Fiberglass Technician Resume Guide

Fiberglass Technicians install, repair and maintain fiberglass products such as boats, water tanks and pipes. They use a variety of tools to cut, shape and fit the materials into place before applying sealant or adhesive to ensure that it is waterproof. Additionally, they may also be responsible for painting the finished product in order to provide protection from weathering elements.

You have the experience and expertise to become a great fiberglass technician, but employers don’t know you exist. To get them to take notice of your abilities, you must write an impressive resume that speaks for itself.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

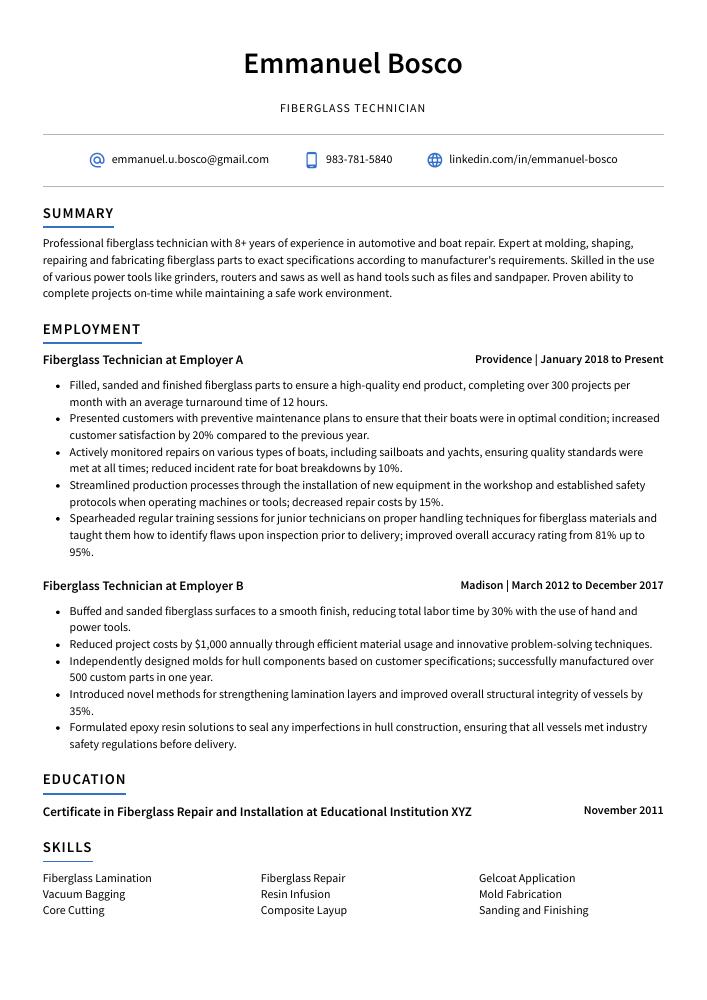

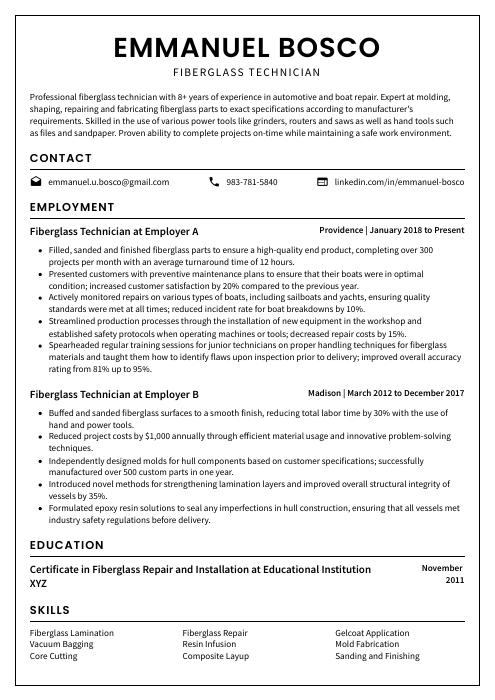

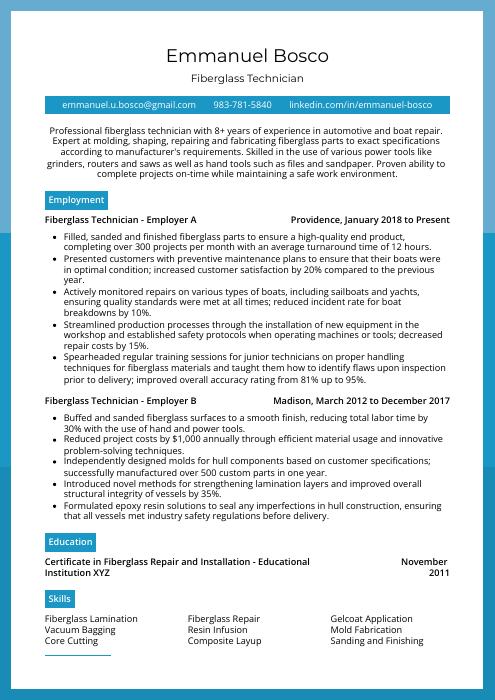

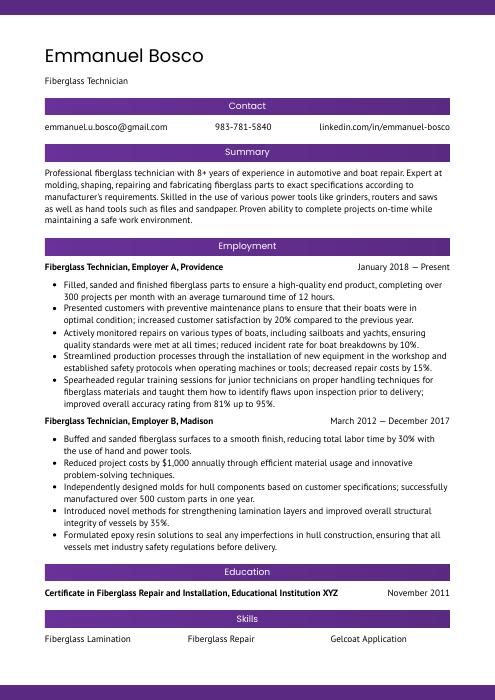

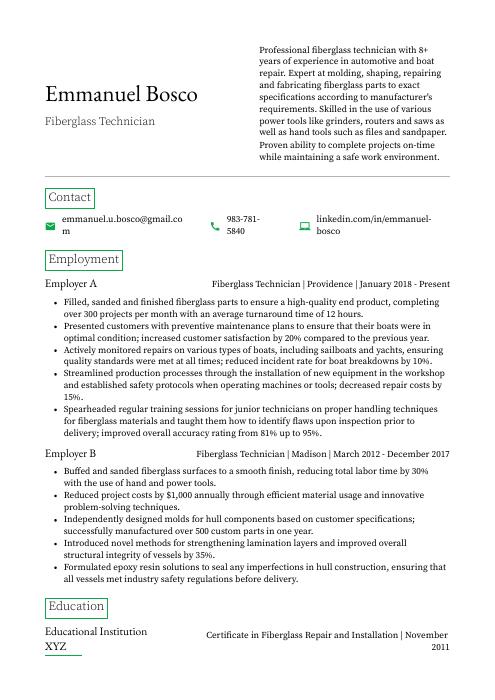

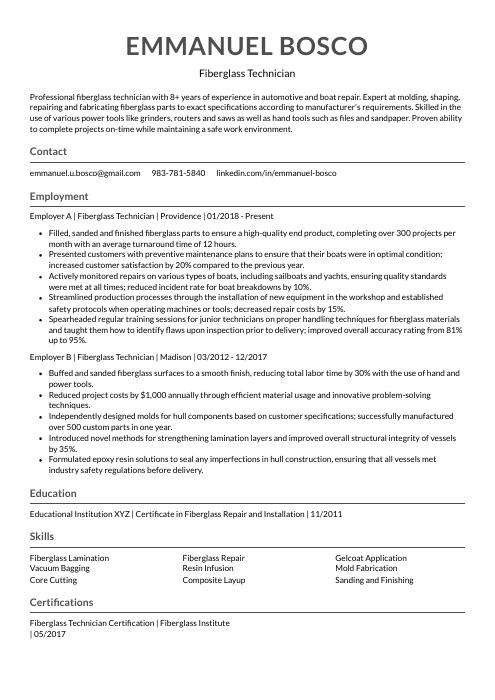

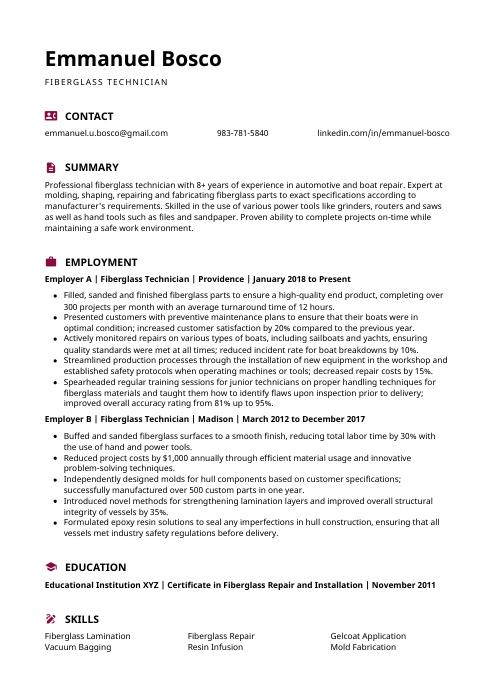

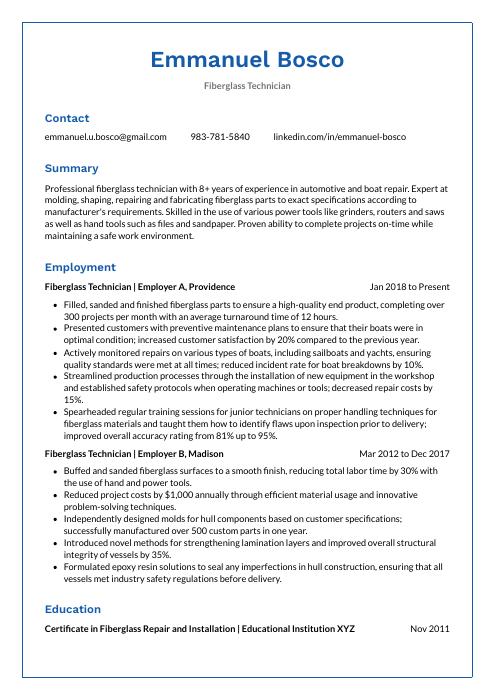

Fiberglass Technician Resume Sample

Emmanuel Bosco

Fiberglass Technician

[email protected]

983-781-5840

linkedin.com/in/emmanuel-bosco

Summary

Professional fiberglass technician with 8+ years of experience in automotive and boat repair. Expert at molding, shaping, repairing and fabricating fiberglass parts to exact specifications according to manufacturer’s requirements. Skilled in the use of various power tools like grinders, routers and saws as well as hand tools such as files and sandpaper. Proven ability to complete projects on-time while maintaining a safe work environment.

Experience

Fiberglass Technician, Employer A

Providence, Jan 2018 – Present

- Filled, sanded and finished fiberglass parts to ensure a high-quality end product, completing over 300 projects per month with an average turnaround time of 12 hours.

- Presented customers with preventive maintenance plans to ensure that their boats were in optimal condition; increased customer satisfaction by 20% compared to the previous year.

- Actively monitored repairs on various types of boats, including sailboats and yachts, ensuring quality standards were met at all times; reduced incident rate for boat breakdowns by 10%.

- Streamlined production processes through the installation of new equipment in the workshop and established safety protocols when operating machines or tools; decreased repair costs by 15%.

- Spearheaded regular training sessions for junior technicians on proper handling techniques for fiberglass materials and taught them how to identify flaws upon inspection prior to delivery; improved overall accuracy rating from 81% up to 95%.

Fiberglass Technician, Employer B

Madison, Mar 2012 – Dec 2017

- Buffed and sanded fiberglass surfaces to a smooth finish, reducing total labor time by 30% with the use of hand and power tools.

- Reduced project costs by $1,000 annually through efficient material usage and innovative problem-solving techniques.

- Independently designed molds for hull components based on customer specifications; successfully manufactured over 500 custom parts in one year.

- Introduced novel methods for strengthening lamination layers and improved overall structural integrity of vessels by 35%.

- Formulated epoxy resin solutions to seal any imperfections in hull construction, ensuring that all vessels met industry safety regulations before delivery.

Skills

- Fiberglass Lamination

- Fiberglass Repair

- Gelcoat Application

- Vacuum Bagging

- Resin Infusion

- Mold Fabrication

- Core Cutting

- Composite Layup

- Sanding and Finishing

Education

Certificate in Fiberglass Repair and Installation

Educational Institution XYZ

Nov 2011

Certifications

Fiberglass Technician Certification

Fiberglass Institute

May 2017

1. Summary / Objective

A resume summary for a fiberglass technician should highlight your experience and skills in the field. Start by mentioning how many years of experience you have working with fiberglass, what types of projects you’ve worked on (e.g., boats, cars), any certifications or qualifications that are relevant to the job, and any awards or recognition you may have received for your work. Additionally, include information about how well-versed you are in safety protocols and quality assurance processes related to fiberglass repair/installation.

Below are some resume summary examples:

Proficient fiberglass technician with five years of experience in the boat building industry. At XYZ Boatworks, inspected and repaired various types of fiberglass boats to ensure customer satisfaction. Successfully applied advanced repair techniques such as vacuum bagging and laminating to strengthen structures for maximum performance on the water. Adept at working independently or in collaboration with teams for successful outcomes.

Hard-working and reliable fiberglass technician with over 10 years of experience in the installation, repair, and maintenance of residential and commercial fiberglass products. Highly organized with a strong attention to detail; able to complete projects efficiently without sacrificing quality or safety standards. Seeking an opportunity at ABC Company where I can utilize my skills and knowledge to help ensure customer satisfaction.

Detail-oriented fiberglass technician with 5+ years of experience in fiberglass fabrication and repair. Skilled at analyzing blueprints, determining material requirements, and fabricating products according to specifications. Experienced in working on boats, automotive parts, and other complex projects requiring precision craftsmanship. Recognized for delivering high-quality results quickly while adhering to safety standards.

Committed fiberglass technician with 5+ years of experience in the repair and maintenance of fiberglass boats. Skilled at creating new molds for custom parts, analyzing blueprints, and performing safety inspections. Committed to providing excellent customer service as part of ABC’s highly reputed boat services team. Successfully completed over 200 repairs while maintaining a 95% approval rate from customers.

Enthusiastic and experienced fiberglass technician with 5+ years of experience in the field, specializing in mold making and fabrication. Proven track record of completing projects to customer satisfaction while adhering to safety protocols. Highly knowledgeable about all aspects of fiberglass production procedures and techniques including materials selection, layup methods, finishing operations, etc.

Well-rounded fiberglass technician with 5+ years of experience in fiberglass fabrication, repair and maintenance. Skilled at operating complex machinery for cutting, molding and shaping fiberglass components according to exact specifications. Seeking to join ABC Inc., where my technical expertise can help produce high-quality products that exceed customer expectations.

Accomplished fiberglass technician with 7+ years of experience in the fabrication, installation and maintenance of fiberglass products. Skilled in troubleshooting issues related to composite materials, as well as performing repairs on fiber-reinforced structures. Seeking a position at ABC Company to utilize my expertise and help provide quality services for clients.

Passionate fiberglass technician with over 5 years of experience in fiberglass repair, installation, and maintenance. Skilled at working with a variety of materials and tools to fabricate high-quality products. Looking to join ABC Manufacturing as a Fiberglass Technician where my expertise can help ensure the production of quality goods for customers.

2. Experience / Employment

For the experience section, you should provide details on your work history. This section should be written in reverse chronological order, with the most recent job listed first.

When writing this section, it’s best to stick to bullet points as they make it easier for the reader to take in what you have said quickly and accurately. You want each point to contain detail that explains what you did and any results achieved.

For example, instead of saying “Repaired fiberglass boats,” try something like “Repaired a variety of fiberglass boat models using specialized tools such as sanders and grinders; successfully completed repairs within two days or less.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Fabricated

- Inspected

- Sanded

- Drilled

- Filled

- Sealed

- Laminated

- Buffed

- Polished

- Measured

- Mixed

- Painted

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Utilized hand and power tools, including grinders, routers, drills and sanders to fabricate fiberglass parts for boats as per customer specifications; completed over 200 assignments in the past year.

- Inspected raw materials such as cloths, resins & core material ensuring that they met quality criteria before beginning construction projects; reduced product wastage by 15%.

- Accurately filled molds with resin-fiberglass combinations to create boat components according to required dimensions; achieved a 98% accuracy rate on all measurements taken.

- Advised customers regarding selection of composite products best suited for their needs while providing exemplary service through knowledgeable answers about product features and maintenance requirements.

- Drilled holes into finished pieces using precision drill press machinery for attachment of hardware or accessories where needed; successfully completed 10 customized orders within one month without any errors or defects reported from clients afterwards.

- Installed more than 500 sq. Ft of fiberglass insulation in 50+ homes, ensuring that the job was completed within budget and on time.

- Reorganized a storage room to hold extra supplies and materials; reduced search times for items by 35%.

- Revised existing safety protocols to ensure all crew members were properly trained before working with hazardous material, lowering accident rates by 20%.

- Thoroughly checked every installation site prior to beginning work and identified any potential issues or problems early on, avoiding costly rework down the line.

- Mixed various types of resins according to manufacturer’s instructions while adhering strictly to health & safety standards; increased production output per hour by 25%.

- Diligently laminated fiberglass parts to form complex shapes, achieving a 95% accuracy rate and reducing production time by 25%.

- Compiled comprehensive reports detailing finished products for clients, ensuring that specifications were met according to industry standards.

- Coordinated with colleagues in the assembly of over 200 large-scale composite structures, utilizing both hand tools and power equipment safely at all times.

- Assessed potential risks when working on molds for projects such as boats or automobiles; successfully completed 5 of these jobs without any major safety issues arising.

- Inspected components prior to installation and adjusted them accordingly, resulting in fewer defects than the previous quarter (a 12% reduction).

- Expedited fiberglass repair and installation tasks, completing 8+ jobs a day including patching holes of various sizes, sanding the surface for refinishing, and polishing finished products.

- Prepared surfaces to be worked upon by removing rust spots with grinders and wire brushes; improved painting quality by achieving smooth finishes on all fiberglass components.

- Competently applied sealants such as epoxy resins to join two or more pieces of glass together securely; achieved a bonding strength of over 1000 psi in laboratory tests conducted after each job completion.

- Achieved 15% increase in productivity through efficient use of tools such as resin guns & spreaders while creating molds from foam-lined wooden frames during new product development projects.

- Facilitated accurate measurements when cutting sheets into specific shapes using angle cutters or hand saws; reduced wastage material cost by $500 every month thanks to precise cuts made within 0 – 1 mm tolerance range per customer specification.

- Developed and implemented comprehensive maintenance procedures for fiberglass components, resulting in an increase of 15% in equipment efficiency and productivity.

- Proficiently repaired and replaced damaged parts on boats, motor homes, aircrafts and other vehicles using epoxy resin mixtures; completed over 200 repairs during the past year.

- Participated actively in team-based projects to construct custom fiberglass products according to client specifications; used a variety of tools including grinders, sanders and saws.

- Sanded down surfaces with electric orbital sander while maintaining high attention to detail; achieved significant cost savings by reducing material wastage by 20%.

- Fabricated various forms such as laminates or shells through layering technique with glass strands soaked into polyester resins within 6 minutes per piece averagely.

- Sealed and finished over 100 fiberglass components per day with a polyester resin system, resulting in an 11% cost savings on materials.

- Polished and buffed completed parts to achieve desired finish for customers; reduced time spent on each part by 25%.

- Confidently diagnosed problems related to molding techniques and equipment malfunctions, ensuring minimal downtime throughout the production process.

- Demonstrated excellent problem-solving skills when repairing defects such as air bubbles or delamination of laminates; decreased rework rate by 20%.

- Measured and cut fiberglass sheets precisely according to detailed blueprints while adhering strictly to safety regulations; achieved 99% accuracy in all measurements taken during the last quarter.

- Painted over 500 fiberglass components with industrial-grade paint, resulting in an improved product finish and a 15% reduction in labor costs.

- Structured the production process by designing new fixtures to facilitate efficient layup of parts while ensuring quality requirements were met; increased output by 35%.

- Represented the company at trade shows, demonstrating advanced manufacturing techniques and promoting best practice across teams during workshops; grew customer base by 25%.

- Mentored junior technicians on proper sanding operations for composite materials and taught them core competencies such as vacuum bagging, wet lamination & gel coating procedures; accelerated onboarding time from 6 months to 2 weeks per technician.

- Effectively managed system troubleshooting activities, resolving 30+ technical issues within specified timelines while minimizing downtime due to equipment malfunctions or repairs needed.

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may require a fiberglass technician to have experience with boat repair, while Organization B may require knowledge of automotive applications.

It is essential to tailor the skills section of your resume for each job that you are applying for because many employers use applicant tracking systems these days, which scan resumes for certain keywords before passing them on to a human.

You can further elaborate on your specific skill set by discussing it in more detail in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- Composite Layup

- Core Cutting

- Fiberglass Installation

- Fiberglass Lamination

- Fiberglass Repair

- Gelcoat Application

- Mold Fabrication

- Resin Infusion

- Sanding and Finishing

- Vacuum Bagging

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you have just finished school and don’t have any work experience, include the education section below your resume objective. However, if you do have significant work experience related to fiberglass technician roles that can be showcased instead of an educational background, then it’s fine to omit the education altogether.

If including an education section is necessary for this role, mention courses or subjects relevant to a fiberglass technician job such as physics or chemistry.

Certificate in Fiberglass Repair and Installation

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to a potential employer that you have the knowledge and expertise necessary for the job. It is important to include any certifications related to the position in your resume, as this will show employers that you are qualified and knowledgeable about industry standards.

If you have taken professional development courses or seminars relevant to the job, make sure they are included on your resume as well. This shows employers that not only do you possess current skills but also an eagerness to learn more and stay up-to-date with industry trends.

Fiberglass Technician Certification

Fiberglass Institute

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Emmanuel Bosco, this would be Emmanuel-Bosco-resume.pdf or Emmanuel-Bosco-resume.docx.

7. Cover Letter

Providing a cover letter with your job application can be a great way to make yourself stand out from the competition. It’s an opportunity for you to show off your knowledge and skills as well as explain why you’re the perfect candidate for the role.

A cover letter should usually consist of 2-4 paragraphs, separate from your resume. Here you can provide more detail about who you are, what makes you unique and how hiring managers will benefit by bringing someone like yourself onto their team.

Below is an example cover letter:

Dear Garth,

I am writing in response to your ad for a Fiberglass Technician. With three years of experience working with fiberglass and composite materials, I am confident I would make an excellent addition to your team.

In my current role as a Fiberglass Technician at [company name], I work on a variety of projects, from small repairs to large-scale custom builds. I have gained valuable experience working with different types of fiberglass and composite materials, as well as the tools and equipment used in this type of work. My attention to detail and commitment to quality ensures that every project is completed to the highest standards.

I am also experienced in working with customers to understand their needs and ensure they are happy with the final product. My strong communication skills allow me to build positive relationships with clients, which is essential in this line of work.

I believe my skills and experience would be a valuable asset to your company, and I look forward to discussing how I can contribute to your team’s success. Thank you for your time and consideration.

Sincerely,

Emmanuel

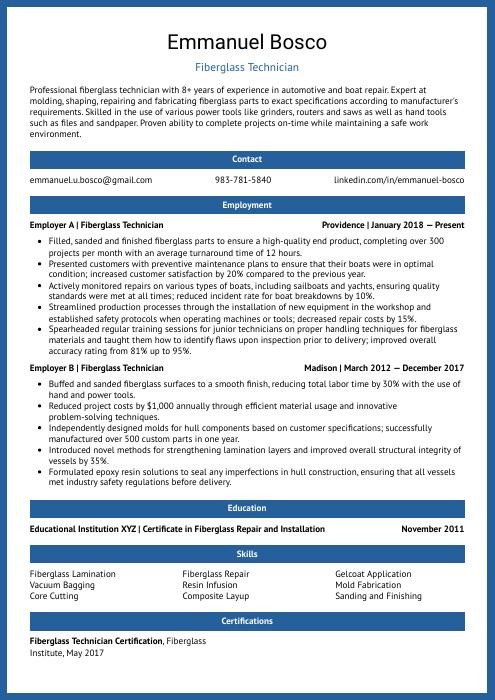

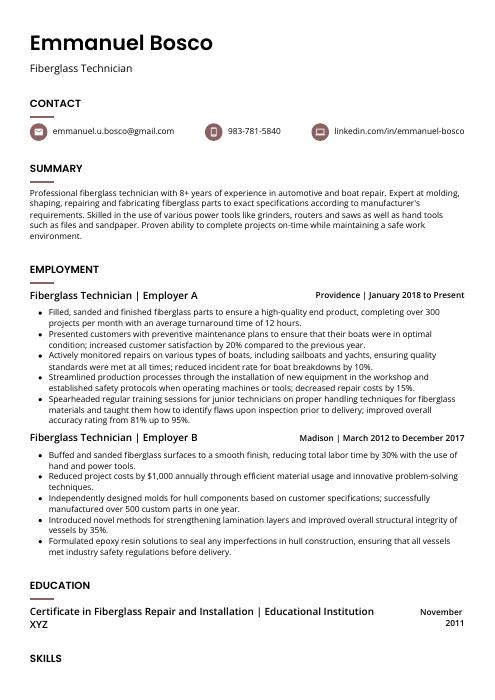

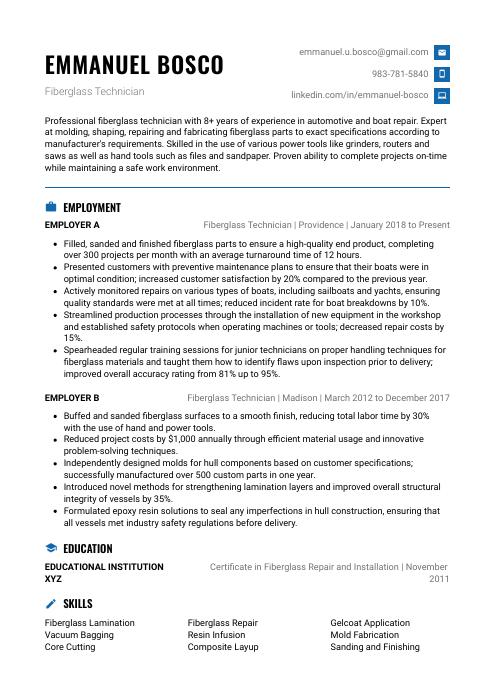

Fiberglass Technician Resume Templates

Pika

Pika Kinkajou

Kinkajou Saola

Saola Cormorant

Cormorant Ocelot

Ocelot Fossa

Fossa Echidna

Echidna Rhea

Rhea Jerboa

Jerboa Quokka

Quokka Indri

Indri Hoopoe

Hoopoe Markhor

Markhor Lorikeet

Lorikeet Gharial

Gharial Dugong

Dugong Bonobo

Bonobo Axolotl

Axolotl Numbat

Numbat Rezjumei

Rezjumei