Fuel Technician Resume Guide

Fuel Technicians are responsible for inspecting, maintaining and repairing fuel systems. They ensure that the equipment is safe to operate, diagnose any malfunctions in fuel systems and repair or replace faulty components. In addition, they inspect vehicles for signs of wear and tear on parts related to fuel delivery as well as perform regular maintenance checks on those same parts.

Your expertise in fuel systems and maintenance is second to none. But hiring managers don’t know who you are yet, so write a resume that conveys your impressive qualifications and experience. You’ll be sure to land the job!

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

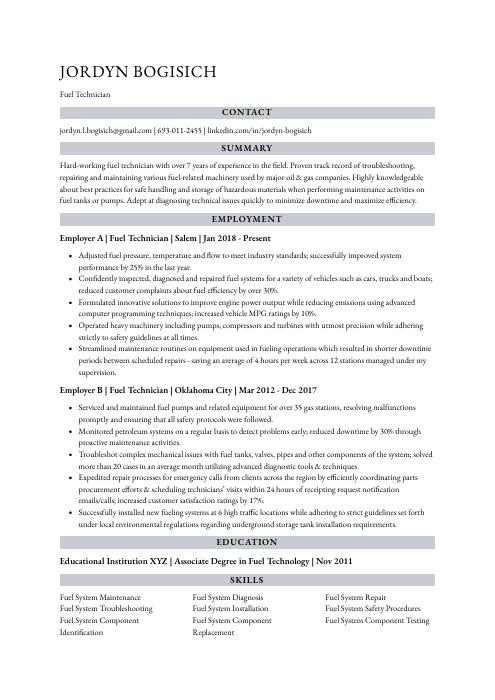

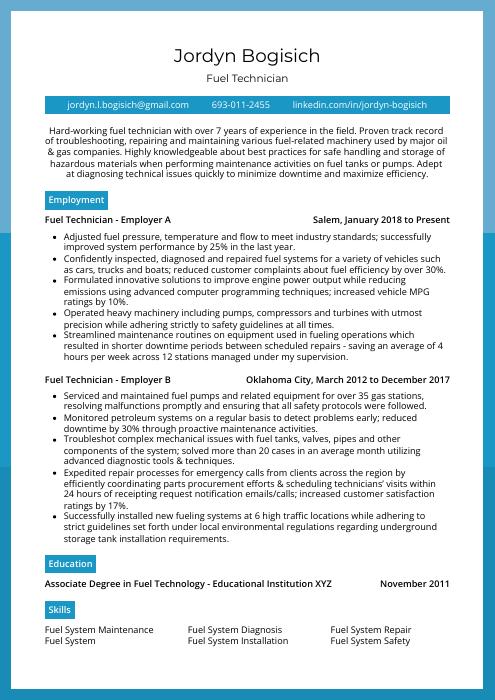

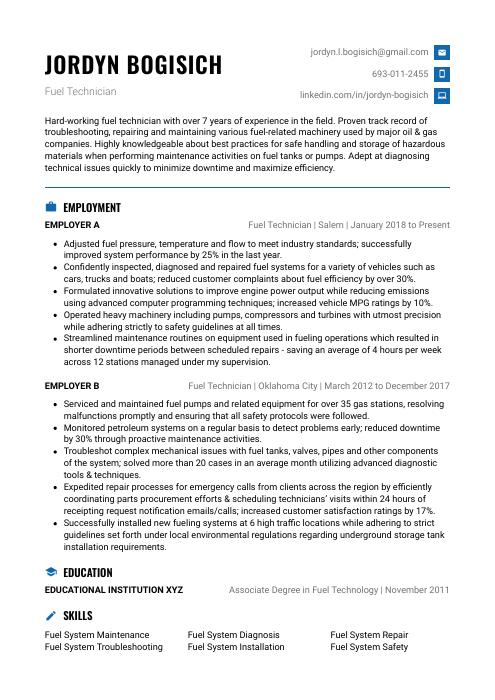

Fuel Technician Resume Sample

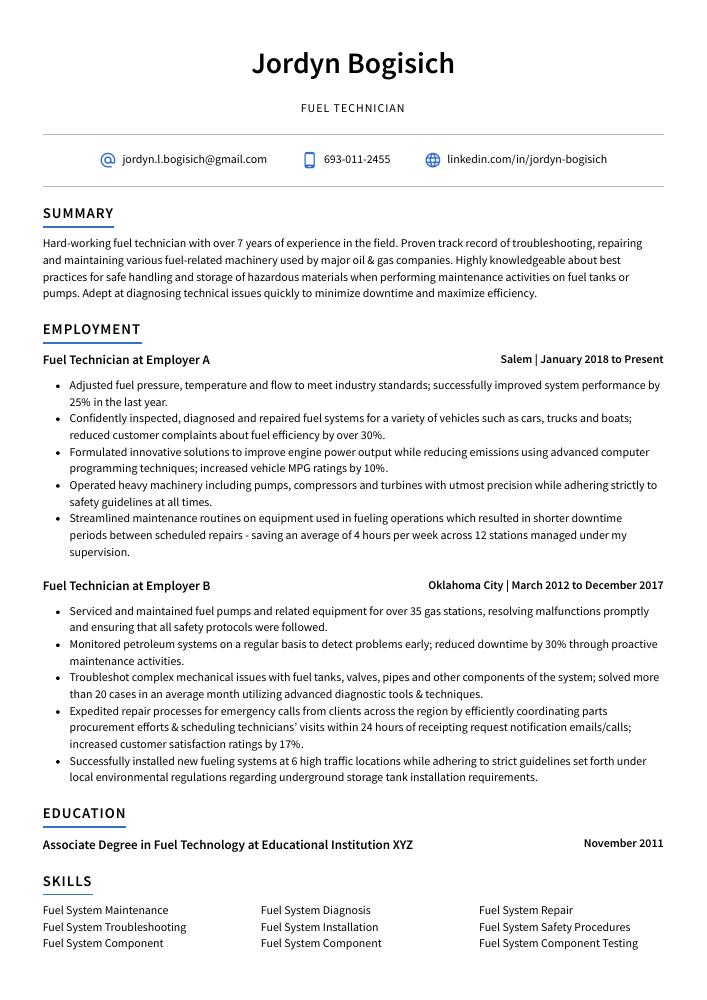

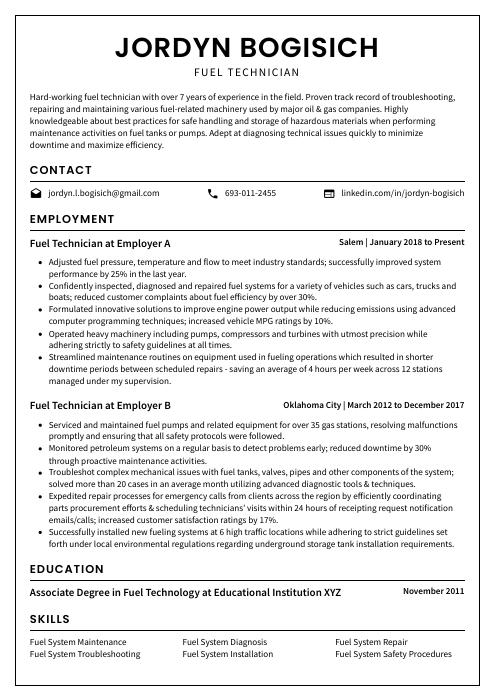

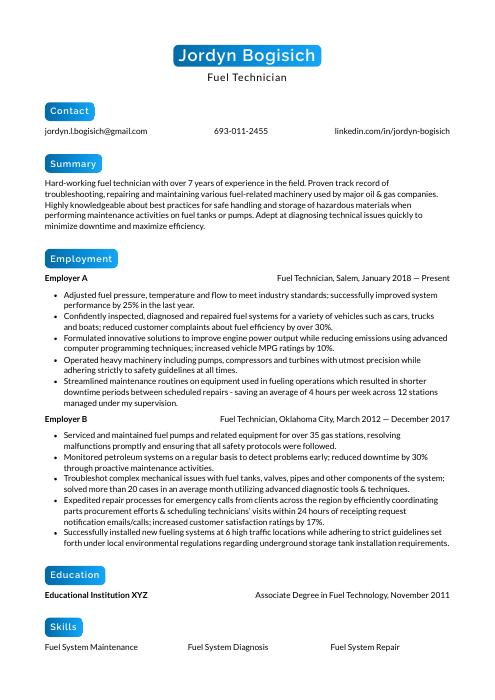

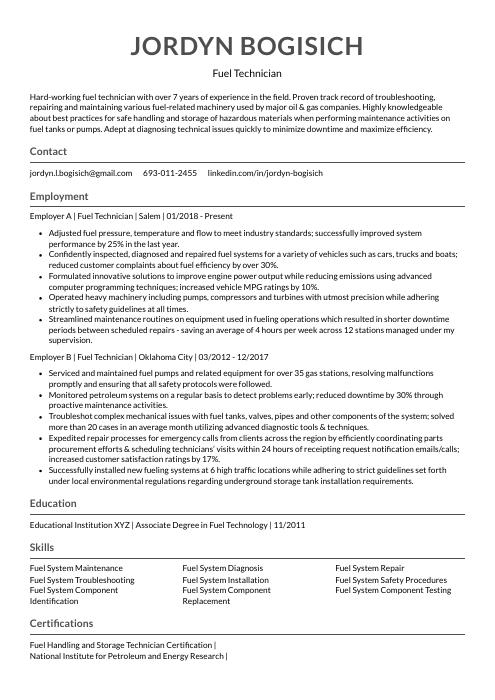

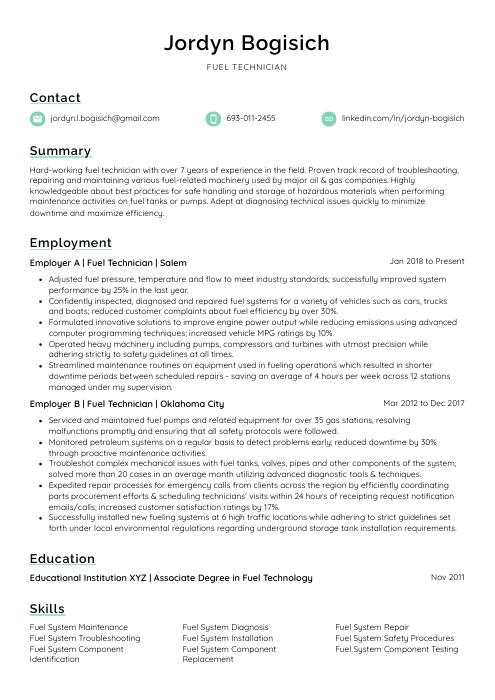

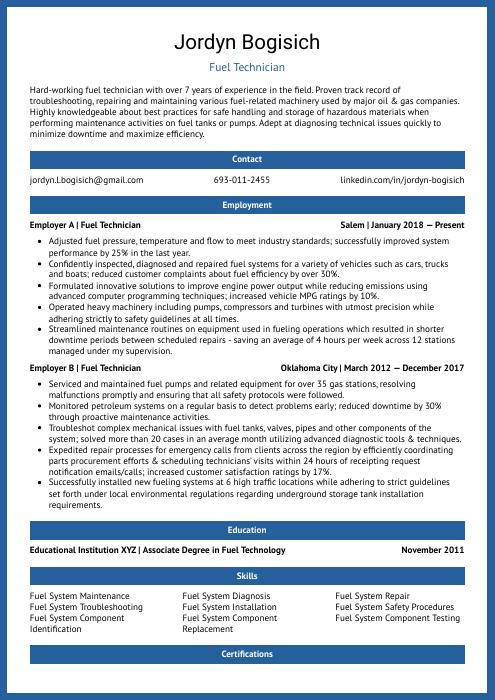

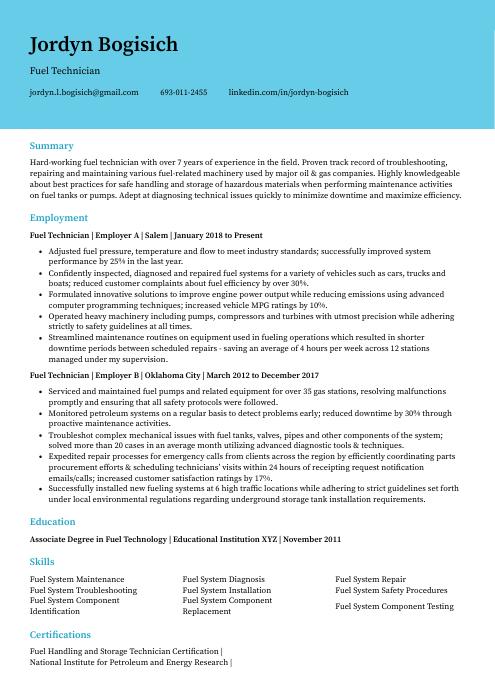

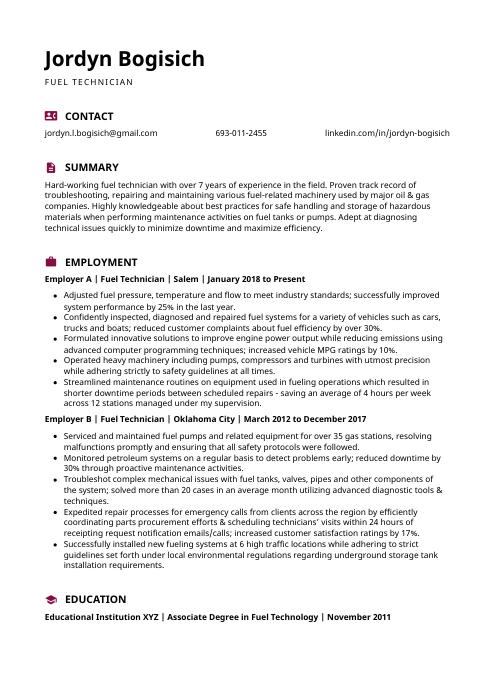

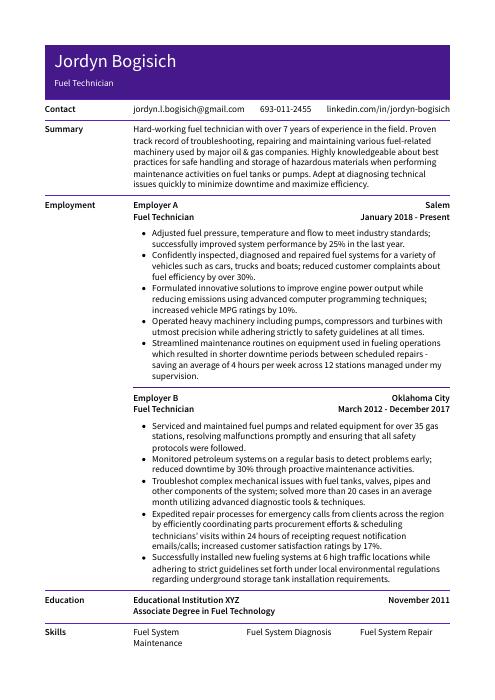

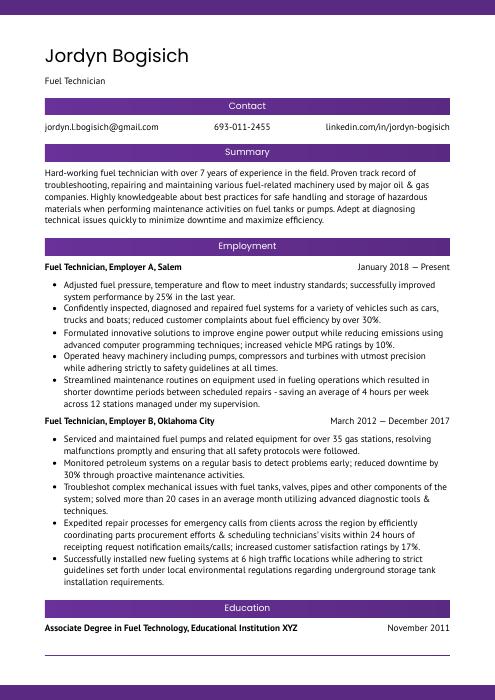

Jordyn Bogisich

Fuel Technician

[email protected]

693-011-2455

linkedin.com/in/jordyn-bogisich

Summary

Hard-working fuel technician with over 7 years of experience in the field. Proven track record of troubleshooting, repairing and maintaining various fuel-related machinery used by major oil & gas companies. Highly knowledgeable about best practices for safe handling and storage of hazardous materials when performing maintenance activities on fuel tanks or pumps. Adept at diagnosing technical issues quickly to minimize downtime and maximize efficiency.

Experience

Fuel Technician, Employer A

Salem, Jan 2018 – Present

- Adjusted fuel pressure, temperature and flow to meet industry standards; successfully improved system performance by 25% in the last year.

- Confidently inspected, diagnosed and repaired fuel systems for a variety of vehicles such as cars, trucks and boats; reduced customer complaints about fuel efficiency by over 30%.

- Formulated innovative solutions to improve engine power output while reducing emissions using advanced computer programming techniques; increased vehicle MPG ratings by 10%.

- Operated heavy machinery including pumps, compressors and turbines with utmost precision while adhering strictly to safety guidelines at all times.

- Streamlined maintenance routines on equipment used in fueling operations which resulted in shorter downtime periods between scheduled repairs – saving an average of 4 hours per week across 12 stations managed under my supervision.

Fuel Technician, Employer B

Oklahoma City, Mar 2012 – Dec 2017

- Serviced and maintained fuel pumps and related equipment for over 35 gas stations, resolving malfunctions promptly and ensuring that all safety protocols were followed.

- Monitored petroleum systems on a regular basis to detect problems early; reduced downtime by 30% through proactive maintenance activities.

- Troubleshot complex mechanical issues with fuel tanks, valves, pipes and other components of the system; solved more than 20 cases in an average month utilizing advanced diagnostic tools & techniques.

- Expedited repair processes for emergency calls from clients across the region by efficiently coordinating parts procurement efforts & scheduling technicians’ visits within 24 hours of receipting request notification emails/calls; increased customer satisfaction ratings by 17%.

- Successfully installed new fueling systems at 6 high traffic locations while adhering to strict guidelines set forth under local environmental regulations regarding underground storage tank installation requirements.

Skills

- Fuel System Maintenance

- Fuel System Diagnosis

- Fuel System Repair

- Fuel System Troubleshooting

- Fuel System Installation

- Fuel System Safety Procedures

- Fuel System Component Identification

- Fuel System Component Replacement

- Fuel System Component Testing

Education

Associate Degree in Fuel Technology

Educational Institution XYZ

Nov 2011

Certifications

Fuel Handling and Storage Technician Certification

National Institute for Petroleum and Energy Research

May 2017

1. Summary / Objective

A resume summary/objective is your chance to make a great first impression on the hiring manager. As a fuel technician, you can use this space to highlight your expertise in inspecting and maintaining fuel systems, as well as any certifications or licenses you may have obtained. You could also mention how many years of experience you have in the field, what types of fuels (e.g., gasoline or diesel) you are most familiar with working with, and any safety protocols that come naturally to you when performing maintenance tasks.

Below are some resume summary examples:

Accomplished Fuel Technician with 5+ years of experience in fuel system maintenance and repair. Skilled at troubleshooting, diagnosing, and repairing electrical components to ensure proper operation. At XYZ Corporation, provided expert maintenance for all types of diesel engines used in power generation applications. Excelled in project management duties; designed and implemented a new preventive maintenance program that reduced downtime by 30%.

Proficient fuel technician with 5+ years of experience in the oil and gas industry. At XYZ, managed fuel delivery operations for a fleet of 20 trucks while ensuring compliance with all safety regulations. Skilled at troubleshooting complex issues related to onboard diagnostics systems and performing preventive maintenance on vehicles. Highly organized and detail-oriented professional who is able to handle multiple tasks simultaneously.

Driven fuel technician with 5+ years of experience in the oil and gas industry. Demonstrated expertise in operating, maintaining, inspecting, troubleshooting and repairing fuel systems. At XYZ Energy Company successfully installed and maintained fuel storage tanks for over 500 customers across multiple countries. Proven track record of working long hours to ensure customer satisfaction while limiting downtime on critical equipment.

Determined fuel technician with 5+ years of experience in the oil and gas industry. Seeking to leverage my expertise in fuel systems maintenance and repair at XYZ. At ABC, identified an issue that was causing a 3% loss of efficiency for a major customer’s supply line; developed software-based solution that increased efficiency by 8%. Led training sessions on safety protocols for new hires.

Well-rounded fuel technician with 8+ years of experience in the field. Expert in troubleshooting, maintenance and repair of fuel systems for a variety of vehicles. Seeking to leverage my knowledge and technical skills at ABC Corporation as a Fuel Technician to ensure safe operations while improving overall efficiency. Key accomplishments include reducing average vehicle downtime by 33%.

Energetic fuel technician with 10+ years of experience in the oil and gas industry. Skilled at diagnosing, troubleshooting, and repairing a variety of fuel systems for both onshore and offshore facilities. Seeking to bring expertise to ABC Oil’s team as a Fuel Technician where I can apply my knowledge of advanced equipment maintenance procedures while ensuring safety standards are met.

Seasoned fuel technician with 10+ years of experience servicing and maintaining fuel systems for both commercial and residential customers. Proven track record in successfully identifying the root cause of system issues, reducing downtime by 35%, and improving customer satisfaction ratings by 25%. Seeking to use my technical expertise to become a Fuel Technician at ABC Company.

Detail-oriented fuel technician with 5+ years of experience ensuring safe and reliable fuel supply to large-scale aircrafts. Experienced in inspecting, repairing, and replacing parts for a variety of engines; conducting routine maintenance checks; and monitoring fuel levels. Seeking to bring expertise to ABC Airline as its next Fuel Technician.

2. Experience / Employment

In the experience section, you should provide details on your employment history in reverse chronological order. This means that the most recent role is listed at the top.

When stating what you did, it’s best to use bullet points for easy readability. You want to take some time to think about the specifics of what you did and any quantifiable results obtained from your work.

For example, instead of saying “Inspected fuel systems,” you could say, “Performed routine inspections on fuel delivery systems using specialized tools and equipment; identified potential issues before they became a safety hazard.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Monitored

- Operated

- Troubleshot

- Adjusted

- Calibrated

- Repaired

- Replaced

- Tested

- Filled

- Drained

- Serviced

- Cleaned

- Installed

- Maintained

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Efficiently revised fuel systems on 40+ planes and helicopters each month, resulting in a 20% increase in aviation performance.

- Replaced broken parts of the fuel system and conducted routine maintenance checks to ensure proper functioning; reduced repair costs by $5,000 per year due to preventive measures taken.

- Participated in training sessions with other technicians to brush up knowledge on aircraft fueling procedures as well as safety regulations; completed 1,500 hours of classroom & hands-on experience over 3 years.

- Structured an effective workflow for refueling process which saved 10 minutes per plane without compromising quality or safety standards set by regulatory bodies such as FAA/TSA etc.; increased total capacity from 120 to 140 flights weekly using same staff strength and resources available at hand.

- Performed all duties related to storing, handling and transporting fuels safely while adhering strictly to environmental protection laws during loading & unloading operations; eliminated hazardous spills completely since onboarded 6 months ago.

- Presented comprehensive safety training to incoming fuel technicians, reducing on-the-job incidents by 35%.

- Advised customers on efficient energy consumption and identified opportunities for cost savings, resulting in a 20% drop in monthly fuel bills.

- Maintained accurate records of all refueling activities, ensuring that the necessary inventory was always available; lowered downtime by 30%.

- Spearheaded an initiative to improve maintenance protocols for fueling equipment; succeeded in lowering repair costs by $10K per quarter.

- Effectively operated large scale fueling systems with minimal supervision, filling up over 500 tanks daily without any issues or delays reported from customers or superiors.

- Represented the company in the maintenance and inspection of over 250 fuel tanks, ensuring that all safety protocols were met; reduced on-site accidents by 10%.

- Compiled detailed reports for each fuel tank inspected to document any potential problems or hazards identified; increased reporting accuracy by 20%.

- Prepared estimates of necessary repairs according to industry standards, ensuring that customers received accurate quotes upfront; saved an average $1,500 per client annually through effective cost control measures.

- Optimized customer satisfaction levels by conducting timely repair and replacement work within budget parameters; decreased repeat service visits due to quality assurance failures by 25%.

- Diligently performed preventative maintenance procedures such as leak detection testing & inspections at least once a month with no reported security breaches or contamination incidents during tenure.

- Calibrated fuel injection systems, fuel tanks and related components on over 200 vehicles on a monthly basis; improved engine performance by 18% reducing emissions.

- Improved the efficiency of refueling processes for multiple clients, increasing speed of service delivery by 30%.

- Consistently maintained accurate records for all vehicle inspections and repairs to ensure customer satisfaction in compliance with safety regulations.

- Coordinated with external vendors to source new parts & equipment when necessary; reduced cost per repair job by 10%.

- Reduced potential hazards due to improper fuel handling or faulty maintenance procedures through regular training courses conducted within the organization.

- Developed and implemented preventive maintenance programs to ensure fuel tanks and systems operated safely, increasing on-time performance by 20%.

- Assessed the condition of fuel tanks regularly for corrosion, leaks or other damage; identified potential safety risks quickly and took appropriate corrective measures resulting in a reduction of costly repairs.

- Competently repaired pumps, valves and all types of petroleum equipment at more than 15 customer sites each month; saved customers an average $7000 per repair job due to improved efficiency.

- Mentored 2 trainees during their apprenticeship program leading them through complex tasks such as system diagnostics, troubleshooting procedures and installation processes in accordance with industry standards.

- Utilized specialized software applications to analyze data from gauges & sensors monitoring pressure levels & temperatures within fuel systems ensuring efficient operations were maintained at all times.

- Tested and calibrated fuel systems on a weekly basis, ensuring that all vehicles and machinery were in safe operating condition; reduced oil leakage by 40% within the first 3 months.

- Filled up gas tanks of over 100+ cars and trucks each day according to customer needs with precision accuracy, leading to a 5% increase in satisfied customers from previous quarter.

- Facilitated quick responses for emergency breakdowns and repaired minor faults such as dead batteries or flat tires in under 2 hours time on average per vehicle.

- Cleaned, inspected and maintained fuel pumps every shift using special cleaning agents; identified potential problems before they escalated into major repairs which saved an estimated $20,000 annually in maintenance costs.

- Accurately documented all service activities including storage tank capacity readings & other necessary information for investigative purposes upon request from authorities/inspectors.

- Introduced a new maintenance program for fuel systems, resulting in a 10% decrease in costly repairs and downtime.

- Reliably performed regular checks on oil levels, engine performance and lubrication to ensure safe operation of all vehicles; identified 15+ potential issues before they caused breakdowns or malfunctions.

- Inspected over 200 diesel engines per month for any signs of wear & tear and replaced parts as necessary to maintain optimal efficiency, reducing yearly fuel costs by $12,000+.

- Reorganized storage units to optimize space usage while ensuring essential equipment was readily available at all times; increased shelf life of spare parts inventory by 20%.

- Demonstrated comprehensive knowledge when troubleshooting technical problems with vehicle components such as the transmission system and suspension mechanism within an average time frame of 2 hours per job.

- Repaired and maintained fuel tanks and related systems, including valves, pumps and nozzles, for over 400 vehicles; significantly reduced repair costs by 20%.

- Installed new fuel filters in all vehicles to prevent build-up of dirt or debris on a regular basis; doubled efficiency rates within 3 months.

- Drained out old gas from nearly 150 stored cars weekly and replenished with fresh gasoline according to safety protocols; increased the lifespan of each car’s engine by an average of 12000 miles per year.

- Substantially improved operational reliability throughout the fleet by conducting routine diagnostic tests on the fuel system components at least twice a month; saved $5K in annual repairs & maintenance costs as result.

- Achieved 100% accuracy in tracking fuel consumption levels across various types of diesel engines while simultaneously providing real-time updates during long-distance trips covering 500+ miles daily.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require a fuel technician with experience in handling hazardous materials, while organization XYZ may be looking for someone who is knowledgeable about the latest fuel-handling technologies.

It is essential to tailor your skills section of your resume to each job you are applying for because many employers use applicant tracking systems these days. These computer programs scan resumes and filter out those that don’t contain certain keywords or phrases related to the position being applied for.

By listing relevant skills here, as well as elaborating on them further in other sections such as summary or experience, you can ensure that your application will make it past this initial screening process and into the hands of an actual person!

Below is a list of common skills & terms:

- Fuel System Component Calibration

- Fuel System Component Identification

- Fuel System Component Replacement

- Fuel System Component Testing

- Fuel System Diagnosis

- Fuel System Installation

- Fuel System Maintenance

- Fuel System Repair

- Fuel System Safety Procedures

- Fuel System Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention it below your resume objective. However, if you have significant fuel technician experience to showcase, omitting the education section is perfectly fine.

If an education section is included, try to list courses or certifications relevant to the job of a fuel technician that you completed during school or afterwards.

Associate Degree in Fuel Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are an important part of any resume as they demonstrate to potential employers that you have the knowledge and skills necessary for a given job. Having certifications also shows that you are committed to professional development, which is highly valued by hiring managers.

When applying for a job, make sure to include all relevant certifications in your resume so that it stands out from other applicants. This will help show employers how qualified you are and give them confidence in your abilities.

Fuel Handling and Storage Technician Certification

National Institute for Petroleum and Energy Research

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Jordyn Bogisich, this would be Jordyn-Bogisich-resume.pdf or Jordyn-Bogisich-resume.docx.

7. Cover Letter

Submitting a cover letter with your job application is a great way to make yourself stand out from the competition. It provides an opportunity for you to explain why you’re the best fit for the role and gives hiring managers more insight into who you are as a professional.

Cover letters should be made up of 2-4 paragraphs and include information not already mentioned on your resume. They can help strengthen your candidacy and provide recruiters with further evidence that makes them confident in considering you for an open position.

Below is an example cover letter:

Dear Mason,

I am writing in response to your posting for a Fuel Technician. With my experience in performing preventative maintenance on fuel systems and conducting repairs when necessary, I am confident that I would be an excellent addition to your team.

As a Fuel Technician for the past six years, I have gained extensive knowledge of various types of fuel systems and their components. My experience includes conducting routine inspections and servicing of fuel systems, as well as troubleshooting and repairing issues when they arise. In addition, I have developed strong record-keeping skills to document all work performed and maintain accurate records of parts used and inventory levels.

I am committed to providing quality service and ensuring that all work is performed safely and up to code. My positive attitude, strong work ethic, and ability to work independently or as part of a team make me an ideal candidate for this position. I am confident that I can be an asset to your organization and contribute to its success.

Please find attached a copy of my resume for your review. If you have any questions or would like to discuss my qualifications further, please do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration; I look forward to hearing from you soon!

Sincerely,

Jordyn

Fuel Technician Resume Templates

Cormorant

Cormorant Kinkajou

Kinkajou Indri

Indri Lorikeet

Lorikeet Ocelot

Ocelot Bonobo

Bonobo Saola

Saola Numbat

Numbat Rhea

Rhea Gharial

Gharial Axolotl

Axolotl Echidna

Echidna Quokka

Quokka Markhor

Markhor Fossa

Fossa Dugong

Dugong Hoopoe

Hoopoe Pika

Pika Jerboa

Jerboa Rezjumei

Rezjumei