Forklift Technician Resume Guide

Forklift technicians are responsible for maintaining and repairing a variety of forklifts. They diagnose issues, perform preventive maintenance, identify parts that need to be replaced or repaired, and work with customers to ensure the highest level of product performance.

You have the perfect combination of mechanical and problem solving skills, making you a great fit for any forklift technician job. But hiring managers won’t know how experienced and reliable you are unless they read an impressive resume that tells them so.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

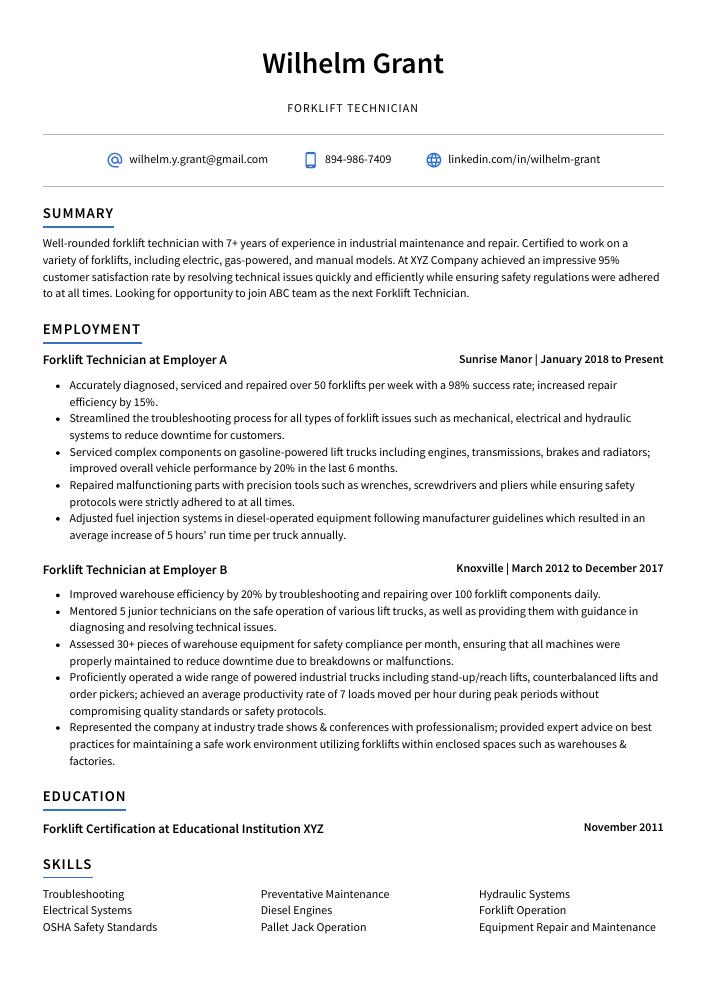

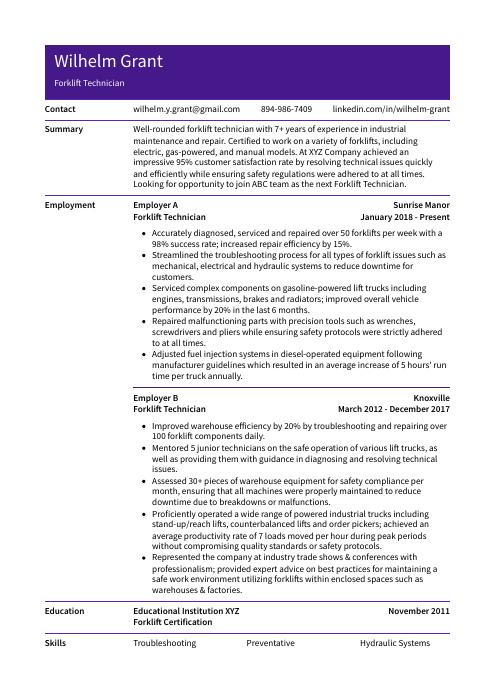

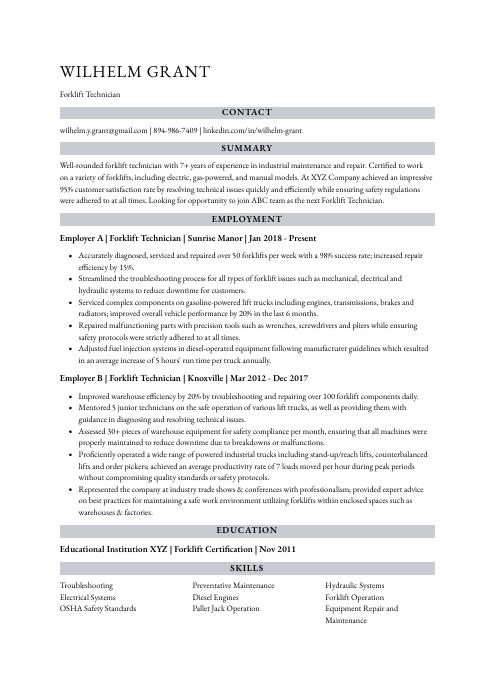

Forklift Technician Resume Sample

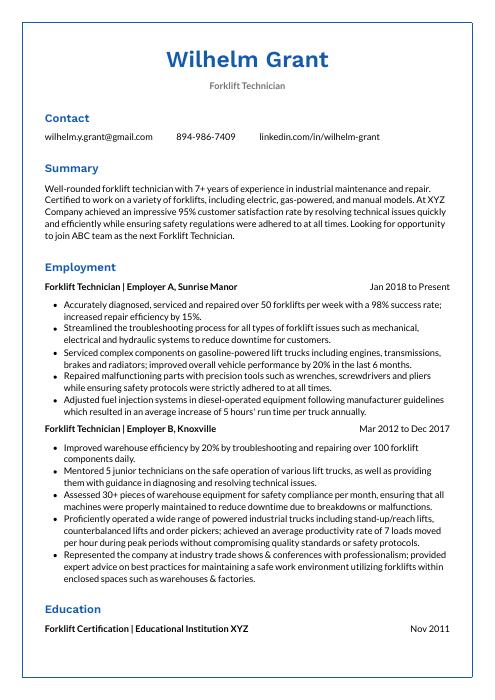

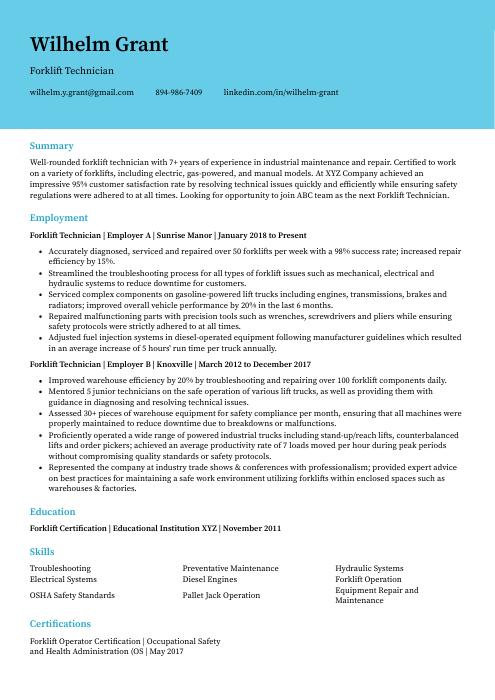

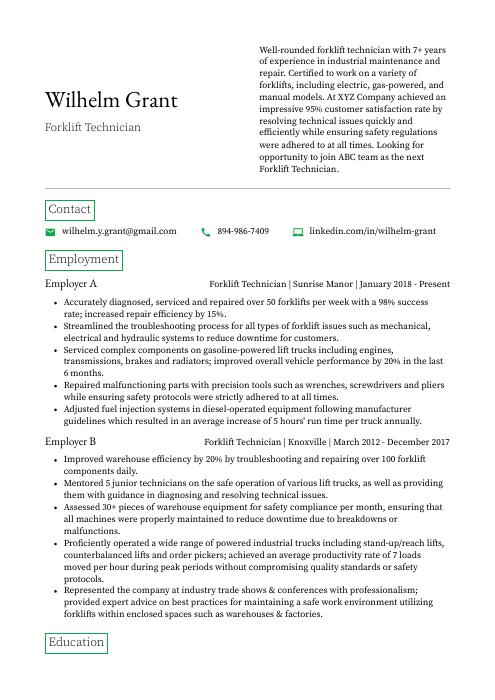

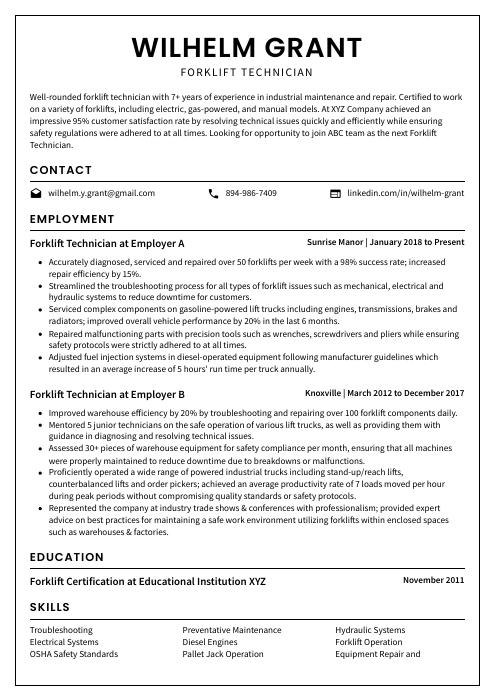

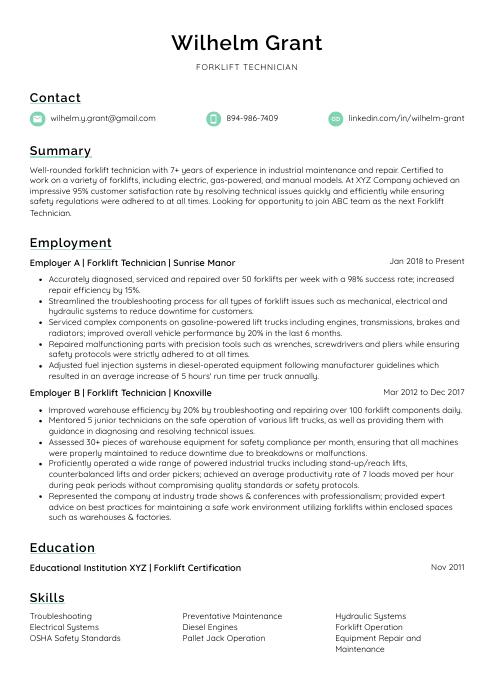

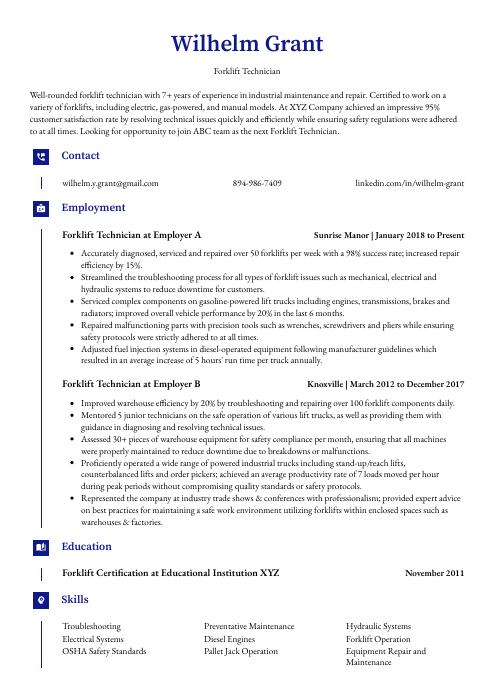

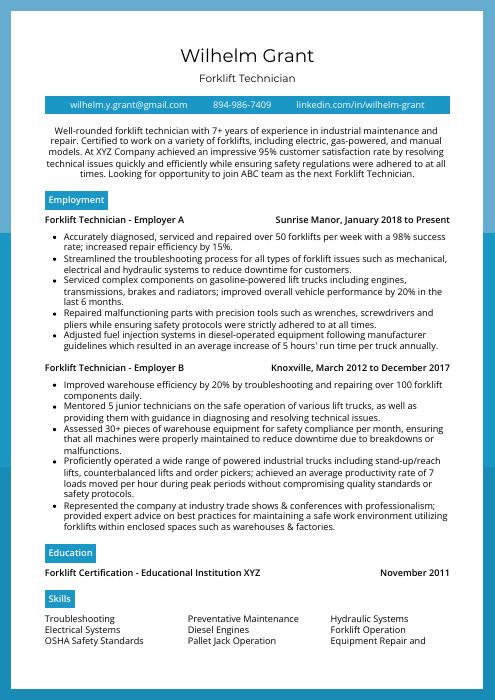

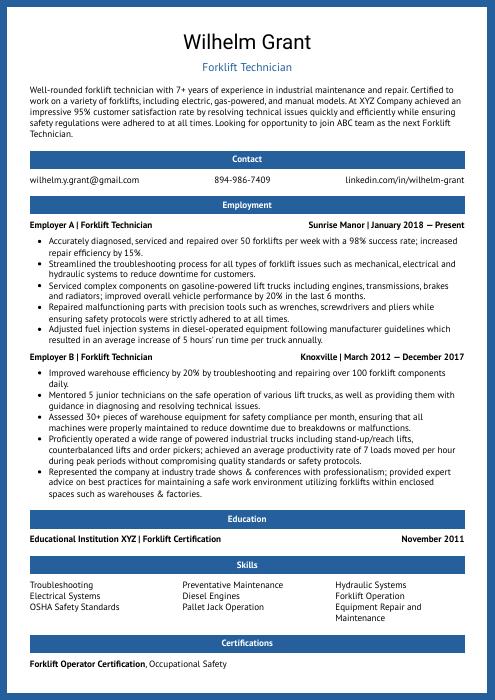

Wilhelm Grant

Forklift Technician

[email protected]

894-986-7409

linkedin.com/in/wilhelm-grant

Summary

Well-rounded forklift technician with 7+ years of experience in industrial maintenance and repair. Certified to work on a variety of forklifts, including electric, gas-powered, and manual models. At XYZ Company achieved an impressive 95% customer satisfaction rate by resolving technical issues quickly and efficiently while ensuring safety regulations were adhered to at all times. Looking for opportunity to join ABC team as the next Forklift Technician.

Experience

Forklift Technician, Employer A

Sunrise Manor, Jan 2018 – Present

- Accurately diagnosed, serviced and repaired over 50 forklifts per week with a 98% success rate; increased repair efficiency by 15%.

- Streamlined the troubleshooting process for all types of forklift issues such as mechanical, electrical and hydraulic systems to reduce downtime for customers.

- Serviced complex components on gasoline-powered lift trucks including engines, transmissions, brakes and radiators; improved overall vehicle performance by 20% in the last 6 months.

- Repaired malfunctioning parts with precision tools such as wrenches, screwdrivers and pliers while ensuring safety protocols were strictly adhered to at all times.

- Adjusted fuel injection systems in diesel-operated equipment following manufacturer guidelines which resulted in an average increase of 5 hours’ run time per truck annually.

Forklift Technician, Employer B

Knoxville, Mar 2012 – Dec 2017

- Improved warehouse efficiency by 20% by troubleshooting and repairing over 100 forklift components daily.

- Mentored 5 junior technicians on the safe operation of various lift trucks, as well as providing them with guidance in diagnosing and resolving technical issues.

- Assessed 30+ pieces of warehouse equipment for safety compliance per month, ensuring that all machines were properly maintained to reduce downtime due to breakdowns or malfunctions.

- Proficiently operated a wide range of powered industrial trucks including stand-up/reach lifts, counterbalanced lifts and order pickers; achieved an average productivity rate of 7 loads moved per hour during peak periods without compromising quality standards or safety protocols.

- Represented the company at industry trade shows & conferences with professionalism; provided expert advice on best practices for maintaining a safe work environment utilizing forklifts within enclosed spaces such as warehouses & factories.

Skills

- Troubleshooting

- Preventative Maintenance

- Hydraulic Systems

- Electrical Systems

- Diesel Engines

- Forklift Operation

- OSHA Safety Standards

- Pallet Jack Operation

- Equipment Repair and Maintenance

Education

Forklift Certification

Educational Institution XYZ

Nov 2011

Certifications

Forklift Operator Certification

Occupational Safety and Health Administration (OS

May 2017

1. Summary / Objective

Your resume summary/objective should be a concise summary of your qualifications as a forklift technician. Include details such as the number of years you have been in the industry, any certifications or licenses you possess, and how many different types of forklifts you are familiar with. You can also mention any awards or recognition that demonstrate your excellent work ethic and commitment to safety standards.

Below are some resume summary examples:

Energetic and experienced Forklift Technician with 8+ years of experience in the industry. Certified to inspect, maintain, and repair all types of forklifts and pallet jacks. At XYZ, increased efficiency by 30% through streamlining processes for maintaining lift trucks. Gained a reputation as an expert troubleshooter who could diagnose problems quickly and accurately solve them on-site without needing additional assistance or external parts/materials.

Talented forklift technician with 8+ years of experience diagnosing and troubleshooting complex forklift systems for commercial, industrial, and residential customers. Proven track record in quickly identifying root causes of problems to reduce downtime and keep productivity levels high. Skilled at preventive maintenance protocols as well as repair work on electric-powered lifts, counterbalance trucks, reach stackers/trucks, pallet jacks/riders.

Reliable forklift technician with 10+ years of experience in equipment maintenance and repair. Demonstrated ability to diagnose complex mechanical problems, troubleshoot electrical systems, and overhaul engines proficiently. Received numerous awards for exceeding productivity goals while maintaining a perfect safety record at XYZ Corporation. Skilled in preventive maintenance as well as providing on-site technical support when needed.

Skilled forklift technician with 6+ years of experience in troubleshooting and maintaining various types of forklifts. Certified by the National Institute for Certification in Engineering Technologies (NICET). Experienced in diagnosing, repairing, and replacing parts on a variety of makes and models. Successfully completed preventative maintenance checks on 50 pieces of equipment at XYZ Warehouse.

Proficient forklift technician with 10+ years of experience in material handling and warehouse operations. Proven track record of troubleshooting forklifts, performing maintenance checks, repairing components, and conducting safety inspections. Seeking to leverage expertise at ABC Company by providing safe and efficient lifting services to increase productivity across the organization.

Driven forklift technician with 7+ years of experience in troubleshooting, repairing and maintaining a variety of forklifts. Skilled at diagnosing complex mechanical problems accurately and efficiently to ensure optimal performance. Proven track record of collaboration with customers to provide timely solutions that meet their needs while adhering to safety regulations.

Determined forklift technician with 5+ years of experience troubleshooting and repairing various types of forklifts. Skilled in diagnosing and resolving mechanical, hydraulic, pneumatic, electrical issues quickly and efficiently. Seeking to join ABC as a Forklift Technician to utilize my knowledge base and expertise for the benefit of their operations.

Passionate forklift technician with 10+ years of experience in both preventive and corrective maintenance. Familiar with a wide range of equipment, including gas, diesel, electric-powered forklifts. Seeking to apply expertise at ABC Corp., where I can use my problem-solving skills to diagnose and repair any type of lift truck quickly and accurately.

2. Experience / Employment

For the experience section, list your work history in reverse chronological order, beginning with your most recent job.

When writing out what you did at each role, use bullet points to make the information easier to digest. You want to provide detail and explain how you achieved results; for instance, instead of saying “Repaired forklifts,” say “Diagnosed and repaired mechanical faults on 25+ forklift models per week using a variety of tools.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Operated

- Inspected

- Troubleshot

- Repaired

- Adjusted

- Installed

- Calibrated

- Tested

- Replaced

- Assembled

- Loaded

- Unloaded

- Programmed

- Monitored

- Serviced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Unloaded and transported over 500 pallets of goods from storage areas and delivery trucks using a forklift daily, ensuring that all items were properly secured during transport.

- Consistently maintained a 95% accuracy rate in the diagnosis and repair of mechanical issues on multiple types of forklifts, reducing downtime by 25%.

- Structured preventative maintenance schedules for 30+ pieces of equipment to ensure optimal performance and minimized breakdowns; identified minor repairs before they escalated into larger problems.

- Facilitated annual training sessions for 15+ operators regarding safety protocols and proper handling techniques while operating a variety of lift trucks; reduced workplace accidents by 40%.

- Operated computerized diagnostics systems to troubleshoot complex technical faults within the system components; decreased turnaround time on repairs by 10 hours per issue on average.

- Calibrated and adjusted over 100 forklifts and other material movement machines, resulting in a 15% increase in equipment efficiency.

- Introduced new maintenance protocols that ensured proper functioning of all forklift components; reduced downtime by 25%.

- Demonstrated expert knowledge when troubleshooting various types of mechanical and electrical issues on the spot with accuracy and precision.

- Reliably conducted regular safety inspections for up to 50 pieces of lifting machinery per day, ensuring full compliance with OSHA regulations at all times.

- Tested newly-repaired lift trucks according to standard guidelines before releasing them back into service; completed repairs 10 hours faster than average turnaround time targets set by management team members.

- Formulated preventative maintenance plans to ensure that all 20+ forklifts in the warehouse were operating at peak efficiency; lowered downtime by 15% and increased productivity.

- Prepared detailed reports on the diagnosis, repair and service of damaged or malfunctioning parts, such as engines, transmissions and electrical components.

- Participated in team projects to upgrade existing systems with new technology; reduced manual labor costs by 27%.

- Substantially decreased spare part replacement expenses for clients after conducting thorough inspections of broken equipment using specialized tools & instruments.

- Compiled comprehensive training manuals which provided guidance on how to safely operate heavy machinery like forklifts and cranes; trained 40+ employees within six months.

- Achieved a 90% success rate in resolving forklift-related issues, such as broken or malfunctioning parts and electrical failures, while servicing over 40 units per month.

- Replaced major components including engines, transmissions, steering systems and hydraulic lifts on 10+ forklifts; reduced downtime by 30%.

- Independently troubleshot and repaired complex problems related to wiring harnesses & back-up alarms for 25 different models of lift trucks with a 95% accuracy rating.

- Advised customers on the best maintenance practices for their individual vehicles based on safety regulations; reduced customer complaints associated with accidents by 20%.

- Presented training classes to new warehouse employees regarding proper operation techniques when utilizing powered industrial equipment like pallet jacks and forklifts; improved employee productivity levels by 15%.

- Programmed and maintained a fleet of 20+ forklifts, increasing their operational efficiency by 10% and reducing downtime significantly.

- Effectively performed preventative maintenance on all forklift parts; repaired over 70 faulty components and generated $5,000 in cost savings for the company during peak season demand.

- Reorganized warehouse shelving units to maximize storage space; developed an efficient tracking system which reduced search time for items by 30%.

- Installed new power sources into electric-powered vehicles and ensured that they met safety requirements before being put back into operation; decreased battery replacement costs by 25%.

- Spearheaded multiple projects involving the installation of advanced systems such as automated guided vehicles (AGVs) in order to improve transport operations within the facility – resulting in a 15% increase in productivity overall.

- Confidently maintained and repaired a fleet of 30+ forklifts, troubleshooting mechanical issues, replacing worn parts and regularly inspecting for safety compliance; reduced downtime by 40%.

- Reduced maintenance costs by 25% through revising the preventative maintenance checklist to ensure regular inspections were conducted on all components.

- Revised operating instructions for warehouse staff to help them understand safe forklift operation procedures while increasing productivity levels by 15%.

- Inspected over 50 lift trucks daily in order to identify potential defects before they caused costly repairs or accidents; reported any issues promptly and effectively rectified them with minimal disruption to operations.

- Optimized electrical systems in order to maximize power efficiency across the entire fleet which increased fuel economy by 20% while lowering CO2 emissions simultaneously.

- Assembled and repaired over 110 forklifts and 15 aerial lift trucks, reducing downtime by 50% and increasing efficiency in the warehouse.

- Coordinated with store managers to schedule regular maintenance checks on all equipment; implemented a system that saved $1,500 in repairs costs per month.

- Utilized specialized tools such as diagnostic computers and hydraulic lifts to identify faults quickly; improved repair speed by 30%.

- Expedited delivery of replacement parts from suppliers when necessary, ensuring all machinery was back up-and-running within 24 hours or less every time.

- Actively trained new technicians on proper operating procedures for forklift & aerial lift truck handling processes; reduced accidental damage incidents by 25%.

- Troubleshot and repaired over 50 forklift units, including electric and gas models; increased repair accuracy by 15% in the last quarter.

- Loaded and unloaded cargo from trucks using a variety of types of forklifts while adhering to all safety requirements; reduced loading time per shipment by 10 minutes on average.

- Competently maintained inventory records for spare parts, ordering new stock when necessary with minimal discrepancies between actual and expected levels (1%).

- Developed preventative maintenance schedule which ensured that every piece of equipment was serviced regularly according to manufacturer’s guidelines; decreased downtime significantly throughout the year (by 30%).

- Monitored performance data from each forklift unit on a daily basis to identify potential issues before they become serious problems; averted 3 major malfunctions this year alone through early detection & prompt action taken accordingly.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in repairing electrical components, while the other may be looking for a candidate who is adept at troubleshooting hydraulic systems.

It is important to tailor your skills section of the resume according to each job you are applying for. This way, when employers use applicant tracking systems (computer programs that scan resumes for certain keywords), they will find yours more relevant and likely pass it on to human recruiters.

In addition, don’t forget to elaborate on some of these skills further in other sections such as summary or work experience; this will help demonstrate why you are an ideal fit for the position.

Below is a list of common skills & terms:

- Diesel Engines

- Electrical Systems

- Equipment Repair and Maintenance

- Forklift Operation

- Hydraulic Systems

- OSHA Safety Standards

- Pallet Jack Operation

- Preventative Maintenance

- Troubleshooting

4. Education

Adding an education section on your resume will depend on how far along you are in your career. If you just graduated and have no experience, mention your education below the objective statement. However, if you have been working as a forklift technician for some time and want to showcase multiple responsibilities from different companies, it might not be necessary to include an education section at all.

If including an education section is appropriate for the job position, try to highlight courses related specifically to forklift operations or maintenance that may give employers more insight into what qualifications you possess.

Forklift Certification

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the knowledge and skills necessary to perform a given job. They also show that you are committed to staying up-to-date with industry trends and best practices.

When applying for jobs, be sure to include any certifications relevant to the position on your resume as they can give hiring managers an indication of your qualifications and commitment level.

Forklift Operator Certification

Occupational Safety and Health Administration (OS

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Wilhelm Grant, this would be Wilhelm-Grant-resume.pdf or Wilhelm-Grant-resume.docx.

7. Cover Letter

Cover letters are an important part of the job application process. They provide employers with a more complete picture of who you are and what you have to offer as a professional.

A cover letter usually consists of 2 to 4 paragraphs that explain why the employer should consider your candidacy for their position. It also gives you an opportunity to express your enthusiasm and excitement about the role, which can be difficult in a resume alone.

Although not all jobs require one, writing a cover letter is highly recommended since it allows potential employers to get to know more about you on both personal and professional levels than what’s written in your resume alone.

Below is an example cover letter:

Dear Letha,

I am writing to apply for the Forklift Technician position at your company. With my experience in repairing and maintaining a variety of forklifts, as well as my strong mechanical aptitude, I am confident that I would be a valuable asset on your team.

In my current role as a Forklift Technician at [company name], I repair and maintain over 100 forklifts per month. My responsibilities include diagnosing problems, performing preventative maintenance, and making repairs. I have gained extensive knowledge of different types of forklifts and their components through my work experience and training courses. In addition, I have developed strong problem-solving skills that enable me to troubleshoot issues quickly and efficiently.

I am also proficient in using computerized diagnostic tools to identify faults in electronic systems. My ability to use these tools, combined with my mechanical aptitude, allows me to locate and repair problems quickly and effectively. Furthermore, I have excellent communication skills which enable me to liaise with customers regarding the status of their repairs.

I believe that my skills and experience make me an ideal candidate for the Forklift Technician position at your company. I am eager to utilize my abilities in a new environment and contribute to the success of your organization. Thank you for your time; please do not hesitate to contact me if you require any further information about my qualifications or suitability for this role.

Sincerely,

Wilhelm

Forklift Technician Resume Templates

Axolotl

Axolotl Kinkajou

Kinkajou Echidna

Echidna Bonobo

Bonobo Pika

Pika Numbat

Numbat Fossa

Fossa Jerboa

Jerboa Markhor

Markhor Dugong

Dugong Quokka

Quokka Cormorant

Cormorant Lorikeet

Lorikeet Gharial

Gharial Hoopoe

Hoopoe Indri

Indri Saola

Saola Rhea

Rhea Ocelot

Ocelot Rezjumei

Rezjumei