Engineering Technician Resume Guide

Engineering technicians help engineers design, test, and manufacture a variety of products. They use technical drawings and specifications to create prototypes or build items from scratch. They also troubleshoot existing systems and offer suggestions for improvements in product performance or cost efficiency.

Your engineering skills make you a perfect fit for any technical team. But employers won’t know what you can bring to the table if they don’t see your resume first. To show them how valuable an asset you are, write a standout resume that highlights your unique skill set and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

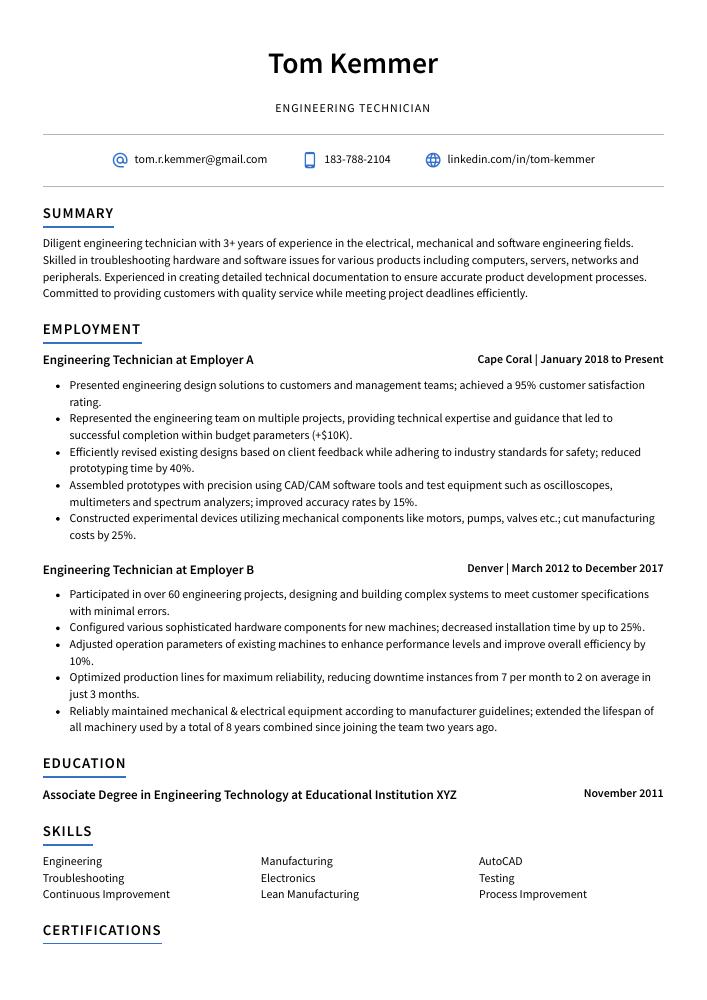

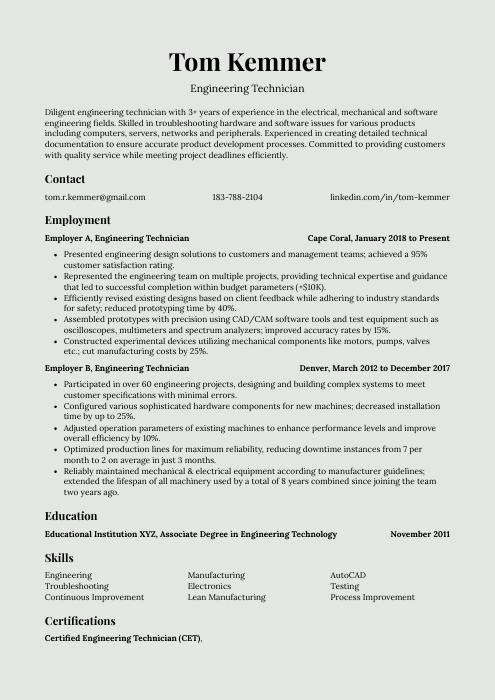

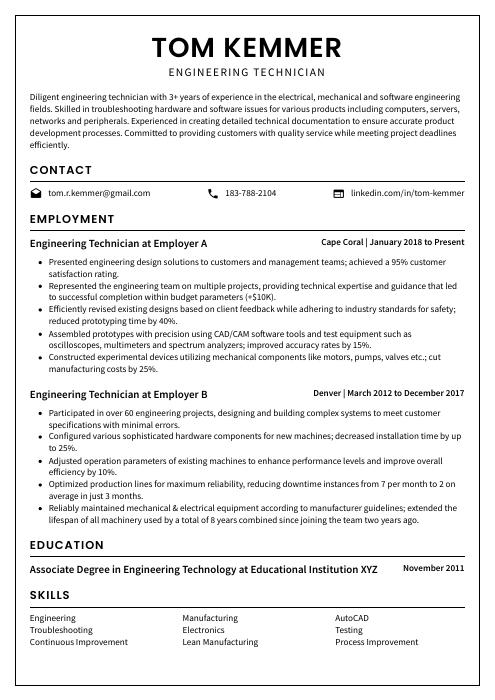

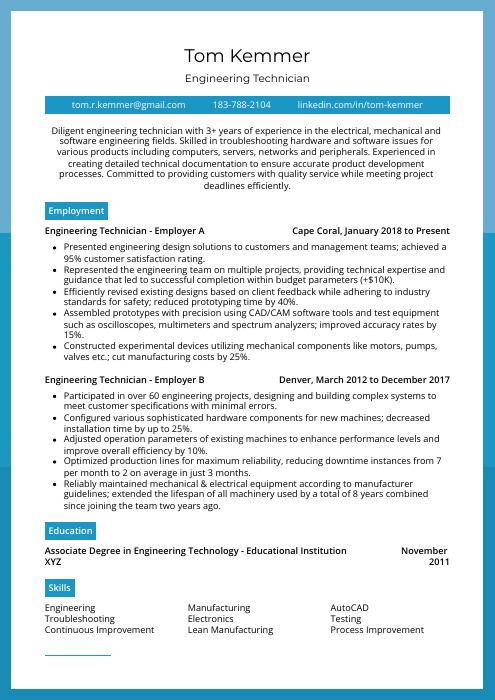

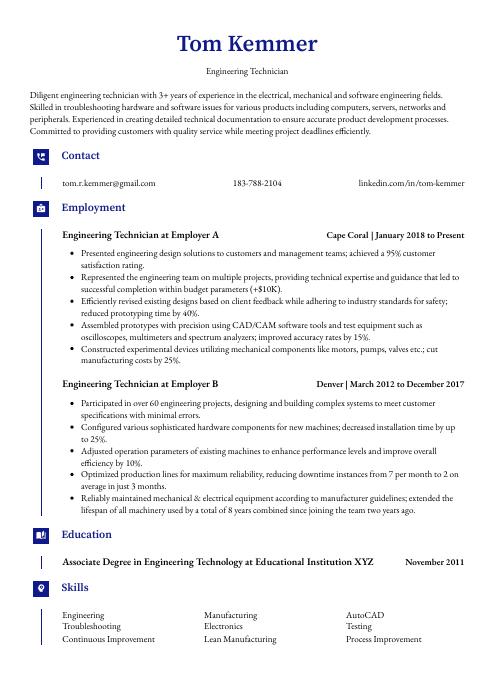

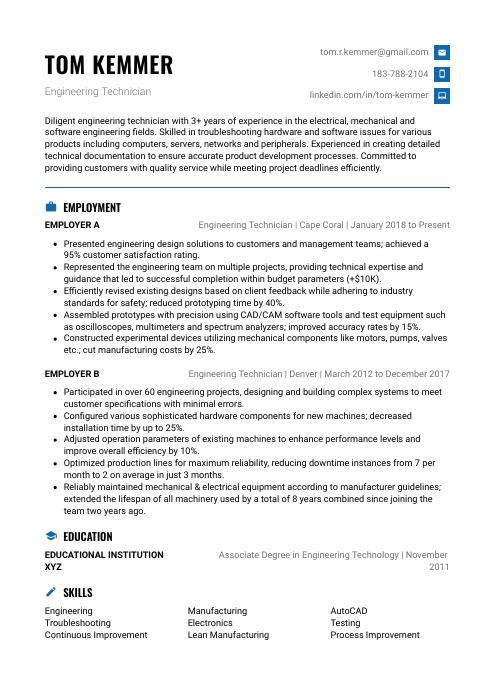

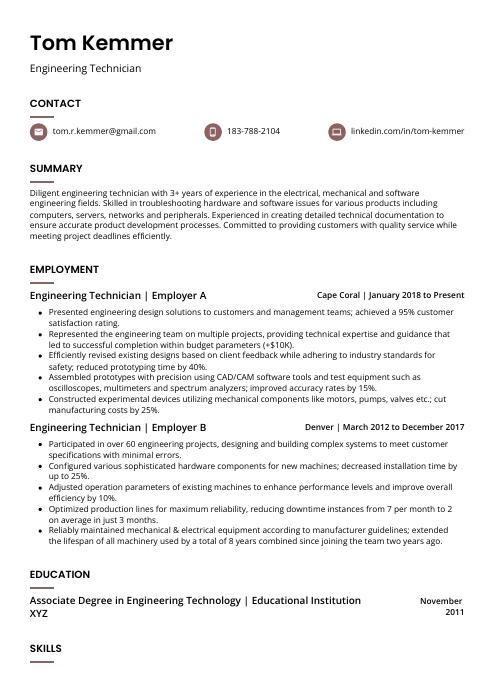

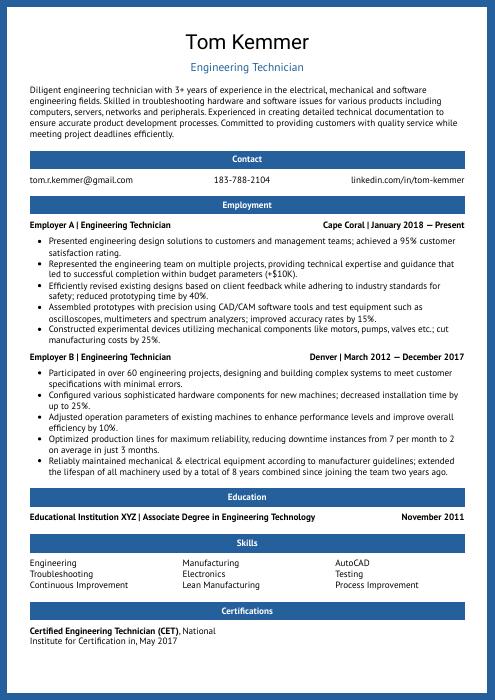

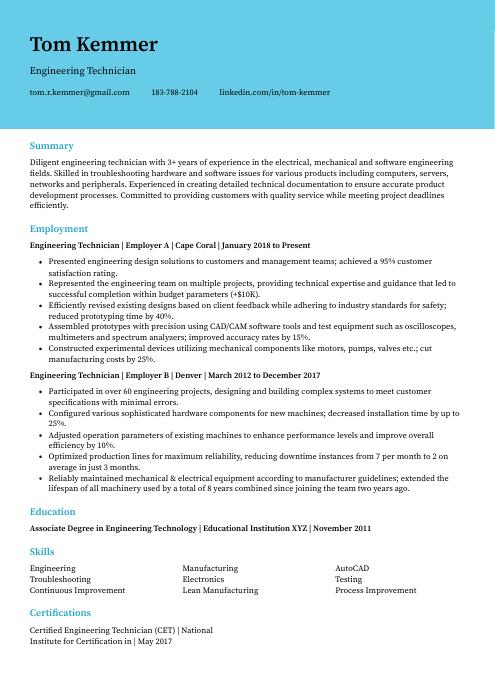

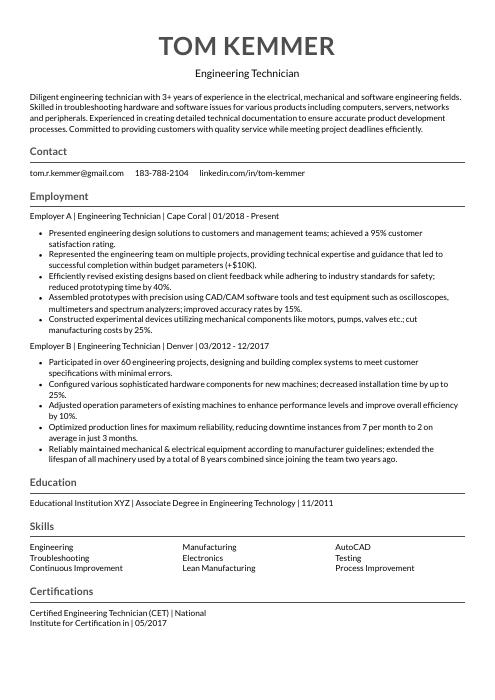

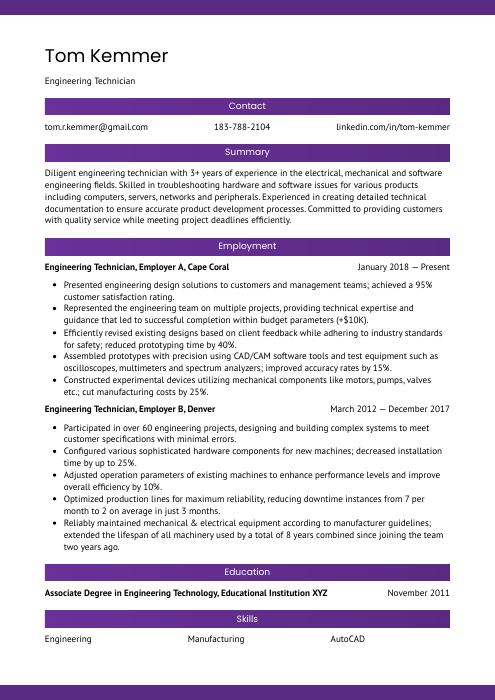

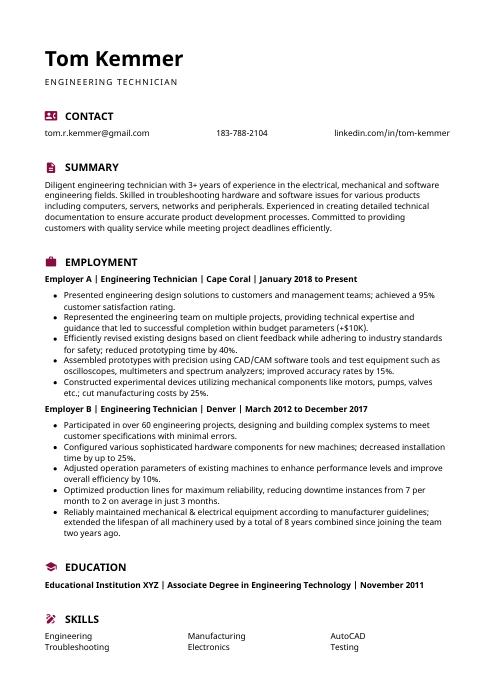

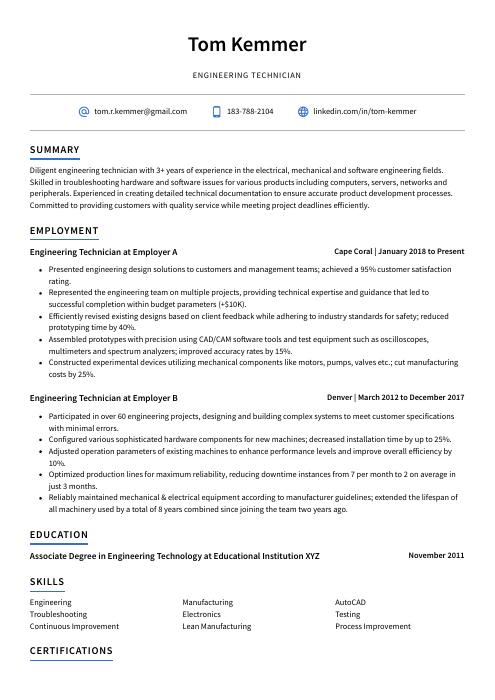

Engineering Technician Resume Sample

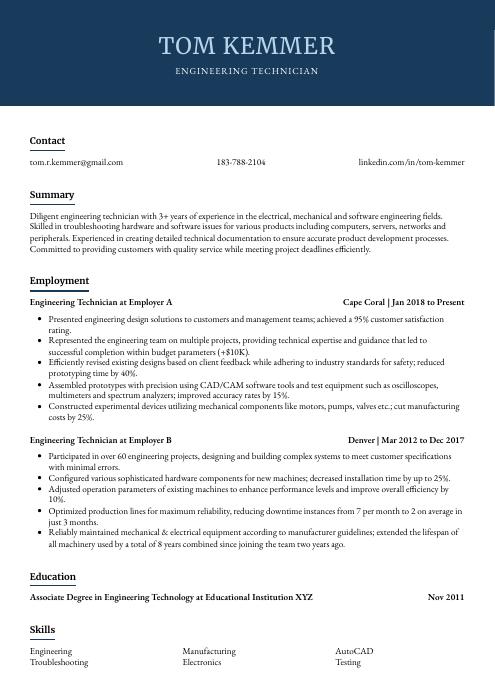

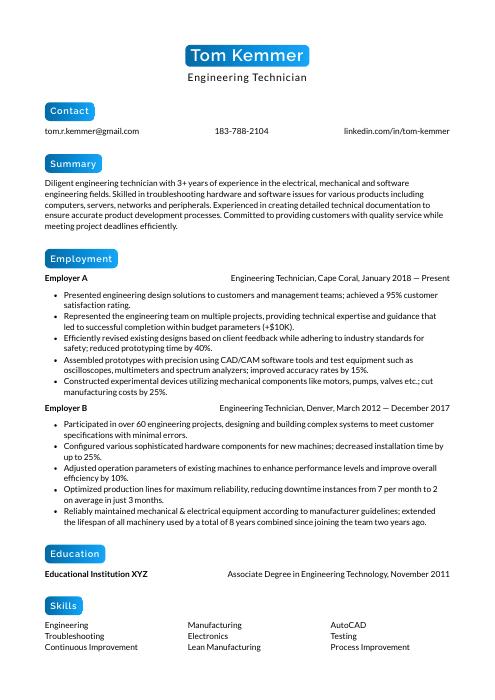

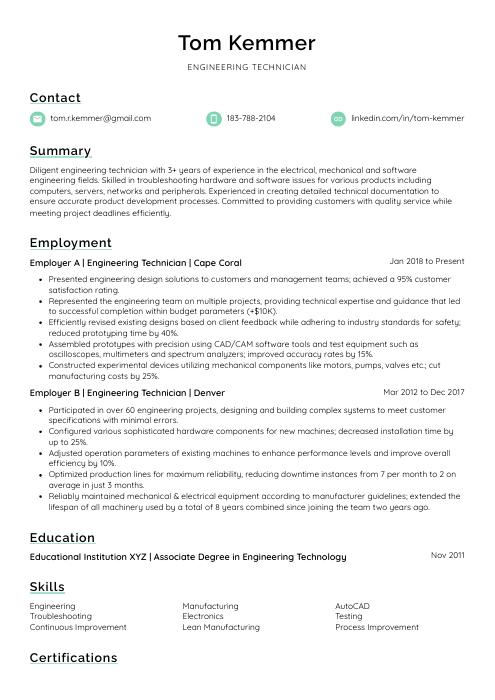

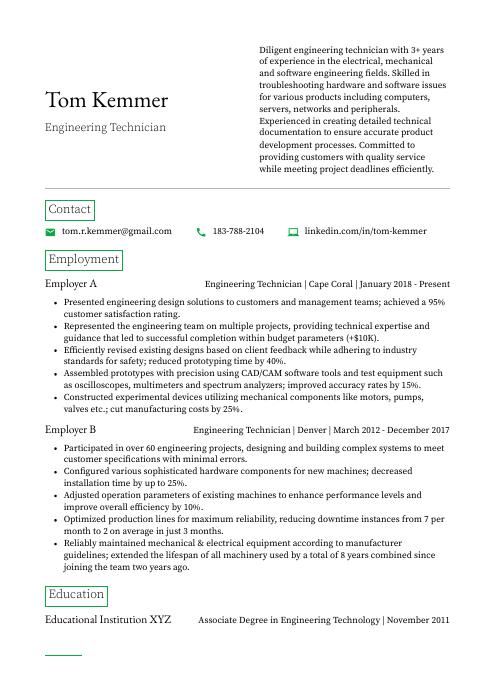

Tom Kemmer

Engineering Technician

[email protected]

183-788-2104

linkedin.com/in/tom-kemmer

Summary

Diligent engineering technician with 3+ years of experience in the electrical, mechanical and software engineering fields. Skilled in troubleshooting hardware and software issues for various products including computers, servers, networks and peripherals. Experienced in creating detailed technical documentation to ensure accurate product development processes. Committed to providing customers with quality service while meeting project deadlines efficiently.

Experience

Engineering Technician, Employer A

Cape Coral, Jan 2018 – Present

- Presented engineering design solutions to customers and management teams; achieved a 95% customer satisfaction rating.

- Represented the engineering team on multiple projects, providing technical expertise and guidance that led to successful completion within budget parameters (+$10K).

- Efficiently revised existing designs based on client feedback while adhering to industry standards for safety; reduced prototyping time by 40%.

- Assembled prototypes with precision using CAD/CAM software tools and test equipment such as oscilloscopes, multimeters and spectrum analyzers; improved accuracy rates by 15%.

- Constructed experimental devices utilizing mechanical components like motors, pumps, valves etc.; cut manufacturing costs by 25%.

Engineering Technician, Employer B

Denver, Mar 2012 – Dec 2017

- Participated in over 60 engineering projects, designing and building complex systems to meet customer specifications with minimal errors.

- Configured various sophisticated hardware components for new machines; decreased installation time by up to 25%.

- Adjusted operation parameters of existing machines to enhance performance levels and improve overall efficiency by 10%.

- Optimized production lines for maximum reliability, reducing downtime instances from 7 per month to 2 on average in just 3 months.

- Reliably maintained mechanical & electrical equipment according to manufacturer guidelines; extended the lifespan of all machinery used by a total of 8 years combined since joining the team two years ago.

Skills

- Engineering

- Manufacturing

- AutoCAD

- Troubleshooting

- Electronics

- Testing

- Continuous Improvement

- Lean Manufacturing

- Process Improvement

Education

Associate Degree in Engineering Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Engineering Technician (CET)

National Institute for Certification in

May 2017

1. Summary / Objective

A resume summary/objective is the first thing a potential employer will read and is your chance to make an impression. As an engineering technician, you should use this section to highlight your technical skills and experience as well as any certifications or awards you have earned in the past. You could also mention how many years of experience you have working with various types of machinery, what kind of projects you’ve worked on, and any specializations that set you apart from other candidates.

Below are some resume summary examples:

Committed engineering technician with 5+ years of experience in a variety of industries. Experienced in troubleshooting, repairing, and maintaining complex mechanical systems. At ABC Engineering Company, supervised the installation and maintenance of machines for several projects while ensuring accuracy and safety standards were met. Highly organized professional who is able to manage multiple tasks simultaneously with excellent time management skills.

Driven engineering technician with over 8 years of experience in design, development and maintenance of electronic systems. Experienced with troubleshooting complex electrical problems on site or in the lab. Proven ability to develop innovative solutions for challenging engineering projects and create clear documentation for customer service use. Awarded Technician Of The Year at XYZ Inc for consistently demonstrating excellent problem-solving skills.

Seasoned engineering technician with 8+ years of experience in designing, building and installing complex systems. Passionate about applying technical expertise to develop innovative solutions that meet customer needs. Experienced in troubleshooting problems, analyzing data and leading teams on challenging projects. Looking to join ABC Tech as an Engineering Technician where I can leverage my skillset for the benefit of the company’s success.

Amicable engineering technician with 4+ years of experience troubleshooting and repairing complex electronic systems. Highly adept in identifying issues, performing preventative maintenance, installing new parts and components, preparing reports on repairs/maintenance activities, and providing technical support to end-users. Proven record of successfully completing projects under tight deadlines while adhering to safety regulations.

Skilled engineering technician with over 5 years of experience in the design, development, and testing of mechanical systems. Expertise includes troubleshooting complex equipment issues to identify root cause and develop creative solutions. Recent success at XYZ Company included designing a new system that increased production efficiency by 20%. Looking to bring my knowledge and skillset to ABC Tech as an Engineering Technician.

Dependable engineering technician with 10+ years of experience in hands-on roles for design and fabrication, project management, and CAD/CAM operations. Achieved an average 20% reduction in production costs by improving process efficiency at previous employers. Seeking to join ABC Engineering to apply expertise towards the development of innovative products that meet customer requirements while staying within budget constraints.

Talented engineering technician with 5+ years of experience in the engineering and manufacturing industry. Skilled in troubleshooting, diagnosing, and repairing complex problems associated with various types of industrial machinery. Experienced in developing preventative maintenance plans for systems to reduce downtime costs by 25%. Achieved certification as a Quality Engineer Technician at XYZ Corporation.

Energetic engineering technician with 8+ years of experience troubleshooting and repairing complex mechanical, electrical, and electronic systems. Experienced in designing prototypes and providing technical guidance on product development projects. Seeking to join ABC Tech as an engineering technician so I can use my expertise to develop innovative solutions that meet customer needs.

2. Experience / Employment

The work history/experience section is where you list your past employment. It should be written in reverse chronological order, with the most recent job listed first.

Stick to bullet points when writing this section; it makes it easier for the reader to take in what you have said quickly and efficiently. When describing what you did, provide detail and quantifiable results whenever possible.

For example, instead of saying “Performed maintenance on engineering equipment,” say something like “Conducted preventative maintenance on 10+ pieces of engineering equipment per week, resulting in a 25% reduction of downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Installed

- Operated

- Calibrated

- Troubleshot

- Inspected

- Programmed

- Monitored

- Tested

- Repaired

- Fabricated

- Analyzed

- Adjusted

- Documented

- Configured

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Achieved a 95% success rate in the installation, testing and maintenance of complex engineering systems for over 100 clients.

- Compiled detailed technical instructions on troubleshooting equipment malfunctions to reduce repair time by 40%.

- Mentored 25+ junior technicians on safety standards, quality assurance processes and electrical/mechanical principles; increased team efficiency by 30%.

- Installed 50+ computer programs used to support sophisticated machine operations with minimal supervision from engineers or managers.

- Resourcefully designed automated solutions for 24 production lines that improved output accuracy by 20% and saved $10,000 in labor costs.

- Successfully operated mechanical, electrical and hydraulic systems/equipment to conduct experiments with a 95% success rate; reduced errors in test data by 22%.

- Developed technical documents such as drawings, datasheets and schematics to ensure that engineering components met industry standards; decreased time of design reviews by 25 hours per week.

- Structured testing processes for new products using innovative techniques which increased product reliability and quality assurance by 7%.

- Programmed robotic automation systems used in manufacturing production lines while ensuring safe working conditions; improved output efficiency by 5%.

- Tested electronic circuits under different environmental conditions (temperature, humidity etc) according to customer specifications within 3 days of turnaround time on average.

- Utilized CAD software and 3D printing technology to design, build and test complex engineering systems; reduced prototype development time by 25%.

- Assessed incoming materials for quality assurance purposes prior to use in production processes, ensuring that all components met the required technical specifications; minimized defective parts rate from 10% to 2%.

- Meticulously maintained system logs of calibration certifications and preventive maintenance records on a daily basis according to industry safety standards; curbed downtime incidents by 20%.

- Spearheaded projects involving automation implementation initiatives, resulting in improved equipment performance with an increase of $50K annually in productivity savings.

- Streamlined manufacturing operations through process optimization strategies such as line balancing & cycle time reduction activities, cutting lead times by 15%.

- Analyzed complex engineering designs and systems, utilizing CAD software to develop 3D models of new products; improved accuracy by 15%.

- Reduced downtime in production processes by 20%, through the effective maintenance and repair of mechanical equipment such as pumps, motors and valves.

- Repaired faulty electrical components using hand tools and specialized diagnostic instruments; successfully completed 30+ repairs within a 2-hour window on average.

- Thoroughly tested all repaired or replaced parts for quality assurance before returning them to service; increased functional efficiency rate from 65% to 95%.

- Troubleshot problems with industrial robotic arms, installing new programming sequences when necessary over 10 occasions during last quarter alone to minimize disruption in operations workflow.

- Prepared and implemented technical solutions and procedures to improve engineering operations by 15%; generated new designs, plans and drawings using CAD/CAM software.

- Improved the accuracy of parts production processes by meticulously inspecting components for defects; identified opportunities for streamlining assembly tasks which saved 10% in man-hours per week.

- Reorganized existing databases of engineering materials, tools and equipment to ensure efficient tracking systems were utilized at all times; reduced search time by 25%.

- Diligently maintained machine shop facilities with daily repairs on machines such as lathes, grinders & milling cutters while adhering strictly to safety protocols established within the organization.

- Monitored complex electronic systems and provided technical support when necessary; created detailed reports on test results which enabled engineers to make critical decisions quickly and accurately resulting in an increase of productivity output by 21%.

- Calibrated and tested engineering components and systems to ensure accuracy, improving precision levels by 10% and reducing product defects.

- Expedited the development of new products by researching customer needs, developing prototypes and providing technical support during design process; reduced time-to-market for projects by 25%.

- Coordinated with engineers to collect data from experimental trials, analyze results using advanced mathematical calculations & draw conclusions/recommendations on further improvements needed in project designs.

- Demonstrated strong problem solving abilities when troubleshooting issues related to electrical devices such as motors, generators or switchboards; resolved problems within 4 hours with 90% success rate.

- Confidently operated high end testing equipment including oscilloscopes, signal analyzers & function generators for debugging complex circuit boards; completed tests in half the standard time frame without compromising on quality standards.

- Substantially improved the efficiency of engineering processes by introducing new tools and technologies, resulting in a 20% reduction in production time.

- Introduced advanced testing procedures to ensure quality control standards were met; inspected over 30 products per hour with an accuracy rate above 99%.

- Inspected and tested various machinery components for functionality, preventing costly repairs or replacements due to malfunctions or breakdowns.

- Documented all test results on a daily basis, ensuring that records were up-to-date at all times; documented findings from over 500 tests each month with zero errors reported throughout this period of employment.

- Advised maintenance teams on suitable technical solutions based on analysis of data gathered during inspections and tests; provided guidance which saved $1,500 worth of repair costs last year alone.

- Tested and evaluated the performance of engineering components, systems and machinery; improved overall efficiency by 20% through effective testing.

- Fabricated complex prototypes from raw materials using mechanical drawings and CAD models; reduced prototyping time by 30%.

- Formulated product specifications based on customer requirements to ensure that each component met all safety standards set out in the relevant industry regulations.

- Facilitated installation and commissioning activities for various machineries at client sites according to technical instructions; completed projects within strict deadlines with minimal supervision.

- Effectively documented maintenance procedures for high-end equipment to reduce machine downtime by 15%.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in using AutoCAD and another may be looking for someone with knowledge of Solidworks.

To ensure that your resume is seen by the right people, you should customize the skills section to each job posting you are applying for. This will help applicant tracking systems pick up on relevant keywords and pass it along to a human reviewer who can then decide if they want to invite you in for an interview or not.

You should also mention some of these skills in other sections such as the summary/objective statement or work experience so that recruiters get a more detailed picture of what makes you qualified for this particular engineering technician position.

Below is a list of common skills & terms:

- AutoCAD

- CAD

- Civil Engineering

- Construction Management

- Continuous Improvement

- DoD

- Electrical Engineering

- Electronics

- Engineering

- Engineering Management

- Lean Manufacturing

- Manufacturing

- Process Improvement

- Product Development

- Program Management

- Project Planning

- Root Cause Analysis

- SOLIDWORKS

- Security Clearance

- Six Sigma

- Team Leadership

- Teamwork

- Test Equipment

- Testing

- Time Management

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it is important to mention your education below the objective statement. However, if you have significant engineering technician experience that needs to be showcased, you may not need an education section at all.

If an education section is included, try to include courses and subjects related to the engineering technician role for which you are applying.

Associate Degree in Engineering Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are an important part of your resume and can help you stand out from other applicants. They demonstrate to potential employers that you have been tested in a given field by a reputable organization, proving that you are proficient in the skill or knowledge required for the job.

Including certifications on your resume is especially beneficial if they relate directly to the position being applied for, as it shows hiring managers that you possess specific qualifications necessary for success in the role.

Certified Engineering Technician (CET)

National Institute for Certification in

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Tom Kemmer, this would be Tom-Kemmer-resume.pdf or Tom-Kemmer-resume.docx.

7. Cover Letter

Providing a cover letter in addition to your resume is an excellent way of introducing yourself and highlighting why you are the best candidate for a role. It consists of 2 to 4 short paragraphs that provide more details about who you are, what experience you have and how it relates to the job in question.

Cover letters aren’t always required by employers, but submitting one will give recruiters greater insight into who you are as a professional and demonstrate your enthusiasm for the position.

Below is an example cover letter:

Dear Lavonne,

I am writing to apply for the engineering technician position at your company. I am a recent graduate of [university name] with a degree in mechanical engineering, and I have been working as an engineering technician for the past two years. In my current role, I work on a variety of projects, including designing and testing prototypes, conducting research, and preparing reports.

I am confident that I can be an asset to your team. My experience has given me strong problem-solving skills and the ability to think creatively when finding solutions. I am also experienced in using various software programs related to engineering, such as CAD and finite element analysis (FEA). In addition, my interpersonal skills are excellent, which is important for working effectively in a team environment.

If you would like to discuss my qualifications further or arrange an interview, please do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration.

Sincerely,

Tom

Engineering Technician Resume Templates

Numbat

Numbat Markhor

Markhor Pika

Pika Saola

Saola Cormorant

Cormorant Rhea

Rhea Gharial

Gharial Echidna

Echidna Fossa

Fossa Ocelot

Ocelot Dugong

Dugong Indri

Indri Jerboa

Jerboa Hoopoe

Hoopoe Axolotl

Axolotl Bonobo

Bonobo Kinkajou

Kinkajou Lorikeet

Lorikeet Quokka

Quokka Rezjumei

Rezjumei