Food Technologist Resume Guide

Food technologists work to develop and improve the production, processing, preservation, packaging, and distribution of food. They are responsible for researching new ingredients and developing recipes that meet customer needs while also considering cost-effectiveness. Additionally, they must ensure product safety by monitoring shelf life expiration dates as well as testing products for nutritional value or potential allergens.

Your food science and processing know-how are unparalleled, yet this is not known to employers. To get the attention of hiring managers, you must write a resume that emphasizes your technical background and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

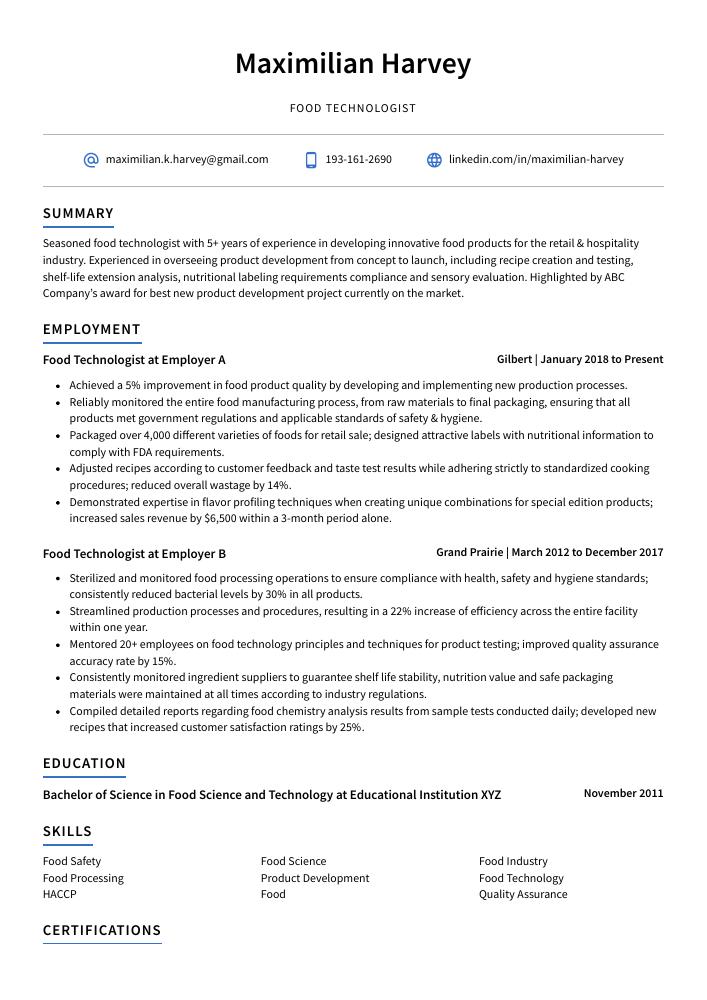

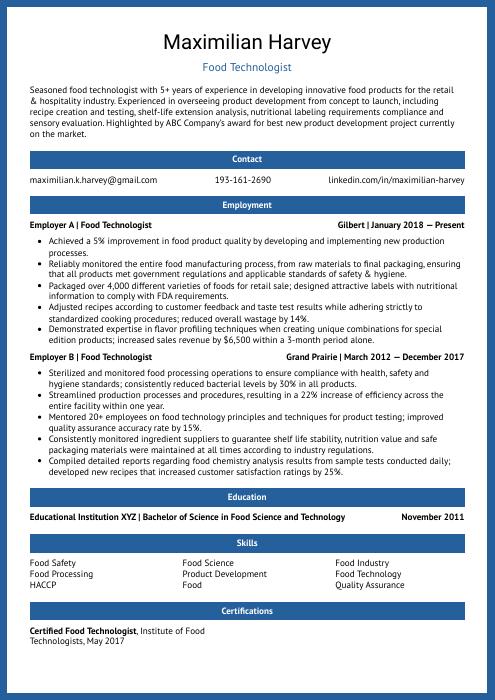

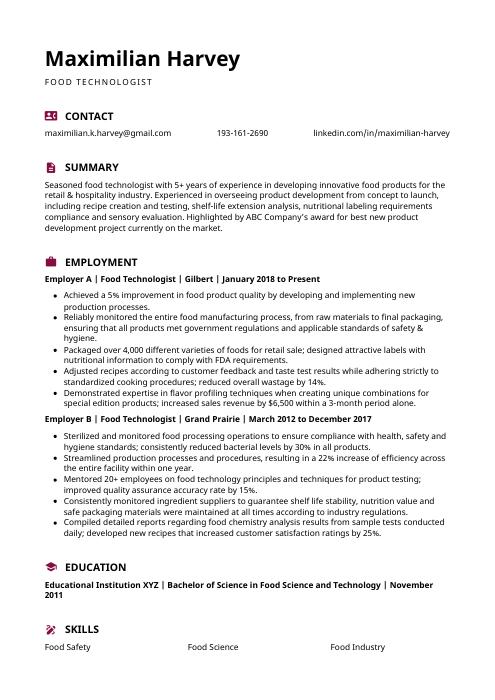

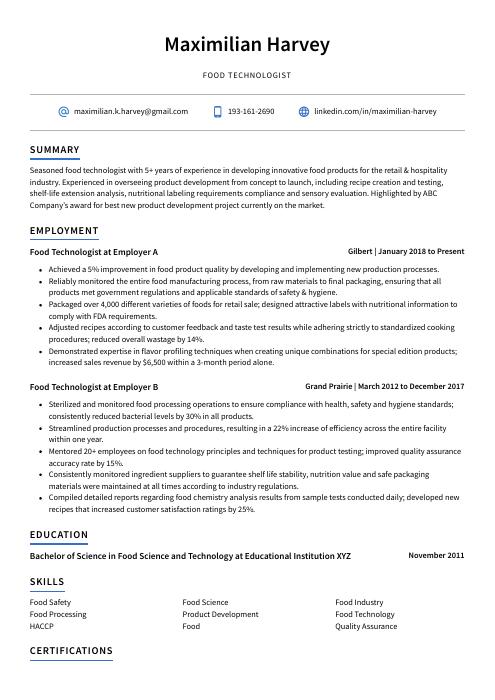

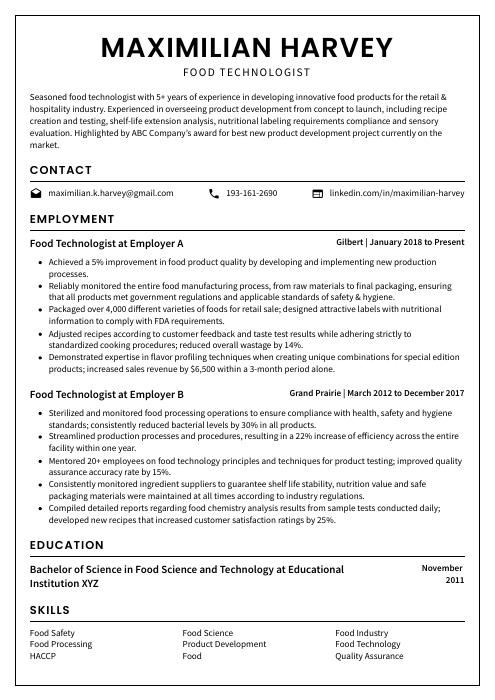

Food Technologist Resume Sample

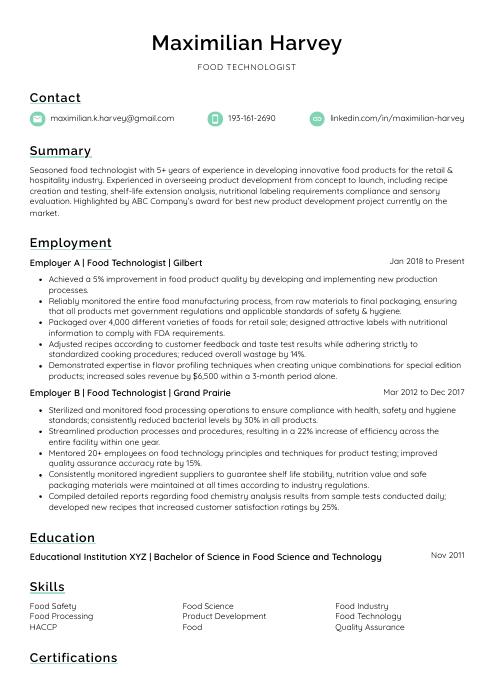

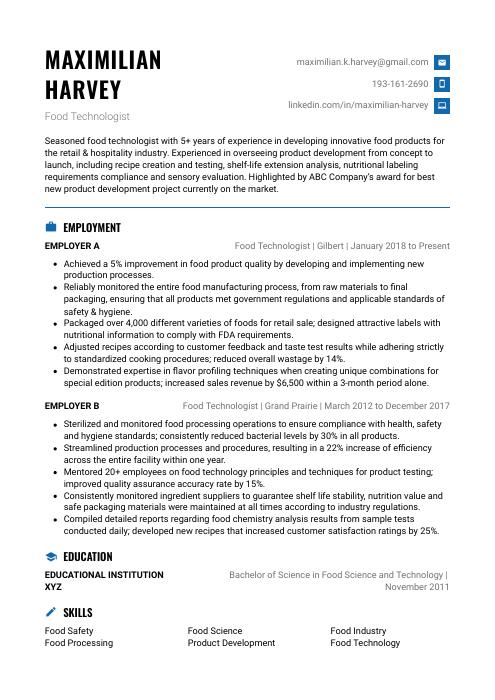

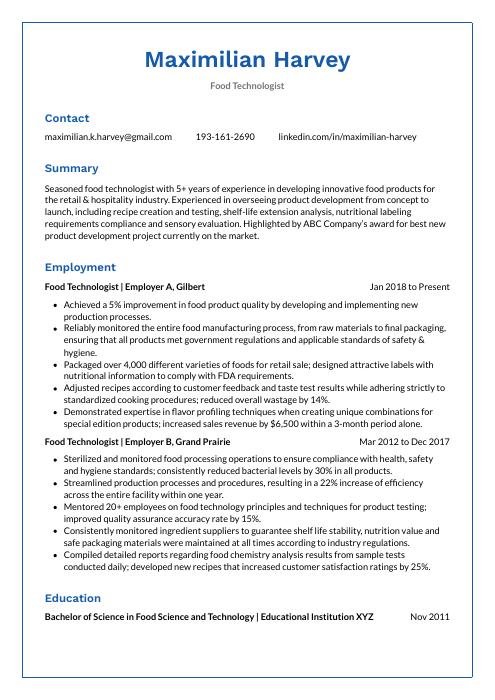

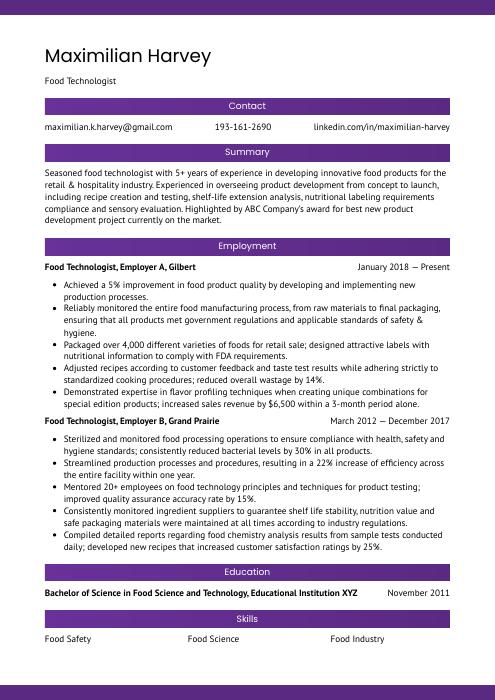

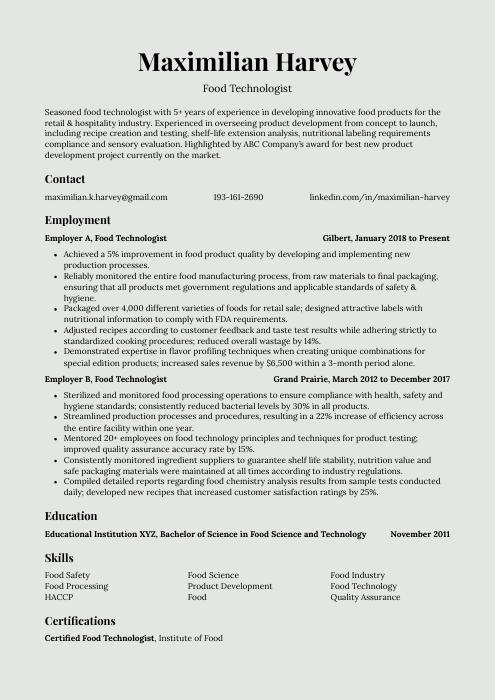

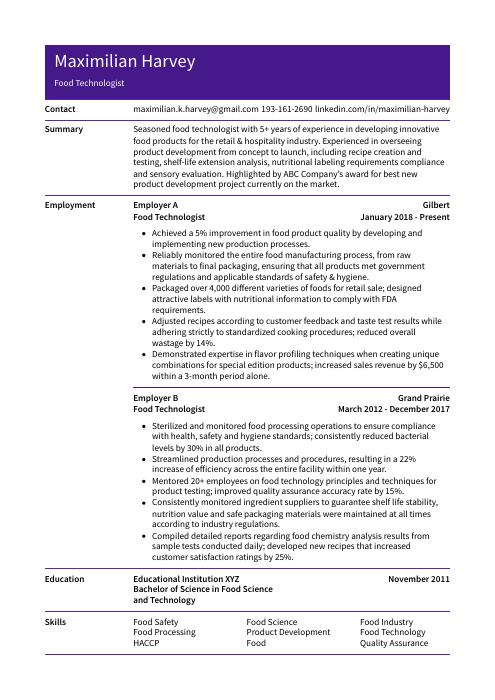

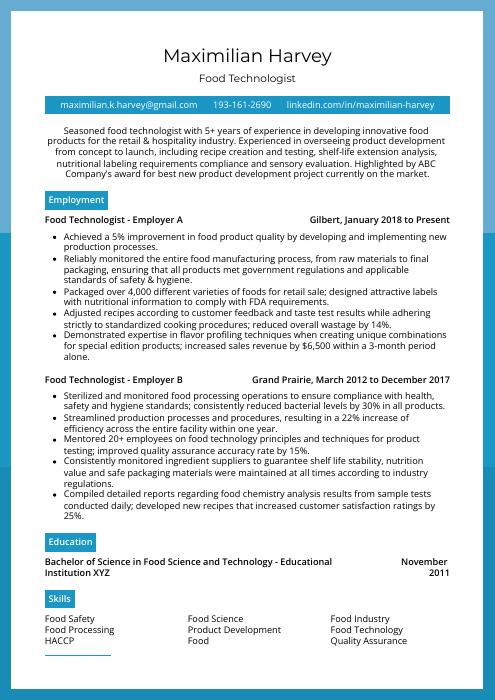

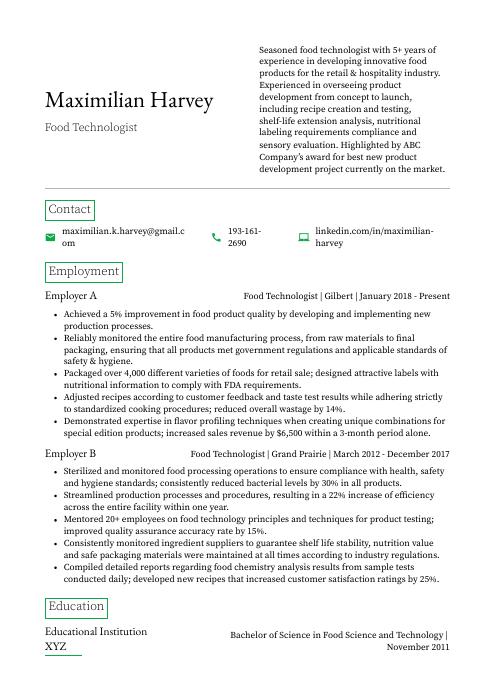

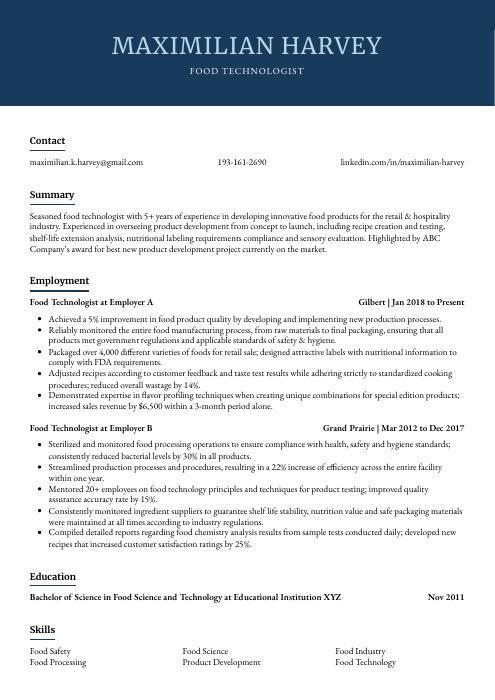

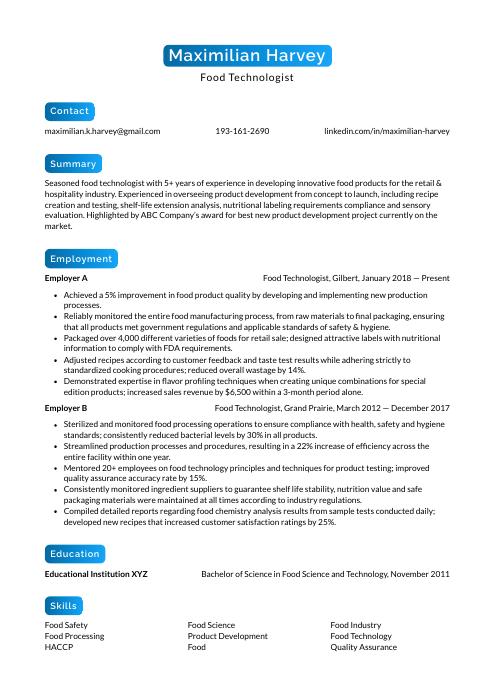

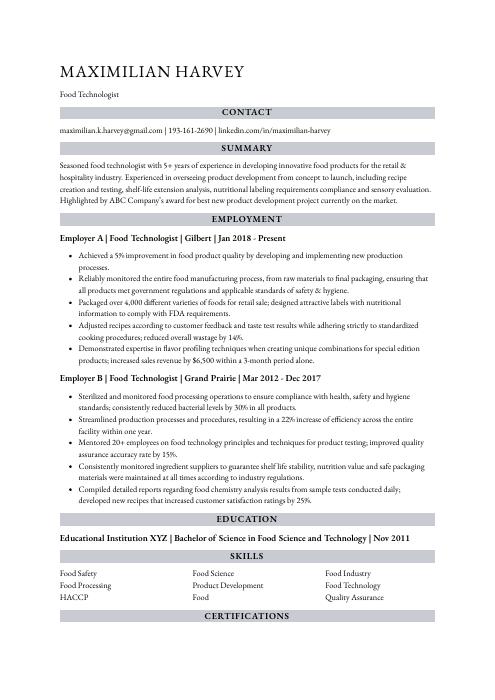

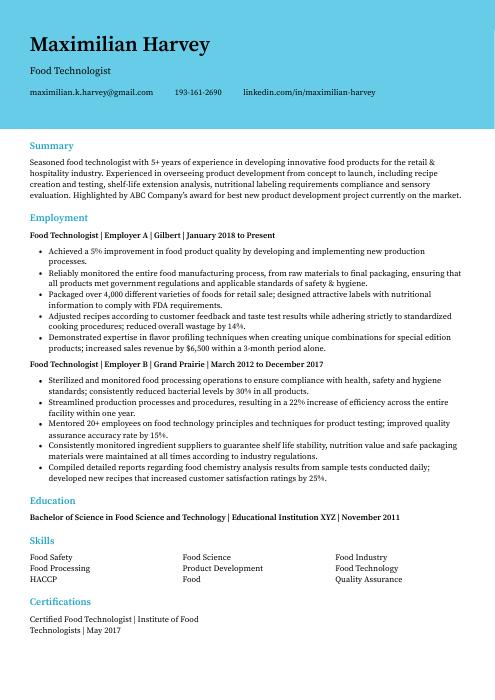

Maximilian Harvey

Food Technologist

[email protected]

193-161-2690

linkedin.com/in/maximilian-harvey

Summary

Seasoned food technologist with 5+ years of experience in developing innovative food products for the retail & hospitality industry. Experienced in overseeing product development from concept to launch, including recipe creation and testing, shelf-life extension analysis, nutritional labeling requirements compliance, and sensory evaluation. Highlighted by ABC Company’s award for best new product development project currently on the market.

Experience

Food Technologist, Employer A

Gilbert, Jan 2018 – Present

- Achieved a 5% improvement in food product quality by developing and implementing new production processes.

- Reliably monitored the entire food manufacturing process, from raw materials to final packaging, ensuring that all products met government regulations and applicable standards of safety & hygiene.

- Packaged over 4,000 different varieties of foods for retail sale; designed attractive labels with nutritional information to comply with FDA requirements.

- Adjusted recipes according to customer feedback and taste test results while adhering strictly to standardized cooking procedures; reduced overall wastage by 14%.

- Demonstrated expertise in flavor profiling techniques when creating unique combinations for special edition products; increased sales revenue by $6,500 within a 3-month period alone.

Food Technologist, Employer B

Grand Prairie, Mar 2012 – Dec 2017

- Sterilized and monitored food processing operations to ensure compliance with health, safety, and hygiene standards; consistently reduced bacterial levels by 30% in all products.

- Streamlined production processes and procedures, resulting in a 22% increase in efficiency across the entire facility within one year.

- Mentored 20+ employees on food technology principles and techniques for product testing; improved quality assurance accuracy rate by 15%.

- Consistently monitored ingredient suppliers to guarantee shelf life stability, nutrition value, and safe packaging materials were maintained at all times according to industry regulations.

- Compiled detailed reports regarding food chemistry analysis results from sample tests conducted daily; developed new recipes that increased customer satisfaction ratings by 25%.

Skills

- Food Safety

- Food Science

- Food Industry

- Food Processing

- Product Development

- Food Technology

- HACCP

- Food

- Quality Assurance

Education

Bachelor of Science in Food Science and Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Food Technologist

Institute of Food Technologists

May 2017

1. Summary / Objective

A resume summary/objective is the perfect place to showcase your skills and experience as a food technologist. In this section, you can highlight any certifications or qualifications that make you stand out from other applicants, such as HACCP certification or expertise in food safety regulations. You could also mention how many years of experience you have working with different ingredients and developing new recipes for products.

Below are some resume summary examples:

Hard-working food technologist with 8+ years of experience in the food industry. Skilled at developing new products, improving existing recipes and processes, and ensuring compliance with all relevant regulations. At ABC Foods Inc., developed a successful process for producing high-quality shelf-stable snacks that reduced wastage by 10%. Experienced in working closely with customers to create custom solutions for their specific needs.

Well-rounded food technologist with 5+ years of experience in the food industry, specializing in product development and quality assurance. Skilled at creating innovative recipes that meet customer needs while adhering to cost constraints and government regulations. Seeking to join ABC Foods as a Senior Food Technologist, leveraging expertise in nutrition science, ingredient selection, and sensory analysis for improved brand appeal.

Determined food technologist with 5+ years of experience in the food industry. Expertise in product development, process optimization and quality control. At XYZ Foods, developed a new line of healthy snacks that increased revenue by 35%. Received “Outstanding Employee” award for contribution to improving production efficiency and reducing waste costs by 20%. Highly knowledgeable about food safety standards and regulations.

Detail-oriented food technologist with 8+ years of experience in product development, research & development and quality assurance. Track record of developing 25 products from scratch for a variety of clients. Skilled at creating innovative recipes to meet customer needs while ensuring compliance with food safety standards. Experienced in conducting shelf-life studies, sensory analysis and nutritional labeling requirements.

Energetic food technologist with 7+ years of experience developing and testing new food products for the consumer market. Skilled in utilizing a variety of techniques to ensure product quality, including sensory evaluation, shelf-life studies, and microbial analysis. Seeking to join ABC Foods as its next Food Technologist where I can use my knowledge and expertise to drive innovation from concept through production.

Committed and driven food technologist with 5+ years of experience in the development and implementation of quality assurance programs. Experienced in ensuring regulatory compliance, managing ingredient supply chains, and creating product specifications for a variety of products across multiple industries. Eager to join ABC Company and use my expertise to develop safe and nutritious foods for customers worldwide.

Reliable food technologist with 5+ years of experience developing, testing, and optimizing food products in a variety of settings. Experienced in formulation development, shelf-life assessment, product optimization processes, and nutritional analysis. At XYZ Corporation developed 10 new products that increased sales by 25%. Received multiple awards for outstanding performance from the company’s management team.

Skilled food technologist with 8+ years of experience developing, testing and marketing food products. Experienced in using raw materials to create innovative recipes that meet customer tastes and industry standards. Seeking a position at ABC Food where I can leverage my expertise in product development, nutrition analysis and sensory evaluation to ensure the highest quality products are produced.

2. Experience / Employment

In the experience/employment/work history section, you should list your most recent job first. This section should be written in reverse chronological order, which means the reader is able to get a clear picture of what you did and when.

When writing out this section, stick to bullet points primarily; doing so makes it easier for the reader to digest what you have said quickly. When stating what you did, provide detail and include quantifiable results if possible.

For example, instead of saying “Developed new food products,” say something like “Developed 10+ innovative food products per year using various ingredients that met all safety regulations.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Formulated

- Analyzed

- Processed

- Inspected

- Monitored

- Evaluated

- Tested

- Packaged

- Stored

- Blended

- Measured

- Adjusted

- Sterilized

- Operated

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Introduced and implemented new food safety protocols and techniques to ensure product quality, reducing instances of contamination by 20%.

- Monitored the composition, texture, flavor and aroma of over 300 products in a fast-paced production facility; identified potential risks/issues before they became widespread problems.

- Stored raw materials for up to 18 months without compromising their nutritional value or taste; reduced spoilage rates from 8% to 4%.

- Developed innovative recipes that increased customer satisfaction ratings by 25%; achieved 50+ five-star reviews on major online review platforms within 3 months alone.

- Meticulously documented all process improvements and monitored key performance indicators such as yield rate & lead time optimization; successfully decreased waste levels by 15%.

- Diligently conducted over 200 food safety inspections, ensuring that all products met industry and regulatory standards in accordance with FDA guidelines; reduced health risk violations by 24%.

- Reorganized the food production process to improve efficiency, resulting in a 35% reduction of product wastage during operations.

- Represented company at industry events as technical representative, providing expert advice on best practices for quality assurance management and achieving a 95% customer satisfaction rating over 3 years.

- Evaluated ingredients used in recipes according to nutritional value and flavor profiles before approving them for use; decreased costs related to ingredient procurement by 15%.

- Inspected incoming shipments of raw materials prior to storage or processing using advanced laboratory equipment; identified potential contamination issues early on, saving $1K+ worth of materials from being discarded annually.

- Optimized food production processes and recipes, resulting in a 17% increase in output while reducing waste by 12%.

- Efficiently managed the development of new food products from conception to launch, dramatically expediting product release timelines by 20%.

- Spearheaded research initiatives involving nutritional value analysis, shelf life testing and sensory evaluations that aided in the development of more than 10 innovative food products over 2 years.

- Presented findings at major industry conventions; led seminars on topics related to cutting-edge developments within the field of Food Science & Technology for over 200 attendees each year.

- Developed comprehensive risk management strategies for identifying potential contamination sources which decreased safety incidents by 25% annually.

- Structured and optimized food production processes, ensuring compliance with USDA and FDA regulations; reduced processing time by 17% and improved overall product quality.

- Operated various laboratory instruments to analyze samples for moisture content, protein values, pH levels and other parameters; identified 10+ quality issues in the last year through detailed testing results.

- Processed over 500 batches of ingredients each week to create high-quality products that met customer expectations; consistently achieved 4/5 star ratings on all customer surveys regarding taste & appearance of goods produced.

- Thoroughly researched new trends in food technology & nutrition every month to recommend process improvements that could reduce costs while increasing efficiency and output yield by 20%.

- Participated actively in meetings with vendors as well as internal team discussions surrounding product development and packaging design changes which led to a 5% decrease in waste generation during production cycles.

- Formulated over 150 new food products and recipes, successfully reducing product development time by 20% while maintaining the highest standards of safety and quality.

- Revised existing production processes to optimize efficiency; implemented a range of cost-saving measures across the board which resulted in an annual savings of $10,000 for the company.

- Actively monitored daily operations at all times with regards to hygiene compliance, ingredient selection & storage temperature regulation; achieved zero non-compliance reports during last audit cycle as a result.

- Reduced inventory waste costs by 50%, having identified root causes that affected shelf life stability issues through thorough review and analysis of current labeling practices & packaging materials used onsite.

- Utilized advanced laboratory techniques such as gas chromatography/mass spectrometry (GCMS) to analyze nutritional content levels in finished food items prior to release into marketplaces nationwide.

- Tested over 400 food samples for various quality and safety parameters per month, ensuring that all regulations were met and the products released on time.

- Blended spices, herbs, flavorings & preservatives into existing recipes to create new product lines; developed 10+ healthy snacks with enhanced nutritional value in record time.

- Advised production teams on formulation techniques and processes to increase yield while maintaining desired taste characteristics; successfully reduced wastage by 25%.

- Prepared scientific reports outlining sensory tests conducted during research projects as well as recommendations regarding future developments or modifications of formulations/recipes used in production process.

- Independently designed a predictive model using statistical data analysis methods which accurately predicted shelf life of packaged foods within 5% deviation rate from actual results achieved after testing phase was complete.

- Measured and monitored food production processes, ensuring that all products were in compliance with federal health and safety regulations; reduced operational costs by 5% due to improved efficiency.

- Coordinated quality control activities for a variety of foods including dairy items, frozen meals and baked goods; identified potential issues before they resulted in product recalls or customer complaints.

- Successfully developed new recipes from scratch using limited ingredients while still meeting strict nutritional guidelines set out by clients; increased sales volume of specialty products by 14%.

- Assessed the physical characteristics (color, flavor, texture) of finished samples against expected standards and prepared detailed reports on findings & recommendations based on results gathered through sensory testing methods.

- Analyzed data collected through chemical & microbiological tests to ensure that all batches met required specifications prior to release into the marketplace; completed over 250 inspections without any major discrepancies noted during audits conducted annually by regulatory authorities.

- Facilitated the development of 10+ new food products, tested and analyzed each product to meet consumer demands, and achieved a 50% increase in revenue.

- Documented all quality control tests performed on ingredients and finished goods; maintained database records with meticulous accuracy for future reference purposes.

- Improved existing processes by introducing innovative technologies such as automated data collection systems for better tracking & analysis of production outputs; reduced wastage costs by 35%.

- Proficiently utilized techniques like sensory evaluation, shelf-life determination, nutrition labeling compliance, statistical process control (SPC) etc., ensuring that all products met health & safety standards set forth by the industry regulations.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might require knowledge of food safety regulations, while another might want someone who is experienced in product development.

It is essential to tailor the skills section of your resume to each job you are applying for because many employers use applicant tracking systems these days that scan resumes and filter out those they deem not to be a good match.

In addition to listing specific skills here, it can also help boost your candidacy if you discuss them in more detail elsewhere – such as the summary or experience sections.

Below is a list of common skills & terms:

- Chemistry

- Communication

- Continuous Improvement

- Cooking

- Dairy

- Data Analysis

- FMCG

- Flavors

- Food

- Food Chemistry

- Food Industry

- Food Manufacturing

- Food Microbiology

- Food Processing

- Food Quality

- Food Safety

- Food Science

- Food Technology

- Food and Beverage

- GMP

- HACCP

- Hazard Analysis and Critical Control Points

- Ingredients

- Laboratory

- Laboratory Skills

- Manufacturing

- Meat

- Microbiology

- Nutrition

- Product Development

- Quality Assurance

- Quality Control

- Quality Management

- Quality System

- R&D

- Research and Development

- Sensory Evaluation

- Teamwork

- Time Management

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, list your education below the objective statement. However, if you have significant work experience to showcase, omitting an education section is perfectly acceptable.

If adding an education section to your resume, include courses and subjects related to food technology that demonstrate a mastery of the field.

Bachelor of Science in Food Science and Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a particular field. They are also an effective tool for showing potential employers that you have taken the time and effort to stay up-to-date with industry trends, regulations, and best practices.

Including certifications on your resume can be beneficial when applying for jobs as they show that you are qualified and knowledgeable about the position’s requirements. Be sure to include any relevant certifications related to the job so hiring managers know what qualifications you possess.

Certified Food Technologist

Institute of Food Technologists

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Maximilian Harvey, this would be Maximilian-Harvey-resume.pdf or Maximilian-Harvey-resume.docx.

7. Cover Letter

Including a cover letter with your job application is a great way to make an impression on potential employers. It’s typically made up of 2 to 4 paragraphs and should include details that aren’t already mentioned in your resume.

Cover letters provide recruiters with more information about you as a professional and allow you the opportunity to explain why you’re an ideal fit for the role. Although most jobs don’t require one, writing a cover letter can be beneficial when applying for positions.

Below is an example cover letter:

Dear Annalise,

I am writing to apply for the food technologist position at XYZ Corporation. With a degree in Food Science and extensive experience working in the food industry, I have the knowledge and skills to contribute to your organization.

In my current role as a food technologist at ABC Corporation, I work with a team of scientists to develop new food products. My responsibilities include conducting research, developing prototypes, and testing products. I have also created numerous process improvements that have resulted in increased efficiency and productivity.

I am confident that I can be an asset to your organization. In addition to my technical expertise, I have strong problem-solving skills and a proven track record of successful project management. I am also an excellent communicator, both written and verbal.

I would welcome the opportunity to discuss how I can be of benefit to XYZ Corporation as your next food technologist. Thank you for your time and consideration; please do not hesitate to contact me if you need any further information about my qualifications or experience.

Sincerely,

Maximilian

Food Technologist Resume Templates

Indri

Indri Gharial

Gharial Fossa

Fossa Lorikeet

Lorikeet Echidna

Echidna Markhor

Markhor Jerboa

Jerboa Saola

Saola Pika

Pika Rhea

Rhea Quokka

Quokka Bonobo

Bonobo Kinkajou

Kinkajou Numbat

Numbat Dugong

Dugong Ocelot

Ocelot Hoopoe

Hoopoe Axolotl

Axolotl Cormorant

Cormorant Rezjumei

Rezjumei