Diesel Engineer Resume Guide

Diesel engineers are responsible for the design, development, and maintenance of diesel engines. They work on a variety of projects ranging from improving engine performance to developing more efficient fuel systems. Additionally, they inspect and repair existing engines to ensure optimal operation.

If you had a diesel engine in front of you, it would be no match for your skills. Still, employers don’t know who or what you can do. To tell them about your capabilities, write a resume that stands out from the rest.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

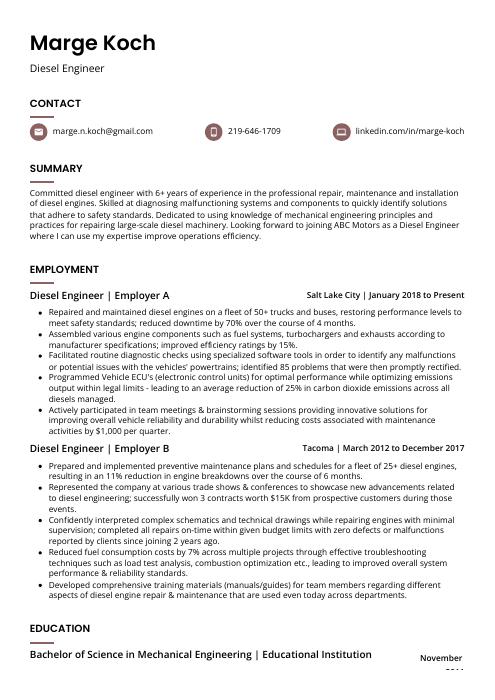

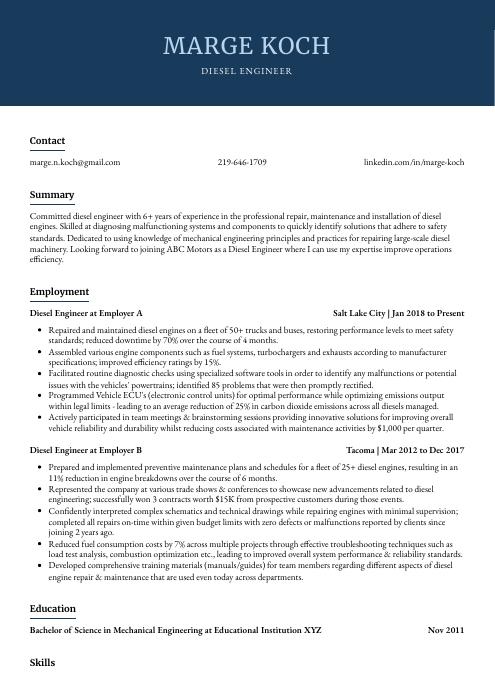

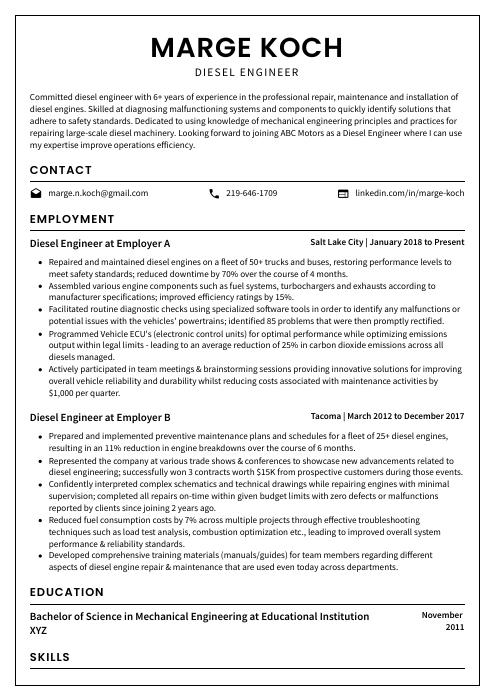

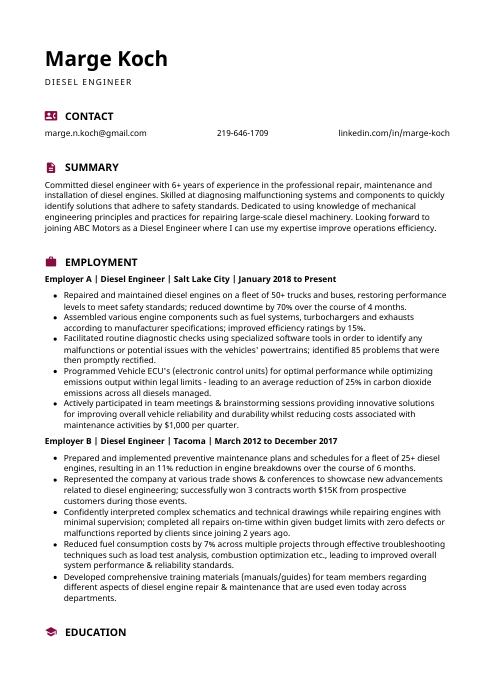

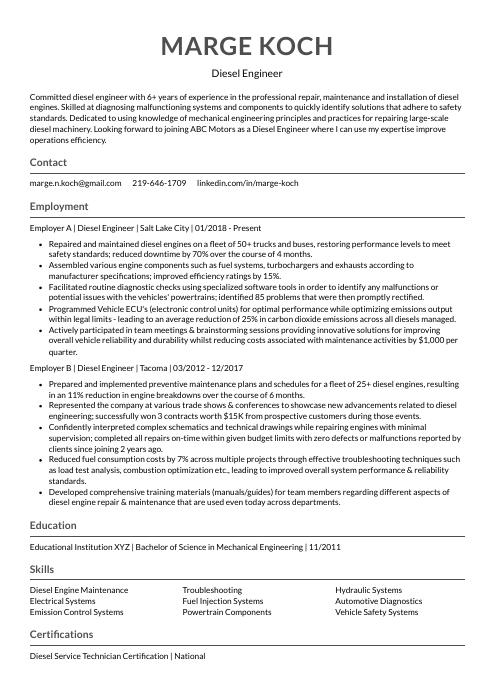

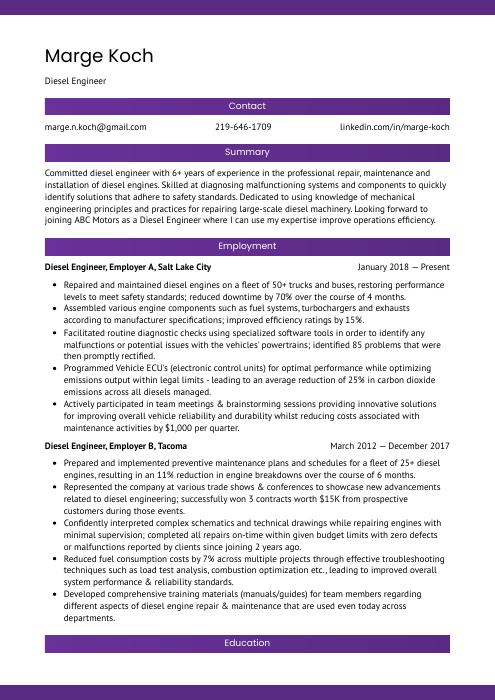

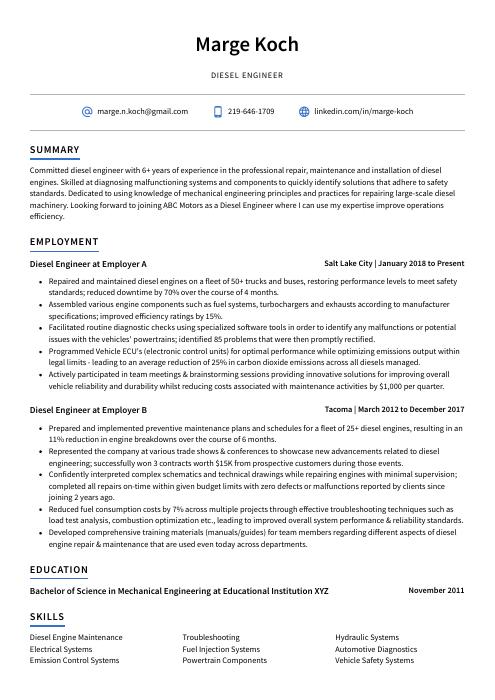

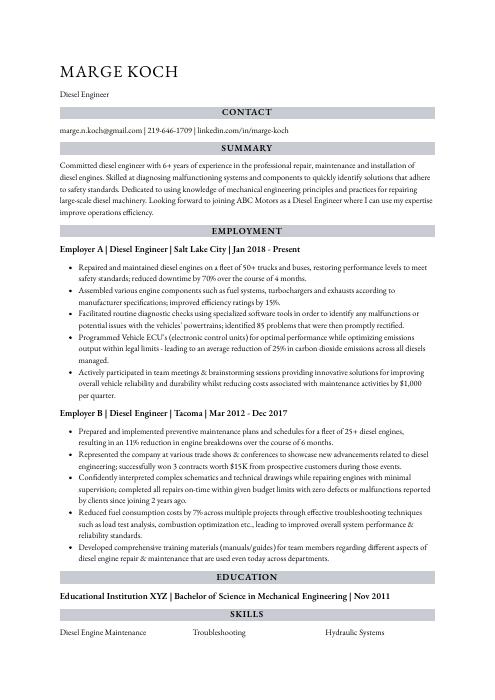

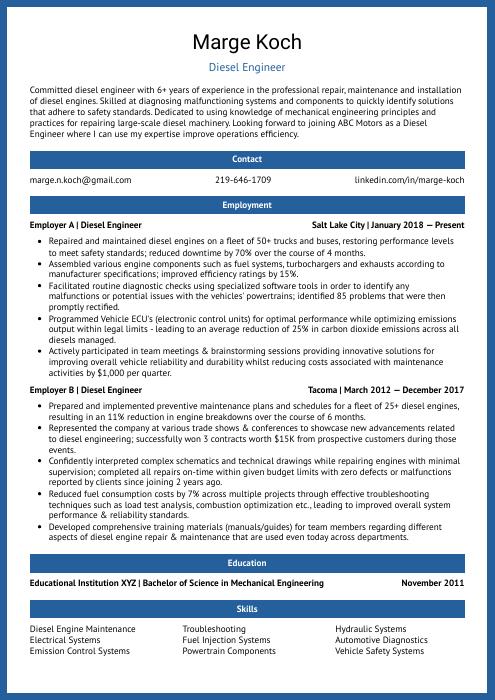

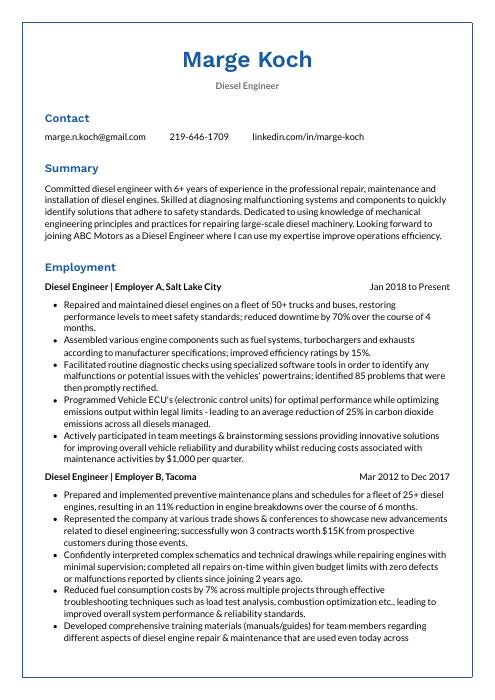

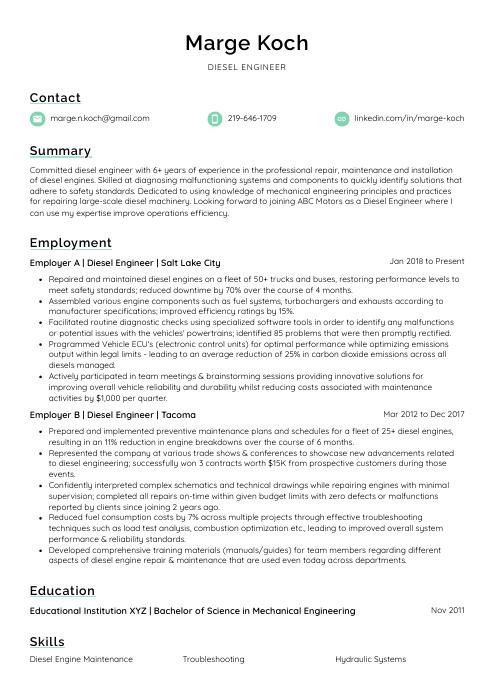

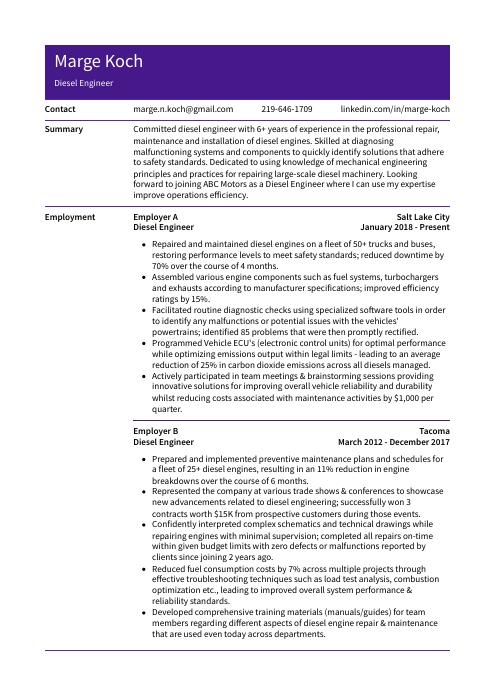

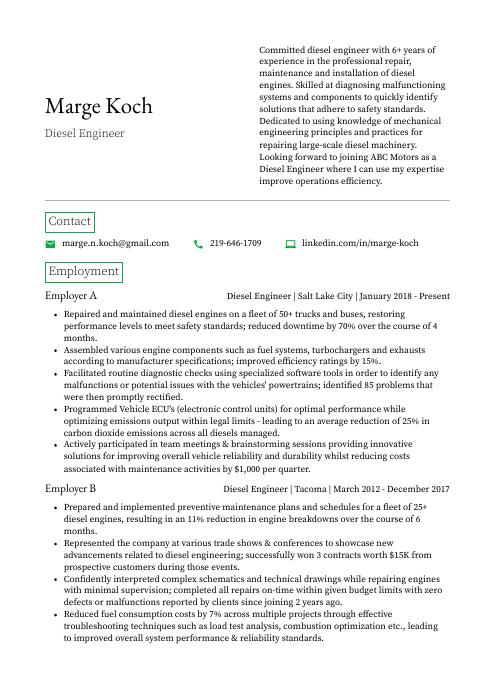

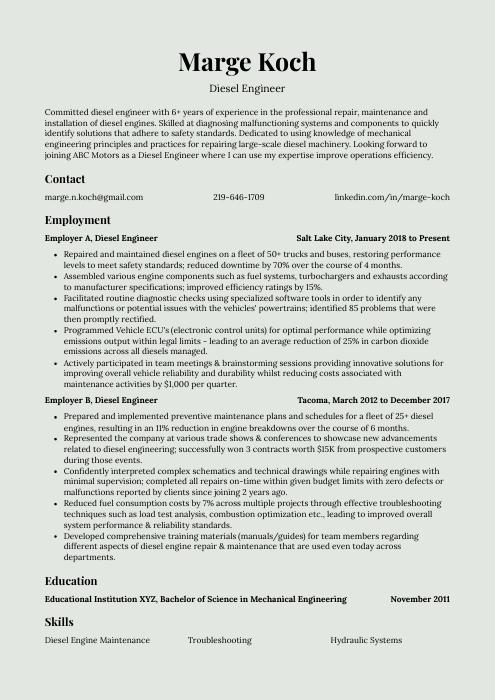

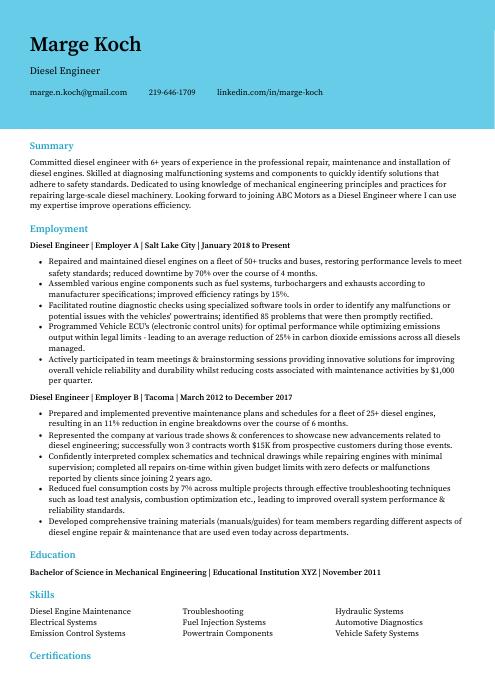

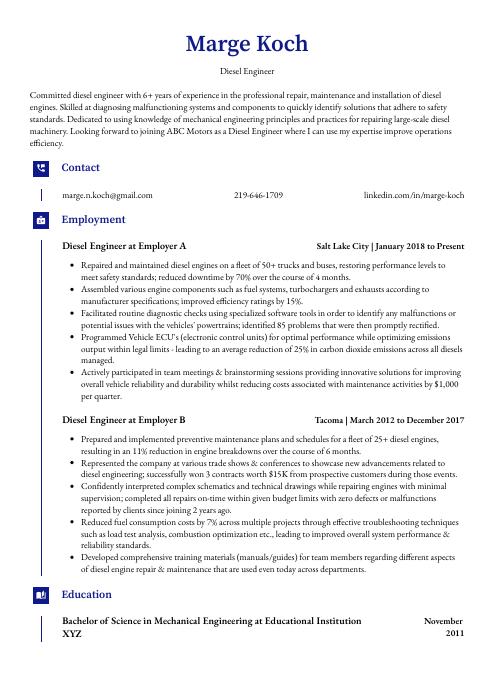

Diesel Engineer Resume Sample

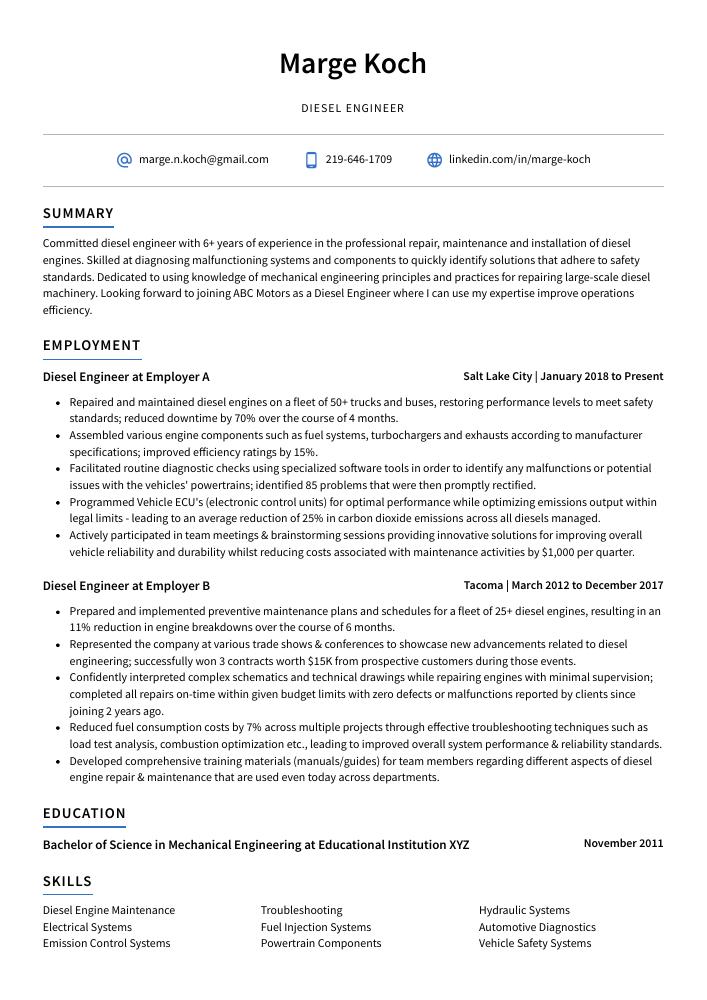

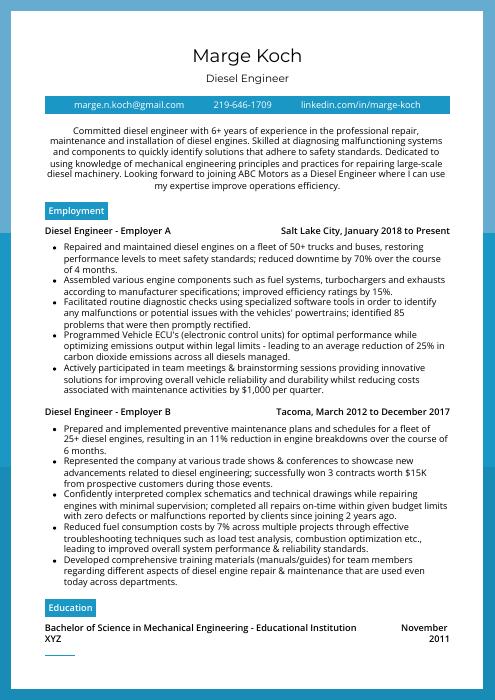

Marge Koch

Diesel Engineer

[email protected]

219-646-1709

linkedin.com/in/marge-koch

Summary

Committed diesel engineer with 6+ years of experience in the professional repair, maintenance and installation of diesel engines. Skilled at diagnosing malfunctioning systems and components to quickly identify solutions that adhere to safety standards. Dedicated to using knowledge of mechanical engineering principles and practices for repairing large-scale diesel machinery. Looking forward to joining ABC Motors as a Diesel Engineer where I can use my expertise improve operations efficiency.

Experience

Diesel Engineer, Employer A

Salt Lake City, Jan 2018 – Present

- Repaired and maintained diesel engines on a fleet of 50+ trucks and buses, restoring performance levels to meet safety standards; reduced downtime by 70% over the course of 4 months.

- Assembled various engine components such as fuel systems, turbochargers and exhausts according to manufacturer specifications; improved efficiency ratings by 15%.

- Facilitated routine diagnostic checks using specialized software tools in order to identify any malfunctions or potential issues with the vehicles’ powertrains; identified 85 problems that were then promptly rectified.

- Programmed Vehicle ECU’s (electronic control units) for optimal performance while optimizing emissions output within legal limits – leading to an average reduction of 25% in carbon dioxide emissions across all diesels managed.

- Actively participated in team meetings & brainstorming sessions providing innovative solutions for improving overall vehicle reliability and durability whilst reducing costs associated with maintenance activities by $1,000 per quarter.

Diesel Engineer, Employer B

Tacoma, Mar 2012 – Dec 2017

- Prepared and implemented preventive maintenance plans and schedules for a fleet of 25+ diesel engines, resulting in an 11% reduction in engine breakdowns over the course of 6 months.

- Represented the company at various trade shows & conferences to showcase new advancements related to diesel engineering; successfully won 3 contracts worth $15K from prospective customers during those events.

- Confidently interpreted complex schematics and technical drawings while repairing engines with minimal supervision; completed all repairs on-time within given budget limits with zero defects or malfunctions reported by clients since joining 2 years ago.

- Reduced fuel consumption costs by 7% across multiple projects through effective troubleshooting techniques such as load test analysis, combustion optimization etc., leading to improved overall system performance & reliability standards.

- Developed comprehensive training materials (manuals/guides) for team members regarding different aspects of diesel engine repair & maintenance that are used even today across departments.

Skills

- Diesel Engine Maintenance

- Troubleshooting

- Hydraulic Systems

- Electrical Systems

- Fuel Injection Systems

- Automotive Diagnostics

- Emission Control Systems

- Powertrain Components

- Vehicle Safety Systems

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Diesel Service Technician Certification

National Institute for Automotive Service Excellence (

May 2017

1. Summary / Objective

A resume summary/objective for a diesel engineer should demonstrate your expertise in the field, as well as highlight any special qualifications or certifications you may have. For example, you could mention the number of years of experience working on heavy-duty engines and vehicles, any specialized training courses taken to stay up to date with industry trends and technology advancements, and how you successfully troubleshooted complex mechanical issues at previous employers.

Below are some resume summary examples:

Driven diesel engineer with 5+ years of experience in the automotive industry. At XYZ, developed and implemented a new engine design that increased fuel efficiency by 20% and reduced emissions by 30%. Experienced in troubleshooting diesel engines, diagnosing problems, ordering parts as needed to complete repairs, and performing preventive maintenance. Possess excellent knowledge of mechanical engineering principles combined with strong analytical skills.

Well-rounded diesel engineer with 5+ years of experience in the diesel engine industry. Skilled at troubleshooting and repairing all types of diesel engines, from single-cylinder to multi-cylinder systems. Experienced in diagnosing complex problems and developing cost-effective solutions for optimal performance. Proven ability to collaborate with engineers, mechanics, technicians and operators on projects related to diesel technology advancement.

Seasoned diesel engineer with 5+ years of experience in providing expert technical support to diesel engines, power plants and related equipment. Expertise includes preventive maintenance and troubleshooting for a wide range of engine models. At XYZ Company, implemented performance-enhancing strategies that increased fuel efficiency by 11%. Achieved 100% customer satisfaction targets on all projects due to excellent problem-solving skills.

Accomplished diesel engineer with 8+ years of experience in the automotive industry. Possess a deep understanding of diesel engine systems and their components, as well as expertise in troubleshooting and repairing them. At XYZ, overhauled engines on 100 vehicles resulting in an increase of 5% efficiency while reducing emissions by 7%. Adept at working both independently and collaboratively to ensure successful outcomes.

Proficient diesel engineer with 8+ years of experience in the maintenance and repair of diesel engines for a wide range of industrial applications. Seeking to leverage technical expertise, troubleshooting skills, and knowledge of up-to-date engineering principles at ABC Company. At XYZ Corporation, improved engine efficiency by 20% through preventive maintenance techniques and advanced diagnostic methods.

Diligent diesel engineer with 10+ years of experience in developing and maintaining diesel engines. Adept at troubleshooting and repairing complex systems, diagnosing problems, creating preventative maintenance plans, and optimizing performance. Seeking to join ABC Diesel as a senior engineer to lead the team’s efforts in designing and building fuel-efficient engines for large commercial vehicles.

Detail-oriented diesel engineer with 8+ years of experience diagnosing, repairing, and maintaining diesel engines in a variety of working environments. Seeking to join ABC Company where expertise can be used to help maintain the highest level of performance for all vehicles and machines. In previous roles, reduced maintenance costs by 20% while ensuring 95% uptime on equipment utilization.

Enthusiastic diesel engineer with 7+ years of experience specializing in diesel engine design, maintenance, and performance optimization. Proven track record of successfully developing new systems to improve fuel efficiency while also reducing emissions by up to 50%. Seeking a position at ABC Co., where I can utilize my strong engineering background and creative problem-solving skills.

2. Experience / Employment

For the experience section, list your employment history in reverse chronological order, starting with the most recent job. Stick to bullet points to make it easier for readers to take in what you have said quickly.

When writing about each role, provide details on what you did and the results achieved. For example, instead of saying “Repaired diesel engines,” say something like “Diagnosed and repaired over 100+ faulty diesel engines per month using specialized tools.” This will give a better understanding of your capabilities as an engineer.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Diagnosed

- Inspected

- Operated

- Repaired

- Installed

- Troubleshot

- Assembled

- Adjusted

- Overhauled

- Tested

- Replaced

- Monitored

- Calibrated

- Programmed

- Serviced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Thoroughly inspected and maintained diesel engines in accordance with company standards, reducing equipment downtime by 45%.

- Formulated cost-effective solutions to repair major defects which resulted in a 20% decrease in maintenance costs over the course of 3 months.

- Troubleshot complex engine components using diagnostic tools; identified issues quickly and accurately saving up to 8 hours per incident on average.

- Expedited production process by optimizing machine operations, enabling the team to produce 10 units more than planned each day for three consecutive months resulting in an increase of $1300 in total revenue generated from sales during that period.

- Monitored fuel consumption levels across all vehicles within fleet and implemented new strategies for efficiency improvements which reduced overall usage by 12%.

- Competently maintained and repaired diesel engines in over 4,000 heavy-duty vehicles; reduced downtime by 30% due to accurate diagnosis of technical issues.

- Utilized advanced diagnostic software such as Cummins Insite & Detroit Diesel DDEC to troubleshoot complex problems across different makes and models of trucks.

- Participated in onsite visits for engine installations and repairs, providing solutions within agreed timelines while meeting all customer expectations with a 95% satisfaction rate.

- Spearheaded the development of innovative maintenance strategies that improved fuel efficiency by 10%, resulting in cost savings totaling $50,000 annually for the organization.

- Replaced defective parts according to industry standards using appropriate tools; restored equipment functionality with minimal disruption at an average repair time of 2 hours per vehicle.

- Serviced and maintained diesel engines and related equipment, ensuring that all safety protocols were followed; successfully completed 100+ repairs with no accidents or incidents reported.

- Operated various diagnostic systems to identify mechanical defects in engines, fuel pumps and other parts of the machinery; reduced repair time by 25% on average per engine.

- Inspected vehicles for damage and wear-and-tear issues such as broken hoses or loose connections, executing maintenance procedures within established deadlines; decreased downtime hours by 50%.

- Efficiently tested new components for compatibility with existing systems prior to installation, resulting in an increase of project completion rate from 75% to 95%.

- Overhauled 10+ diesel motors a week using advanced tools like torque wrenches & pressure gauges while adhering to prescribed industry standards; improved efficiency levels by 40%.

- Structured and maintained a fleet of 15 diesel engines and related parts, with regular inspections to ensure optimal performance; reduced engine downtime by 25%.

- Streamlined maintenance operations for all company vehicles through continuous monitoring of their condition and preventive servicing; increased overall vehicle efficiency by 30% in the last quarter.

- Calibrated over 50 pieces of advanced diagnostic equipment used in identifying problems within diesel engines, saving up to $5,000 on repairs annually.

- Successfully designed and implemented an automation system for scheduling routine engine checks, reducing labor hours required per checkup by 45%.

- Revised existing technical manuals according to changes made in the industry standards & protocols regarding repair techniques or new machinery specifications; improved safety ratings across all work sites by 10%.

- Reorganized production process for diesel engine repairs and maintenance, increasing work efficiency by 30% and reducing downtime by 2 hours per shift.

- Demonstrated advanced knowledge of engineering principles through successful diagnosis and repair of 20+ complex diesel engines in the last year.

- Tested components to identify mechanical issues with a range of small-scale industrial equipment; reduced need for costly replacements by 40%.

- Independently designed 5 new schematics to improve operational performance within a fleet of vehicles, resulting in fuel savings equivalent to $12K annually.

- Assessed technical data while inspecting existing systems onsite; identified potential safety hazards that were addressed quickly before any incidents occurred.

- Reliably maintained, serviced and repaired diesel engines for over 200 vehicles in the fleet; improved vehicle uptime by 21%.

- Improved fuel efficiency of an entire fleet of trucks by 23%, resulting in a cost reduction of $10,000 per quarter.

- Achieved highest customer satisfaction ratings year-over-year through timely diagnosis and repair of mechanical issues across all types of diesel engines.

- Advised technical teams on best practices related to service & maintenance activities to ensure quality outputs; reduced average turnaround time from 8 hours to 3 hours within 6 months.

- Presented detailed reports at monthly meetings outlining current trends & challenges related to diesel engine performance, as well as strategies/solutions proposed for improvement initiatives.

- Coordinated with other engineers to build and maintain diesel engines with a 30% increase in efficiency over the past year.

- Optimized engine performance by diagnosing issues and recommending repairs, resulting in an average reduction of repair costs by $4,500 per month.

- Installed more than 50 new diesel engines into various vehicles while adhering to safety regulations, successfully completing all projects on time and within budget constraints.

- Consistently maintained high-quality standards for engine parts procurement and assembly processes; improved customer satisfaction ratings from 75% up to 98%.

- Compiled reports & documentation related to periodic maintenance activities as well as any breakdowns encountered during work hours—resulted in 15+ successful preventative maintenance actions taken each week that minimized downtime or potential accidents caused by faulty machinery/engines.

- Introduced and implemented upgrades to the existing diesel engine fleet, resulting in an improved fuel efficiency of 13% and a reduction of CO2 emissions by 8%.

- Mentored junior engineers on proper maintenance routines for diesel engines and advised senior management on potential cost savings measures; reduced repair costs by $20,000 over 3 months.

- Diagnosed various problems with malfunctioning truck engines through troubleshooting techniques and skillful use of computer-based diagnostic tools; repaired 75+ vehicles within budgeted time frames each month.

- Adjusted engine components such as injectors, valves & filters according to manufacturer guidelines while utilizing specialized tools like torque wrenches and micrometers; upgraded 10 trucks per week from manual to automated systems without errors or delays.

- Proficiently operated both stationary rebuilders/test benches for overhauls along with mobile service units for remote repairs at customer sites; completed 200+ jobs within expected timelines during the last year’s peak season demand period alone.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for someone with experience in diesel engine maintenance and repair, whereas Organization XYZ may require knowledge of emissions control systems.

It is important to tailor the skills section of your resume to each job that you are applying for because many employers use applicant tracking systems these days. These computer programs scan resumes for certain keywords before passing them on to a human.

In addition to listing relevant skills here, it’s also advisable to discuss them further in other areas such as the summary or experience sections.

Below is a list of common skills & terms:

- Automotive Diagnostics

- Diesel Engine Maintenance

- Electrical Systems

- Emission Control Systems

- Fuel Injection Systems

- Hydraulic Systems

- Powertrain Components

- Troubleshooting

- Vehicle Safety Systems

- Welding and Fabrication

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you just graduated and have no work experience, list your education below your resume objective. However, if you’ve been working as a diesel engineer for years with plenty of different responsibilities to showcase, omitting the education section is totally fine.

If an education section is included, try to mention courses and subjects related to the diesel engineering job role that you are applying for.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field and can be an invaluable asset when applying for jobs. Employers will often look favorably on applicants who have taken the time to obtain certifications that are relevant to their industry, as it shows dedication and commitment.

When listing any certifications you may have obtained, make sure they are up-to-date and include details such as where you received them from, what level of certification was achieved, and how long ago it was earned. This information is important for employers so they know exactly what qualifications you possess.

Diesel Service Technician Certification

National Institute for Automotive Service Excellence (

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Marge Koch, this would be Marge-Koch-resume.pdf or Marge-Koch-resume.docx.

7. Cover Letter

Submitting a cover letter with your job application is an important step in the process of finding a new role. It’s made up of 2 to 4 paragraphs, usually separate from your resume, and provides more detail about who you are and why you’re the best fit for the position.

Cover letters give hiring managers insight into what kind of person you are, providing them with invaluable information that can’t be found on a resume alone. Although not always required by employers, writing one could make all the difference when it comes to getting noticed and securing an interview.

Below is an example cover letter:

Dear Susana,

I am writing in regards to your posting for a diesel engineer. With over 7 years of experience working as a diesel engine mechanic, I have the skills and knowledge to fill this role. I am confident that I can maintain and repair your fleet of trucks according to your specifications.

In my current position, I work with a team of mechanics to keep a fleet of 50 trucks on the road. We perform routine maintenance as well as repairs when necessary. My experience includes diagnosing problems, ordering parts, and making repairs. I have also performed complete engine rebuilds when needed.

I understand the importance of keeping costs down and will do everything possible to minimize downtime and maximize efficiency. My goal is always to get the job done right the first time so that your drivers can stay on schedule.

Please find attached my resume for your review along with three references from my supervisors who can attest to my skills as a diesel engine mechanic. If you have any questions or would like to discuss my qualifications further, please don’t hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration; I look forward hearing from you soon about this opportunity!

Sincerely,

Marge

Diesel Engineer Resume Templates

Rhea

Rhea Echidna

Echidna Kinkajou

Kinkajou Fossa

Fossa Bonobo

Bonobo Cormorant

Cormorant Hoopoe

Hoopoe Indri

Indri Jerboa

Jerboa Axolotl

Axolotl Numbat

Numbat Ocelot

Ocelot Markhor

Markhor Lorikeet

Lorikeet Pika

Pika Quokka

Quokka Saola

Saola Dugong

Dugong Gharial

Gharial Rezjumei

Rezjumei