Equipment Technician Resume Guide

Equipment Technicians are responsible for maintaining, troubleshooting and repairing a variety of equipment. They inspect machines to identify any issues, perform repairs as needed and ensure that the equipment is functioning correctly before returning it to its original state. Additionally, they may provide preventative maintenance services on an ongoing basis in order to keep the machine running properly.

You know all the ins and outs of equipment maintenance, so you’d make a great asset to any technician team. To get your foot in the door, though, you must write an impressive resume that shows off your abilities and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Equipment Technician Resume Sample

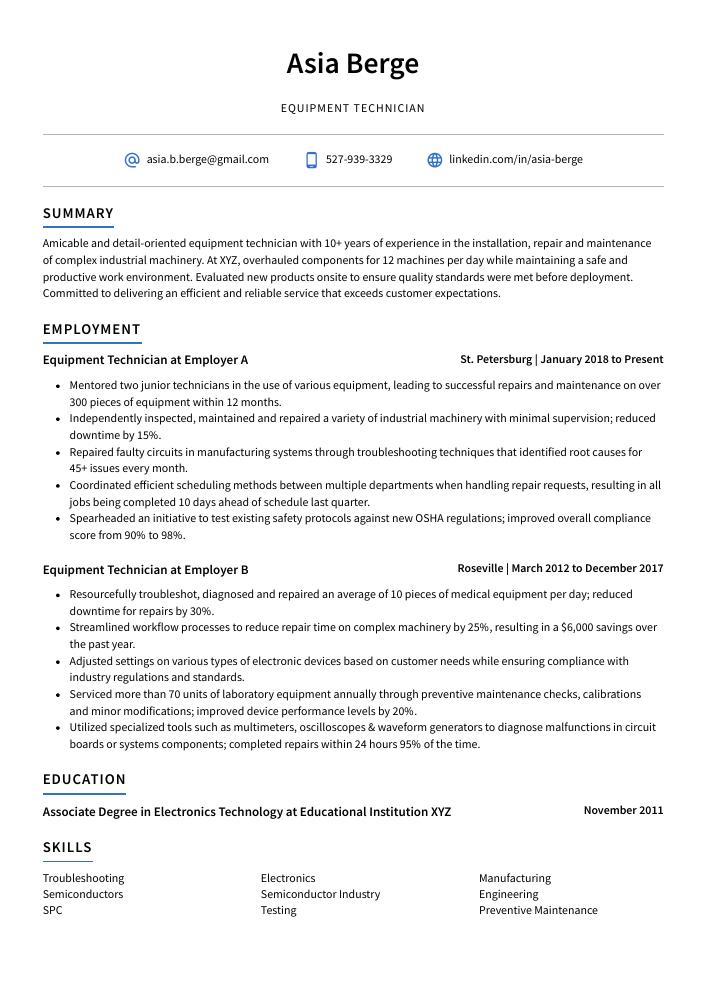

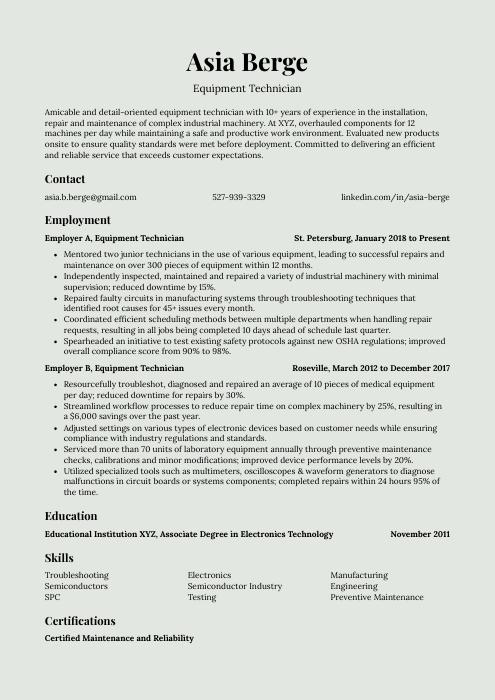

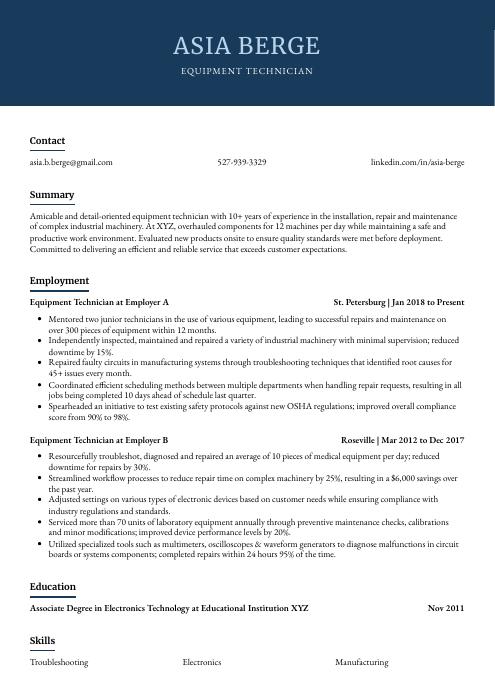

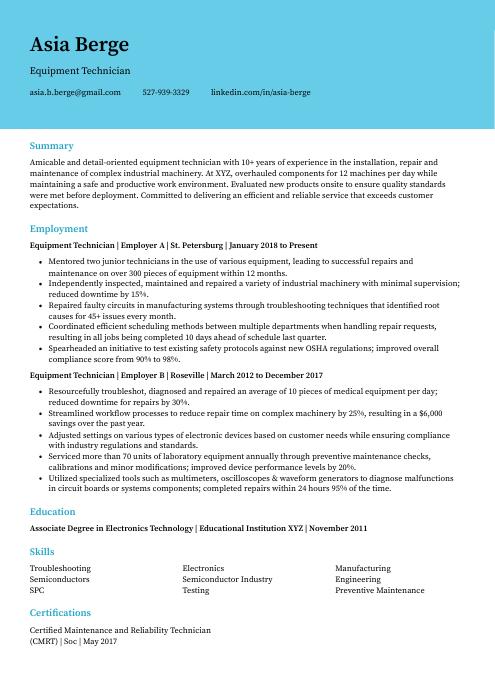

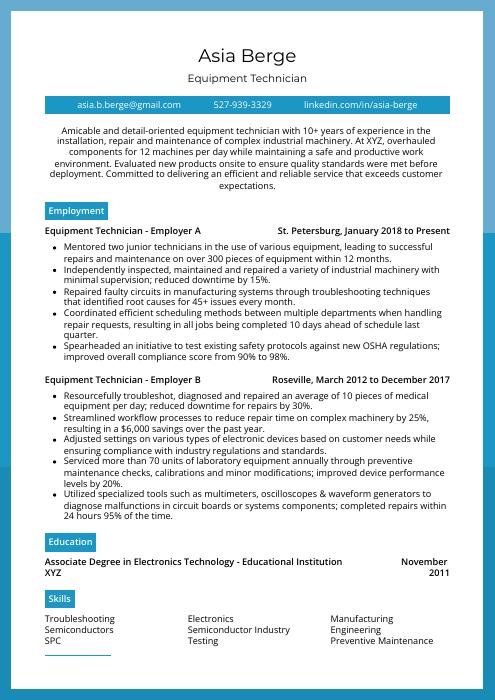

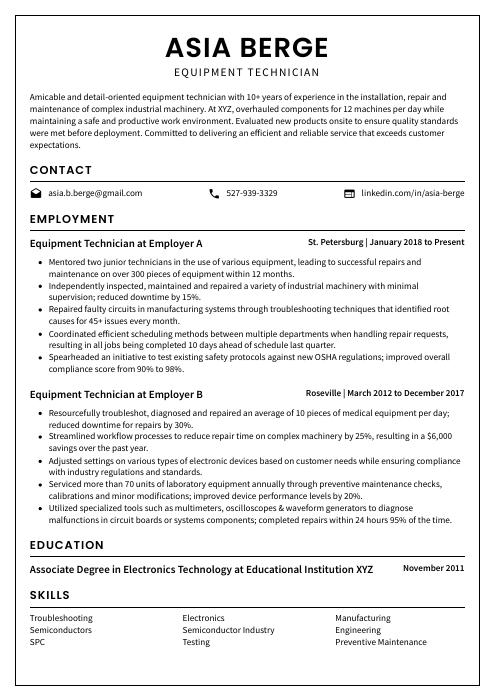

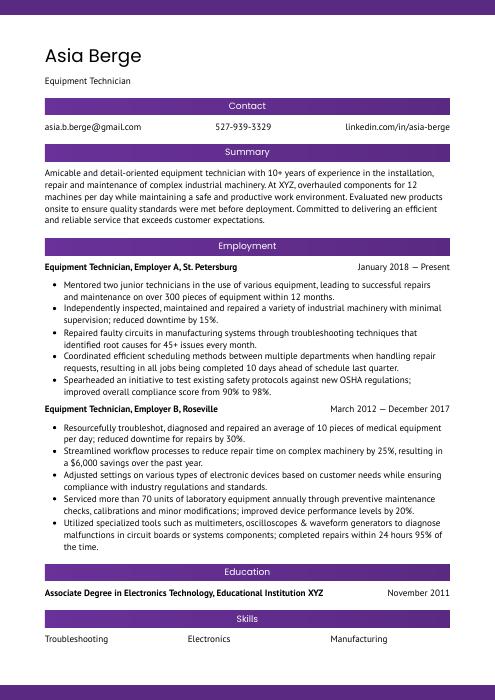

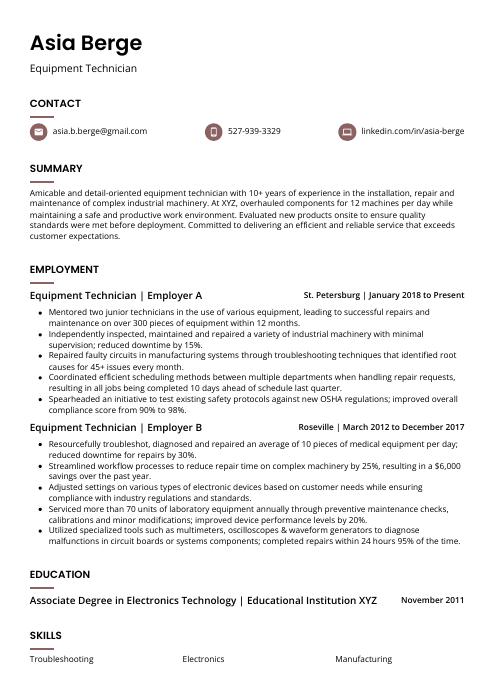

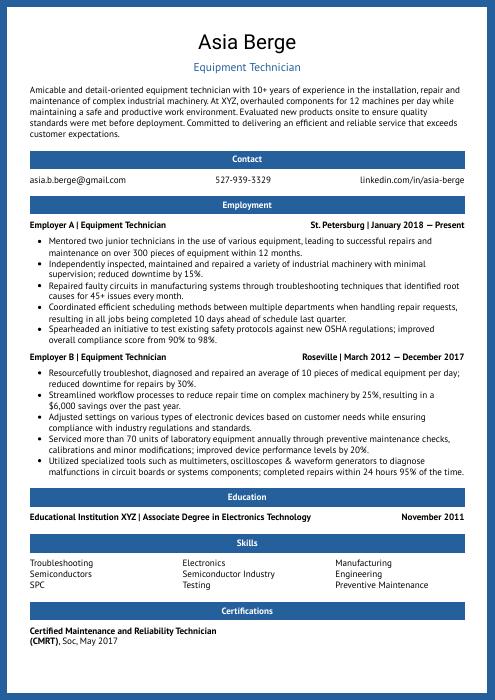

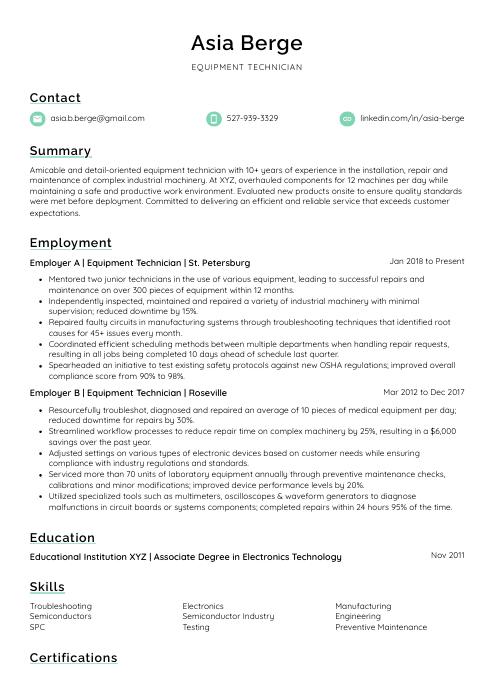

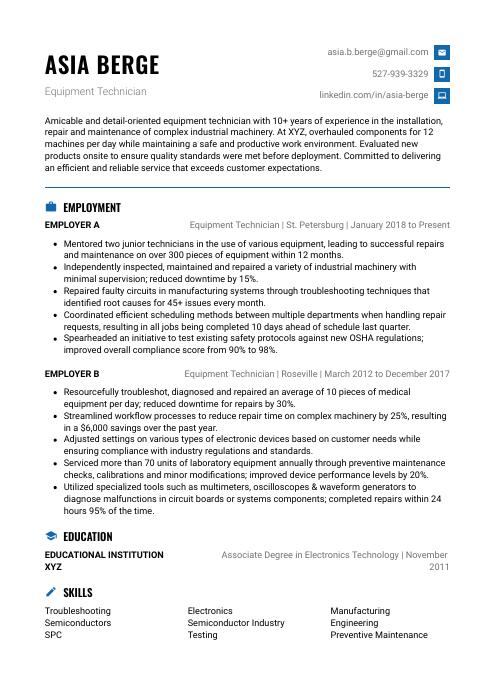

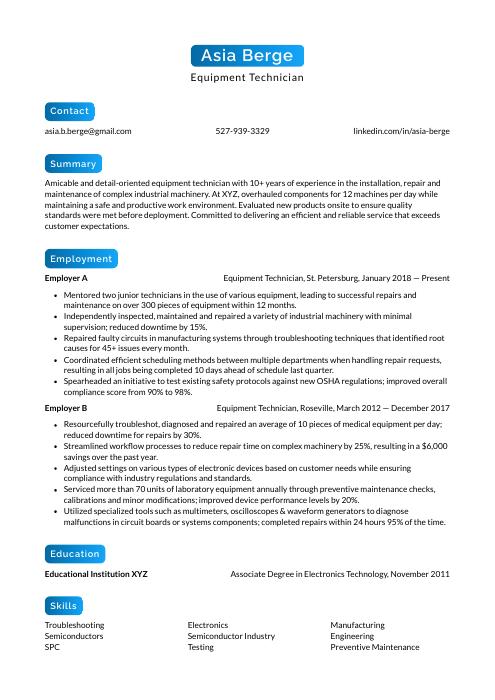

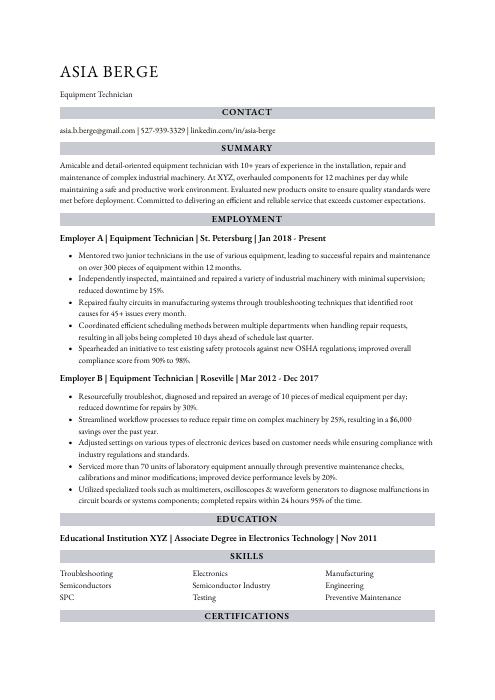

Asia Berge

Equipment Technician

[email protected]

527-939-3329

linkedin.com/in/asia-berge

Summary

Amicable and detail-oriented equipment technician with 10+ years of experience in the installation, repair and maintenance of complex industrial machinery. At XYZ, overhauled components for 12 machines per day while maintaining a safe and productive work environment. Evaluated new products onsite to ensure quality standards were met before deployment. Committed to delivering an efficient and reliable service that exceeds customer expectations.

Experience

Equipment Technician, Employer A

St. Petersburg, Jan 2018 – Present

- Mentored two junior technicians in the use of various equipment, leading to successful repairs and maintenance on over 300 pieces of equipment within 12 months.

- Independently inspected, maintained and repaired a variety of industrial machinery with minimal supervision; reduced downtime by 15%.

- Repaired faulty circuits in manufacturing systems through troubleshooting techniques that identified root causes for 45+ issues every month.

- Coordinated efficient scheduling methods between multiple departments when handling repair requests, resulting in all jobs being completed 10 days ahead of schedule last quarter.

- Spearheaded an initiative to test existing safety protocols against new OSHA regulations; improved overall compliance score from 90% to 98%.

Equipment Technician, Employer B

Roseville, Mar 2012 – Dec 2017

- Resourcefully troubleshot, diagnosed and repaired an average of 10 pieces of medical equipment per day; reduced downtime for repairs by 30%.

- Streamlined workflow processes to reduce repair time on complex machinery by 25%, resulting in a $6,000 savings over the past year.

- Adjusted settings on various types of electronic devices based on customer needs while ensuring compliance with industry regulations and standards.

- Serviced more than 70 units of laboratory equipment annually through preventive maintenance checks, calibrations and minor modifications; improved device performance levels by 20%.

- Utilized specialized tools such as multimeters, oscilloscopes & waveform generators to diagnose malfunctions in circuit boards or systems components; completed repairs within 24 hours 95% of the time.

Skills

- Troubleshooting

- Electronics

- Manufacturing

- Semiconductors

- Semiconductor Industry

- Engineering

- SPC

- Testing

- Preventive Maintenance

Education

Associate Degree in Electronics Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

1. Summary / Objective

The summary/objective at the start of your equipment technician resume is like a movie trailer – it provides the hiring manager with an overview of who you are and why they should consider you for the position. This section is where you can highlight your best qualities; for example, mention how many years’ experience in maintenance and repair work you have, any certifications or qualifications that make you stand out from other applicants, and how quickly and efficiently you complete repairs.

Below are some resume summary examples:

Seasoned equipment technician with 7+ years of experience in the medical device industry. Skilled in troubleshooting and repairing a variety of complex machinery, including robotic systems, laboratory equipment, and imaging devices. Looking to join ABC as an Equipment Technician to ensure optimal performance for their high-end clients. At XYZ Inc., achieved 99% customer satisfaction ratings due to quick response times and successful repairs.

Accomplished equipment technician with over 10 years of experience in the maintenance, repair and installation of complex medical equipment. Proven track record for successfully troubleshooting malfunctioning machines to restore optimal performance. At XYZ, reduced downtime by 50% through implementation of preventative maintenance procedures. Collaborated closely with engineers & clinicians to ensure successful product launches & upgrades.

Committed equipment technician with 5+ years of experience in troubleshooting and repairing a wide range of equipment. At XYZ, maintained over 200 pieces of heavy machinery while adhering to all safety regulations. Led the implementation of an automated maintenance system that improved repair efficiency by 25%. Experienced in both electrical and mechanical repairs, welding techniques, and advanced problem-solving strategies.

Detail-oriented equipment technician with 6+ years of experience in the electronic/mechanical maintenance field. Proven record of efficiently troubleshooting, repairing and maintaining a wide range of equipment. Self-motivated to stay current on cutting edge technology through continued education courses and certifications. Skilled at managing multiple projects simultaneously while meeting deadlines and KPIs.

Skilled equipment technician with 8+ years of experience in the maintenance and repair of a wide variety of medical equipment. Experienced in troubleshooting, calibrating, and repairing sophisticated machinery while adhering to safety protocols. Seeking to apply knowledge and expertise at ABC Medical as an Equipment Technician where I can use my interpersonal skills to provide excellent customer service.

Passionate equipment technician with 5+ years of experience in maintenance and troubleshooting. Skilled at installing, repairing, and maintaining a variety of medical equipment for ABC Healthcare. Seeking to use my expertise to help ensure patient safety by providing reliable service on all medical devices. Key achievements include cutting downtime by 25% while increasing overall reliability by 37%.

Dependable equipment technician with 10+ years experience diagnosing and repairing a variety of industrial machinery. Proven track record of reducing downtime for clients by an average 25%. Seeking to apply skillset and expertise to ABC’s team as the next equipment maintenance specialist. Committed to upholding safety standards while boosting productivity through thorough troubleshooting techniques.

Reliable and results-driven equipment technician with 5+ years of experience in troubleshooting and repairing complex industrial machinery. At XYZ, managed the installation, maintenance and repair of over 100 pieces of heavy equipment while working efficiently to complete all tasks on time. Adaptable problem solver who contributes fresh ideas for optimizing machine performance and safety standards.

2. Experience / Employment

In the experience section, you should provide details about your work history. It’s best to list these in reverse chronological order, which means the most recent job is listed first.

When writing what you did for each role, use bullet points primarily; this makes it easier for the reader to digest your information quickly. When stating what you did and achieved, be sure to include quantifiable results where possible.

For example, instead of saying “Repaired broken equipment,” you could say “Diagnosed and repaired complex electrical systems on industrial machinery with a 95% success rate.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Inspected

- Calibrated

- Troubleshot

- Repaired

- Assembled

- Configured

- Operated

- Tested

- Adjusted

- Replaced

- Monitored

- Diagnosed

- Upgraded

- Serviced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Improved the reliability of equipment by 20% through preventative maintenance and repairs on over 500 pieces of mechanical and electrical machinery.

- Configured complex systems with up-to-date software, ensuring that all new technical installations were successful.

- Introduced several innovative methods for optimizing the processing time of various machines, resulting in a 15% increase in output rates per hour overall.

- Assembled parts and components to construct specialized tools or machines; successfully completed 10 orders within tight deadlines while meeting customer expectations every time.

- Meticulously inspected materials prior to assembly according to industry standards; identified potential defects beforehand thus reducing repair costs by $7,500 annually.

- Reduced repair and maintenance costs by 20% through the optimization of existing equipment.

- Advised managers on best practices for repair and maintenance, resulting in a decrease of overall downtime by 15 hours per month.

- Presented new ideas to enhance operational efficiency, saving an additional $5,000 over six months period.

- Successfully installed 60 pieces of medical equipment with accuracy and precision within 2 weeks timeframe; maintained 100% compliance rate with safety regulations while doing so.

- Prepared monthly reports outlining repairs done, preventive measures taken & recommendations made to increase system reliability; reduced customer complaints due to faulty equipments by 25%.

- Developed preventive maintenance procedures for over 500 pieces of equipment, resulting in a 50% reduction in downtime.

- Expedited repairs to malfunctioning machinery and achieved an average repair time of 5 hours or less; increased speed/efficiency by 20%.

- Competently installed, serviced and tested electrical systems on various types of industrial machinery with up to 25 kW power rating per system.

- Represented the company at trade shows and conventions; secured 10 new clients within 3 months due to exemplary customer service skills & product knowledge presentations.

- Optimized operations through troubleshooting existing processes, identifying areas for improvement and implementing changes that saved $10K annually in energy costs and improved productivity by 15%.

- Revised and maintained over 500 pieces of equipment, ensuring that all systems and components were functioning correctly at all times; lowered repair costs by 15%.

- Replaced malfunctioning parts in a variety of machines such as generators and HVAC units to improve operational performance; completed repairs on 10+ large-scale projects within budget constraints.

- Assessed operations for safety hazards in the workplace, identifying potential problems before they occurred and taking corrective measures to prevent any accidents or injuries from occurring.

- Upgraded existing tools and machinery with new technology to increase efficiency levels across production processes; improved output by 30% within 3 months of implementation.

- Accurately documented service activities including repairs, installations, inspections & maintenance using electronic databases for future reference purposes; reduced data entry errors by 8%.

- Compiled a comprehensive inventory of all equipment parts and supplies, ensuring accuracy in documentation to facilitate quick repairs; decreased repair time by 15%.

- Operated specialized maintenance tools and machines, such as lathes, welding torches and power drills, with a high degree of precision to diagnose problems in malfunctioning machinery.

- Reliably inspected the condition of production lines on a daily basis to identify potential issues before they caused disruption; averted over $4K worth of losses due to unexpected downtime last year.

- Facilitated seamless communication between supervisors and technicians when troubleshooting technical malfunctions or carrying out preventive maintenance tasks; completed 85+ service requests within 24 hours this year alone.

- Achieved ISO 9001 & 14001 certifications through successful implementation of new safety protocols for electrical works while maintaining zero reported incidents during the certification process period.

- Reorganized the maintenance schedule of all equipment, resulting in a 40% increase in efficiency and an average 15 minute reduction per repair.

- Tested over 200 pieces of medical equipment daily to ensure safety standards were met; identified and corrected any malfunctions before they became hazardous issues.

- Consistently updated software programs on the hospital’s computers, increasing system stability by 70%.

- Troubleshot various types of machinery using specialized knowledge and experience; achieved a 95% success rate for repairs within 24 hours or less without compromising quality control protocols.

- Calibrated high-tech imaging devices such as CT scanners with precision accuracy, reducing device errors by 45%.

- Demonstrated advanced knowledge in the maintenance and repair of electrical, mechanical, hydraulic and pneumatic equipment; successfully installed over 250 new pieces of machinery with a 98% success rate.

- Thoroughly tested all components for safety compliance prior to installation or after repairs were made; ensured that each machine was functioning properly at peak capacity before putting them into use.

- Structured an effective preventative maintenance program that reduced downtime by 35%, saving $25K in labor costs per month.

- Formulated innovative solutions to complex problems related to miscellaneous machines on-site including drills, lathes, saws etc.; restored functionality on 97% of these tools within 2 hours average time limit set by management team members.

- Installed and calibrated sensors/instruments such as pressure gauges & thermometers according to manufacturer’s instructions while adhering strictly to established safety protocols during processes involving hazardous materials or chemicals.

- Inspected and maintained 60+ pieces of medical equipment daily, ensuring optimal performance and reducing repair costs by 25%.

- Diagnosed problems quickly using advanced troubleshooting techniques; repaired 85% of issues in 30 minutes or less with a success rate exceeding 95%.

- Monitored the condition of equipment on a regular basis to detect potential malfunctions before they became major repairs; reduced breakdowns by 23% over 3 months.

- Participated in product development sessions and provided valuable feedback for improving existing designs, resulting in an average 15% reduction in production costs per model.

- Actively engaged customers to ensure their needs were met and that all instructions were properly followed; increased customer satisfaction ratings from 78-92%.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for an individual with experience in repairing and maintaining medical equipment, while another might require expertise in the maintenance of industrial machinery.

It is essential to tailor your skills section according to the job you are applying for because many companies utilize applicant tracking systems these days. These computer programs scan resumes for certain keywords before passing them on to a human; therefore, it’s important that you include all relevant skills related to the position being advertised.

Besides just listing skills here, you should also discuss them in more detail elsewhere – such as within your summary or work history sections – so that employers can get a better understanding of how they would benefit from hiring you.

Below is a list of common skills & terms:

- Analog

- Automation

- Continuous Improvement

- Cross Functional Team Leadership

- Design of Experiments

- Electronics

- Engineering

- Equipment Maintenance

- Failure Analysis

- Hydraulics

- IC

- Inspection

- Lean Manufacturing

- Maintenance and Repair

- Manufacturing

- Metrology

- Preventive Maintenance

- Process Improvement

- Project Planning

- Root Cause Analysis

- SPC

- Semiconductor Industry

- Semiconductors

- Silicon

- Six Sigma

- Supervisory Skills

- Team Leadership

- Teamwork

- Test Equipment

- Testing

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, list your education below your resume objective. However, if you have significant work experience that is more relevant to the equipment technician role than any courses or qualifications from school, it might be best to omit an education section altogether.

If including an education section is necessary, try to mention courses and subjects related to the equipment technician position such as electronics engineering or mechanical engineering technology.

Associate Degree in Electronics Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have taken the time and effort to gain knowledge about specific topics, which can help set you apart from other applicants.

Include any certifications related to the job position on your resume so hiring managers know that you are qualified for the role. Make sure to include information such as where and when it was obtained, as well as what type of certification it is.

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Asia Berge, this would be Asia-Berge-resume.pdf or Asia-Berge-resume.docx.

7. Cover Letter

Including a cover letter with your resume is an important step in the job application process. It helps to provide more detail about who you are and what makes you a great fit for the role. A cover letter typically consists of 2 to 4 paragraphs, which should be written with clarity and professionalism.

Although it’s not always mandatory, having a well-crafted cover letter can make all the difference when competing against other applicants for a position. By highlighting your skills and experiences that match up with those required by the employer, it could give you an edge over others vying for the same opportunity.

Below is an example cover letter:

Dear Eino,

I am writing to apply for the Equipment Technician position at XYZ Company. With more than 10 years of experience in equipment maintenance and repairs, I am confident I will make an immediate contribution to your team.

Most recently, I worked as an equipment technician at ABC Company where I was responsible for maintaining and repairing a wide range of industrial machinery. Prior to that, I held a similar role at DEF Corporation. In both positions, I gained extensive experience troubleshooting equipment issues and performing preventative maintenance. My technical skills combined with my ability to work independently makes me confident that I can exceed your expectations in this role.

In addition to my hands-on experience, I also have a degree in mechanical engineering from GHI University. This educational background has given me a strong foundation in the principles of machine operation which comes into play on a daily basis in my current role.

If you are looking for an experienced and reliable equipment technician who is ready to hit the ground running, then please consider me for this position. You can reach me anytime by phone or email if you should like to discuss my application further or arrange an interview at your earliest convenience. Thank you very much for your time and consideration!

Sincerely,

Asia

Equipment Technician Resume Templates

Indri

Indri Quokka

Quokka Hoopoe

Hoopoe Saola

Saola Bonobo

Bonobo Pika

Pika Gharial

Gharial Dugong

Dugong Rhea

Rhea Cormorant

Cormorant Jerboa

Jerboa Fossa

Fossa Ocelot

Ocelot Lorikeet

Lorikeet Echidna

Echidna Kinkajou

Kinkajou Numbat

Numbat Axolotl

Axolotl Markhor

Markhor Rezjumei

Rezjumei