Inspection Technician Resume Guide

Inspection Technicians are responsible for examining products and components to ensure that they meet the required safety, quality, and performance standards. They inspect parts before assembly, after production or repair is complete, and prior to shipment. They use tools such as calipers, gauges, microscopes, x-ray machines and other specialized equipment to check items for defects.

Your attention to detail is second-to-none. But potential employers don’t know about your talents yet. To make them aware of what you can do, you need to write a resume that stands out from the rest and showcases your skill set.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

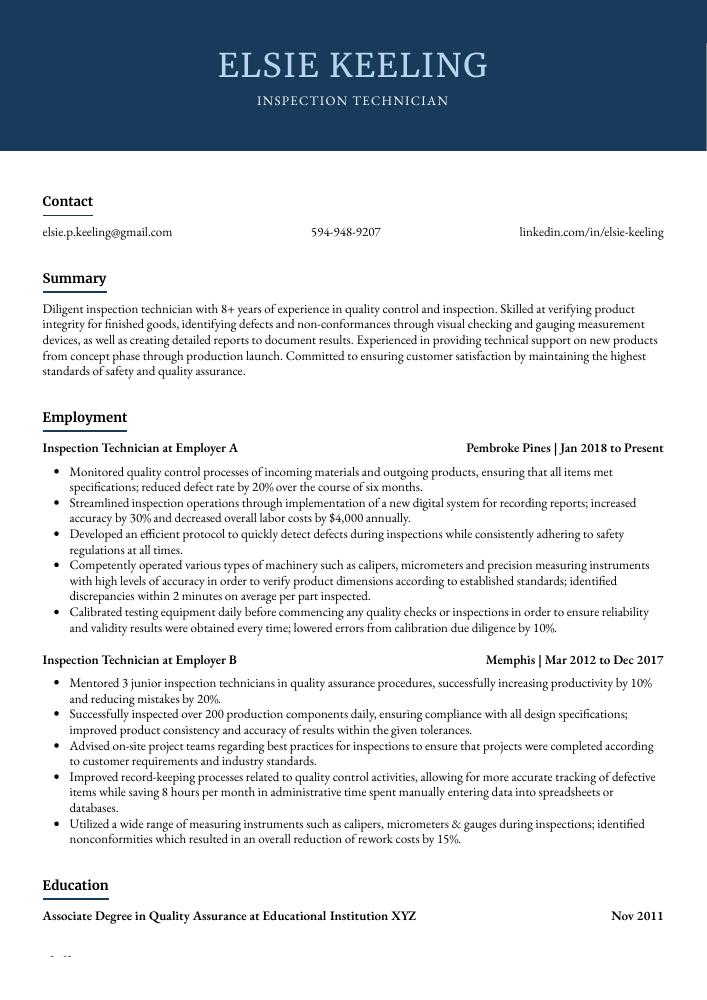

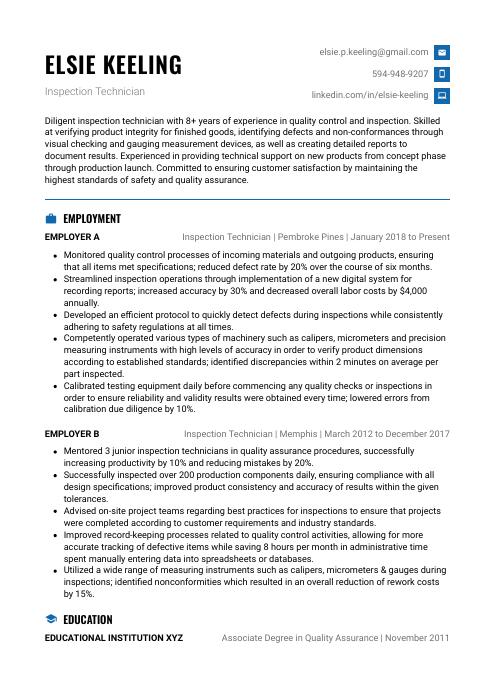

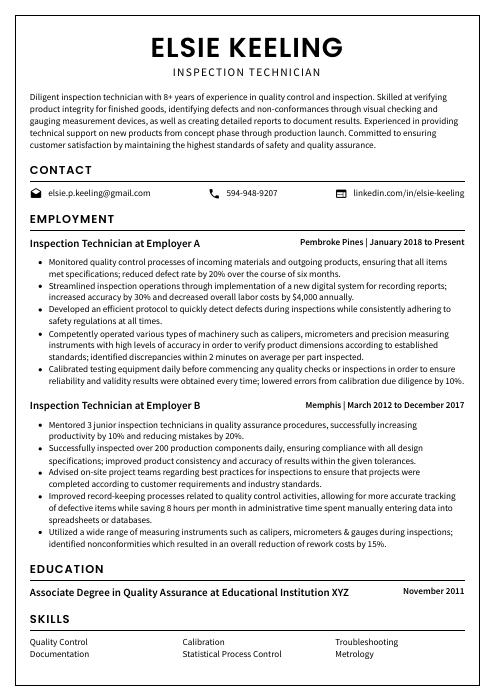

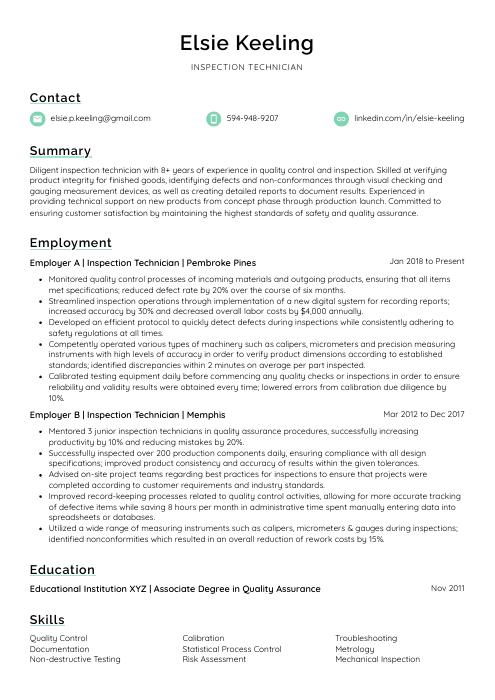

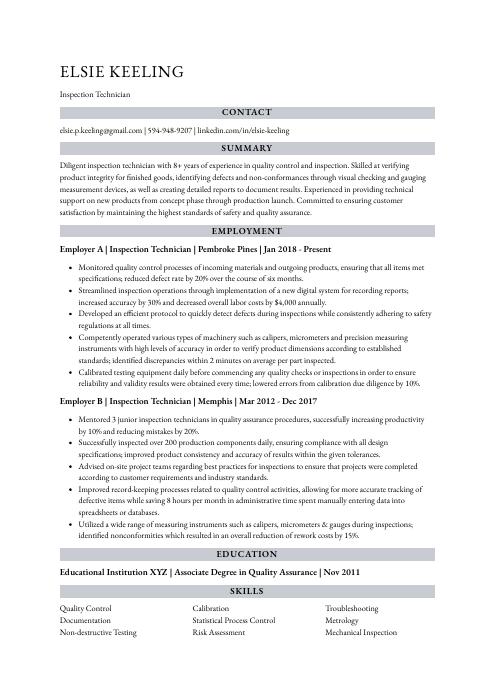

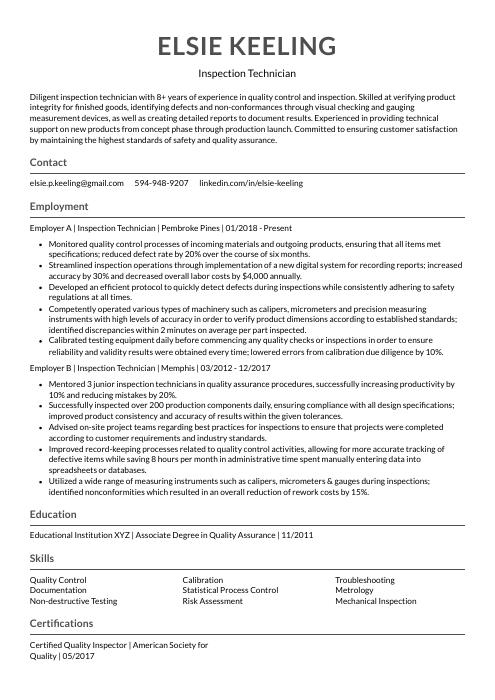

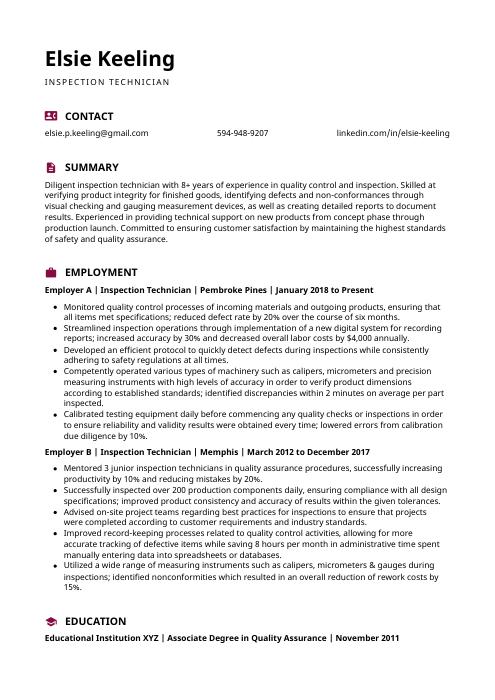

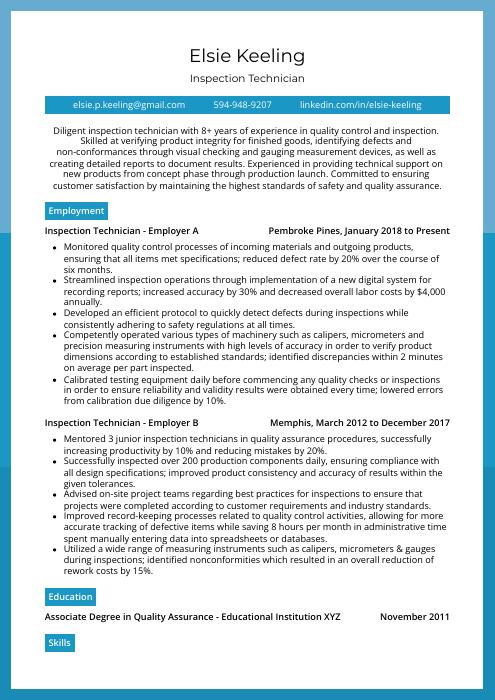

Inspection Technician Resume Sample

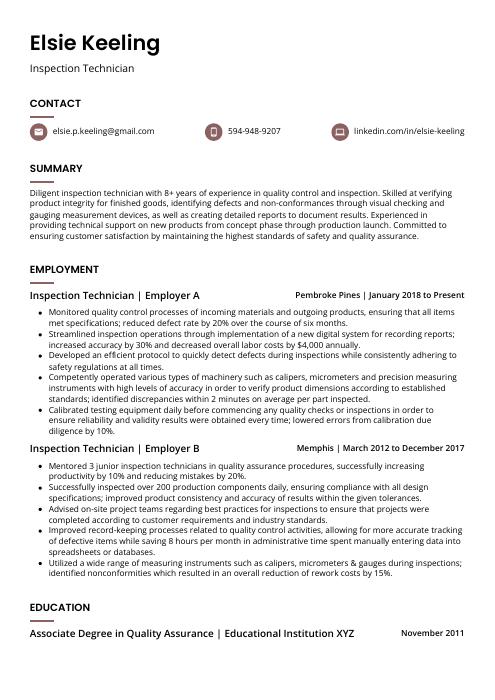

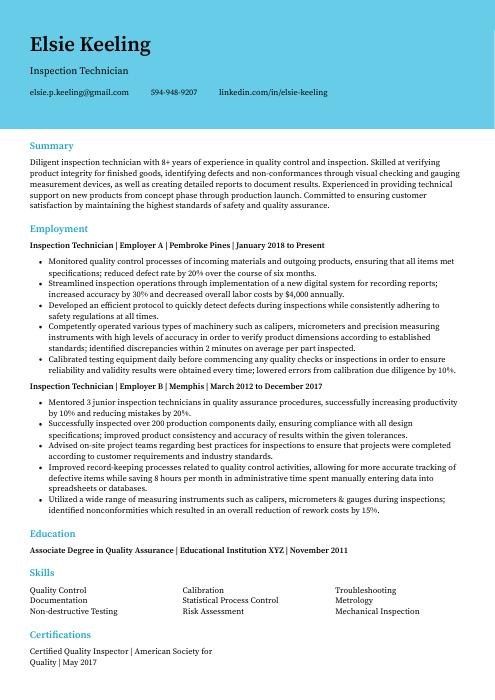

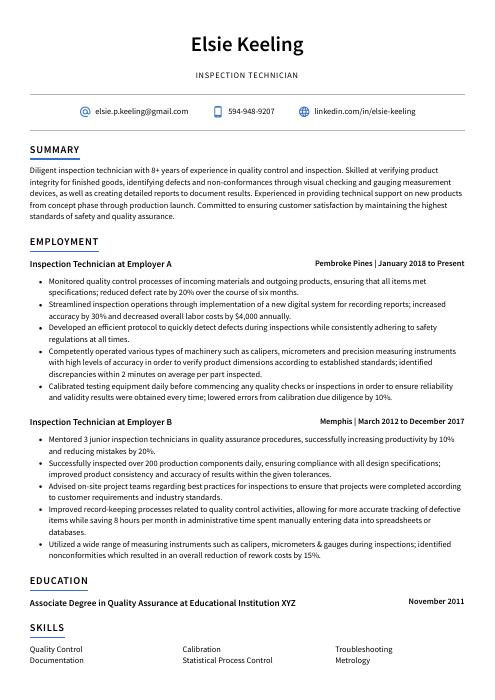

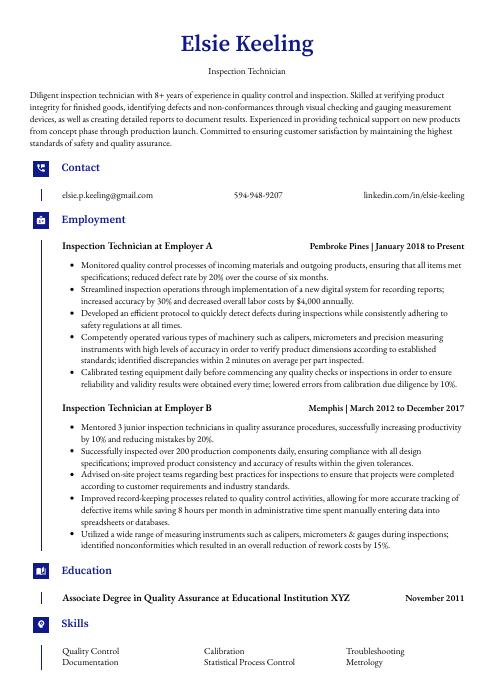

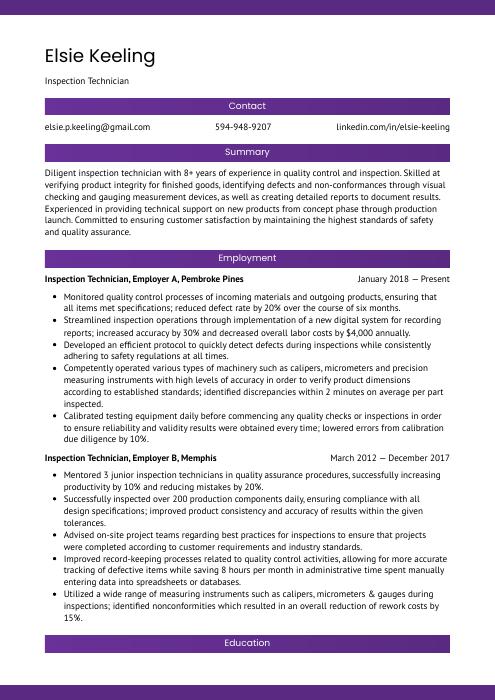

Elsie Keeling

Inspection Technician

[email protected]

594-948-9207

linkedin.com/in/elsie-keeling

Summary

Diligent inspection technician with 8+ years of experience in quality control and inspection. Skilled at verifying product integrity for finished goods, identifying defects and non-conformances through visual checking and gauging measurement devices, as well as creating detailed reports to document results. Experienced in providing technical support on new products from concept phase through production launch. Committed to ensuring customer satisfaction by maintaining the highest standards of safety and quality assurance.

Experience

Inspection Technician, Employer A

Pembroke Pines, Jan 2018 – Present

- Monitored quality control processes of incoming materials and outgoing products, ensuring that all items met specifications; reduced defect rate by 20% over the course of six months.

- Streamlined inspection operations through implementation of a new digital system for recording reports; increased accuracy by 30% and decreased overall labor costs by $4,000 annually.

- Developed an efficient protocol to quickly detect defects during inspections while consistently adhering to safety regulations at all times.

- Competently operated various types of machinery such as calipers, micrometers and precision measuring instruments with high levels of accuracy in order to verify product dimensions according to established standards; identified discrepancies within 2 minutes on average per part inspected.

- Calibrated testing equipment daily before commencing any quality checks or inspections in order to ensure reliability and validity results were obtained every time; lowered errors from calibration due diligence by 10%.

Inspection Technician, Employer B

Memphis, Mar 2012 – Dec 2017

- Mentored 3 junior inspection technicians in quality assurance procedures, successfully increasing productivity by 10% and reducing mistakes by 20%.

- Successfully inspected over 200 production components daily, ensuring compliance with all design specifications; improved product consistency and accuracy of results within the given tolerances.

- Advised on-site project teams regarding best practices for inspections to ensure that projects were completed according to customer requirements and industry standards.

- Improved record-keeping processes related to quality control activities, allowing for more accurate tracking of defective items while saving 8 hours per month in administrative time spent manually entering data into spreadsheets or databases.

- Utilized a wide range of measuring instruments such as calipers, micrometers & gauges during inspections; identified nonconformities which resulted in an overall reduction of rework costs by 15%.

Skills

- Quality Control

- Calibration

- Troubleshooting

- Documentation

- Statistical Process Control

- Metrology

- Non-destructive Testing

- Risk Assessment

- Mechanical Inspection

Education

Associate Degree in Quality Assurance

Educational Institution XYZ

Nov 2011

Certifications

Certified Quality Inspector

American Society for Quality

May 2017

1. Summary / Objective

A resume summary/objective is your chance to make a great first impression on the hiring manager. As an inspection technician, you should use this space to highlight your experience in inspecting and testing products for quality assurance purposes. You can also mention any certifications or qualifications that demonstrate your expertise in the field, such as ISO 9001 certification or Six Sigma training. Additionally, you could talk about how you have successfully identified issues with products before they reached customers and implemented corrective measures to prevent them from happening again.

Below are some resume summary examples:

Reliable and detail-oriented inspection technician with 5 years of experience in performing detailed inspections and maintenance to ensure safety, quality, and accuracy. Eager to join ABC Engineering as an Inspection Technician where I can use my expertise in using measurement tools such as calipers, micrometers, gauges, and microscopes to inspect parts for defects or discrepancies. Awarded “Employee of the Month” on three separate occasions due to excellent job performance.

Professional inspection technician with 8+ years of experience in performing quality assurance and control inspections for the manufacturing industry. Skilled at inspecting parts, assemblies, tools, materials, and processes to ensure compliance with customer requirements. At XYZ Company successfully completed 600 daily visual inspection tests for a new product line. Received company award for outstanding performance in improving production efficiency by 15%.

Amicable and detail-oriented inspection technician with 8+ years of experience in quality assurance and testing. Skilled at utilizing a range of sophisticated tools to ensure product compliance, safety standards, and aesthetic requirements. Proven track record for minimizing customer complaints by quickly detecting production defects with an accuracy rate of 98%. Seeking to join ABC Company as the next Inspection Technician.

Driven inspection technician with 5+ years of experience in quality assurance and control. Experienced in performing visual, mechanical and electrical inspections on a variety of components for military aircrafts. Committed to meeting customer requirements by adhering to AS9100 standards. Proven track record of identifying defects quickly and accurately, leading to improved product quality ratings from customers.

Detail-oriented inspection technician with 10+ years of experience in quality assurance and product inspection. Skilled at using a variety of tools, including microscopes, calipers, and gauges to inspect components for defects. At XYZ Company identified problems that led to the recall of over 20 units from production lines. Recognized as an outstanding performer by management twice during my tenure there.

Hard-working and detail-oriented inspection technician with 5+ years of experience in quality assurance. Proven track record of adhering to strict standards and procedures while ensuring the highest levels of product safety, performance, and reliability. Seeking to join ABC’s manufacturing team as an Inspection Technician where I can use my skillset to ensure top-notch products are delivered on time.

Dependable and detail-oriented Inspection Technician with 8+ years of experience in the food industry. Skilled at performing product inspections and conducting equipment calibrations to ensure quality standards are met. At XYZ, reduced product spoilage by 30% through improved inspection protocols and procedures. Received “Outstanding Employee” award for contributions to the company’s success.

Seasoned inspection technician with 10+ years of experience in quality control and assurance. Skilled at inspecting a variety of parts, components, and raw materials for defects using visual inspection methods as well as specialized tools such as calipers and micrometers. Looking to join ABC Company’s team to ensure the highest standards of product quality.

2. Experience / Employment

For the experience section, you should list your employment history in reverse chronological order, meaning the most recent job is listed first.

Stick to bullet points when describing what you did; this makes it easier for readers to take in the information quickly. When writing each point, think about providing detail and quantifiable results that demonstrate how well you performed a task or project.

For example, instead of saying “Performed safety inspections,” you could say, “Conducted weekly safety inspections on all equipment used at [Company], resulting in zero incidents over two years.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Tested

- Analyzed

- Monitored

- Evaluated

- Recorded

- Calibrated

- Troubleshot

- Repaired

- Adjusted

- Operated

- Confirmed

- Documented

- Certified

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reorganized inspection process to improve accuracy and efficiency, resulting in a 10% reduction in inspection time.

- Compiled detailed reports on product inspections for management review; identified issues with over 200 products per week leading to corrective actions that improved overall quality standards by 25%.

- Coordinated daily activities of up to 4 inspectors while overseeing the delivery and storage of inspected goods, ensuring all safety protocols were followed at all times.

- Expedited the testing process by implementing new tools and procedures which increased production output by 30%.

- Reliably managed multiple projects concurrently while adhering closely to deadlines, completing an average of 12 weekly inspections within budget without compromising accuracy or quality.

- Resourcefully conducted inspections on over 200 machinery components daily, ensuring all safety regulations and quality standards were met.

- Analyzed inspection results using specialized software to identify any defects or discrepancies; reduced customer complaints by 15%.

- Demonstrated expertise in performing preventive maintenance procedures such as lubrication, replacing faulty parts and cleaning equipment for optimal performance of machines.

- Spearheaded the implementation of a new defect-detection system that saved 4 hours per shift in manual inspection time and decreased production costs by 10%.

- Achieved 50% faster throughput rates while maintaining an accuracy rate of 99%, resulting in increased client satisfaction levels with improved product delivery timescales.

- Evaluated and inspected over 300 manufactured products daily to ensure they met quality standards and regulations; identified 15% fewer defects compared to the previous year.

- Recorded detailed test results, measurements and notes in a timely manner for all inspection processes; improved accuracy of data entry by 10%.

- Facilitated repairs on defective parts using specialized tools such as calipers, gauges and micrometers; reduced repair time per part by 25%.

- Structured comprehensive testing protocols according to customer specifications while adhering strictly to safety guidelines at all times; increased adherence rate from 82% – 97%.

- Diligently monitored equipment performance during inspections with minimal supervision, detecting 3 potential malfunctions before they occurred which saved $1,000 in costs associated with downtime.

- Revised and implemented quality control protocols to ensure the highest standards of safety and reliability for 100+ products, resulting in a 15% reduction in reported errors.

- Presented inspection reports to senior management on a weekly basis detailing actual versus expected results; generated additional revenue of $7,000 through process optimization initiatives.

- Participated actively in daily production meetings with other departments, providing feedback and recommending solutions to improve product performance metrics by 25%.

- Optimized testing procedures to reduce cycle time per unit inspected by 40%, allowing for more thorough inspections while boosting overall productivity levels significantly.

- Meticulously examined components such as circuitry boards, connectors and cables using advanced equipment like oscilloscopes & multimeters according to industry specifications within strict deadlines.

- Certified as an inspection technician and successfully inspected over 500 components, assemblies and products for defects within a given time frame; reduced rework by 25%.

- Formulated detailed test plans according to specifications, requirements and customer needs while adhering to strict quality control standards.

- Assessed the performance of parts, assemblies or systems during testing process while documenting any discrepancies in reports with 100% accuracy rate.

- Inspected up to 30 items per hour using precision measuring instruments such as calipers, micrometers & vibration testers; identified defective items quickly & effectively before assembly was completed resulting in cost savings of $10K annually.

- Confidently operated various types of machinery used for inspecting goods being manufactured including 3-D X-ray machines & ultrasonic welders ensuring that all safety guidelines were followed at all times without compromising on efficiency levels.

- Introduced new inspection protocols and quality control processes that increased accuracy of final product inspections by 56%.

- Troubleshot, repaired and adjusted various production machinery components regularly to ensure efficient operation; reduced machine down time from 12 hours per month to 6 hours on average.

- Substantially improved the overall level of compliance with industry standards for inspected products by conducting detailed visual checks on over 700 items a day in accordance with established procedures.

- Reduced defect rate among tested parts by 44% through meticulous tracking and documentation of data related to physical measurements taken during testing process each week.

- Confirmed adherence to safety rules when operating equipment such as calipers, micrometers, gauges & indicators; reported all non-conforming findings/issues immediately upon discovery during audit sessions twice monthly.

- Represented the company at over 500 inspection sites to oversee equipment operability, accuracy and safety; detected and reported problems with machinery in order to ensure minimal downtime.

- Prepared detailed reports for senior management on all test results, recording findings accurately and providing recommendations for improvements resulting in an 18% increase in efficiency.

- Tested products during the manufacturing process using a variety of specialized instruments (e.g., infrared spectrometers) while adhering strictly to quality assurance standards prescribed by the industry; identified potential defects quickly, allowing supervisors to take corrective action before further damage occurred or additional production costs were incurred.

- Actively participated in troubleshooting exercises when malfunctions arose within plant systems or processes; successfully reduced repair time from 4 hours per incident down to 1 hour through efficient utilization of resources available such as spare parts & tools inventory etc..

- Repaired obsolete machines that had been malfunctioning due to wear-and-tear caused by long use periods, saving $1 million worth of replacement costs annually through preventive maintenance techniques adopted after thorough research into modern technology solutions available on the market today.

- Reduced defective product rate by 10% through inspecting and testing of electronic components, materials, assemblies and other items.

- Efficiently operated inspection equipment such as digital calipers, microscopes and test benches to perform detailed quality control inspections for over 500 parts daily.

- Operated computer-aided design software to create 3D models of inspected products in order to provide accurate visual representations for clients upon request.

- Documented all results from inspection activities accurately on company tracking systems; prepared written reports summarizing overall findings at the end of each shift for supervisors’ review.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with a knowledge of the latest safety regulations, while another might prefer someone with experience in using specific tools and equipment.

The skills section of your resume should be tailored to each job you are applying for; this is important because many employers use applicant tracking systems that scan resumes for certain keywords before passing them on to a human.

In addition to simply listing these qualifications here, it can also help if you elaborate on some of them further down in other sections such as the summary or work history.

Below is a list of common skills & terms:

- Calibration

- Computer Aided Design (CAD)

- Documentation

- Mechanical Inspection

- Metrology

- Non-destructive Testing

- Quality Control

- Risk Assessment

- Statistical Process Control

- Troubleshooting

4. Education

Including an education section on your resume will depend largely on how far along you are in your career. If you just graduated and have no prior experience, mention your education below the objective statement. However, if you have a few years of work experience under your belt, it may be best to omit an education section altogether.

If including an education section is necessary or desired, make sure to highlight courses related to the inspection technician role that you are applying for.

Associate Degree in Quality Assurance

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the knowledge and expertise in a certain field. It is important to include any certifications relevant to the job you are applying for, as it will show your commitment and dedication towards professional development.

Including certifications on your resume can be beneficial when trying to stand out from other applicants, so make sure they are up-to-date and accurate.

Certified Quality Inspector

American Society for Quality

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Elsie Keeling, this would be Elsie-Keeling-resume.pdf or Elsie-Keeling-resume.docx.

7. Cover Letter

Cover letters are an important part of the job application process. They are usually made up of 2 to 4 paragraphs and provide more detail than a resume can offer. Not only do they give recruiters insights about your experience, but also help you explain why you’re the perfect fit for the role.

Although cover letters are not required in most cases, writing one is highly recommended as it allows you to showcase your personality and demonstrate how passionate and motivated you are for the position.

Below is an example cover letter:

Dear Sylvia,

I am writing to apply for the Inspection Technician position at ABC Corporation. With more than 5 years of experience in quality control and inspection, I am confident I would be a valuable asset to your team.

In my current role as Quality Control Inspector at XYZ Manufacturing, I conduct inspections on all products before they are shipped out to customers. This includes visual inspections, measurements, and testing using various tools and equipment. I also document all findings in our computer system and create reports for management when necessary. My attention to detail has prevented many defective products from reaching our customers, which has saved the company a lot of money in replacement costs over the years.

I have also been involved in several process improvement initiatives during my time at XYZ Manufacturing. For example, I led a team that implemented a new inspection procedure that reduced rework by 30%. We were also able to reduce customer complaints by 20% after implementing another initiative that I spearheaded involving better communication between different departments within the company.

My experience inspecting products for defects, leading process improvement initiatives, and maintaining accurate records would make me a perfect fit for your organization. I look forward to discussing my qualifications further with you during an interview soon. Thank you for your time!

Sincerely,

Elsie

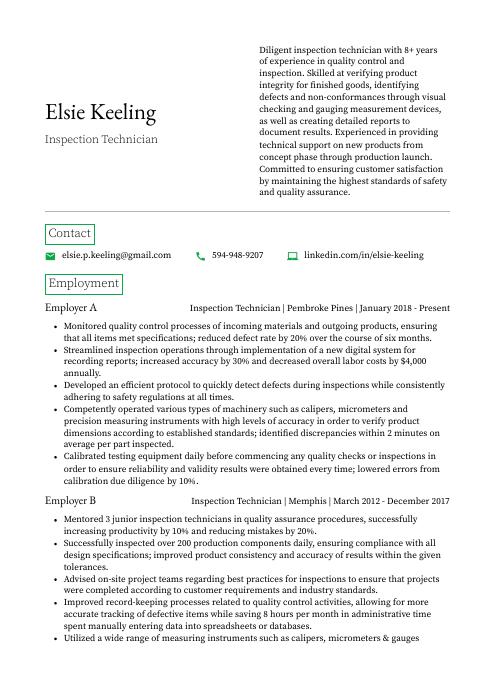

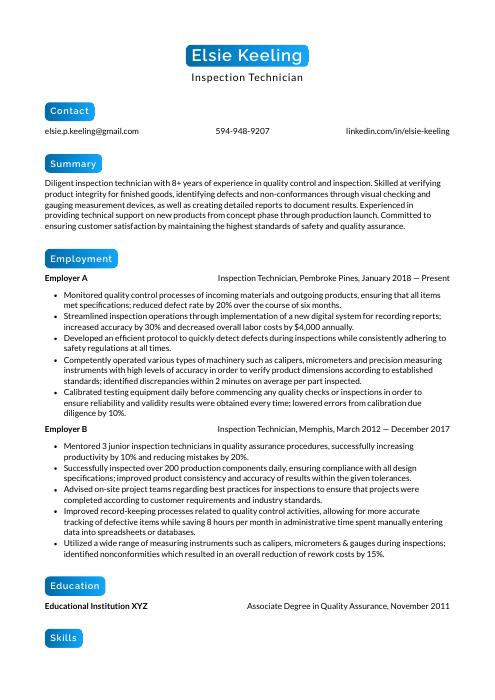

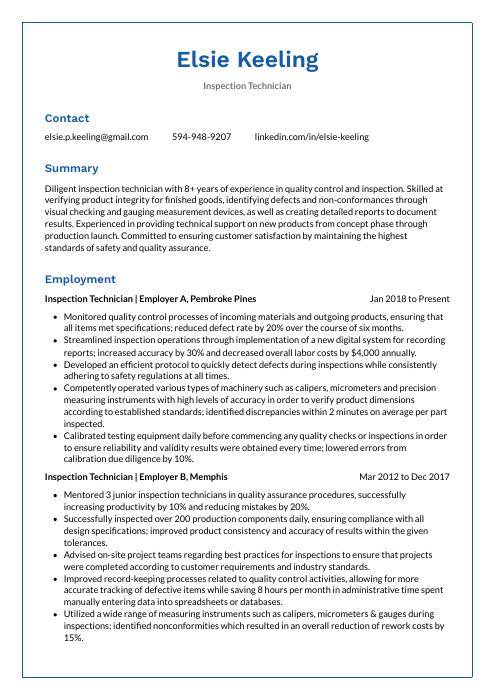

Inspection Technician Resume Templates

Echidna

Echidna Cormorant

Cormorant Lorikeet

Lorikeet Fossa

Fossa Dugong

Dugong Ocelot

Ocelot Pika

Pika Numbat

Numbat Indri

Indri Hoopoe

Hoopoe Rhea

Rhea Axolotl

Axolotl Quokka

Quokka Kinkajou

Kinkajou Saola

Saola Markhor

Markhor Gharial

Gharial Jerboa

Jerboa Bonobo

Bonobo Rezjumei

Rezjumei