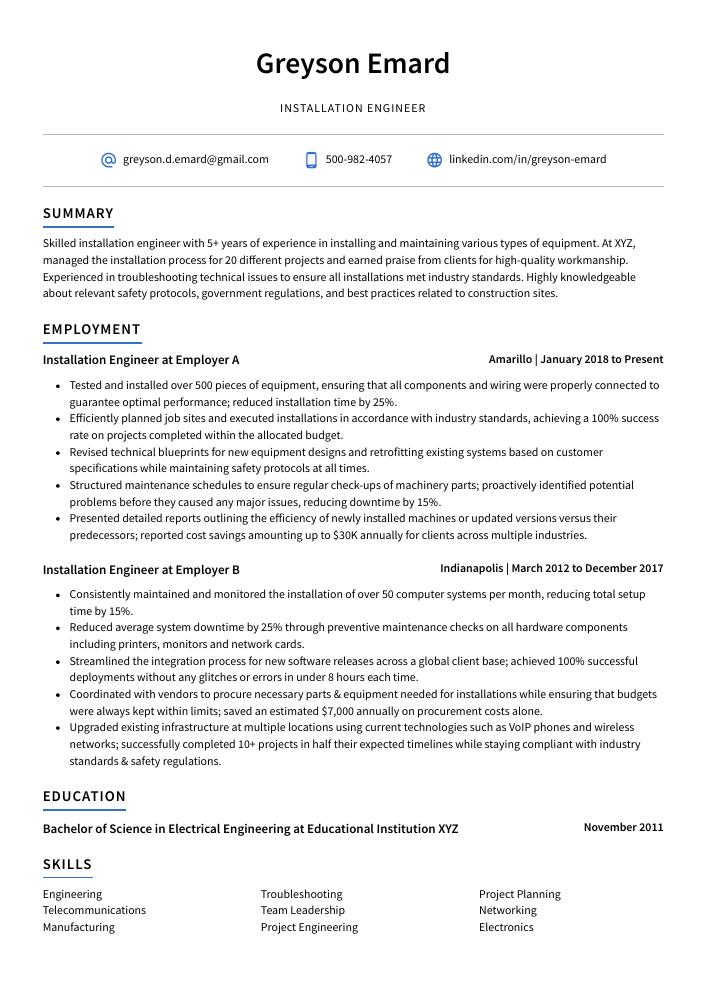

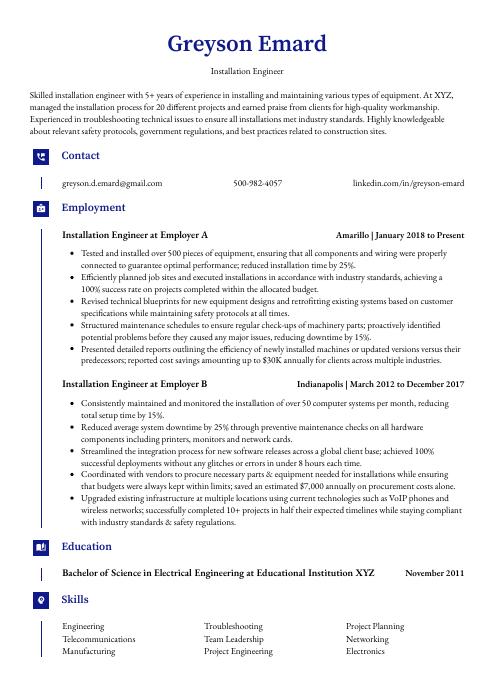

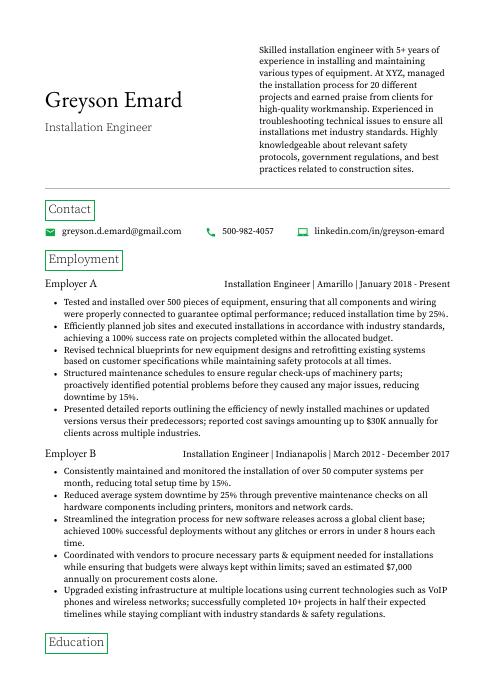

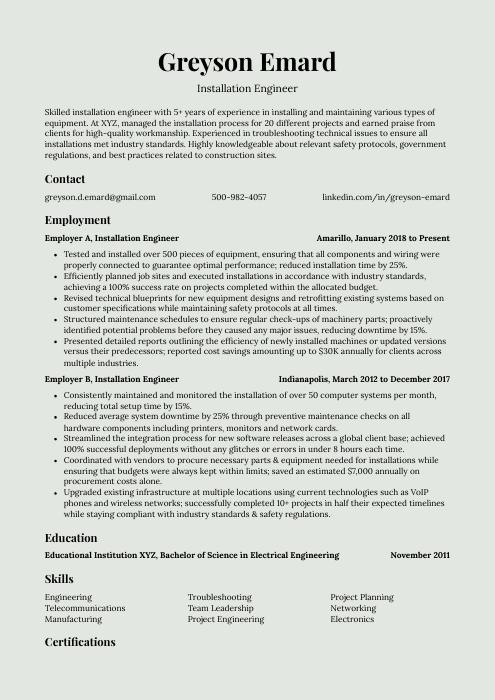

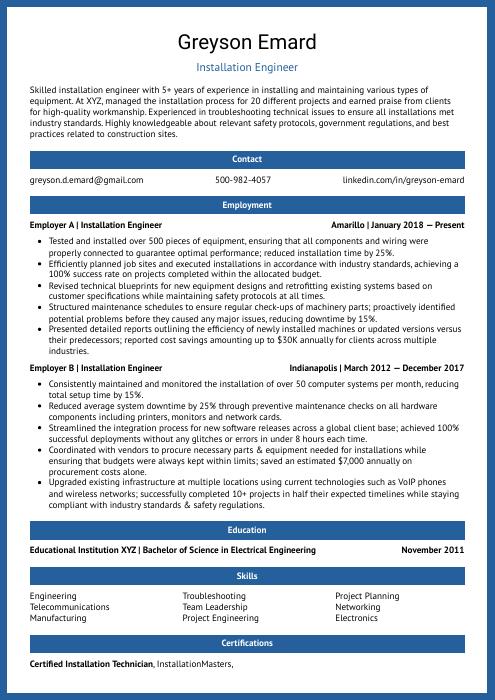

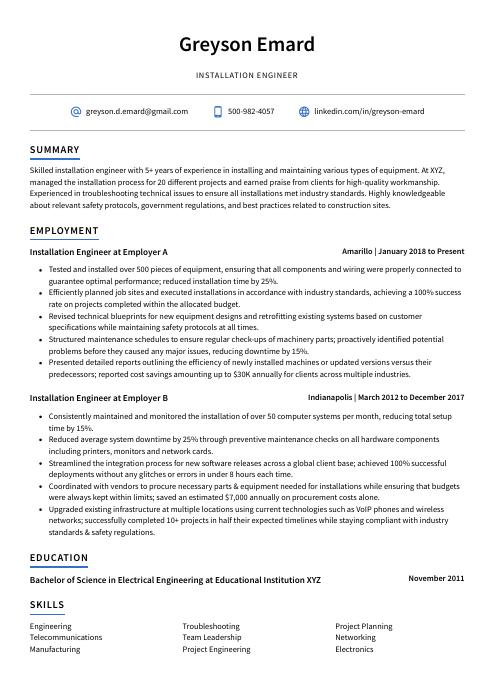

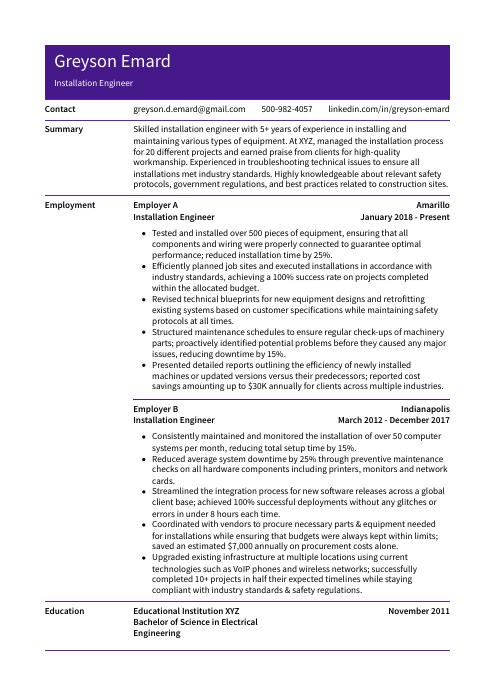

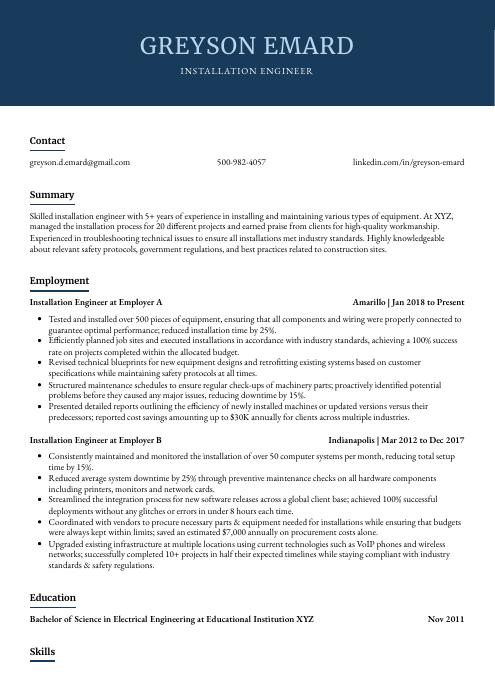

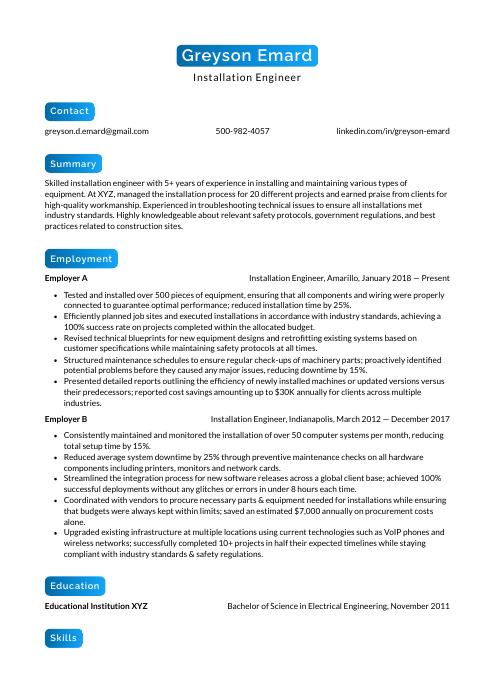

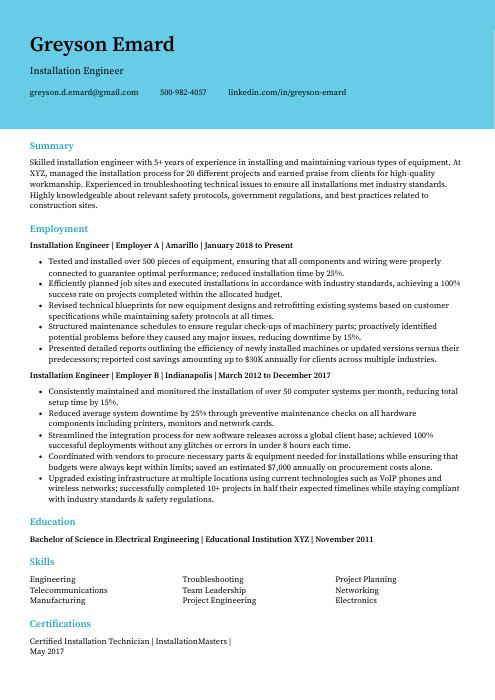

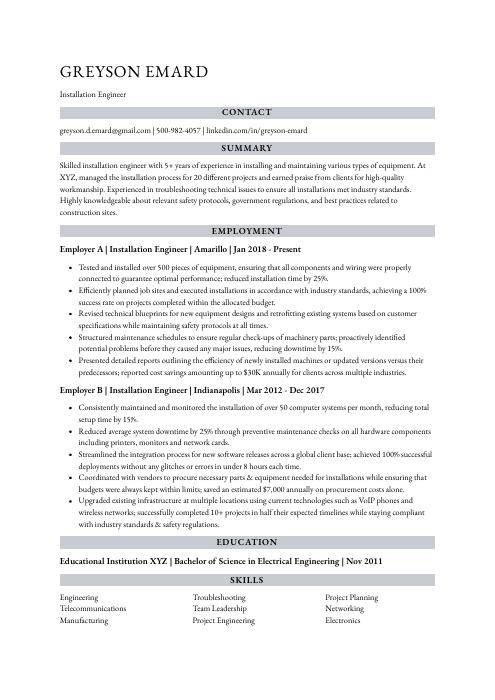

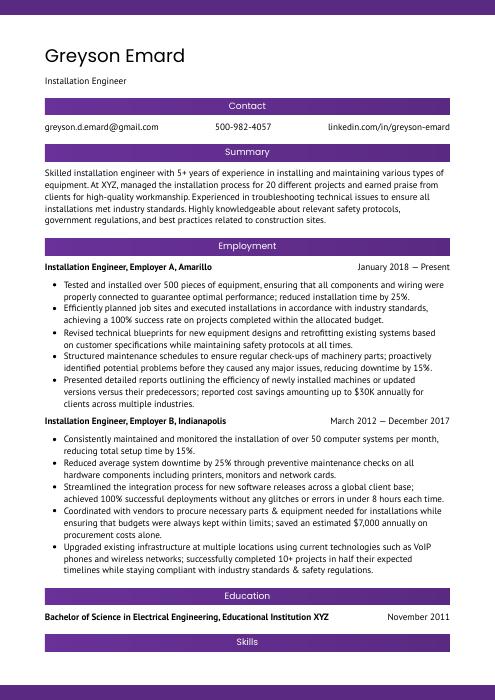

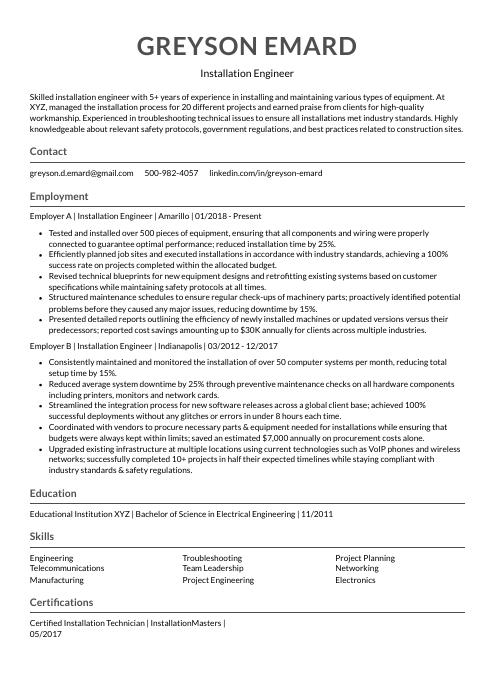

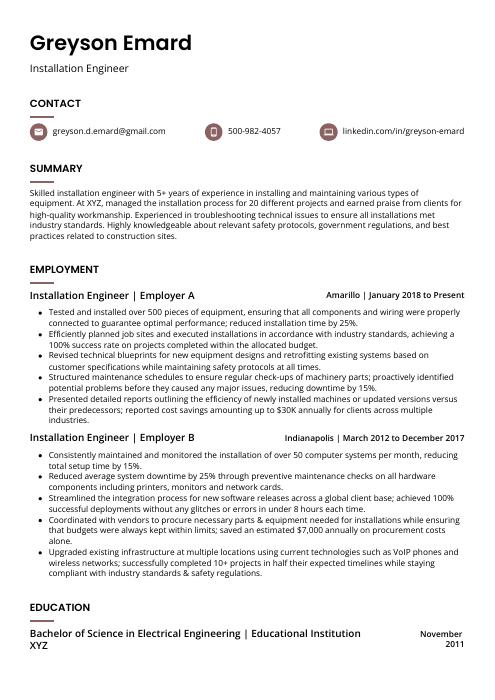

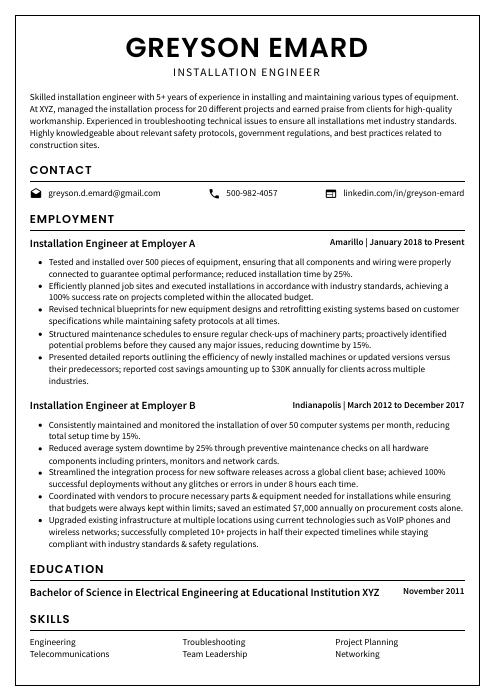

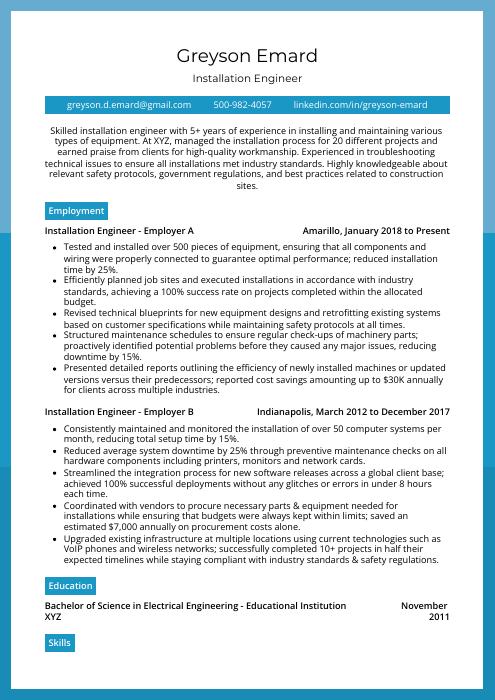

Greyson Emard

Installation Engineer

[email protected]

500-982-4057

linkedin.com/in/greyson-emard

Summary

Skilled installation engineer with 5+ years of experience in installing and maintaining various types of equipment. At XYZ, managed the installation process for 20 different projects and earned praise from clients for high-quality workmanship. Experienced in troubleshooting technical issues to ensure all installations met industry standards. Highly knowledgeable about relevant safety protocols, government regulations, and best practices related to construction sites.

Experience

Installation Engineer, Employer A

Amarillo, Jan 2018 – Present

- Tested and installed over 500 pieces of equipment, ensuring that all components and wiring were properly connected to guarantee optimal performance; reduced installation time by 25%.

- Efficiently planned job sites and executed installations in accordance with industry standards, achieving a 100% success rate on projects completed within the allocated budget.

- Revised technical blueprints for new equipment designs and retrofitting existing systems based on customer specifications while maintaining safety protocols at all times.

- Structured maintenance schedules to ensure regular check-ups of machinery parts; proactively identified potential problems before they caused any major issues, reducing downtime by 15%.

- Presented detailed reports outlining the efficiency of newly installed machines or updated versions versus their predecessors; reported cost savings amounting up to $30K annually for clients across multiple industries.

Installation Engineer, Employer B

Indianapolis, Mar 2012 – Dec 2017

- Consistently maintained and monitored the installation of over 50 computer systems per month, reducing total setup time by 15%.

- Reduced average system downtime by 25% through preventive maintenance checks on all hardware components including printers, monitors and network cards.

- Streamlined the integration process for new software releases across a global client base; achieved 100% successful deployments without any glitches or errors in under 8 hours each time.

- Coordinated with vendors to procure necessary parts & equipment needed for installations while ensuring that budgets were always kept within limits; saved an estimated $7,000 annually on procurement costs alone.

- Upgraded existing infrastructure at multiple locations using current technologies such as VoIP phones and wireless networks; successfully completed 10+ projects in half their expected timelines while staying compliant with industry standards & safety regulations.

Skills

- Engineering

- Troubleshooting

- Project Planning

- Telecommunications

- Team Leadership

- Networking

- Manufacturing

- Project Engineering

- Electronics

Education

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Installation Technician

InstallationMasters

May 2017

1. Summary / Objective

Your resume summary or objective should be the equivalent of a movie trailer – it provides the hiring manager with essential information and, if written correctly, should compel them to read on. The summary is where you can showcase your best qualities; for example, you could mention how many years of experience you have in installation engineering, any certifications or specializations that make you stand out from other candidates, and what makes your approach to installations unique.

Below are some resume summary examples:

Talented installation engineer with 8+ years of experience in the installation and maintenance of electrical, plumbing, HVAC, and other systems. Highly skilled at troubleshooting problems quickly to ensure minimal disruption. At XYZ Corporation, provided technical support for a wide range of customers across multiple industries resulting in increased customer satisfaction ratings by 22%. Committed to delivering quality results on time and within budget.

Amicable installation engineer with 8+ years of experience in installing and maintaining industrial equipment. Skilled at troubleshooting, diagnosing issues on the spot, and ensuring that all installations are done correctly according to safety regulations. Experienced in working with a wide range of machinery from various manufacturers. At XYZ Company, completed product installation for more than 200 industries across 15 states within the US.

Determined installation engineer with 5+ years of experience in managing large-scale installations and maintenance projects. Experienced in working on high-value, complex engineering systems such as HVAC systems, telecom networks, and power plants. At XYZ Corporation reduced installation costs by 10% through careful project planning & management. Proven ability to build effective teams that deliver outstanding results within tight deadlines.

Accomplished installation engineer with 10+ years of experience in the installation, maintenance, and repair of various technical equipment. Proven track record for completing installations on time and within budget. Skilled at troubleshooting complex systems to identify root causes and develop effective solutions quickly. Highly organized approach with a focus on customer satisfaction while ensuring compliance with safety regulations.

Reliable installation engineer with 10+ years of experience in the installation and maintenance of a wide variety of building systems. Looking to join ABC Systems as an Installation Engineer, leveraging my expertise in troubleshooting equipment and providing technical support for customers. My past successes include reducing customer downtime by 50% through proactive maintenance scheduling while also increasing system uptime by 25%.

Energetic installation engineer with 5+ years of experience overseeing the installation and repair of complex electronics in domestic and commercial settings. Utilizing expertise in troubleshooting, wiring diagrams, customer service, safety regulations and system configurations to ensure optimal performance for ABC’s clients. Most recently improved efficiency by 25% via a new standard operating procedure for installations.

Committed installation engineer with 10+ years of experience in the field service industry. Seeking to join ABC Tech as a senior installation engineer and provide superior technical support for customers. In my current role, I have successfully installed 15 new systems while maintaining an up-time rate of 94%. My ability to troubleshoot complex problems has significantly improved customer satisfaction by 30%.

Detail-oriented installation engineer with 10+ years of hands-on experience installing, configuring and troubleshooting hardware components. Proficient in a variety of operating systems and networking protocols. Seeking to join ABC Tech as an installation specialist where I can use my technical expertise to ensure smooth system deployment for the company’s clients.

2. Experience / Employment

In the experience/employment/work history section, you should provide details on your past roles. This section should be written in reverse chronological order, with the most recent role at the top.

When writing this section, it’s best to stick to bullet points. Doing so allows for a quick read and makes it easier for the reader to take in what you have said. You want each point to include detail about what you did and any quantifiable results that were achieved as a result of your work.

For example, instead of saying “Installed new equipment,” you could say, “Successfully installed 10+ pieces of industrial machinery per month within budgeted timeframes.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Configured

- Troubleshot

- Monitored

- Optimized

- Calibrated

- Assembled

- Tested

- Repaired

- Inspected

- Programmed

- Upgraded

- Replaced

- Analyzed

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Improved installation efficiency by 20% by streamlining existing processes and introducing new technologies.

- Introduced a range of automated installation solutions, resulting in an increase of productivity by $60k annually.

- Reliably completed installations within the timeline while adhering to safety guidelines and quality standards at all times.

- Utilized cutting-edge techniques such as robotics, automation programming & artificial intelligence for successful implementation of projects with minimal disruption to customers/clients operations onsite or offsite; reduced downtime from 2 days per project to 1 day on average.

- Developed several complex systems for large-scale commercial sites that enabled efficient management and control over integrated systems with data accuracy rate reaching 95%.

- Monitored and maintained the installation of over 250 pieces of equipment, ensuring accurate configurations and successful operations within an average turnaround time of three days.

- Represented company in several customer sites to install or upgrade systems; successfully completed projects on-time without compromising safety standards and achieved a 95% customer satisfaction rate.

- Achieved 30% cost reduction for installation materials by negotiating with suppliers/vendors and ordering parts in bulk when possible.

- Documented details related to each project such as timelines, costs, configuration changes & service requests; created user guides that were widely appreciated by customers who could easily operate new systems independently post-installation.

- Diligently tested all installed components before delivery to ensure compatibility between hardware/software elements and meet quality assurance requirements every single time.

- Configured and installed over 200 pieces of IT equipment, such as computers, routers and modems; increased network speed by 30% in the last quarter.

- Analyzed customer requirements to ensure that all installation projects were completed within budget and timeline constraints; reduced costs on average by $1,500 per project.

- Meticulously tested hardware components for functionality before connecting them to the network system; lowered service outages from 2 hours a week to zero since starting employment at the company.

- Facilitated seamless integration between existing hardware systems with new installations for improved performance; saved 3 days worth of manual labor every month through automated processes implementation.

- Replaced outdated computer parts with up-to-date models resulting in an extended life cycle of 8 years+ while reducing energy consumption rates by 42%.

- Programmed, configured and tested over 200 software installations with an accuracy rate of 99%, reducing system errors by 25%.

- Independently managed the installation process for computer networks, servers, storage systems and other IT components in 5 new offices within 8 weeks.

- Optimized performance of server hardware to reduce energy usage by 30% while increasing data throughput speeds by 20%.

- Installed 70+ pieces of equipment across 4 sites per day on average; reduced manual labor costs by $4,000 a month through efficient project management techniques.

- Troubleshot technical issues quickly and accurately with minimal disruption to customers’ operations; resolved 90% cases on first attempt without escalating them further.

- Repaired and calibrated over 100 electrical installations and systems, reducing service time by 30% within the last 6 months.

- Inspected existing installation designs to identify potential safety hazards, updating them in accordance with current regulations and standards; decreased code violations by 25%.

- Formulated cost-effective solutions for customer needs while minimizing waste of materials; achieved $10k savings on material costs in the past year alone.

- Mentored junior engineers on best practices related to installing equipment and monitoring performance levels; improved team efficiency by 10 hours per week averagely.

- Thoroughly tested newly installed systems prior to implementation using cutting edge diagnostic tools & techniques, ensuring that all components were functioning properly at optimal capacity before deployment into production environments.

- Calibrated and installed over 300 pieces of complex equipment, such as CNC machines and robotic arms, within the specified timeframe; reduced assembly time per machine by 15%.

- Compiled detailed reports on new and existing installations to identify potential areas for improvement in operational efficiency, resulting in a 10% reduction in production costs.

- Substantially increased customer satisfaction levels through timely delivery of completed projects with minimal defects or malfunctions.

- Demonstrated ability to troubleshoot installation issues quickly and efficiently while adhering to all safety protocols; resolved 70% of technical problems without requiring external support services from vendors or partners.

- Advised clients on product selection based on their needs and preferences, leading to an increase in sales volume by 12%.

- Resourcefully installed, configured and tested manufacturing machinery in 15+ facilities across the country, eliminating downtime of production equipment by up to 50%.

- Spearheaded installation projects valued at over $800K; ensured that all safety protocols were followed throughout the process and met project deadlines with 99% accuracy.

- Assessed customers’ requirements for installation services and developed custom plans accordingly; achieved customer satisfaction ratings above 90%.

- Participated in testing electrical systems, wiring switches & outlets as well as installing security cameras/alarms during each project; reduced errors by 25% on average compared to industry standards.

- Assembled a team of 10 installers which completed 5 large-scale projects ahead of schedule while simultaneously saving 20% on overall costs per job site visit.

- Successfully installed and configured technical equipment for 200+ customers, cutting installation time by 30% on average.

- Reorganized the existing inventory system to optimize parts acquisition processes; increased efficiency of warehouse operations by 20%.

- Prepared detailed reports outlining testing results, maintenance requirements and other necessary project documentation within tight deadlines; improved accuracy of data entry by 10%.

- Expedited repair procedures while troubleshooting complex network issues with clients across multiple sites, resolving problems in a timely manner and reducing downtime significantly (by 45%).

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual who has experience with installing and troubleshooting complex electrical systems, while the other may be looking for someone who is knowledgeable about industrial automation.

Therefore, it is essential to tailor the skills section of your resume to each job that you are applying for. This will help ensure that applicant tracking systems (computer programs used by many employers) recognize keywords relevant to their requirements when scanning resumes.

In addition, you should also make sure to discuss any important qualifications in more detail within other sections of your resume; this could include talking about them in the summary or work experience section.

Below is a list of common skills & terms:

- Access Control

- Account Management

- Alarm Systems

- AutoCAD

- CCTV

- Cabling

- Commissioning

- Electrical Engineering

- Electricians

- Electronics

- Engineering

- Fire Alarm

- IP

- IP CCTV

- Integration

- Manufacturing

- Mechanical Engineering

- Networking

- Process Improvement

- Project Engineering

- Project Planning

- Security

- Software Installation

- Team Leadership

- Teamwork

- Technical Support

- Telecommunications

- Testing

- Troubleshooting

- VoIP

- Windows

4. Education

Mentioning an education section on your resume will depend on how far into your career you are. If you just graduated and have no prior experience, include an education section below your resume objective. However, if you have a few years of experience in installation engineering, omitting the education section altogether might be best to focus more attention on past job roles and accomplishments instead.

If including an education section is necessary, try to mention courses or subjects related to the installation engineer role that you are applying for.

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have been tested and certified by an authoritative organization, which can give you the edge over other applicants who don’t possess such qualifications.

Including certifications on your resume is especially important if the job advert emphasizes specific skills or knowledge areas; having certification in these fields will make it easier for hiring managers to assess whether or not you are suitable for the role.

Certified Installation Technician

InstallationMasters

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Greyson Emard, this would be Greyson-Emard-resume.pdf or Greyson-Emard-resume.docx.

7. Cover Letter

Cover letters are often overlooked when applying for jobs but they can be a great way to make yourself stand out from the competition. They are typically made up of 2 to 4 paragraphs and provide an opportunity for you to introduce yourself, highlight your qualifications, and explain why you’re the best fit for the role.

Whilst cover letters may not always be required as part of your application, taking time to write one is highly recommended. It will help demonstrate that you have taken time to think about how your skills match those listed in the job description.

Below is an example cover letter:

Dear Lloyd,

I am writing to apply for the position of Installation Engineer at XYZ Company. With over five years of experience in installation, maintenance, and repair of a variety of equipment, I am confident I can be an asset to your team.

In my previous role as an installation engineer at ABC Company, I was responsible for installing and maintaining HVAC systems in commercial and industrial buildings. I have a strong working knowledge of a variety of HVAC systems and control panels, which enables me to troubleshoot problems quickly and efficiently. In addition, I have experience reading blueprints and schematics, which is essential for correctly install new systems.

My interpersonal skills are also excellent; I am able to effectively communicate with customers to ensure their needs are met in a timely manner. My ability to work independently or as part of a team makes me adaptable to any situation. Finally, my clean driving record ensures that I can safely transport equipment to job sites.

I believe that my skills and experience make me the perfect candidate for this position. Please find attached my resume for your review; if you have any questions do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration; I look forward to hearing from you soon!

Sincerely,

Greyson

Installation Engineer Resume Templates

Gharial

Gharial Quokka

Quokka Saola

Saola Ocelot

Ocelot Axolotl

Axolotl Markhor

Markhor Hoopoe

Hoopoe Pika

Pika Bonobo

Bonobo Lorikeet

Lorikeet Kinkajou

Kinkajou Dugong

Dugong Numbat

Numbat Jerboa

Jerboa Indri

Indri Echidna

Echidna Fossa

Fossa Cormorant

Cormorant Rhea

Rhea Rezjumei

Rezjumei