Engineering Technologist Resume Guide

Engineering technologists use their knowledge of engineering principles and technology to design, develop, test, and maintain products or systems. They work closely with engineers to ensure that designs are practical and cost-effective while meeting customer needs. Engineering technologists also conduct experiments in the laboratory or onsite at a manufacturing plant to evaluate product performance.

Your engineering expertise is unparalleled, and you could easily be the next star employee of any company. To get noticed by employers, you must write a resume that highlights your technical abilities and achievements.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

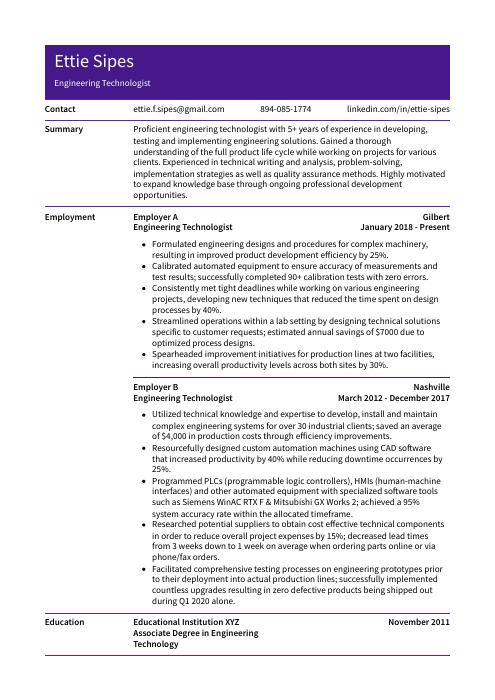

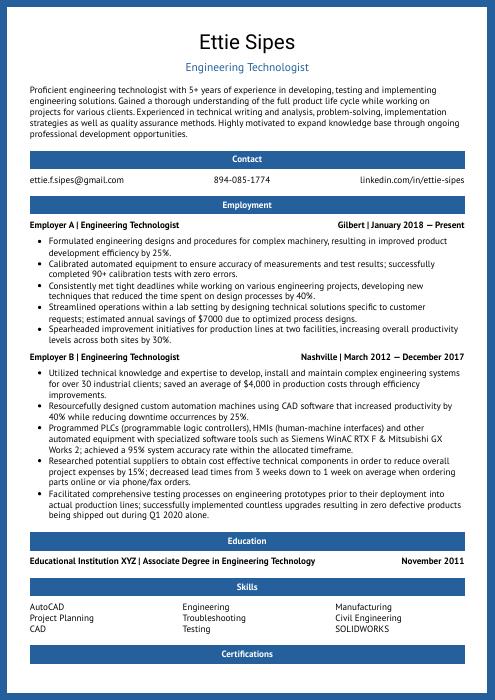

Engineering Technologist Resume Sample

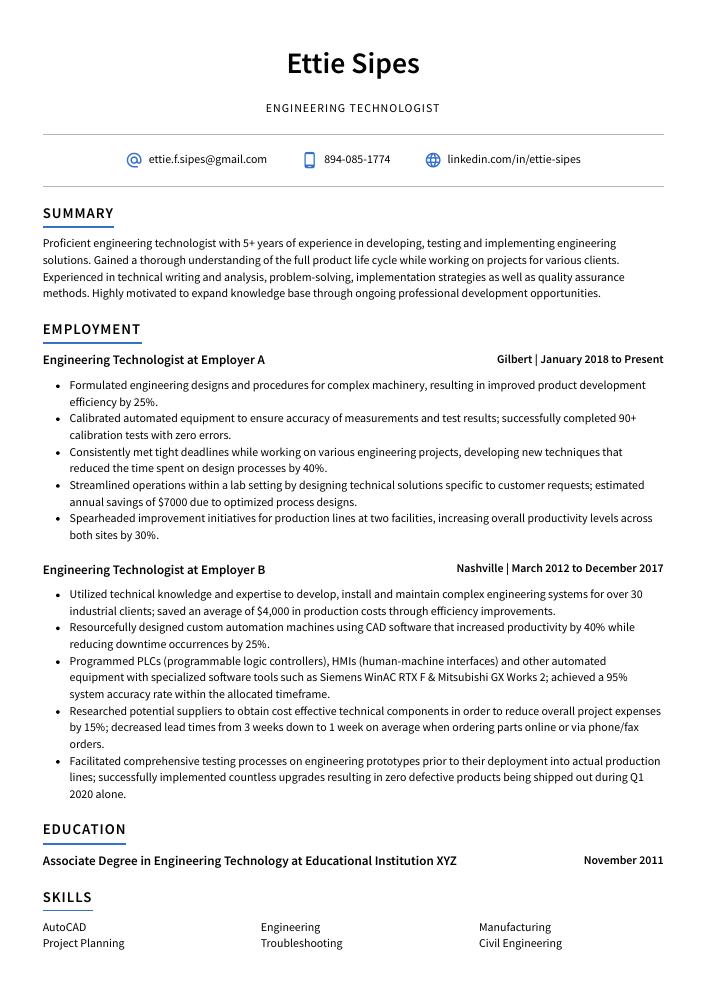

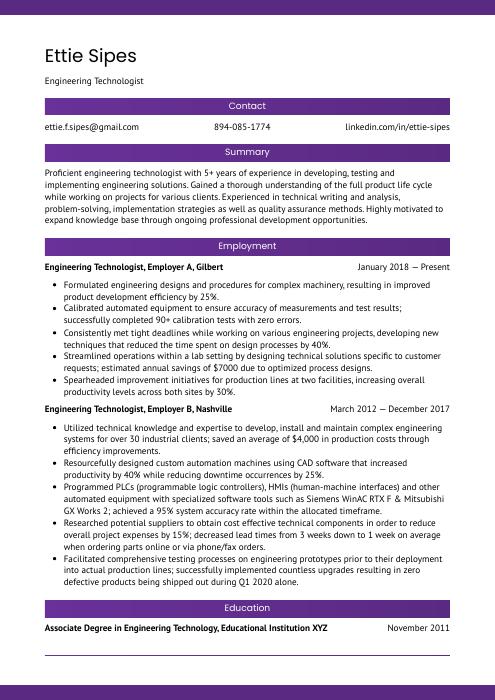

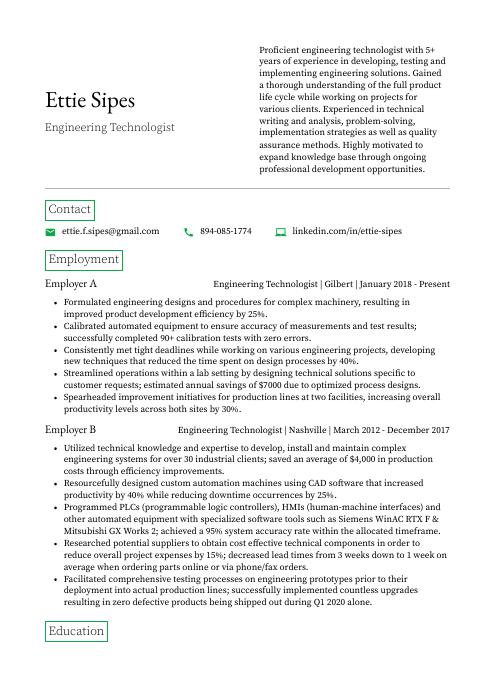

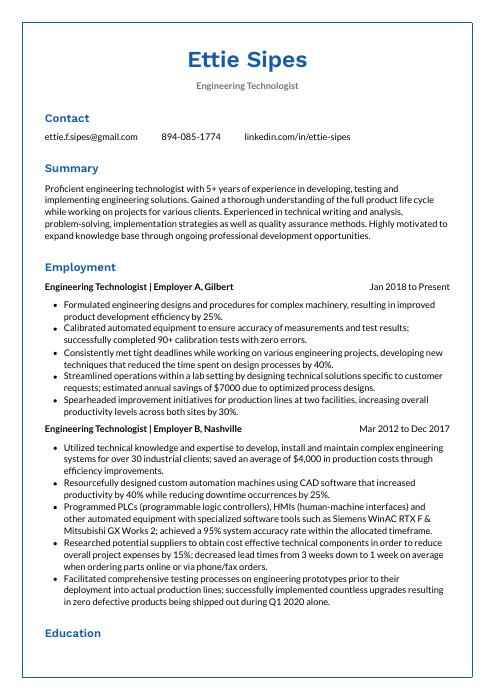

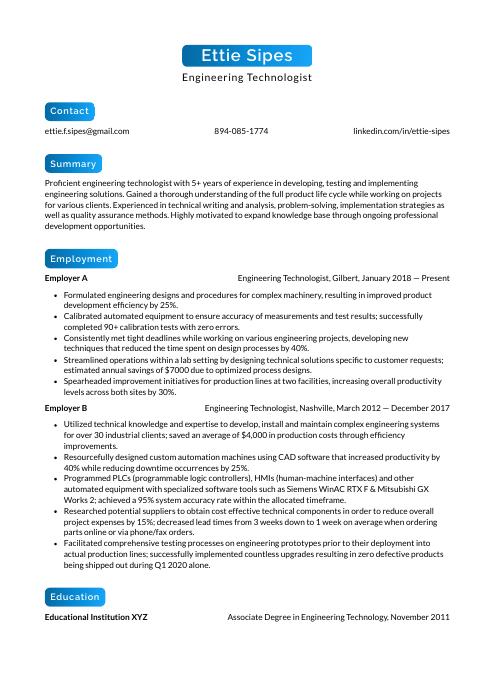

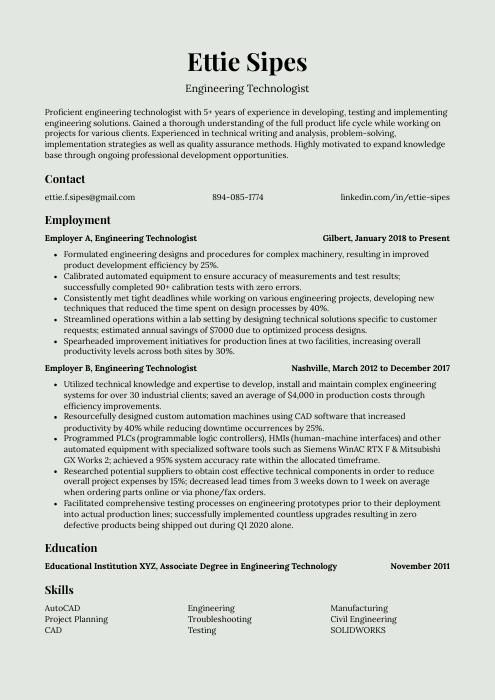

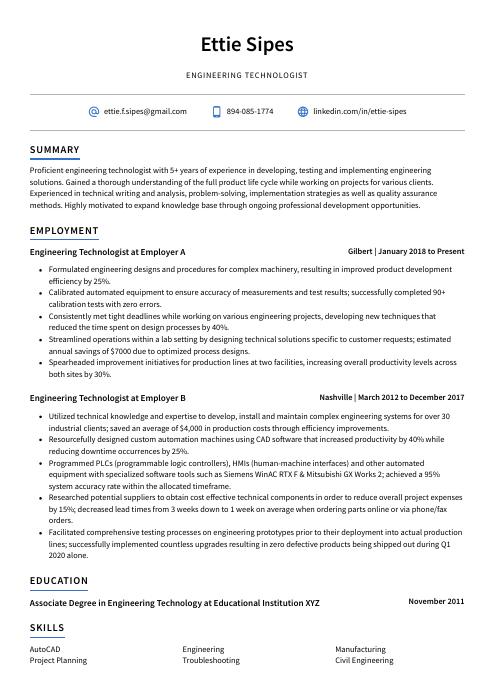

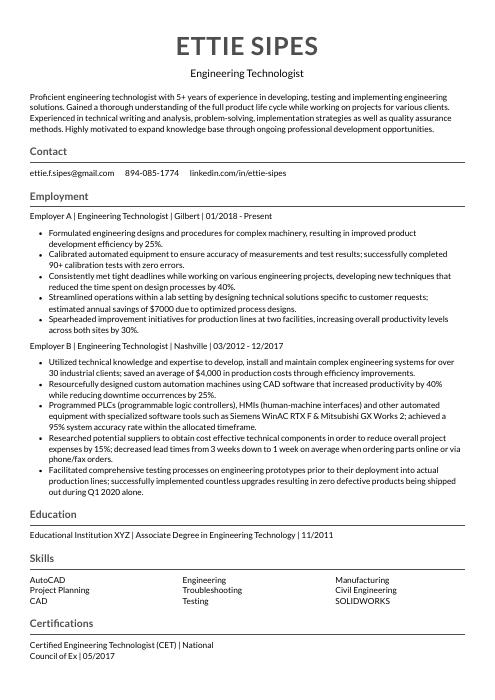

Ettie Sipes

Engineering Technologist

ettie.f.sipes@gmail.com

894-085-1774

linkedin.com/in/ettie-sipes

Summary

Proficient engineering technologist with 5+ years of experience in developing, testing and implementing engineering solutions. Gained a thorough understanding of the full product life cycle while working on projects for various clients. Experienced in technical writing and analysis, problem-solving, implementation strategies as well as quality assurance methods. Highly motivated to expand knowledge base through ongoing professional development opportunities.

Experience

Engineering Technologist, Employer A

Gilbert, Jan 2018 – Present

- Formulated engineering designs and procedures for complex machinery, resulting in improved product development efficiency by 25%.

- Calibrated automated equipment to ensure accuracy of measurements and test results; successfully completed 90+ calibration tests with zero errors.

- Consistently met tight deadlines while working on various engineering projects, developing new techniques that reduced the time spent on design processes by 40%.

- Streamlined operations within a lab setting by designing technical solutions specific to customer requests; estimated annual savings of $7000 due to optimized process designs.

- Spearheaded improvement initiatives for production lines at two facilities, increasing overall productivity levels across both sites by 30%.

Engineering Technologist, Employer B

Nashville, Mar 2012 – Dec 2017

- Utilized technical knowledge and expertise to develop, install and maintain complex engineering systems for over 30 industrial clients; saved an average of $4,000 in production costs through efficiency improvements.

- Resourcefully designed custom automation machines using CAD software that increased productivity by 40% while reducing downtime occurrences by 25%.

- Programmed PLCs (programmable logic controllers), HMIs (human-machine interfaces) and other automated equipment with specialized software tools such as Siemens WinAC RTX F & Mitsubishi GX Works 2; achieved a 95% system accuracy rate within the allocated timeframe.

- Researched potential suppliers to obtain cost effective technical components in order to reduce overall project expenses by 15%; decreased lead times from 3 weeks down to 1 week on average when ordering parts online or via phone/fax orders.

- Facilitated comprehensive testing processes on engineering prototypes prior to their deployment into actual production lines; successfully implemented countless upgrades resulting in zero defective products being shipped out during Q1 2020 alone.

Skills

- AutoCAD

- Engineering

- Manufacturing

- Project Planning

- Troubleshooting

- Civil Engineering

- CAD

- Testing

- SOLIDWORKS

Education

Associate Degree in Engineering Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Engineering Technologist (CET)

National Council of Ex

May 2017

1. Summary / Objective

Your resume summary/objective is your chance to make a great first impression and convince the hiring manager that you are the right fit for their engineering technologist position. In this section, you can highlight your experience with CAD software, any certifications or licenses you have obtained, and how many successful projects you’ve completed in the past. You should also mention what sets you apart from other candidates – such as being able to troubleshoot complex technical issues quickly and efficiently.

Below are some resume summary examples:

Dependable engineering technologist with 5+ years of experience in the design, implementation and maintenance of complex electrical systems. Experienced in troubleshooting issues related to power generation, distribution, control and automation projects. Adept at working closely with engineers to develop solutions that meet customer needs while staying within budget constraints. Possesses a Bachelor’s Degree in Electrical Engineering from XYZ University.

Determined engineering technologist with 5+ years of experience in design, development and testing of advanced components, systems and equipment. Proven track record of meeting tight deadlines while ensuring high-quality results by coordinating resources and effectively managing projects from concept to completion. Seeking to join ABC Tech as a Senior Engineering Technologist where I can use my expertise to contribute to the overall success of the team.

Reliable engineering technologist with over 8 years of experience in the design and development of complex mechanical systems. Proficient in CAD software, engineering calculations, product testing, and process optimization. Adept at troubleshooting issues to ensure operational efficiency while meeting industry standards within tight deadlines. Seeking a position at ABC Technologies to utilize my skills and knowledge for their cutting-edge projects.

Accomplished engineering technologist with 10+ years of experience developing and testing new products, processes, and systems. Skilled in performing complex calculations, researching data sources to validate results, preparing reports detailing findings, and presenting solutions to upper management. Seeking a position at ABC Company where I can use my knowledge of engineering fundamentals to improve efficiency within the organization.

Diligent engineering technologist with 5+ years of experience in designing, testing, and maintaining complex engineering systems. Highly knowledgeable about CAD software such as AutoCAD and Solidworks. Proven track record of successfully managing projects from concept to completion on time and under budget. Seeking to join ABC Tech where my technical skills can be used to help develop innovative solutions for the company’s clients.

Talented engineering technologist with 5+ years of experience in developing and maintaining complex systems. Proven ability to design, build, test and implement solutions in a timely manner. Skilled at working independently as well as collaboratively with cross-functional teams on projects across the product life cycle. Committed to delivering high-quality results while remaining cost conscious throughout all stages of production.

Professional engineering technologist with 8+ years of experience in designing, testing, and implementing various engineering projects. Proven ability to manage teams and coordinate multiple tasks while meeting deadlines. Adept at working efficiently under pressure while maintaining high standards for quality assurance. At XYZ Engineering Solutions developed a new system that reduced manufacturing costs by 20%.

Committed engineering technologist with a proven track record of success in the application of engineering principles to solve complex problems. Skilled at designing, developing, and testing products for commercial use. Experienced in project management and product development from concept to completion. Seeking an opportunity to utilize my expertise within ABC’s innovative team environment.

2. Experience / Employment

In the experience/employment/work history section, you should provide details on your past roles. This section should be written in reverse chronological order, with the most recent role listed at the top.

When writing this section, it’s best to stick to bullet points as they are easier for readers to digest quickly. You want each point to explain what you did and any results or accomplishments achieved while doing so. For example, instead of saying “Assisted engineers,” you could say, “Collaborated with engineering team members on a variety of projects resulting in an average 10% increase in efficiency.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Constructed

- Programmed

- Operated

- Monitored

- Inspected

- Calibrated

- Troubleshot

- Analyzed

- Documented

- Implemented

- Tested

- Improved

- Researched

- Assembled

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Structured engineering plans and procedures for the development of x+ new products, resulting in a 10% reduction in design costs.

- Advised engineering projects teams on technical requirements while ensuring compliance with industry codes and standards; eliminated non-conformance issues by 50%.

- Revised product designs to improve functionality, reduce manufacturing costs and ensure customer satisfaction; improved quality rating from 85% to 95%.

- Reliably tested prototypes for accuracy prior to production roll out, uncovering potential flaws that could have caused system failure or safety risks if not caught early on.

- Designed test equipment schematics using CAD software, enabling engineers to accurately diagnose problems within minutes instead of hours spent troubleshooting manually before this innovation was put into place.

- Mentored and supervised a team of 3 engineering technicians in the development and testing of new products, resulting in an 18% increase in productivity.

- Represented the company at trade shows and industry conferences to promote its latest technologies; generated over $250,000 in sales leads within 6 months.

- Successfully designed, tested and deployed 10+ custom-built prototypes for client projects according to project specifications with zero errors or delays.

- Reorganized existing engineering processes into more efficient workflows that improved overall customer satisfaction by 19%.

- Constructed complex industrial machinery using advanced CAD/CAM software tools while adhering to all safety regulations; completed 5 major installations ahead of schedule by 15 hours on average each time.

- Expedited the development of new engineering projects by 25% through efficient project management and organization.

- Assembled and tested various mechanical, electrical and electronic components for prototype products; conducted quality assurance checks to ensure all specifications were met before production launch.

- Demonstrated strong technical knowledge when troubleshooting complex issues with existing systems, reducing downtime from 3 hours to 1 hour on average per issue resolution.

- Effectively designed schematics for automated control systems using CAD software programs; improved overall operational efficiency by 10%.

- Documented product design tests results in compliance with ISO 9001 requirements, enabling product validation within the shortest time possible.

- Achieved a 20% increase in production efficiency by optimally utilizing engineering systems, machinery and processes.

- Reduced downtime associated with equipment maintenance and repairs by 33%, streamlining the entire process and saving $50,000 annually.

- Optimized existing designs of electronic components to ensure they met necessary industry standards while conforming to safety regulations; increased product quality by 15%.

- Participated actively in cross-functional teams for various research & development projects; successfully designed several prototypes within a 3 month period using CAD software programs such as SolidWorks® and Autodesk Inventor® Pro 2019+.

- Diligently followed project timelines set out by management when completing assigned tasks, resulting in completion times being cut down from an average of 6 weeks to 4 weeks per project cycle on average.

- Coordinated and managed the design, development and testing of various engineering projects; reduced product cost by 10% while increasing performance efficiency by 15%.

- Compiled complex test results from laboratory experiments to develop detailed reports for senior management team; implemented new protocols that resulted in a 20-hour reduction in project completion time.

- Proficiently utilized CAD software such as AutoCAD, SolidWorks and Revit for designing mechanical systems parts, fixtures and assemblies with high precision accuracy (+/- 0.1 mm).

- Presented technical solutions to clients based on their specific requirements using presentations & visual aids; secured $50K worth of contracts after successful negotiations with customers last quarter.

- Implemented innovative processes across multiple departments within organization to increase productivity levels while minimizing resources costs by 25%.

- Introduced new processes and technologies to improve efficiency of engineering systems, increasing productivity by 25% in the past year.

- Analyzed test data from experiments and simulations to identify patterns, trends and discrepancies; identified root causes of issues that had caused a production downtime issue for 3 months.

- Monitored quality control tests on various engineering components used in manufacturing plants; reduced instances of defective parts by 40%.

- Operated CNC machinery safely with precision accuracy when producing parts according to design specifications, reducing wastage levels by 11%.

- Substantially increased energy efficiency at two major factories through optimizing existing systems as well as recommending new technology upgrades; saved over $50K annually in utility costs alone.

- Developed and implemented 12 new engineering processes to ensure the quality of designs and reduce production time by 25%.

- Tested, evaluated and documented results for over 50 mechanical systems in order to assess performance standards and suggest improvements where needed.

- Troubleshot complex technical issues for 10+ clients across various industries; reduced downtime by 33% with successful resolution of problems on average within two hours.

- Accurately collected data using sophisticated equipment such as oscilloscopes, calipers and micrometers while conducting experiments in laboratory settings; saved $7000 annually on supplies due to efficiency gains from improved accuracy rates.

- Assessed project specifications prior to development phases in order to determine feasibility before allocating resources; completed projects ahead of schedule with a 15% cost savings compared against initial budget estimates.

- Independently inspected and tested engineering designs, components and prototypes to ensure they met the highest quality standards; improved production efficiency by 33%.

- Prepared detailed technical reports on completed projects that provided comprehensive data analysis and insight into performance metrics; reduced development time by 18%.

- Improved existing product design specifications through reverse-engineering tests of customer feedback samples; increased customer satisfaction scores by 56%.

- Developed 3D models using AutoCAD software for a range of mechanical parts in support of prototyping activities, achieving an average accuracy score of 97% across all test results.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require a candidate to be proficient in AutoCAD, while Organization XYZ may expect the applicant to have experience with Solidworks.

It is important to tailor your skills section of your resume for each job you are applying for because many employers use applicant tracking systems (ATS) these days. These computer programs scan resumes for certain keywords before passing them on to a human.

Once listed here, it can also be beneficial to elaborate further on the most pertinent engineering technologist skills in other sections such as the summary or experience section.

Below is a list of common skills & terms:

- AutoCAD

- AutoCAD Civil 3D

- CAD

- Civil Engineering

- Construction Management

- Continuous Improvement

- Contract Management

- Electrical Engineering

- Electronics

- Energy

- Engineering

- Engineering Management

- GIS

- Gas

- Inspection

- Lean Manufacturing

- Manufacturing

- Mechanical Engineering

- Petroleum

- Process Improvement

- Product Development

- Project Engineering

- Project Planning

- Road

- Root Cause Analysis

- SOLIDWORKS

- Surveying

- Team Leadership

- Teamwork

- Testing

- Time Management

- Troubleshooting

4. Education

Adding an education section to your engineering technologist resume is highly recommended, especially if you are fresh out of school or have limited work experience. If you have been in the industry for a while and want to showcase more relevant job history, then it may be better to omit an education section altogether.

If you include an education section on your resume, make sure to mention courses related to the engineering technologist role as well as any notable projects or assignments that demonstrate your skillset.

Associate Degree in Engineering Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have been tested and certified by an accredited organization, giving them confidence in your abilities.

If the job posting mentions any specific certifications or qualifications, make sure to include these on your resume so hiring managers can quickly see how qualified you are for the position. Additionally, if there are any professional development courses or other industry-related training programs that you have completed, be sure to list those as well!

Certified Engineering Technologist (CET)

National Council of Ex

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Ettie Sipes, this would be Ettie-Sipes-resume.pdf or Ettie-Sipes-resume.docx.

7. Cover Letter

Writing a cover letter is an essential part of the job application process. It is a document that accompanies your resume and should be tailored to each position you apply for.

Cover letters provide recruiters with more information about who you are, what skills and experiences you have to offer and why they should hire you over other applicants. They also give hiring managers insight into how well written and articulate you are – two qualities highly sought after in today’s competitive job market!

Below is an example cover letter:

Dear Glenda,

I am writing to apply for the Engineering Technologist position at your company. With my experience in engineering design and project management, as well as my knowledge of various software programs, I am confident that I would be a valuable asset to your team.

In my current role as an Engineering Technologist at [company name], I have been responsible for designing and overseeing the construction of various projects, such as bridges and highways. I have also managed teams of engineers and technicians, ensuring that projects are completed on time and within budget. In addition, I have developed strong relationships with clients and other stakeholders, which has resulted in repeat business.

I am knowledgeable in a variety of software programs used in engineering, such as AutoCAD, Revit, Civil 3D, STAAD Pro,and Microsoft Project. I am also familiar with environmental regulations and standards related to engineering projects. My combination of technical skills and practical experience will enable me to contribute to the success of your organization.

I look forward to discussing this opportunity with you further. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions about my qualifications or experience.

Sincerely,

Ettie

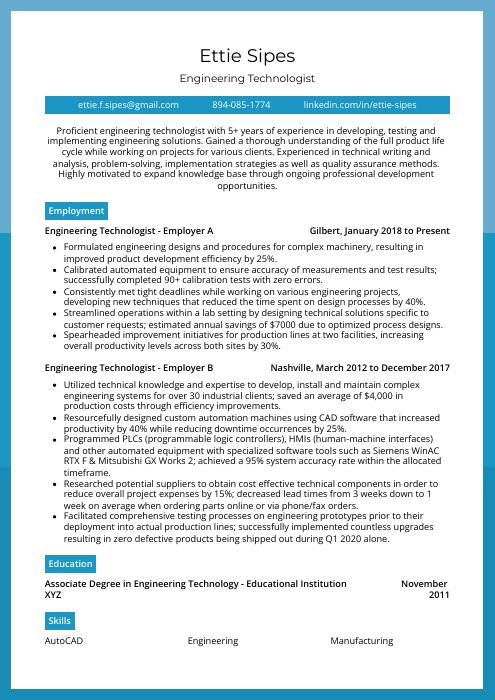

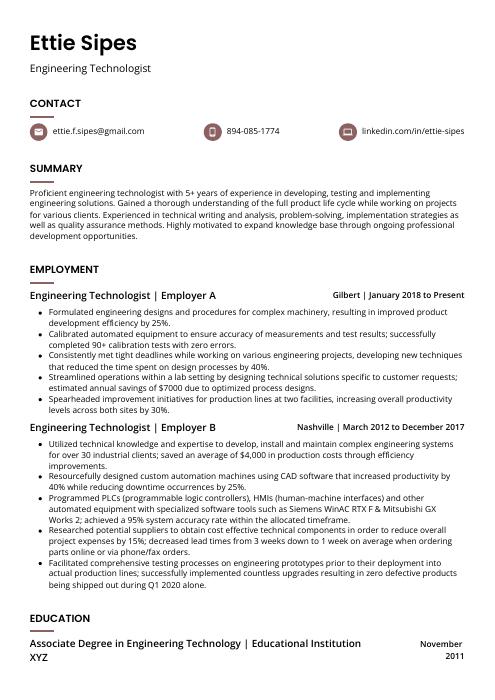

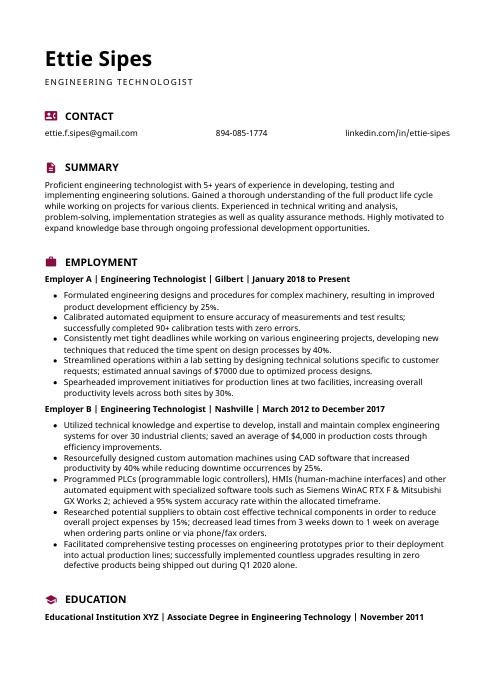

Engineering Technologist Resume Templates

Jerboa

Jerboa Cormorant

Cormorant Dugong

Dugong Pika

Pika Rhea

Rhea Fossa

Fossa Hoopoe

Hoopoe Ocelot

Ocelot Bonobo

Bonobo Lorikeet

Lorikeet Echidna

Echidna Quokka

Quokka Markhor

Markhor Numbat

Numbat Gharial

Gharial Kinkajou

Kinkajou Saola

Saola Axolotl

Axolotl Indri

Indri Rezjumei

Rezjumei