Fabrication Technician Resume Guide

Fabrication Technicians are responsible for operating and maintaining machines to fabricate parts, components, or products from raw materials. They use a variety of tools such as saws, drills, grinders and presses to cut and shape metal into the desired form. They also inspect finished pieces for accuracy before assembly is complete.

Your fabrication abilities are unparalleled, but potential employers aren’t aware of your capabilities. To get their attention and make them realize how great you would be as a member of the team, you must write an exceptional resume that stands out from the competition.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

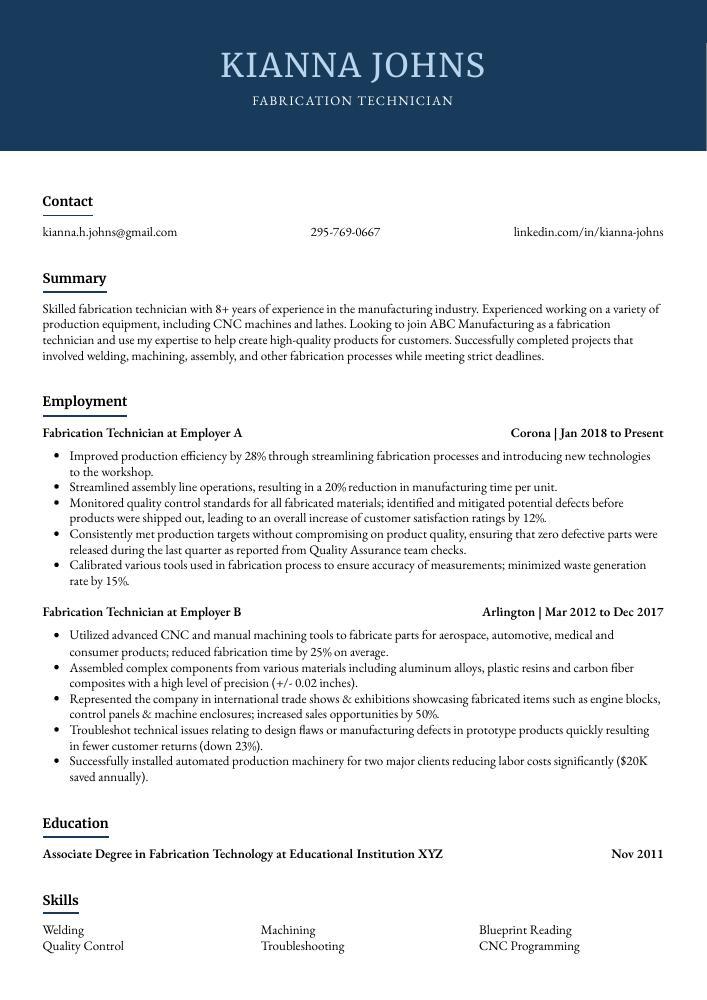

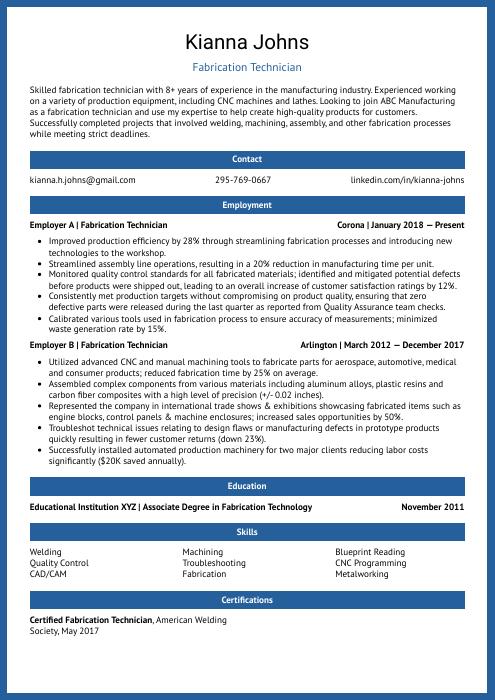

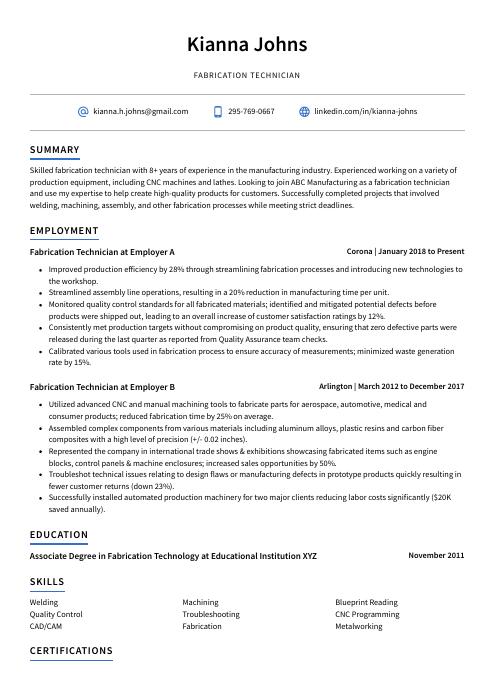

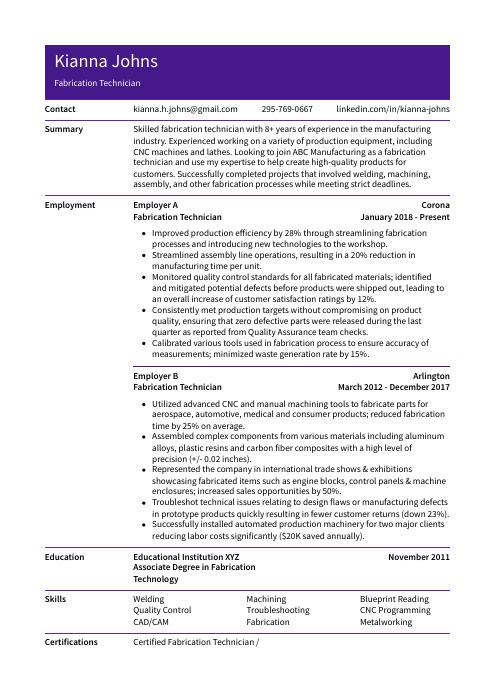

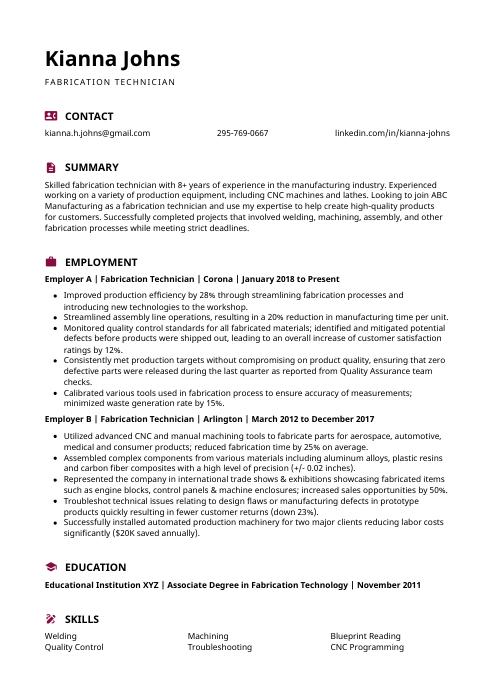

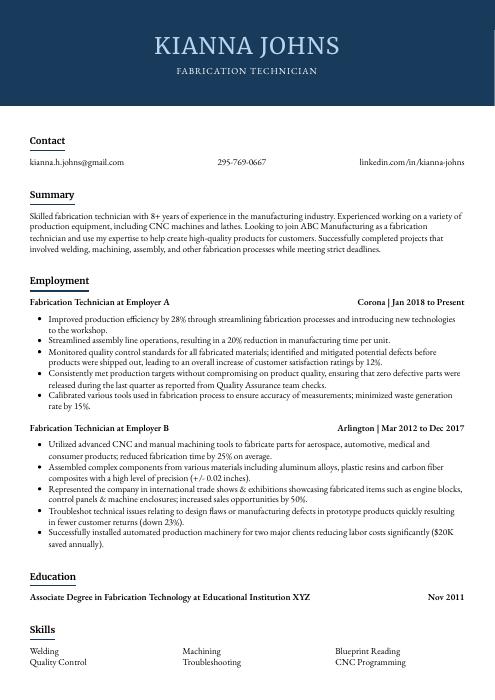

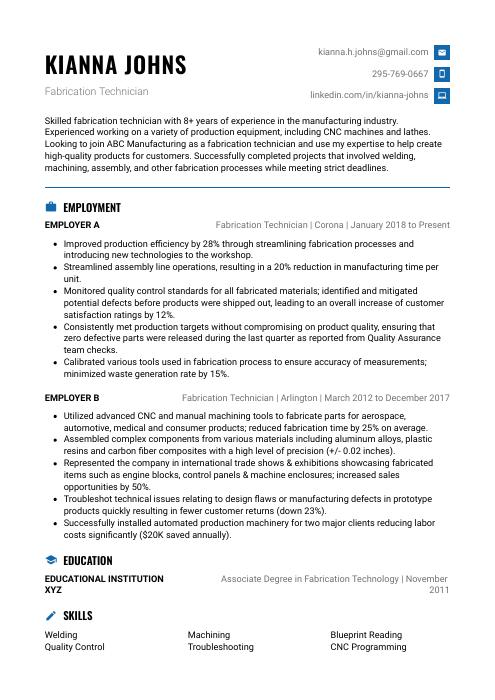

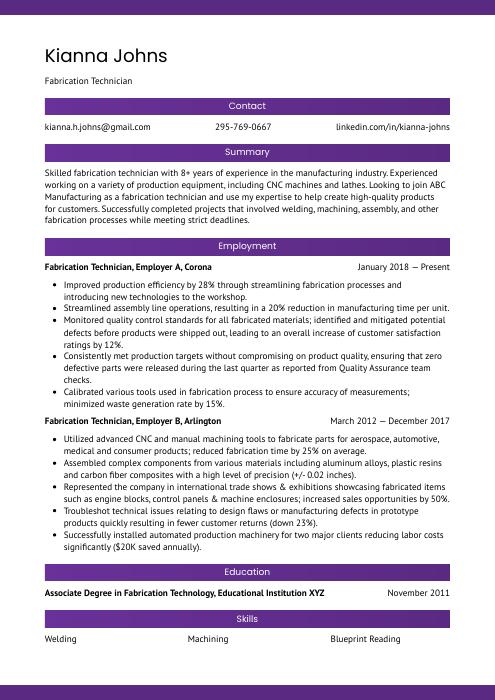

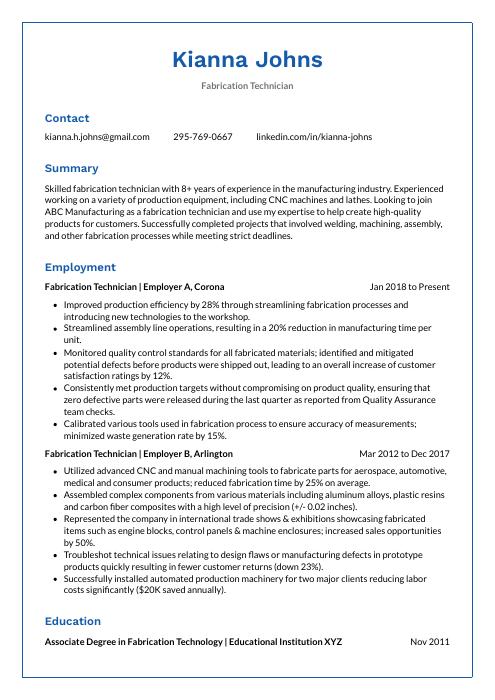

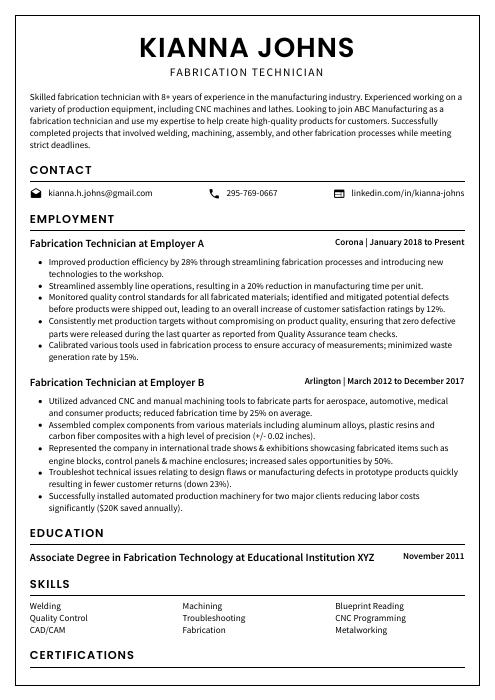

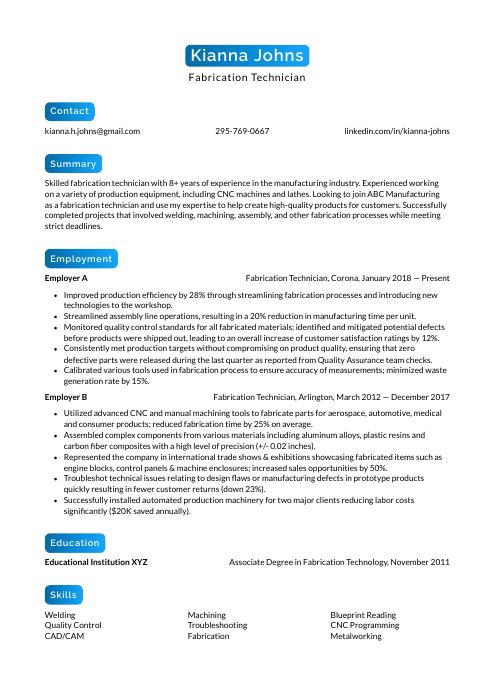

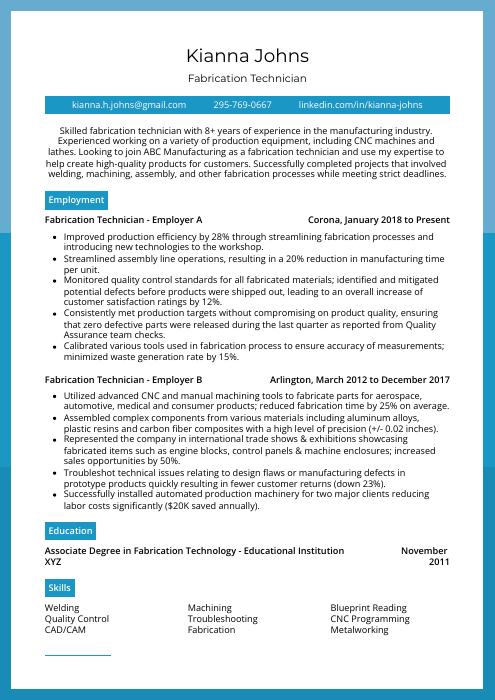

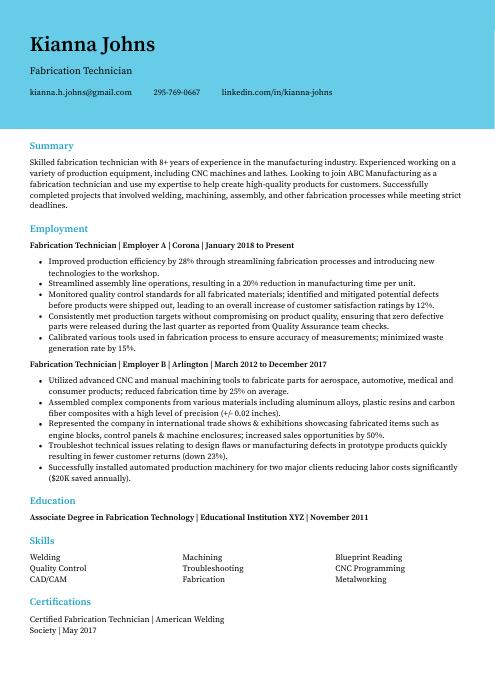

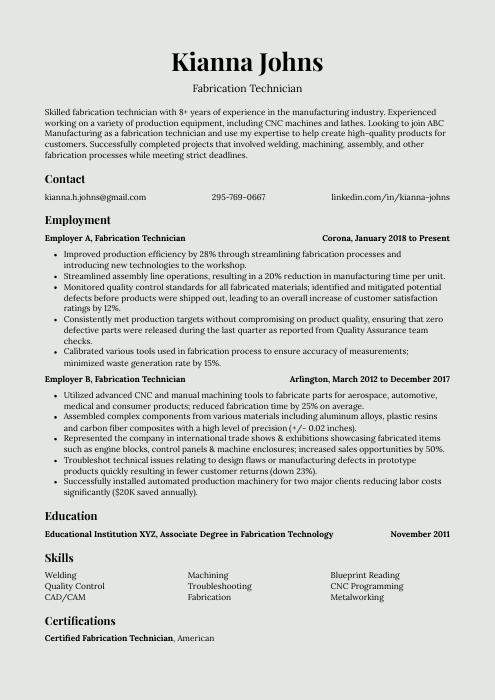

Fabrication Technician Resume Sample

Kianna Johns

Fabrication Technician

[email protected]

295-769-0667

linkedin.com/in/kianna-johns

Summary

Skilled fabrication technician with 8+ years of experience in the manufacturing industry. Experienced working on a variety of production equipment, including CNC machines and lathes. Looking to join ABC Manufacturing as a fabrication technician and use my expertise to help create high-quality products for customers. Successfully completed projects that involved welding, machining, assembly, and other fabrication processes while meeting strict deadlines.

Experience

Fabrication Technician, Employer A

Corona, Jan 2018 – Present

- Improved production efficiency by 28% through streamlining fabrication processes and introducing new technologies to the workshop.

- Streamlined assembly line operations, resulting in a 20% reduction in manufacturing time per unit.

- Monitored quality control standards for all fabricated materials; identified and mitigated potential defects before products were shipped out, leading to an overall increase of customer satisfaction ratings by 12%.

- Consistently met production targets without compromising on product quality, ensuring that zero defective parts were released during the last quarter as reported from Quality Assurance team checks.

- Calibrated various tools used in fabrication process to ensure accuracy of measurements; minimized waste generation rate by 15%.

Fabrication Technician, Employer B

Arlington, Mar 2012 – Dec 2017

- Utilized advanced CNC and manual machining tools to fabricate parts for aerospace, automotive, medical and consumer products; reduced fabrication time by 25% on average.

- Assembled complex components from various materials including aluminum alloys, plastic resins and carbon fiber composites with a high level of precision (+/- 0.02 inches).

- Represented the company in international trade shows & exhibitions showcasing fabricated items such as engine blocks, control panels & machine enclosures; increased sales opportunities by 50%.

- Troubleshot technical issues relating to design flaws or manufacturing defects in prototype products quickly resulting in fewer customer returns (down 23%).

- Successfully installed automated production machinery for two major clients reducing labor costs significantly ($20K saved annually).

Skills

- Welding

- Machining

- Blueprint Reading

- Quality Control

- Troubleshooting

- CNC Programming

- CAD/CAM

- Fabrication

- Metalworking

Education

Associate Degree in Fabrication Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Fabrication Technician

American Welding Society

May 2017

1. Summary / Objective

Your resume summary should provide the hiring manager with a snapshot of your qualifications as a fabrication technician. This is where you can highlight your experience in welding, soldering, and other metalworking techniques; mention any certifications or awards you have received; and emphasize how you successfully managed complex projects from start to finish.

Below are some resume summary examples:

Passionate and experienced fabrication technician with 8+ years of experience in troubleshooting and repairing industrial machinery. Successfully operated two production lines simultaneously at XYZ Company, increasing efficiency by 30%. Recognized for thorough knowledge of welding techniques, machining tools, and electrical systems. Committed to delivering excellent customer service and ensuring the safety of all personnel on-site.

Seasoned fabrication technician with 7+ years of experience working in a production environment. Skilled at reading blueprints and schematics, setting up and operating mechanical equipment, and troubleshooting machine malfunctions to ensure product quality control. Seeking to apply knowledge of fabrication principles, processes, tools & materials at ABC Manufacturing for increased productivity and efficiency.

Talented fabrication technician with over seven years of experience in a wide variety of fabrication processes. Adept at troubleshooting and repair, as well as setting up and operating specialized machinery for the production process. Skilled at reading blueprints to ensure accuracy during the fabrication process. Committed to delivering quality products on time while adhering to safety regulations.

Well-rounded fabrication technician with 5+ years of experience in welding and fabricating metals for various industrial projects. Experienced in working with a variety of hand tools, power tools, and machinery to create custom parts from blueprints. Seeking to join ABC Company as a fabrication technician where I can use my extensive knowledge of metal fabrication to help the team meet their goals.

Accomplished fabrication technician with 10+ years of experience in fabrication, welding and pipefitting. Experienced in operating a variety of tools and equipment including drills, saws and grinders. Skilled at reading blueprints to create custom prototypes for automotive parts. Committed to providing quality workmanship that meets customer specifications while adhering to safety protocols.

Enthusiastic fabrication technician with 5+ years of experience in welding and fabrication. Expertise in developing innovative solutions to complex problems, maintaining safety standards, and producing high-quality products on time. Looking to utilize my skillset at ABC Manufacturing Co. to help create reliable equipment that meets customer needs while promoting workplace productivity.

Hard-working fabrication technician with 5+ years of experience in producing, repairing and maintaining metal products. Skilled in operating a variety of tools and machinery including welding torches, plasma cutters, grinders and lathes. Seeking to bring expertise to XYZ Manufacturing as part of the team responsible for fabricating high-quality components from raw materials.

Professional fabrication technician with 7 years of experience in a variety of fabrication processes and equipment. Seeking to leverage technical expertise and drive for excellence at ABC Technologies. At XYZ, led the production team to a 20% increase in efficiency by optimizing workflow processes and training new staff members on safety protocols.

2. Experience / Employment

The employment (or experience) section should be written in reverse chronological order. This means that your most recent job is listed first.

When writing this section, it’s best to stick primarily to bullet points; doing so allows the reader to take in what you have said more quickly and easily. You should also provide detail on what you did and any results achieved from your work.

For example, instead of saying “Fabricated different parts,” you could say, “Fabricated custom-made parts for various machinery using CNC milling machines with a 0.01mm accuracy rate.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Operated

- Monitored

- Inspected

- Troubleshot

- Fabricated

- Calibrated

- Programmed

- Adjusted

- Welded

- Measured

- Tested

- Repaired

- Installed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Demonstrated technical expertise to effectively fabricate, assemble and weld metal components for a wide range of projects, increasing productivity by 20%.

- Coordinated with other departments to ensure timely delivery of fabrication orders; completed 250+ complex projects on-time and under budget in the last year.

- Formulated creative solutions that reduced material costs by 10% while maintaining high standards of quality control during fabrication process.

- Resourcefully identified cost savings opportunities within existing production processes, resulting in an annual saving of $20,000 in labor costs alone.

- Welded steel & aluminum parts using Arc welding techniques to create finished products according to customer specifications; increased accuracy levels by 15%.

- Programmed CNC machines to fabricate metal components with +/-0.02mm accuracy, increasing production capacity by 30%.

- Competently operated a wide range of fabrication equipment such as drills, grinders and saws while adhering to safety protocols at all times.

- Assessed blueprints and CAD drawings to determine the correct materials needed for projects; successfully completed 10+ complex builds in the past year alone.

- Structured an efficient workflow system which tracked inventory levels, work orders and customer requests; reduced downtime by 40% over 3 months period resulting in $5K savings for company budget.

- Prepared detailed reports on project progress including estimated costs & timelines; identified discrepancies between designs & actual fabricated parts within 5 minutes leading to early cost avoidance of up to $7K per month.

- Installed and maintained 80+ pieces of machinery and manufacturing systems to facilitate fabrication processes, leading to a 20% reduction in production time.

- Repaired complex components on various machines with precision; reduced downtime from 3 hours to 30 minutes, resulting in an increase of $7000 in annual profits.

- Thoroughly tested each piece of equipment after repair or installation for optimal performance; improved safety standards by 40%.

- Facilitated communication between other technicians, engineers & supervisors during machine repairs and construction activities as required; completed all assigned tasks within the given timeline without any delays or setbacks.

- Presented project progress reports monthly at management review meetings that were used to make strategic decisions regarding fabrication operations; generated over $15000 worth of cost savings per year due to better utilization of resources and materials.

- Inspected and tested over 500 fabricated parts and assemblies for accuracy, quality, and adherence to blueprints before releasing them into production; reduced defect rate by 24%.

- Spearheaded a new process of welding steel components together to create more durable equipment frames that increased product life expectancy by 25%.

- Developed an efficient system of cutting raw materials with machine tools in order to minimize wastage while fabricating products, resulting in $10,000 savings over the past year.

- Accurately calculated dimensions and tolerances using precision measuring instruments such as calipers & micrometers prior to assembly; improved consistency across all finished products by 31%.

- Expedited fabrication projects from start-to-finish in under 3 hours without compromising on quality or design specifications; completed 5+ jobs per day ahead of schedule on average.

- Meticulously fabricated high-precision parts using CNC milling, lathe and welding machines; improved fabrication accuracy by 5% in the last quarter.

- Revised production plans for custom orders according to customer specifications, completing all tasks within tight deadlines with no quality issues reported.

- Operated heavy machinery such as forklifts and robotic arms to assemble components into finished products; reduced assembly time per unit by 15 minutes on average.

- Adjusted machine settings according to part sizes and tolerances; implemented a new system that enabled faster speed adjustments without compromising precision or safety standards.

- Collaborated closely with fellow technicians to inspect final products before distribution; identified defects in 2% of units produced over the past year prior to shipment out of factory.

- Measured and cut steel, aluminum and various other metals to exact specifications, achieving a 0.1 mm tolerance in all fabrication projects; reduced the time taken for producing parts by 25%.

- Reduced scrap rate from 10% to 4%, substantially increasing profitability of the company with an additional $50,000 revenue per year.

- Achieved welding certification from ABC Welding Institute and successfully introduced new methods of fabricating components that increased efficiency by 15%.

- Substantially improved accuracy of welded joints using MIG/TIG welding processes on high-end alloy materials such as titanium & stainless steel; decreased rejection rates by 20%.

- Introduced innovative techniques for etching metal surfaces resulting in higher quality surface finish standards while cutting production costs by 30%.

- Mentored and supervised 14 employees in the fabrication process, increasing productivity by 25% and reducing errors by 10%.

- Reorganized the existing storeroom inventory system to improve storage efficiency and accessibility; reduced time spent locating items by 50%.

- Compiled detailed records of material usage for over 300 projects, ensuring that all materials were accounted for accurately and efficiently.

- Proficiently used welding equipment to fabricate metal components such as brackets, support frames & tanks according to customer specifications with no defects or flaws reported upon completion.

- Advised management on cost-effective purchasing strategies for raw materials which resulted in a $7000 reduction in costs within 6 months of implementation.

- Actively participated in the installation of machinery, fabrication and welding of parts, and preparation of components for assembly operations; completed over 1000 production hours with zero safety incidents.

- Participated in testing procedures to ensure correct functionality before products were shipped out; successfully tested 50+ assemblies per day resulting in a customer satisfaction rate increase by 8%.

- Tested prototypes to evaluate designs against product specifications; identified potential design flaws early on leading to an improvement in overall product quality by 15%.

- Optimized existing processes through innovative ideas that improved efficiency by 25%, reducing cost overhead significantly while maintaining high standards of workmanship throughout all projects undertaken.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may require the candidate to be proficient in welding, while another might focus more on machining.

This is why it is important to tailor your skills section for each job you are applying for. Employers often use applicant tracking systems (ATS) that scan resumes for certain keywords; if these words don’t appear in your resume, then chances are it won’t even make it past the first stage of selection.

In addition to listing relevant fabrication technician skills here, you should also discuss them further throughout other sections such as experience and summary.

Below is a list of common skills & terms:

- Blueprint Reading

- CAD/CAM

- CNC Programming

- Fabrication

- Machining

- Metalworking

- Quality Control

- Robotics

- Troubleshooting

- Welding

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you recently graduated and don’t have much work experience, include the education section below your resume objective. However, if you have significant work experience to showcase, omitting an education section is perfectly acceptable.

If including an education section is necessary, try to mention courses or subjects related to fabrication technician roles that could be relevant for employers.

Associate Degree in Fabrication Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your proficiency in a certain field or skill. They show potential employers that you have been tested and certified by an authoritative body, which can make you stand out from other applicants.

Include any certifications relevant to the job position on your resume so that hiring managers know what qualifications you possess. This will give them more confidence in considering you for the role as they know that you are well-trained and knowledgeable about the industry.

Certified Fabrication Technician

American Welding Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Kianna Johns, this would be Kianna-Johns-resume.pdf or Kianna-Johns-resume.docx.

7. Cover Letter

Providing a cover letter as part of your job application is a great way to make a positive impression on hiring managers. It’s usually made up of 2-4 paragraphs and provides an opportunity for you to express yourself in more detail than what’s included in your resume.

Cover letters provide recruiters with valuable insights into who you are as a professional, such as the skills and qualities that make you unique. Although they aren’t always required by employers, it’s highly recommended that applicants include one so they can stand out from other candidates vying for the same role.

Below is an example cover letter:

Dear Sasha,

I am interested in applying for the Fabrication Technician position at your company. I have experience as a welder and fabricator, and I am confident that I would be a valuable asset to your team.

In my current role, I work as a welder and fabricator for a steel fabrication company. In this role, I am responsible for reading blueprints and drawings to determine the best way to cut, shape, and weld metal components together. I also use various hand tools to assemble parts prior to welding them together. In addition, I operate forklifts and cranes to move materials around the shop floor.

I have experience working with all types of metals, including aluminum, stainless steel, and carbon steel. In addition, I am familiar with both MIG and TIG welding techniques. My attention to detail ensures that all products meet or exceed customer expectations in terms of quality and durability.

Finally, my excellent communication skills allow me to work effectively with other members of the fabrication team. My positive attitude ensures that projects are completed on time and within budget constraints.

I believe that my skillset makes me an ideal candidate for the Fabrication Technician position at your company. Thank you for your consideration; please do not hesitate to contact me if you have any questions about my qualifications or experience level.

Sincerely,

Kianna

Fabrication Technician Resume Templates

Quokka

Quokka Lorikeet

Lorikeet Gharial

Gharial Ocelot

Ocelot Axolotl

Axolotl Pika

Pika Hoopoe

Hoopoe Bonobo

Bonobo Echidna

Echidna Indri

Indri Numbat

Numbat Jerboa

Jerboa Markhor

Markhor Cormorant

Cormorant Fossa

Fossa Kinkajou

Kinkajou Rhea

Rhea Dugong

Dugong Saola

Saola Rezjumei

Rezjumei