Inspection Engineer Resume Guide

Inspection Engineers are responsible for ensuring that products and components meet the required quality standards. They conduct tests, analyze data, evaluate results and make recommendations to improve production processes or product designs. They also inspect materials before they are used in manufacturing operations and check finished products for defects prior to shipment.

Your skills as an inspection engineer are unmatched, and the perfect company would be lucky to have you. But they won’t know who you are unless your resume stands out from all the others. To make sure employers notice you, write a dynamite resume that showcases your talents and experience in engineering inspections.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

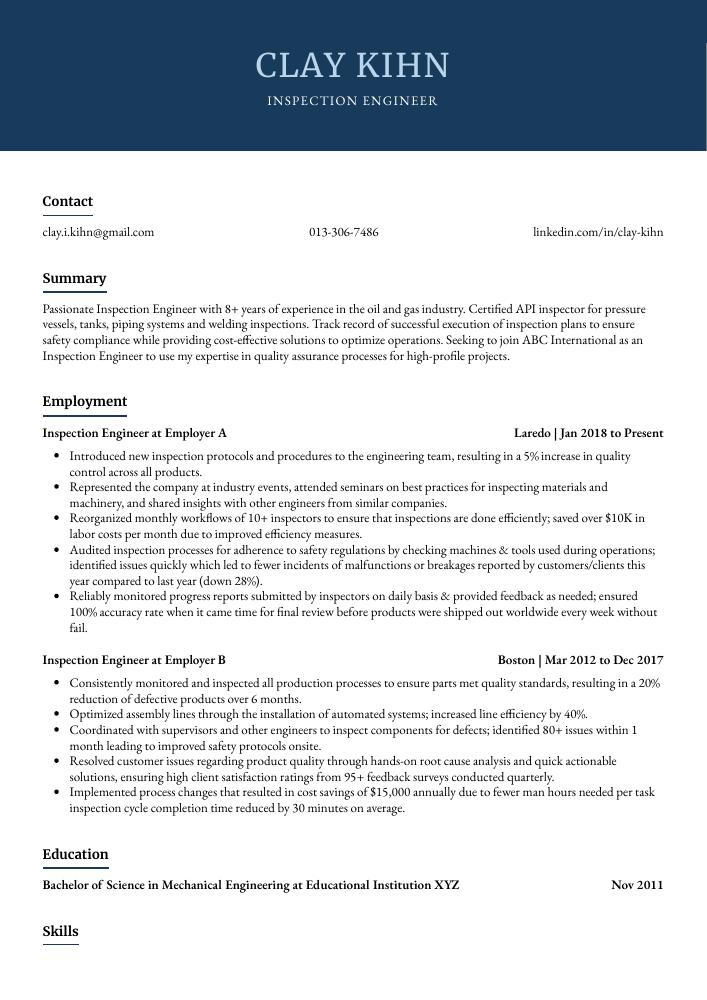

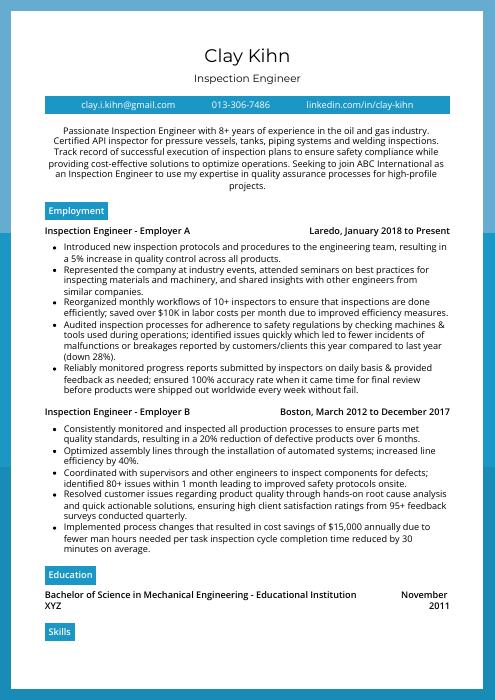

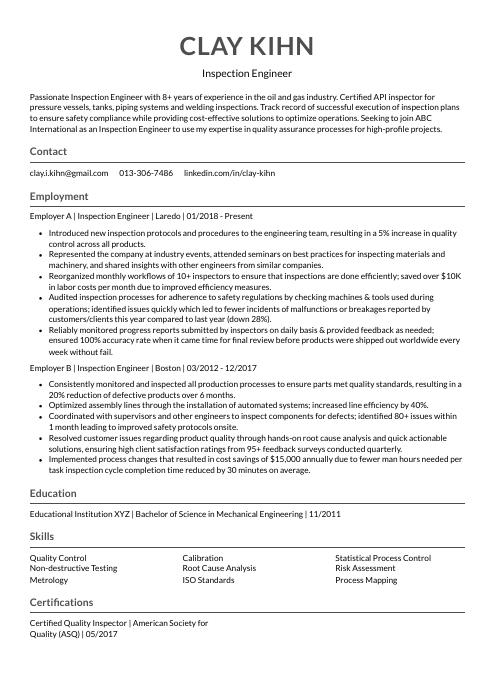

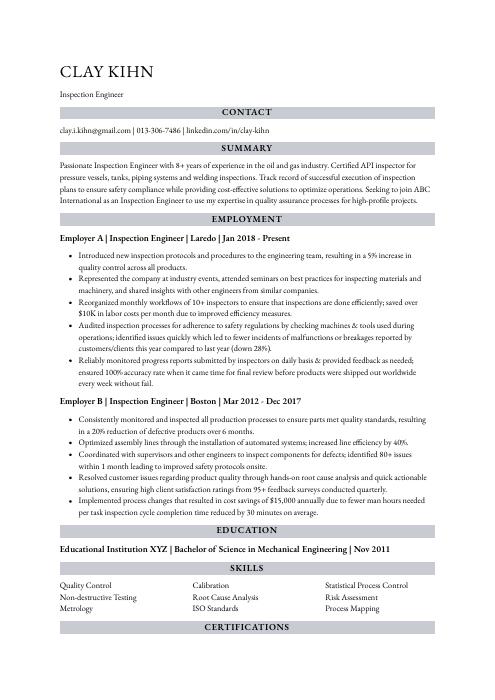

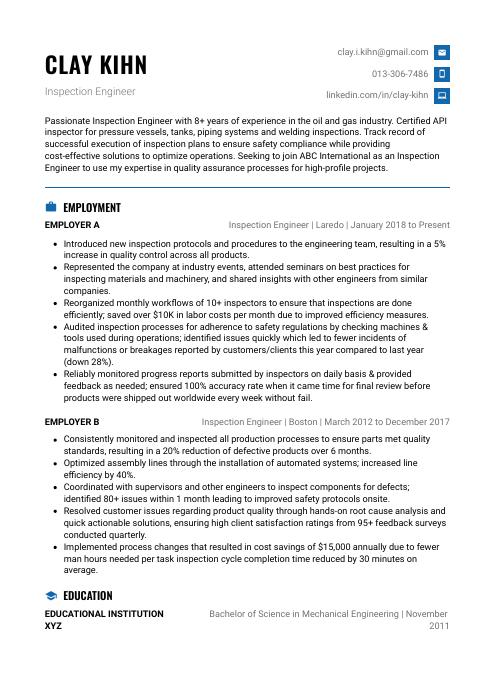

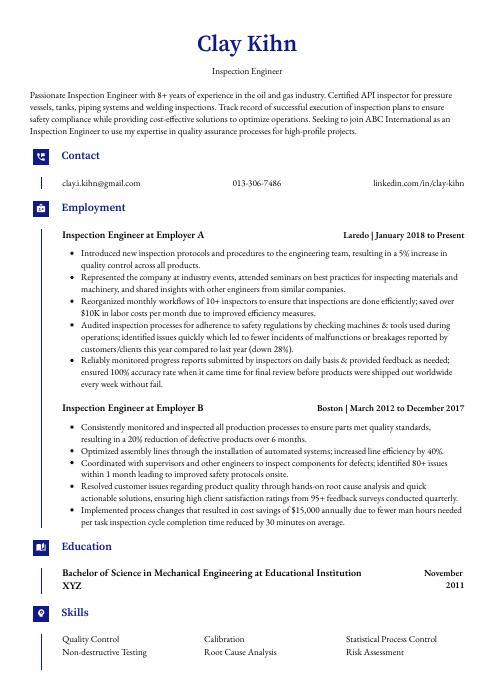

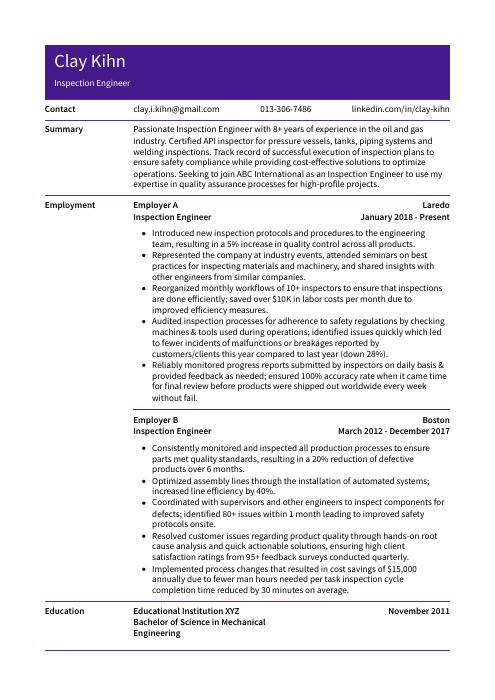

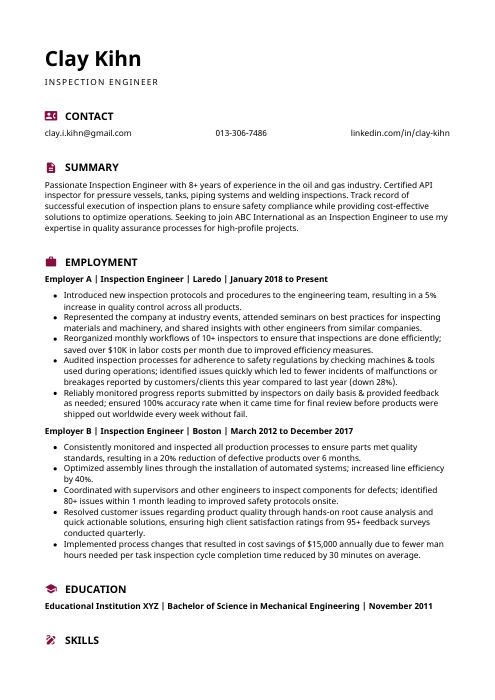

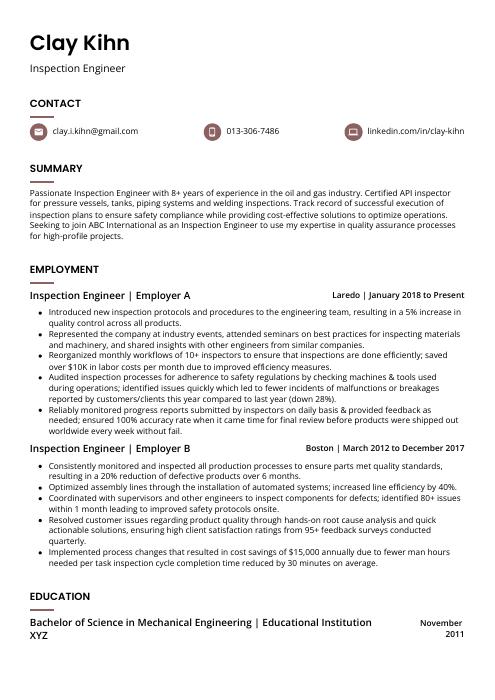

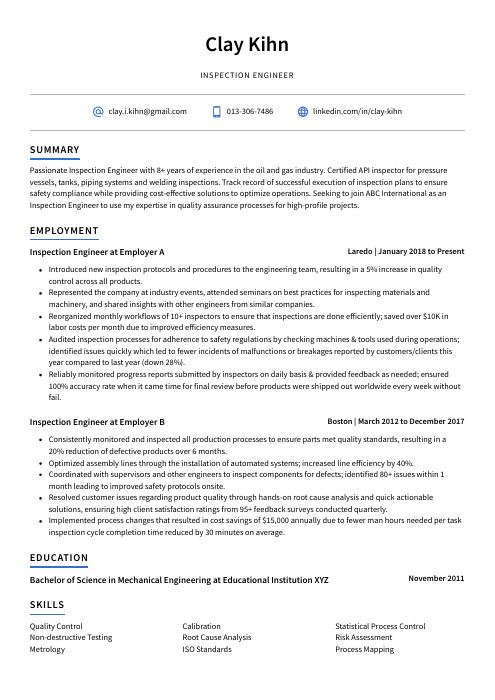

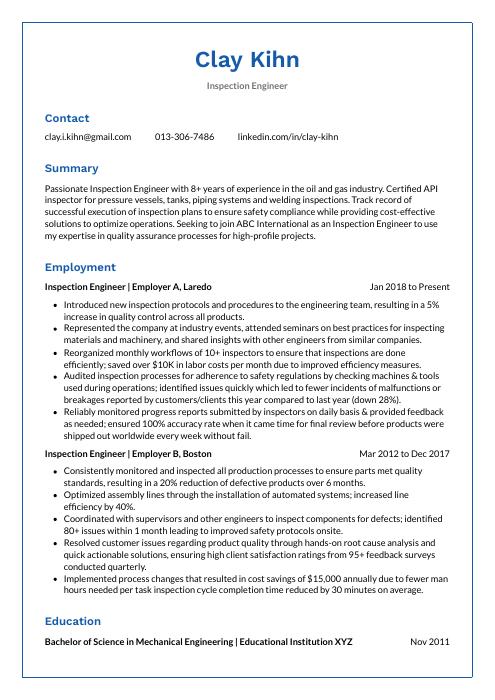

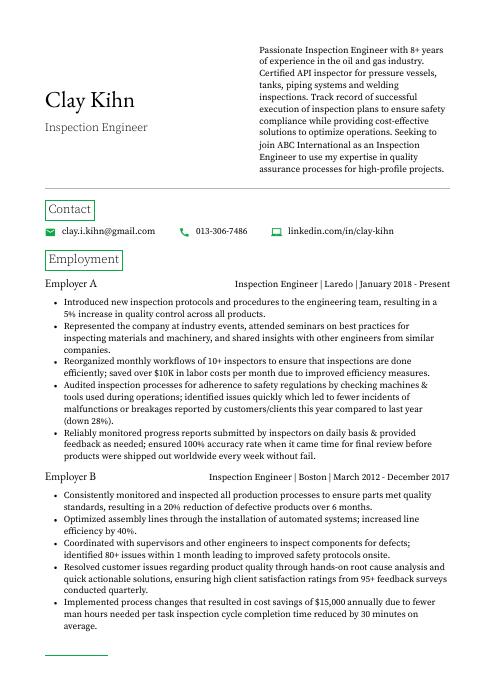

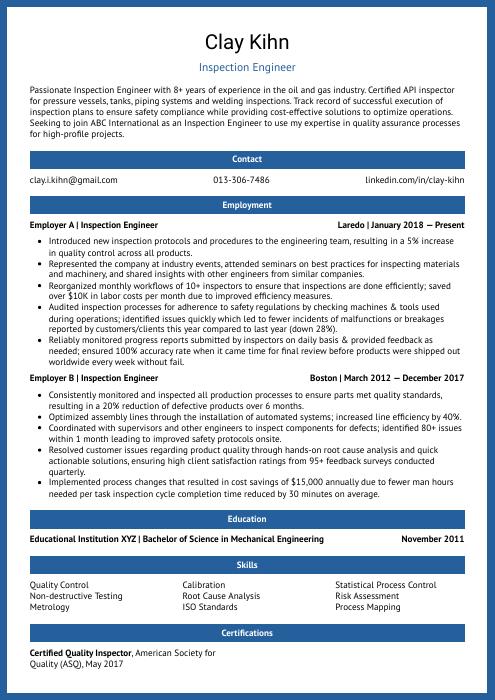

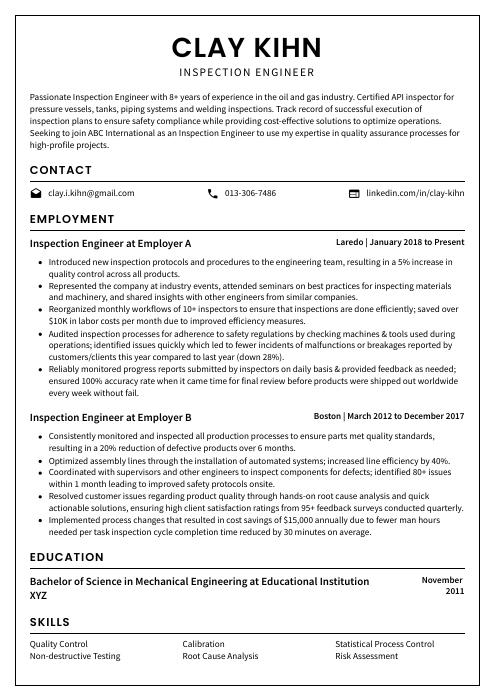

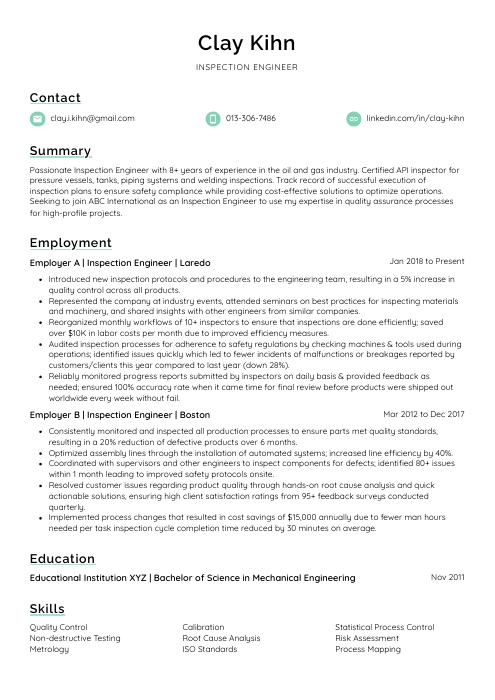

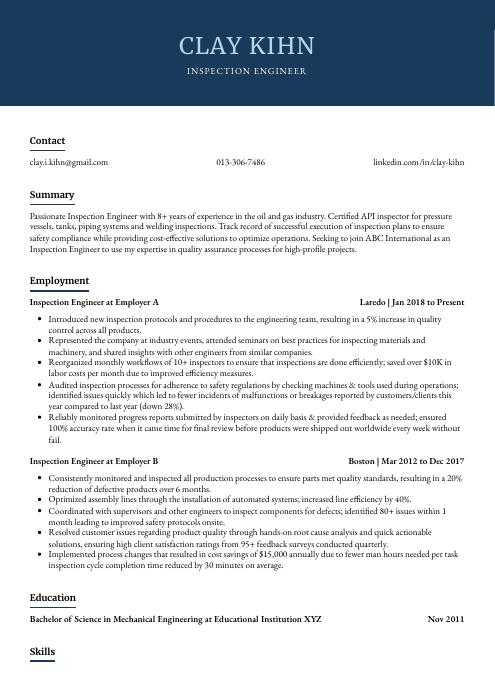

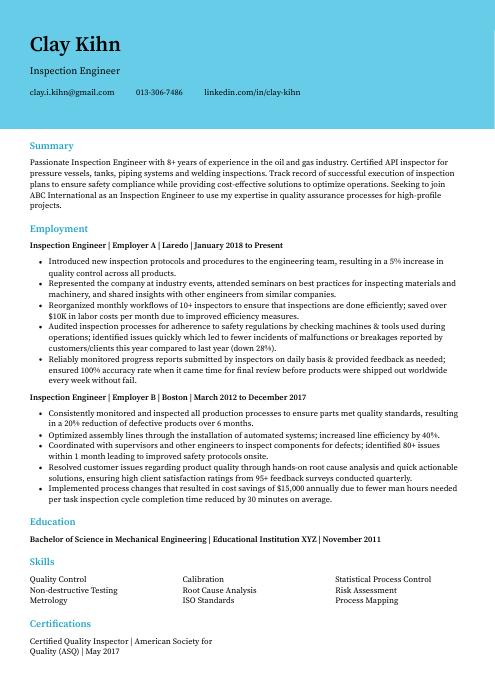

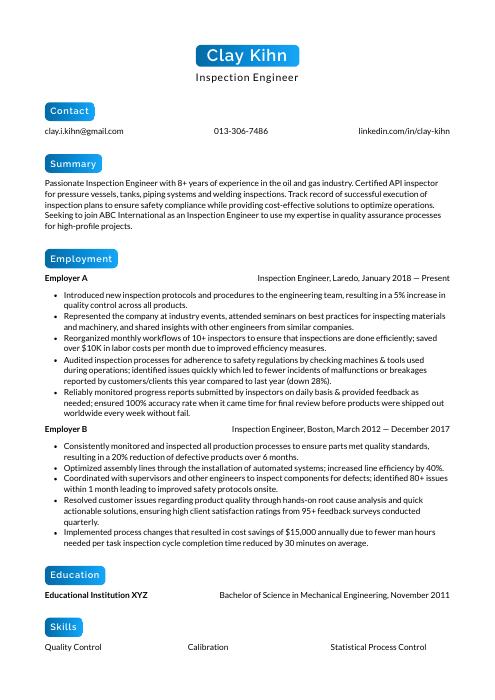

Inspection Engineer Resume Sample

Clay Kihn

Inspection Engineer

[email protected]

013-306-7486

linkedin.com/in/clay-kihn

Summary

Passionate Inspection Engineer with 8+ years of experience in the oil and gas industry. Certified API inspector for pressure vessels, tanks, piping systems and welding inspections. Track record of successful execution of inspection plans to ensure safety compliance while providing cost-effective solutions to optimize operations. Seeking to join ABC International as an Inspection Engineer to use my expertise in quality assurance processes for high-profile projects.

Experience

Inspection Engineer, Employer A

Laredo, Jan 2018 – Present

- Introduced new inspection protocols and procedures to the engineering team, resulting in a 5% increase in quality control across all products.

- Represented the company at industry events, attended seminars on best practices for inspecting materials and machinery, and shared insights with other engineers from similar companies.

- Reorganized monthly workflows of 10+ inspectors to ensure that inspections are done efficiently; saved over $10K in labor costs per month due to improved efficiency measures.

- Audited inspection processes for adherence to safety regulations by checking machines & tools used during operations; identified issues quickly which led to fewer incidents of malfunctions or breakages reported by customers/clients this year compared to last year (down 28%).

- Reliably monitored progress reports submitted by inspectors on daily basis & provided feedback as needed; ensured 100% accuracy rate when it came time for final review before products were shipped out worldwide every week without fail.

Inspection Engineer, Employer B

Boston, Mar 2012 – Dec 2017

- Consistently monitored and inspected all production processes to ensure parts met quality standards, resulting in a 20% reduction of defective products over 6 months.

- Optimized assembly lines through the installation of automated systems; increased line efficiency by 40%.

- Coordinated with supervisors and other engineers to inspect components for defects; identified 80+ issues within 1 month leading to improved safety protocols onsite.

- Resolved customer issues regarding product quality through hands-on root cause analysis and quick actionable solutions, ensuring high client satisfaction ratings from 95+ feedback surveys conducted quarterly.

- Implemented process changes that resulted in cost savings of $15,000 annually due to fewer man hours needed per task inspection cycle completion time reduced by 30 minutes on average.

Skills

- Quality Control

- Calibration

- Statistical Process Control

- Non-destructive Testing

- Root Cause Analysis

- Risk Assessment

- Metrology

- ISO Standards

- Process Mapping

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Quality Inspector

American Society for Quality (ASQ)

May 2017

1. Summary / Objective

The summary/objective at the beginning of your inspection engineer resume should provide a snapshot of who you are and what makes you an ideal candidate for the job. You could mention that you have extensive experience in quality control, knowledge in using specialized tools to inspect parts and components, as well as certifications such as ISO 9001:2015 or ASME IX welding inspector. Additionally, highlight any successful projects where your inspections helped improve safety standards or reduced costs.

Below are some resume summary examples:

Accomplished inspection engineer with 8+ years of experience in the oil and gas industry. Skilled at conducting QA/QC inspections, completing technical reports, and ensuring compliance with safety regulations. Adept at identifying potential risks associated with production processes to prevent costly accidents. Seeking a position as an inspection engineer at ABC Company to utilize my expertise in optimizing operations while maintaining safe working conditions.

Professional inspection engineer with 5+ years of experience in the oil and gas industry. Experienced in performing quality control inspections, managing data analysis and reporting, implementing corrective action plans based on findings, overseeing equipment maintenance activities/programs and developing technical documents. Leveraged my expertise to improve operational efficiency by 25%. Looking to leverage this skill set at XYZ company.

Determined inspection engineer with 5+ years of experience performing product inspections and tests for industrial projects. At XYZ, led inspection teams on 10 high-profile construction sites using non-destructive testing methods. Improved safety metrics by 20% through detailed documentation and close supervision of the quality assurance process. Recognized for ensuring compliance to all industry standards in each project undertaken.

Dependable inspection engineer with 8+ years of experience in the oil and gas industry. At XYZ, inspected offshore drilling rigs for safety compliance according to international standards such as API RP-2A (WSD). Demonstrated expertise in using multiple types of NDT techniques like radiography, ultrasonic testing, and visual inspection. Noted for completing projects on time without compromising quality or safety protocols.

Enthusiastic and detail-oriented inspection engineer with 5+ years of experience in conducting quality control inspections for a variety of products. Proven track record of ensuring product compliance to customer specifications and industry standards through rigorous testing, analysis, and reporting. Seeking to join ABC Company as an Inspection Engineer to help improve the safety and reliability of their products.

Well-rounded inspection engineer with 10+ years of experience in the construction industry. Experienced at providing technical expertise and hands-on inspections to ensure quality assurance standards are met throughout project completion. Adept at utilizing specialized inspection tools and data analysis software to identify discrepancies, recommend solutions, and optimize processes for improved safety outcomes.

Reliable inspection engineer with 7+ years of experience in testing, inspecting and certifying high-precision products for a variety of industries. In past roles, successfully managed quality assurance operations for multiple projects while maintaining strict compliance to safety regulations. Looking to apply my knowledge and skillset at ABC Corporation as the next inspection engineer.

Talented and detail-oriented inspection engineer with 5+ years of experience providing accurate, safe inspections for a wide range of equipment and facilities. Looking to join ABC Corp. to bring my knowledge of international standards and regulations as well as the ability to identify issues quickly and accurately in order to ensure operational efficiency.

2. Experience / Employment

The employment (or experience) section is where you provide details on your work history. This should be written in reverse chronological order, with the most recent job listed first.

Stick to bullet points when writing this section; it makes it easier for the reader to take in what you have to say quickly and easily. When describing what you did, include detail and quantifiable results that demonstrate how successful your efforts were.

For example, instead of saying “Conducted inspections,” you could say, “Performed daily quality assurance checks on finished products using a variety of equipment such as calipers and micrometers; identified defects early which resulted in a 50% reduction of customer returns.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Evaluated

- Analyzed

- Monitored

- Tested

- Certified

- Documented

- Investigated

- Assessed

- Calibrated

- Troubleshot

- Resolved

- Reported

- Audited

Other general verbs you can use are:

- Achieved

- Advised

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Diligently inspected production line equipment and components to ensure compliance with safety regulations; reduced customer complaints by 30% in the past year.

- Revised quality control protocols for inspection procedures, detecting potential problems before they caused costly delays or malfunctions.

- Participated in cross-functional teams to troubleshoot issues that arose during inspections and identify areas of improvement within the manufacturing process.

- Tested electrical wiring, mechanical systems and other elements of factory machinery according to established standards; identified defects that saved $20,000+ in repairs over a 6 month period.

- Facilitated onsite training sessions for new inspectors on safe work practices, quality assurance techniques and industry best practices; improved accuracy rate by 25%.

- Efficiently inspected, tested and evaluated over 100 components for quality assurance in accordance with ISO 9001 standards, resulting in a 20% decrease of defective parts.

- Achieved high accuracy ratings on all inspection processes by using precision measuring tools such as calipers and micrometers; zero errors reported during audits.

- Troubleshot mechanical issues caused by poor workmanship or faulty materials to ensure that products met design specifications before delivering them to customers; reduced customer complaints by 40%.

- Certified 10+ personnel on the use of various testing equipment including hardness testers, spectrophotometers and x-ray machines; improved staff productivity in quality control activities significantly within 3 months time frame.

- Prepared detailed daily reports regarding test results which were then used to improve production methods and reduce costs associated with rework due to nonconformance issues; saved the company $15K annually through process optimization initiatives implemented from these reports.

- Calibrated and tested a range of equipment to ensure that all safety protocols and standards were adhered to, resulting in improved quality control with zero defects.

- Formulated detailed inspection plans tailored for each product line, ensuring efficient use of resources and reducing overall costs by 14%.

- Inspected over 500 products per day for accuracy and compliance with customer requirements; eliminated 100+ defective items from the production process within 2 months on the job.

- Structured consistent monitoring processes across multiple departments, enabling timely corrective action whenever deviations occurred; reduced operational errors by 12%.

- Thoroughly reviewed production reports as part of daily duties while promptly addressing any issues or concerns raised; resolved 98% customer complaints during inspections successfully within 24 hours.

- Compiled detailed inspection reports and documentation for over 200 projects, ensuring compliance with safety standards and regulations.

- Spearheaded the implementation of a new quality assurance system; reduced defect rates by 15% within one month of its introduction.

- Assessed nonconformities in production processes and identified root causes to help improve product quality; decreased customer complaints by 10%.

- Utilized specialized test equipment such as micrometers, calipers, gauges and torque wrenches to check products’ accuracy during visual inspections before shipment or installation on-site.

- Successfully completed 20+ inspections per day while meeting tight deadlines; improved timeliness rate from 70% to 95%.

- Improved overall production efficiency by 16% through the implementation of rigorous inspection protocols and procedures.

- Mentored new engineering staff on proper quality control techniques, ensuring that all products were inspected to industry standards before release.

- Developed a system for tracking defects in samples taken from large manufacturing batches, leading to an increase in customer satisfaction ratings by 20%.

- Analyzed data collected during inspections and wrote detailed reports outlining any product discrepancies or areas requiring improvement; suggested corrective actions which reduced rework time by 30%.

- Accurately documented findings following each inspection round and provided feedback to management about potential improvements; reduced errors per shift by 25%.

- Meticulously inspected, tested and verified the quality of over 200 components for aerospace systems daily; reduced product defects by 25% within 6 months.

- Evaluated engineering drawings, blueprints and customer specifications to identify potential problems with products before assembly; proactively prevented 15 errors from propagating through production line.

- Streamlined inspection processes using automated testing equipment; cut process time per unit by 20%, resulting in a $4,000 cost savings each month.

- Reported detailed results of inspections to management as well as customers and suppliers on a regular basis while maintaining strict confidentiality standards at all times.

- Reduced warranty claims against defective parts by 50% since implementing improved testing protocols & procedures across entire manufacturing facility.

- Documented results of mechanical, electrical and environmental inspections in detail across 25+ sites, ensuring that all data was accurate and up-to-date.

- Demonstrated technical proficiency when operating state-of-the art inspection tools such as thermal cameras and borescopes to identify potential safety hazards; identified 20% more problems than anticipated in recent project.

- Actively collaborated with other engineers to investigate any issues found during the inspection process; reduced resolution time by 35%.

- Presented detailed reports on findings from each site visit along with proposed solutions for corrective action; improved customer satisfaction ratings by 12%.

- Advised both internal teams and external clients on best practices for preventative maintenance measures which saved an average of $7000 per quarter in repair costs due to timely inspections performed.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in conducting non-destructive testing, while the other may be looking for someone with a background in metallurgy.

It is therefore important to tailor the skills section of your resume to each job that you are applying for. This will ensure that applicant tracking systems (which most companies use these days) pick up on all relevant keywords and phrases associated with the role, increasing your chances of being shortlisted. In addition to listing them here, it would also help if you discussed some of your key qualifications more thoroughly elsewhere – such as within the summary or work history sections.

Below is a list of common skills & terms:

- Calibration

- ISO Standards

- Metrology

- Non-destructive Testing

- Process Mapping

- Quality Control

- Risk Assessment

- Root Cause Analysis

- Statistical Process Control

- Technical Report Writing

4. Education

Mentioning your education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, include this section below your resume objective. However, if you have extensive work experience that is relevant to the inspection engineer role for which you are applying, it may be best not to mention any educational qualifications at all.

If an education section is included, try to highlight courses and certifications related specifically to the job of an inspection engineer.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field. They can be used to prove that you have the necessary knowledge and skills required for the job, as well as show potential employers that you are committed to staying up-to-date with industry trends.

Including any certifications relevant to the position on your resume is an excellent way of showing employers how qualified you are for the role. Make sure they’re listed prominently so hiring managers will take notice!

Certified Quality Inspector

American Society for Quality (ASQ)

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Clay Kihn, this would be Clay-Kihn-resume.pdf or Clay-Kihn-resume.docx.

7. Cover Letter

Attaching a cover letter to your resume is a great way to stand out from other applicants and express why you are the best fit for the role. This document usually consists of 2-4 paragraphs that give recruiters more insight into who you are, what makes you unique and how your skills can benefit the company.

Cover letters aren’t always mandatory when applying for jobs but they certainly help make an impression on employers. They provide additional detail about yourself that cannot be found in a standard resume, allowing them to gain better understanding of your abilities as an applicant.

Below is an example cover letter:

Dear Hazle,

I am writing to apply for the Inspection Engineer position with your company. With over 10 years of experience in quality assurance and inspection, I have the skills and knowledge to contribute to your organization.

In my previous role as an inspection engineer at ABC Corporation, I was responsible for inspecting products during production and ensuring that they met quality standards. I also created reports detailing any defects or issues that were found. In addition, I developed and implemented new methods and procedures to improve the efficiency of the inspection process. As a result of my efforts, ABC Corporation received ISO 9001 certification.

I am knowledgeable about various inspection techniques and tools, including coordinate measuring machines (CMMs) and optical comparators. I am also familiar with international standards such as ISO 9000 and AS9100. My excellent communication skills allow me to effectively communicate with other departments within an organization, as well as with customers or suppliers.

I am confident that I can be a valuable asset to your organization as an inspection engineer. My experience, knowledge, and skills will enable me to make a positive contribution to your company. I look forward to speaking with you soon about this opportunity.

Sincerely,

Clay

Inspection Engineer Resume Templates

Rhea

Rhea Indri

Indri Jerboa

Jerboa Numbat

Numbat Echidna

Echidna Gharial

Gharial Pika

Pika Hoopoe

Hoopoe Fossa

Fossa Axolotl

Axolotl Markhor

Markhor Quokka

Quokka Ocelot

Ocelot Cormorant

Cormorant Saola

Saola Lorikeet

Lorikeet Bonobo

Bonobo Dugong

Dugong Kinkajou

Kinkajou Rezjumei

Rezjumei