Control Systems Engineer Resume Guide

Control systems engineers design, develop, install and maintain automated control systems used to monitor and control machinery or processes. They analyze the performance of existing hardware in order to identify areas for improvement, recommend changes based on their findings and test new equipment before it is implemented.

Your experience in control systems engineering is unparalleled, but employers don’t know who you are yet. To make them aware of your unique qualifications, create a resume that leaves them impressed.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

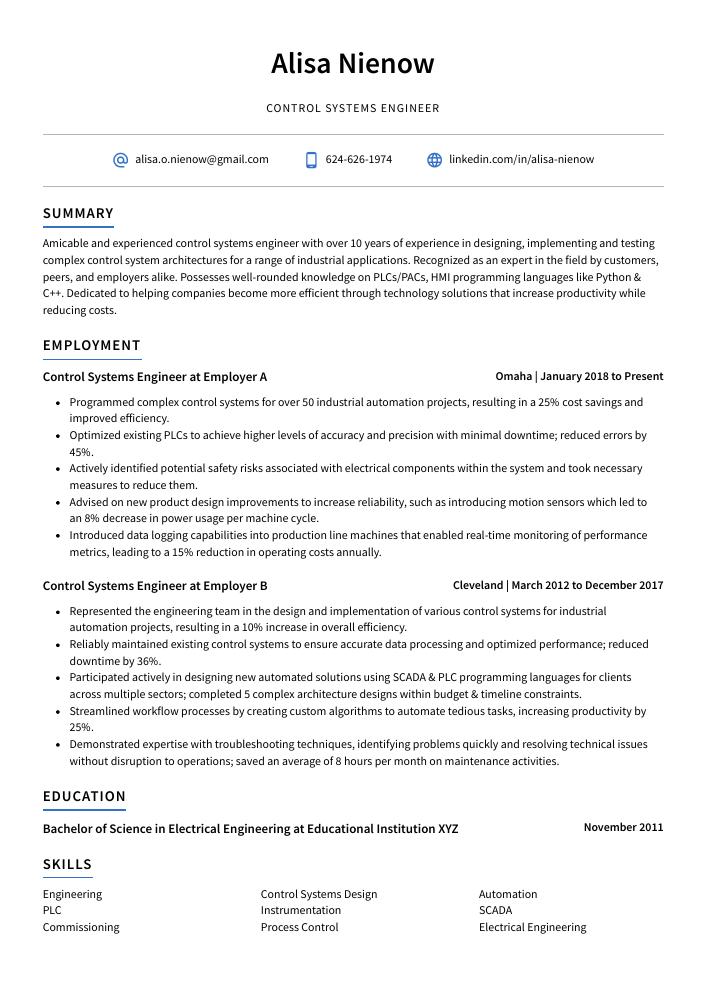

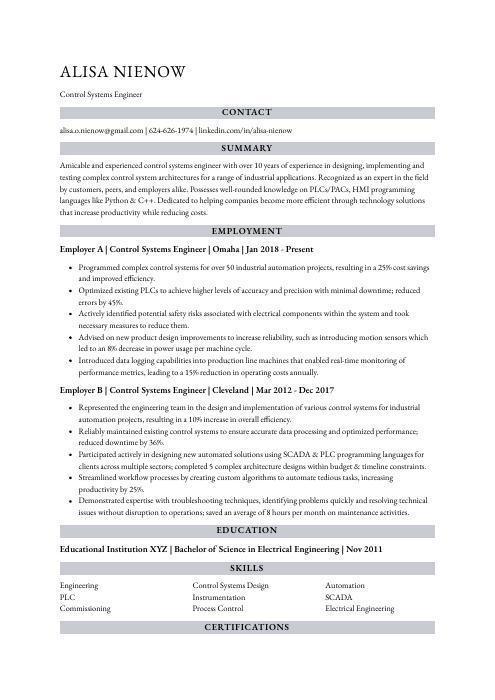

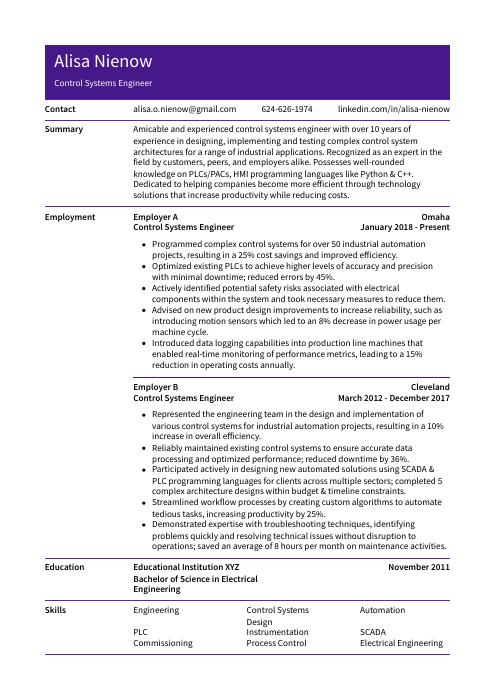

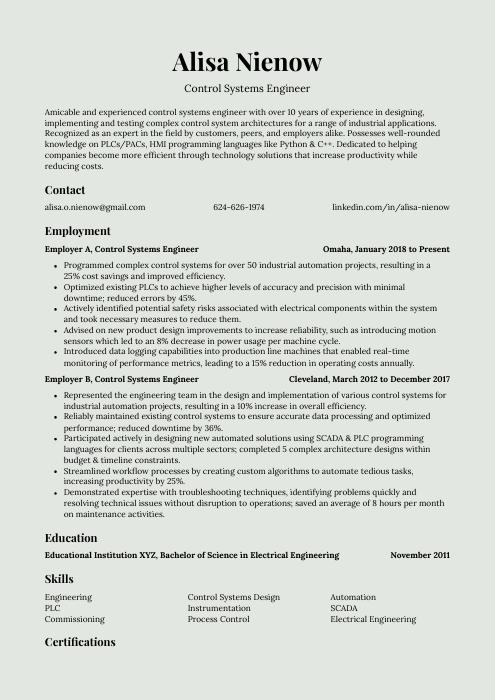

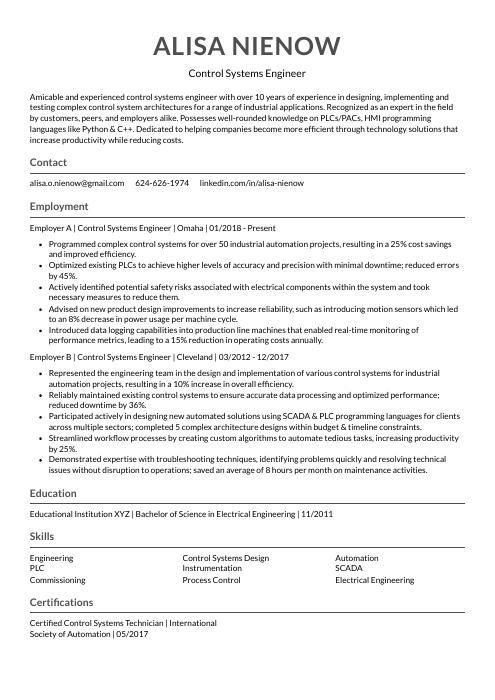

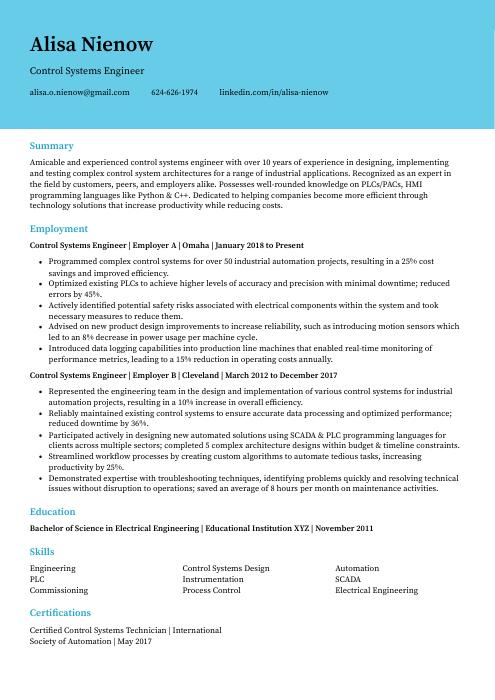

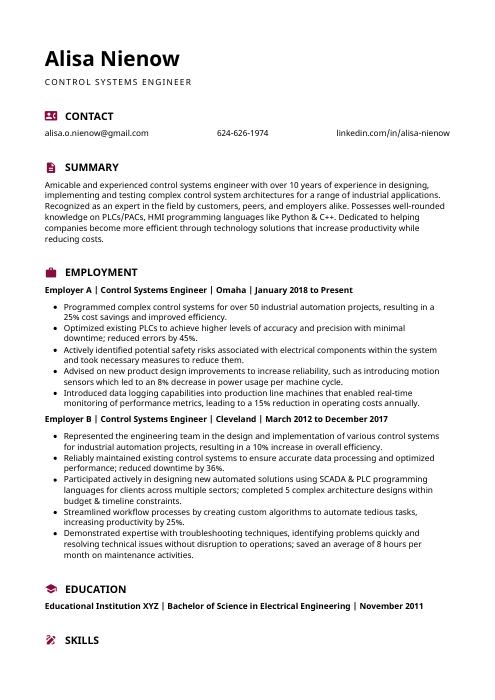

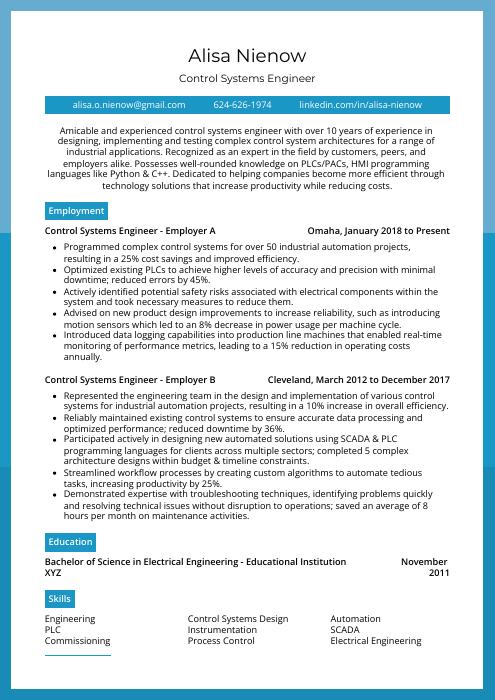

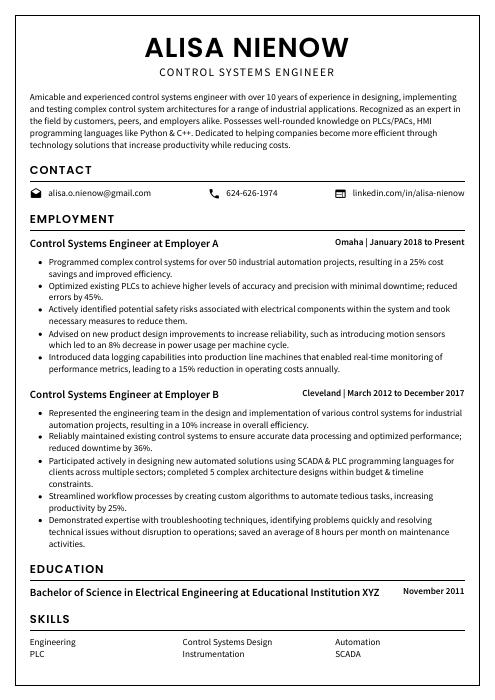

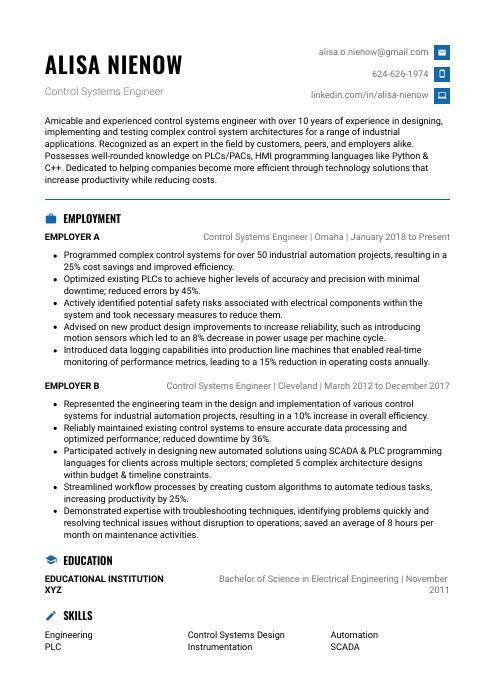

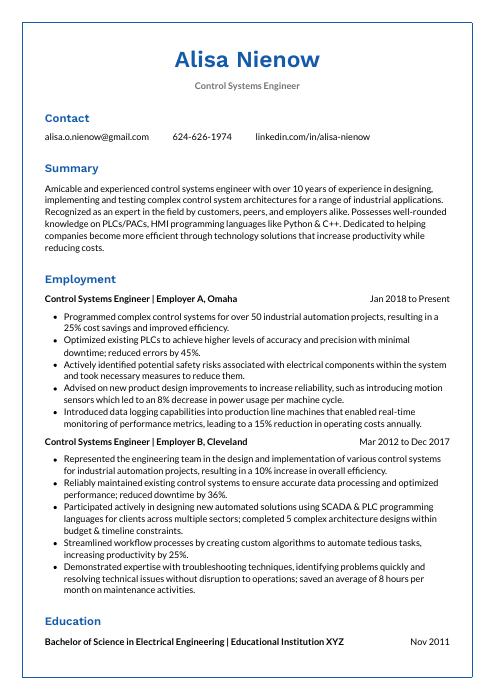

Control Systems Engineer Resume Sample

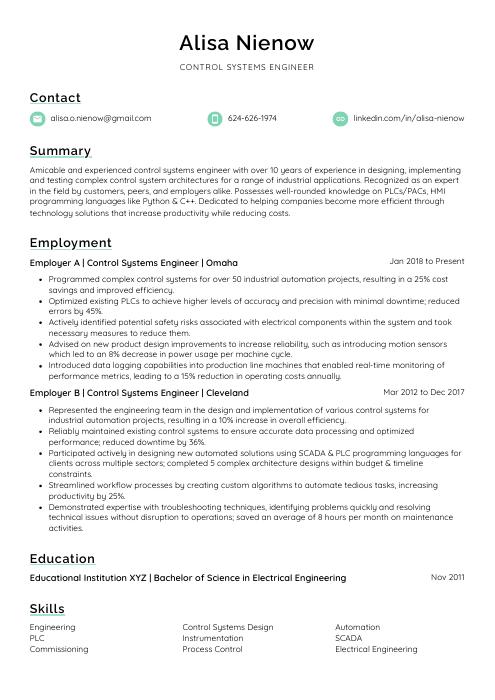

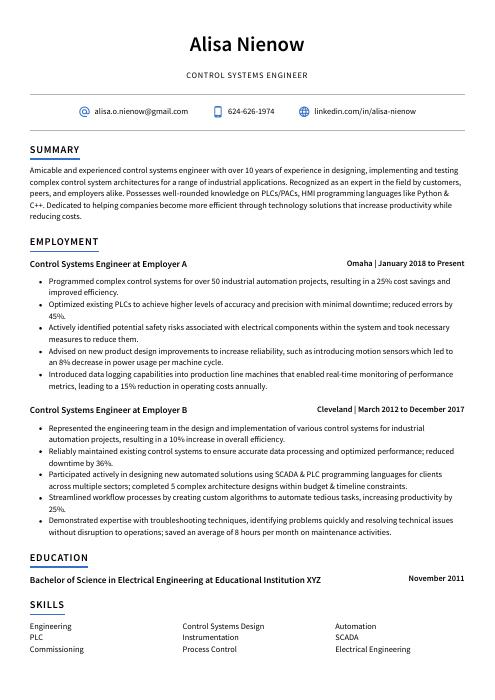

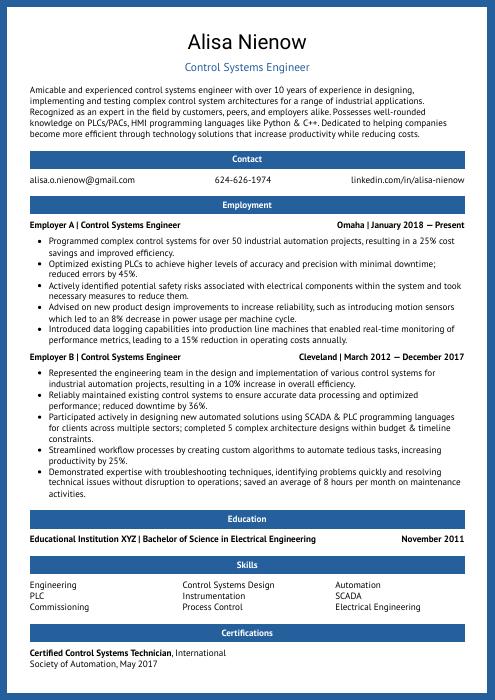

Alisa Nienow

Control Systems Engineer

[email protected]

624-626-1974

linkedin.com/in/alisa-nienow

Summary

Amicable and experienced control systems engineer with over 10 years of experience in designing, implementing and testing complex control system architectures for a range of industrial applications. Recognized as an expert in the field by customers, peers, and employers alike. Possesses well-rounded knowledge on PLCs/PACs, HMI programming languages like Python & C++. Dedicated to helping companies become more efficient through technology solutions that increase productivity while reducing costs.

Experience

Control Systems Engineer, Employer A

Omaha, Jan 2018 – Present

- Programmed complex control systems for over 50 industrial automation projects, resulting in a 25% cost savings and improved efficiency.

- Optimized existing PLCs to achieve higher levels of accuracy and precision with minimal downtime; reduced errors by 45%.

- Actively identified potential safety risks associated with electrical components within the system and took necessary measures to reduce them.

- Advised on new product design improvements to increase reliability, such as introducing motion sensors which led to an 8% decrease in power usage per machine cycle.

- Introduced data logging capabilities into production line machines that enabled real-time monitoring of performance metrics, leading to a 15% reduction in operating costs annually.

Control Systems Engineer, Employer B

Cleveland, Mar 2012 – Dec 2017

- Represented the engineering team in the design and implementation of various control systems for industrial automation projects, resulting in a 10% increase in overall efficiency.

- Reliably maintained existing control systems to ensure accurate data processing and optimized performance; reduced downtime by 36%.

- Participated actively in designing new automated solutions using SCADA & PLC programming languages for clients across multiple sectors; completed 5 complex architecture designs within budget & timeline constraints.

- Streamlined workflow processes by creating custom algorithms to automate tedious tasks, increasing productivity by 25%.

- Demonstrated expertise with troubleshooting techniques, identifying problems quickly and resolving technical issues without disruption to operations; saved an average of 8 hours per month on maintenance activities.

Skills

- Engineering

- Control Systems Design

- Automation

- PLC

- Instrumentation

- SCADA

- Commissioning

- Process Control

- Electrical Engineering

Education

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Control Systems Technician

International Society of Automation

May 2017

1. Summary / Objective

Your resume summary or objective should provide the hiring manager with a snapshot of your qualifications and experience as a control systems engineer. In this section, you can highlight any relevant certifications or training courses you have completed, mention the types of control systems you are familiar with (PLCs, SCADA etc.), and discuss how your work has helped to improve safety standards in past roles.

Below are some resume summary examples:

Driven Control Systems Engineer with 5+ years of experience in the development and deployment of control systems for industrial applications. Expertise in designing, programming, testing, commissioning & troubleshooting various PLCs like Siemens S7-300/400/1200 series (TIA Portal), Allen Bradley CompactLogix / ControlLogix L32E / 1756 Series and DeltaV DCS System. Proven track record of completing projects on time while meeting customer needs by providing advanced technical solutions.

Well-rounded Control Systems Engineer with 8+ years of experience in industrial automation and robotics. Proven track record of successful deployments throughout North America, Europe, and Asia-Pacific regions. Skilled at designing automated processes from the ground up, ensuring efficient operation through testing before deployment. Expertise in PLC programming using multiple languages such as C++ and Python for control systems applications.

Detail-oriented control systems engineer with 5+ years of experience in the design and implementation of automated control solutions for a variety of industries. Proven success in identifying, analyzing, and resolving complex technical problems to ensure optimal system performance. Seeking to join ABC Tech as a Control Systems Engineer where I can utilize my knowledge and expertise to improve operational efficiency.

Professional control systems engineer with 8+ years of experience in the design, implementation and maintenance of control systems for industrial automation. Skilled at developing optimal solutions that meet customer needs while keeping costs under budget. Seeking to join ABC Tech as their lead Control Systems Engineer and use my expertise in PLC programming to increase efficiency within their production processes.

Hard-working Control Systems Engineer with 8+ years of experience in designing, installing, and troubleshooting systems for automated machinery. Skilled at developing custom solutions for unique engineering problems using a variety of programming languages and industrial protocols. Seeking to join ABC Technologies as their Control System Engineer to provide the highest quality control system designs possible.

Seasoned control systems engineer with 8+ years of experience in designing, developing and implementing control systems for industrial processes. Adept at troubleshooting complex issues related to hardware, software integration, machine vision and robotics. Seeking to leverage my expertise as a Control Systems Engineer at ABC Technologies to provide innovative solutions for cost-effective automation.

Reliable Control Systems Engineer with 5+ years of experience in designing, developing, and implementing control systems for industrial automation. Skilled at programming PLCs using ladder logic, troubleshooting software issues on the fly and modifying existing code to improve throughput and accuracy. At XYZ Company created a distributed control system that reduced production costs by 18%.

Enthusiastic control systems engineer with 7+ years of experience in the design and implementation of control system solutions. Looking to join ABC Technologies to develop innovative solutions for challenging projects. At XYZ, increased automation efficiency by 33% through optimization techniques on existing processes and driving innovation across multiple teams.

2. Experience / Employment

For the experience section, you want to list your job history in reverse chronological order, meaning the most recent role should be listed first.

When writing about what you did for each role, stick to bullet points. This makes it easier for the reader to take in all of your information quickly and efficiently. When providing details on what you did, make sure that they are quantifiable results or accomplishments whenever possible.

For example, instead of saying “Developed control systems,” you could say “Designed and implemented a PID controller system that reduced production cycle time by 25%, resulting in an increase in efficiency.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Programmed

- Automated

- Monitored

- Simulated

- Analyzed

- Optimized

- Implemented

- Troubleshot

- Configured

- Calibrated

- Tested

- Debugged

- Documented

- Upgraded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Prepared and tested multiple control systems for various engineering projects, resulting in a 30% decrease in manual labor and production costs.

- Formulated new monitoring protocols to ensure the reliability of automated machines and equipment; successfully reduced downtime by 25%.

- Reorganized existing processes within the department to improve efficiency, increasing productivity levels by 40%.

- Independently designed components for a fully functional robotic arm assembly system that increased throughput rates by 50%.

- Assessed potential risk associated with automation integration processes at three major client sites, leading to successful implementation without any incidents or safety hazards reported.

- Facilitated the design, development and implementation of automated control systems for 10+ industrial projects, resulting in a 50% reduction in production time.

- Expedited the troubleshooting process on malfunctioning existing control systems by 20%, increasing system efficiency and accuracy.

- Simulated different environment conditions to test & evaluate over 15 new control systems prior to deployment; identified 6 potential issues that were addressed before launch date.

- Substantially improved workflow processes at 3 manufacturing facilities through automation of data collection, storage & retrieval functions within the established timeline constraints while ensuring high levels of safety standards were met throughout the project duration.

- Tested newly designed/upgraded software programs to ensure compatibility with current operating systems; diagnosed and resolved any discovered discrepancies or errors quickly without compromising system performance integrity.

- Designed and implemented control systems for automation projects in manufacturing and production plants, increasing productivity by 25% and reducing costs by $17,000.

- Spearheaded the development of high-performance robotics platforms that integrated visioning technology to support automated material handling processes.

- Efficiently debugged issues in existing PLC software programs using a combination of manual methods and simulation tools; reduced troubleshooting time from 2 hours to 15 minutes on average per issue.

- Automated complex control system operations with intuitive user interfaces based on graphical programming principles; improved operational efficiency across 5+ facilities with zero downtime or disruption caused during implementation phases.

- Developed custom algorithms for real-time monitoring & measurement functions which enabled faster response times when dealing with critical faults (+10%).

- Successfully designed, tested and implemented 20+ control systems for various manufacturing processes; improved operational efficiency by 15%.

- Presented technical proposals to upper management and clients on the cost-effectiveness of automation solutions; secured $1 million in new business over two years.

- Coordinated with teams of engineers, technicians and project managers to develop PLCs (Programmable Logic Controllers) for automated production lines within established timelines & budgets.

- Developed custom software programs that integrated existing hardware components into a single unified platform; reduced system maintenance costs by 25%.

- Revised electrical wiring diagrams according to customer specifications and industry standards while ensuring code compliance at all times; completed projects 200% faster than average completion time.

- Calibrated, adjusted, and maintained all control systems to ensure optimal performance; improved system accuracy by 10% in 3 months.

- Analyzed data from automated equipment & instrumentation and compiled comprehensive reports for management review.

- Compiled detailed documentation of technical specifications for control systems and structured processes to maximize efficiency across the organization’s operations.

- Structured an effective monitoring system that detected malfunctions before they impacted production; reduced downtime hours by 25%.

- Effectively implemented modifications on existing software programs to increase automation capabilities and improve end-user experience with a 30% decrease in user errors reported per month.

- Monitored and maintained control systems of 20+ industrial machinery and equipment, ensuring safe operation and increasing productivity by 10%.

- Implemented new technologies to improve operational efficiency, reducing energy costs by $5,000 in the last quarter.

- Upgraded existing electrical wiring systems for improved safety compliance; reduced potential hazards by 45%.

- Mentored 6 junior engineers on various aspects of control system engineering processes over a period of 1 year; increased team skillset & knowledge retention rate from 65% to 92%.

- Meticulously designed automated controllers using PLCs that integrated with SCADA software platforms for enhanced monitoring capabilities; cut maintenance time down by 25 hours per month on average.

- Documented and maintained system designs, test procedures and other technical documents used in the development of automated control systems; reduced document update time by 40%.

- Reduced total project costs by 10% through effective analysis of existing projects for areas to streamline operations and eliminate redundant processes.

- Configured complex industrial automation systems such as PLCs, HMIs, servo drives and controllers with high accuracy while adhering to safety standards & protocols; saved over 20 hours per project on average due to proficient troubleshooting capabilities.

- Proficiently analyzed engineering data including electrical schematics and drawings using software programs such as AutoCAD Electrical & LabVIEW; completed design drafts within tight deadlines without compromising quality or precision.

- Achieved a 95% success rate when commissioning new equipment installations at customer sites across various industry sectors including oil & gas production, mining and power generation plants.

- Thoroughly tested and debugged analog, digital & hybrid control systems for over 50 projects, resulting in a 15% reduction of engineering time per project.

- Troubleshot over 300 hardware and software issues with PLCs, PACs, HMIs and other devices to ensure that production operations ran smoothly at all times.

- Improved operational efficiency by 30% through the development of new control system architectures utilizing industry-standard programming languages such as C/C++ and Python.

- Utilized advanced techniques like PID loop tuning to optimize equipment performance for clients in industries including automotive manufacturing, aerospace engineering and industrial automation processes; decreased downtime by 45%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for someone with experience in designing and developing control systems, while organization XYZ may require the candidate to have knowledge of embedded programming.

It is essential to keep this in mind because many employers use applicant tracking systems (ATS) these days; their role is to analyze resumes for certain characteristics, filtering out those deemed not a good fit for that particular job. Therefore, you want to tailor your skills section so as it contains keywords related specifically to the position you are applying for.

In addition, make sure you elaborate on your most important skills by discussing them further in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- Allen Bradley

- AutoCAD

- Automation

- C

- C++

- Commissioning

- Continuous Improvement

- Control Logic

- Control Systems Design

- DCS

- Distributed Control System

- EPC

- Electrical Engineering

- Electricians

- Electronics

- Embedded Systems

- Energy

- Engineering

- Engineering Design

- Engineering Management

- Factory

- Gas

- HMI Programming

- HMIS

- Instrumentation

- LabVIEW

- MATLAB

- Manufacturing

- Mechanical Engineering

- Modbus

- Oil and Gas

- P&ID

- PLC

- PLC Programming

- PROFIBUS

- Petrochemical

- Petroleum

- Power Generation

- Process Automation

- Process Control

- Process Engineering

- Programmable Logic Controller

- Programming

- Project Engineering

- Project Planning

- Python

- RSLogix

- Refinery

- Robotics

- SCADA

- SOLIDWORKS

- Simulink

- Systems Engineering

- Team Leadership

- Teamwork

- Testing

- Troubleshooting

- Variable Frequency Drives

- Wonderware

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, include an education section below your resume objective. However, if you have been working as a control systems engineer for many years with plenty of work experience to showcase, omitting the education section is perfectly acceptable.

If including an education section, try to mention courses and subjects related to the control systems engineering job that you are applying for.

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the necessary qualifications and expertise in a particular field. They also show that you are committed to keeping your skills up-to-date, as certifications often require ongoing professional development courses or exams.

If you possess any relevant certifications for the job position, make sure to include them on your resume so they can be seen by hiring managers. This will help demonstrate how qualified and knowledgeable you are about the industry and role at hand.

Certified Control Systems Technician

International Society of Automation

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Alisa Nienow, this would be Alisa-Nienow-resume.pdf or Alisa-Nienow-resume.docx.

7. Cover Letter

A cover letter is an important part of any job application. It’s a document that should be tailored to the role you’re applying for and provide more detail than what is included in your resume.

Cover letters are not required by most employers, but they can make all the difference when it comes to making yourself stand out from other applicants. They give hiring managers insight into who you are as a person, why you’re interested in the position, and how your skillset will help them reach their goals.

Below is an example cover letter:

Dear Jerrold,

I am writing to apply for the Control Systems Engineer position at XYZ Corporation. With my experience in designing and implementing control systems for a variety of industrial applications, I am confident I will be an asset to your organization.

In my current role as Control Systems Engineer at ABC Company, I have designed and implemented control systems for production lines, HVAC systems, and other industrial applications. My experience has given me a thorough understanding of various control system technologies and how to best apply them to achieve desired results. In addition, I have developed strong problem-solving skills that have come in handy when troubleshooting issues with control systems.

I am excited about the possibility of bringing my knowledge and expertise to XYZ Corporation. I believe my skills and experience would be a valuable asset to your team, and I look forward to contributing to the success of your organization. If you have any questions or if you would like additional information about my qualifications, please do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration.

Sincerely,

Alisa

Control Systems Engineer Resume Templates

Kinkajou

Kinkajou Jerboa

Jerboa Bonobo

Bonobo Numbat

Numbat Pika

Pika Saola

Saola Indri

Indri Dugong

Dugong Gharial

Gharial Hoopoe

Hoopoe Quokka

Quokka Fossa

Fossa Rhea

Rhea Cormorant

Cormorant Echidna

Echidna Markhor

Markhor Lorikeet

Lorikeet Axolotl

Axolotl Ocelot

Ocelot Rezjumei

Rezjumei