Chiller Technician Resume Guide

Chiller Technicians maintain and repair chillers, which are large pieces of equipment used to cool air or liquid in industrial settings. They inspect chiller components for wear, test the performance of systems, diagnose malfunctions and perform repairs as needed. Chiller Technicians also calibrate instruments to ensure proper operation and document all maintenance activities.

Your technical knowledge and expertise in chilled water systems is invaluable to any business. But employers don’t know who you are yet, so writing a resume that accurately reflects your capabilities will help them see why they need to hire you.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Chiller Technician Resume Sample

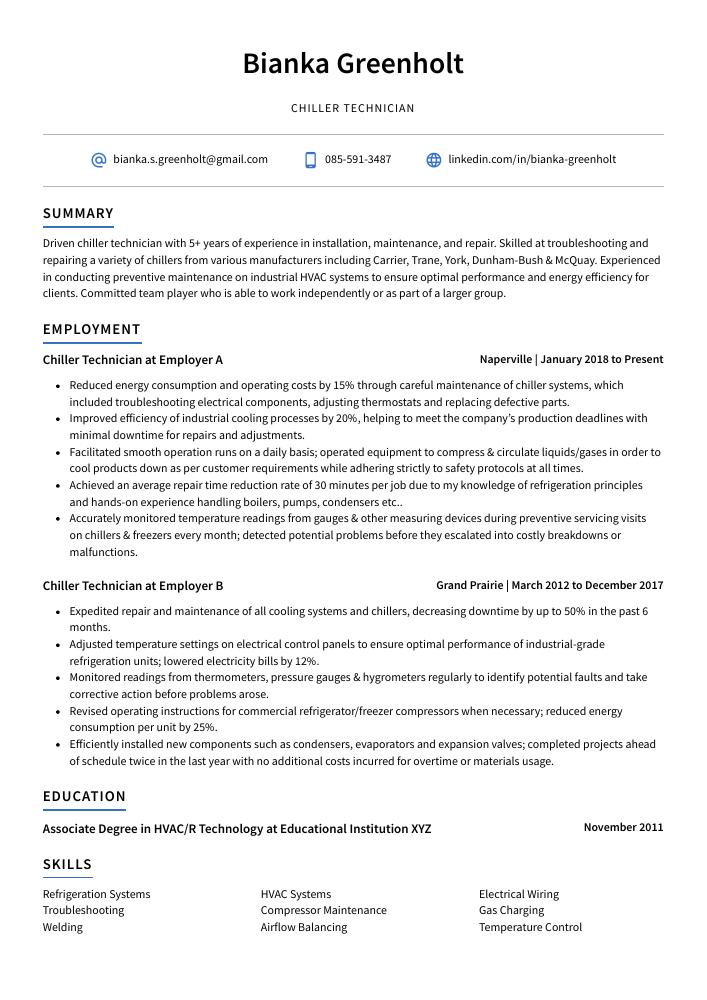

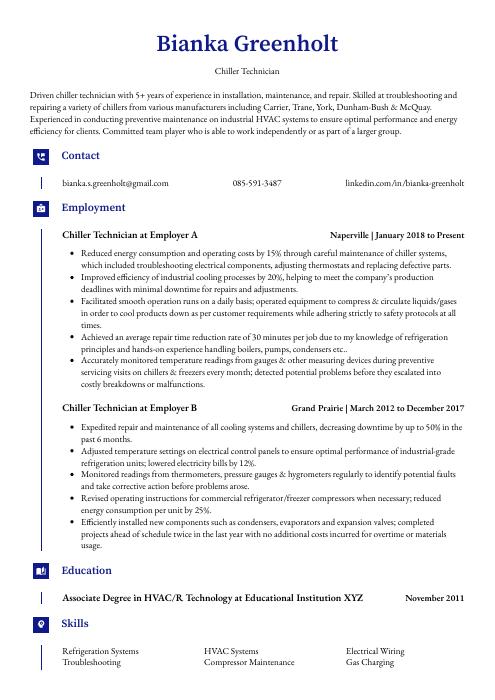

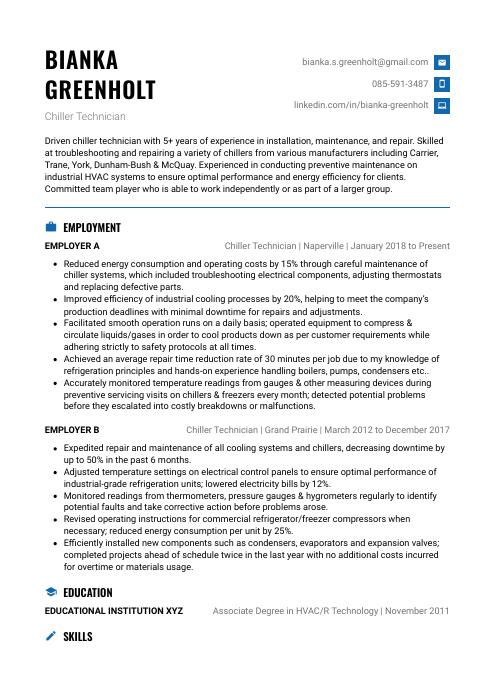

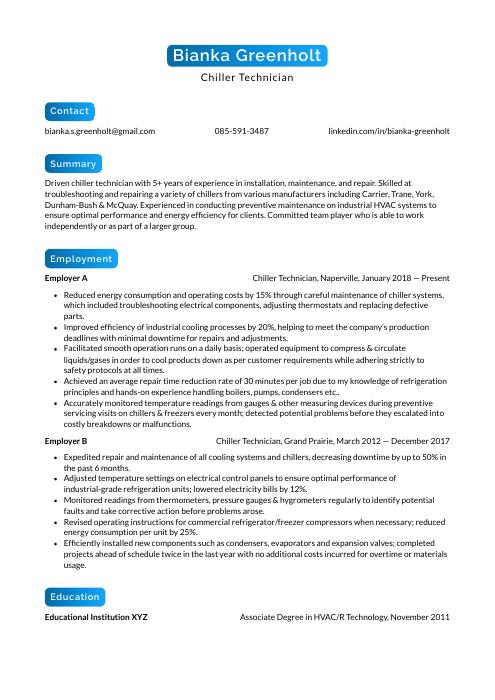

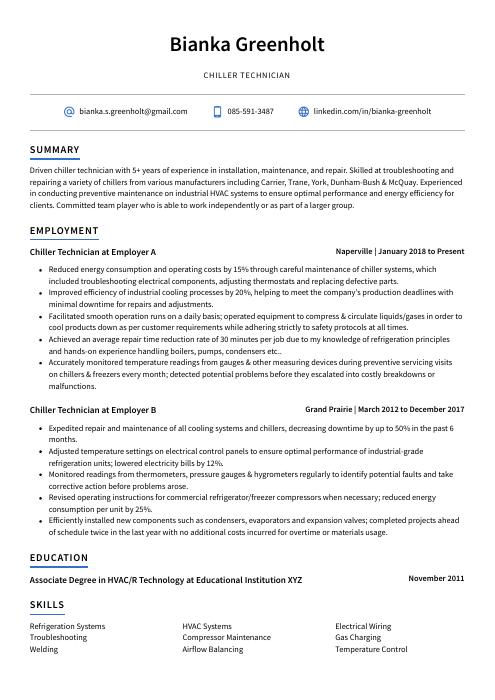

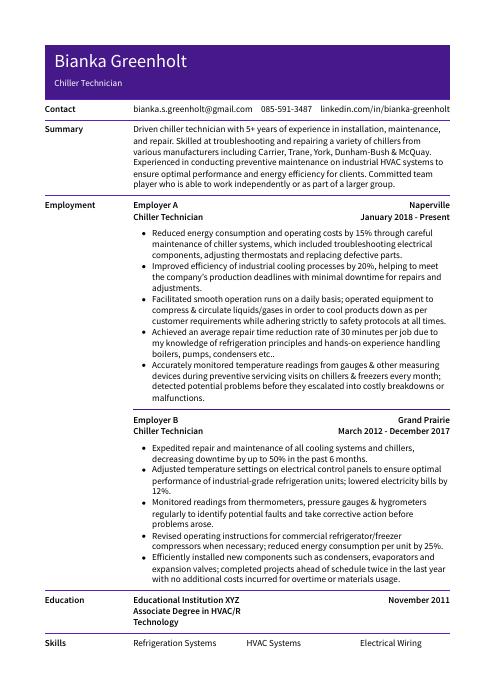

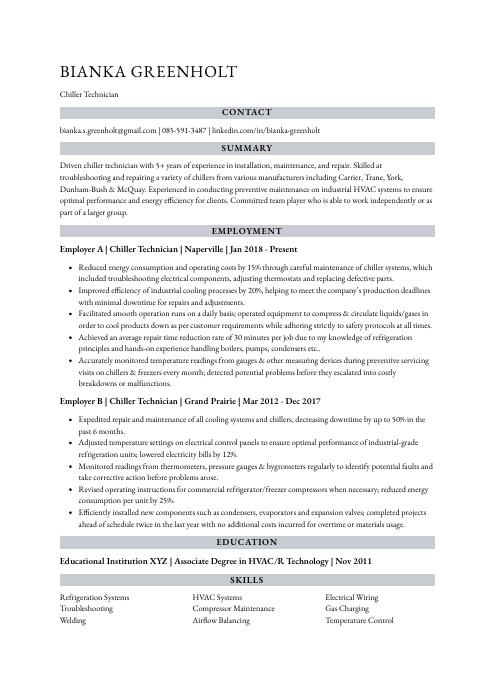

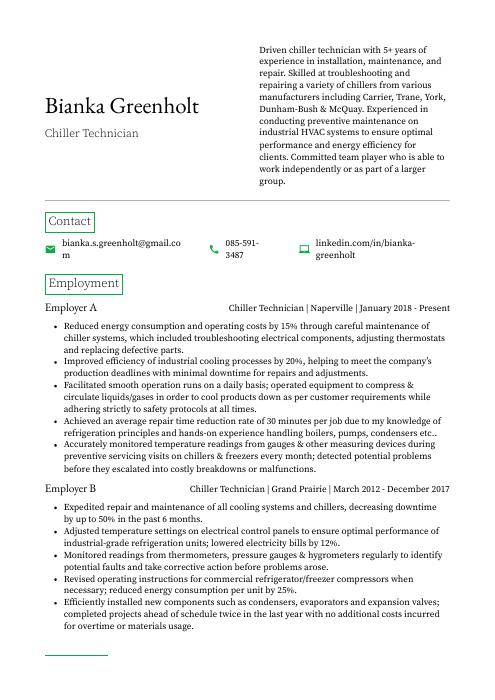

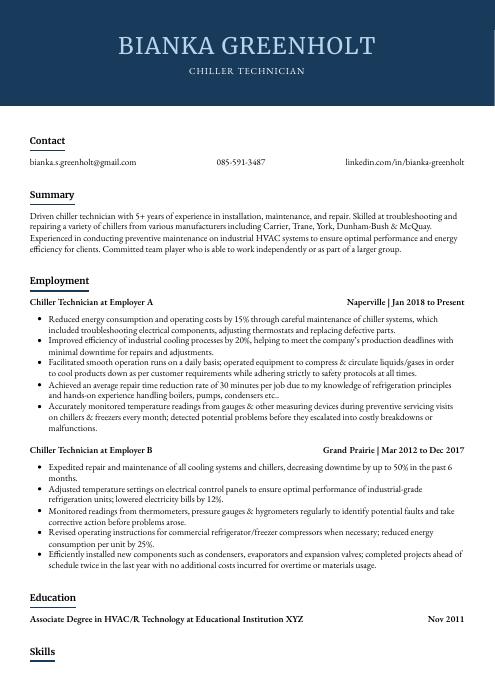

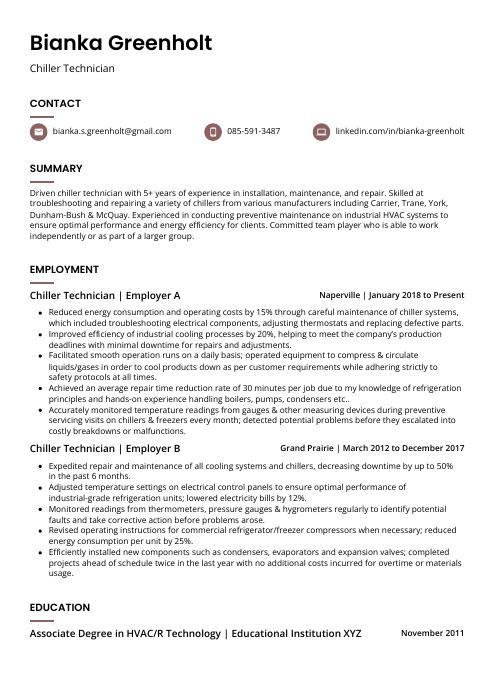

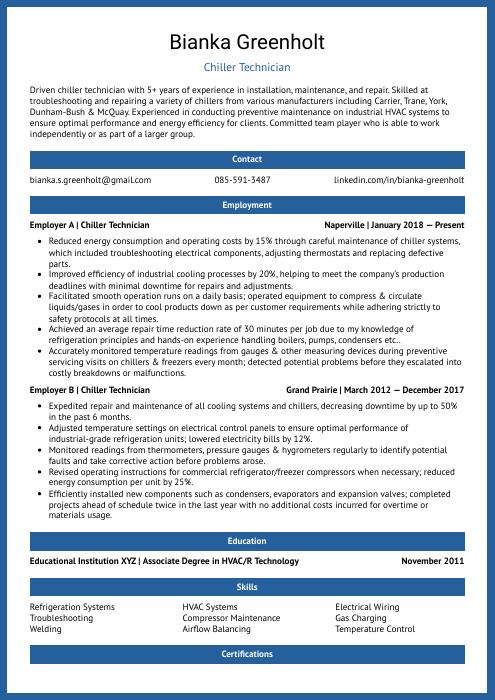

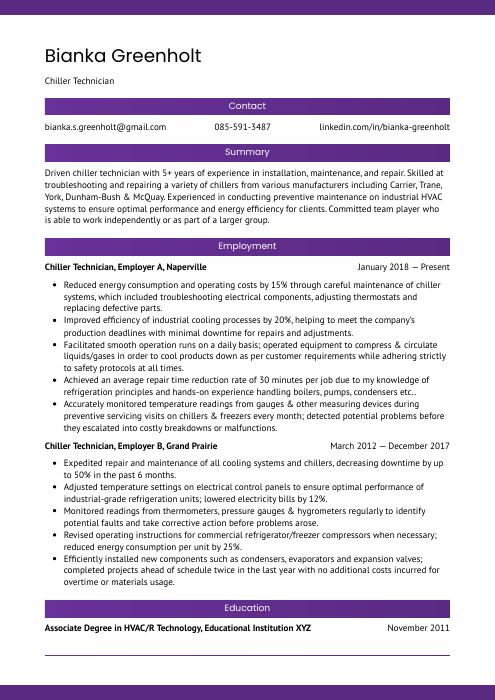

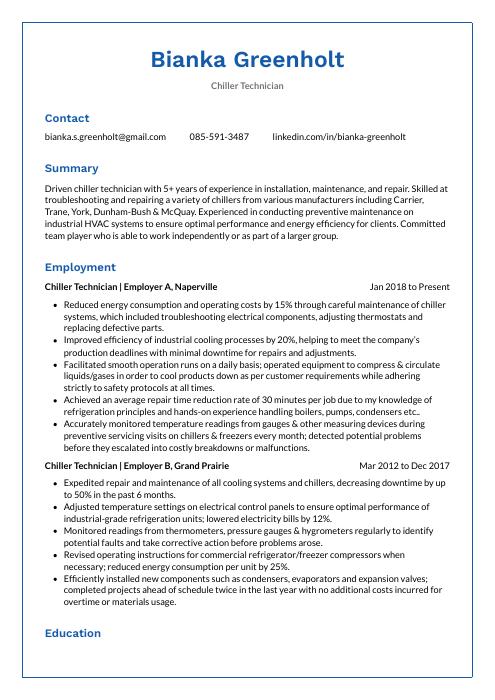

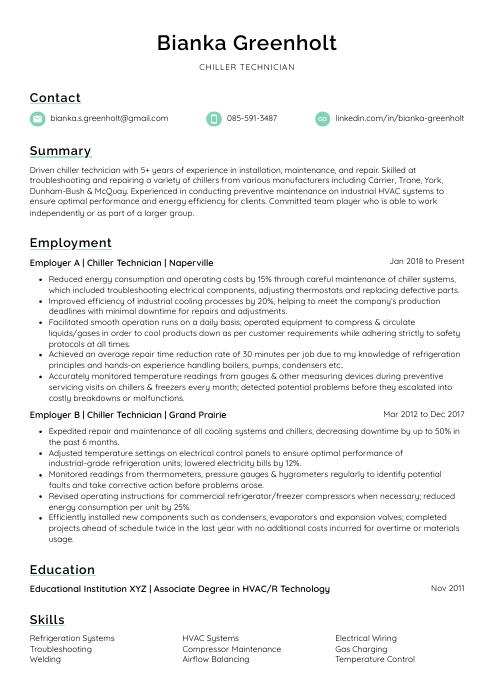

Bianka Greenholt

Chiller Technician

[email protected]

085-591-3487

linkedin.com/in/bianka-greenholt

Summary

Driven chiller technician with 5+ years of experience in installation, maintenance, and repair. Skilled at troubleshooting and repairing a variety of chillers from various manufacturers including Carrier, Trane, York, Dunham-Bush & McQuay. Experienced in conducting preventive maintenance on industrial HVAC systems to ensure optimal performance and energy efficiency for clients. Committed team player who is able to work independently or as part of a larger group.

Experience

Chiller Technician, Employer A

Naperville, Jan 2018 – Present

- Reduced energy consumption and operating costs by 15% through careful maintenance of chiller systems, which included troubleshooting electrical components, adjusting thermostats and replacing defective parts.

- Improved efficiency of industrial cooling processes by 20%, helping to meet the company’s production deadlines with minimal downtime for repairs and adjustments.

- Facilitated smooth operation runs on a daily basis; operated equipment to compress & circulate liquids/gases in order to cool products down as per customer requirements while adhering strictly to safety protocols at all times.

- Achieved an average repair time reduction rate of 30 minutes per job due to my knowledge of refrigeration principles and hands-on experience handling boilers, pumps, condensers etc..

- Accurately monitored temperature readings from gauges & other measuring devices during preventive servicing visits on chillers & freezers every month; detected potential problems before they escalated into costly breakdowns or malfunctions.

Chiller Technician, Employer B

Grand Prairie, Mar 2012 – Dec 2017

- Expedited repair and maintenance of all cooling systems and chillers, decreasing downtime by up to 50% in the past 6 months.

- Adjusted temperature settings on electrical control panels to ensure optimal performance of industrial-grade refrigeration units; lowered electricity bills by 12%.

- Monitored readings from thermometers, pressure gauges & hygrometers regularly to identify potential faults and take corrective action before problems arose.

- Revised operating instructions for commercial refrigerator/freezer compressors when necessary; reduced energy consumption per unit by 25%.

- Efficiently installed new components such as condensers, evaporators and expansion valves; completed projects ahead of schedule twice in the last year with no additional costs incurred for overtime or materials usage.

Skills

- Refrigeration Systems

- HVAC Systems

- Electrical Wiring

- Troubleshooting

- Compressor Maintenance

- Gas Charging

- Welding

- Airflow Balancing

- Temperature Control

Education

Associate Degree in HVAC/R Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Chiller Technician

Refrigerating Engineers & Technicians Association

May 2017

1. Summary / Objective

Your resume summary should provide the hiring manager with an overview of your skills and experience as a chiller technician. In this section, you can highlight any certifications or qualifications you have obtained, such as HVAC certification or refrigeration system maintenance training. You could also mention how many years of experience you have working on chillers, the number of successful repairs and installations you’ve completed in the past, and any other relevant information that would make them want to read more about your background.

Below are some resume summary examples:

Proficient chiller technician with 5+ years of experience troubleshooting, repairing, and maintaining chiller systems. At XYZ Inc., wrote a comprehensive guide to optimize the performance of chillers which decreased maintenance costs by 27%. Self-starter who takes initiative in researching new technologies and techniques for improved efficiency. Proven track record in providing excellent customer service through successful repairs on time and within budget.

Reliable Chiller Technician with 5+ years of experience in the installation, repair and maintenance of industrial chillers. Skilled at troubleshooting problems on a wide range of equipment from single units to entire chiller plants. Experienced in installing new systems as well as performing ongoing preventative maintenance checks for existing ones. Committed to safety standards and ensuring customer satisfaction through efficient job completion.

Professional chiller technician with 8+ years of experience troubleshooting and repairing refrigeration systems. Highly skilled in all aspects of diagnostics, installation, maintenance, and repairs for a variety of chillers. Seeking to join ABC Refrigeration as their lead chiller technician where I can utilize my expertise to ensure optimal performance and efficiency within the company’s equipment fleet.

Seasoned chiller technician with 10+ years of experience in the installation, repair and maintenance of commercial refrigeration equipment. Skilled at troubleshooting complex issues and performing preventive maintenance to ensure optimal performance. Committed to maintaining a safe work environment while providing quality customer service. Possess an EPA 608 certification for handling HFC-based systems.

Well-rounded chiller technician with 10+ years of experience troubleshooting and repairing cooling systems in the industrial sector. Expertise in assessing performance, identifying problems, and providing effective solutions to maximize efficiency while minimizing downtime. Seeking to bring extensive knowledge of HVAC/R principles and practices to ABC Corp as a senior chiller technician.

Hard-working chiller technician with 7+ years of experience performing maintenance, repairs, and installations on a variety of industrial refrigeration systems. Seeking to join ABC Tech as their next chiller technician to help reduce downtime by utilizing my exceptional problem-solving skills. At XYZ Inc., maintained an exemplary safety record while reducing repair costs by 24%.

Committed Chiller Technician with 5 years of experience in the maintenance, troubleshooting, and repair of industrial chillers. Adept at inspecting chiller systems to identify potential problems and implementing corrective measures when needed. Recently reduced downtime by 15% through proactive maintenance activities and preventive care for ABC’s HVAC equipment.

Determined Chiller Technician with 8+ years of experience in performing maintenance, repairs, and installations on commercial HVAC systems. Expertise in troubleshooting malfunctions and replacing faulty components to restore optimal performance. Seeking to join ABC Company where I can utilize my knowledge and skillset to provide superior customer service.

2. Experience / Employment

In the experience section, you should list your work history in reverse chronological order. This means that your most recent job is listed first.

When writing the bullet points for each role, use a concise and detailed approach to explain what you did and the results achieved. For example, instead of saying “Repaired chillers,” you could say, “Performed maintenance on commercial refrigeration systems including diagnostics and repairs; reduced downtime by 30% through proactive preventative measures.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Inspected

- Troubleshot

- Adjusted

- Monitored

- Calibrated

- Repaired

- Replaced

- Tested

- Operated

- Programmed

- Analyzed

- Serviced

- Commissioned

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Serviced and repaired over 100 chillers, freezers and other components daily to ensure proper functioning; reduced average repair time per unit by 10%.

- Calibrated thermometers and pressure gauges weekly to maintain optimal temperature levels in the chiller units; improved accuracy of readings by 15%.

- Substantially decreased energy consumption at all facilities through regular maintenance activities, resulting in a cost savings of $4,000 for the company last quarter.

- Documented detailed reports on repairs performed as well as diagnosis results for future reference; increased record keeping efficiency by 20%.

- Commissioned new chillers with minimum downtime of 30 minutes thus ensuring smooth operations across multiple sites within the organization.

- Mentored and trained three junior technicians in proper chiller maintenance and installation procedures, resulting in a 20% reduction of repair time for new chillers.

- Demonstrated extensive knowledge on HVAC systems when assessing performance issues with various models of refrigeration units; successfully identified faulty components and replaced them to restore system efficiency by 40%.

- Resourcefully developed an inventory tracking system to identify parts availability while ensuring accurate ordering information; reduced expenses related to overstocking & under-ordering by 27%.

- Structured preventive maintenance schedules for 25+ commercial customers’ cooling equipment, increasing its longevity by 20%.

- Participated in the development of comprehensive technical manuals that provide step-by-step instructions on how to properly install and maintain chillers, condensers and other related components according to industry standards.

- Operated and maintained commercial chillers and cooling systems, servicing over 50 units per month with minimal downtime.

- Inspected entire HVAC system for any potential problems or malfunctions; reduced repair costs by 15% through regular maintenance checks.

- Proficiently handled all emergency repairs, ensuring that the temperature of food storage areas was kept within regulatory standards at all times (+1 degree accuracy).

- Coordinated installation projects on new chiller equipment while simultaneously repairing existing ones; completed 3 installations in less than 2 weeks each time, ahead of schedule and under budget ($5K savings).

- Presented detailed reports to supervisors on a weekly basis outlining the condition and performance of every unit serviced during that period; successfully identified 10 out-of-date models resulting in their replacement before major incidents occurred (100% success rate).

- Represented the company in the installation, maintenance and repair of chillers with a specialization in low-temperature systems; reduced service call time by 10% through preventive maintenance planning.

- Optimized chiller performance and cooling efficiency for 30+ businesses around town, resulting in an average energy cost savings of $4,500 per quarter.

- Advised clients on best practices to maintain their refrigeration systems while providing support when needed; answered over 500 technical inquiries regarding equipment operation & safety protocols within one year alone.

- Tested all components using specialized diagnostic tools before system start-up to ensure optimal functioning; improved customer satisfaction ratings by 25%.

- Competently troubleshot problems related to air conditioning units as well as low temperature chillers during emergency calls after business hours or on weekends; resolved issues without delays 95% of the time.

- Compiled daily maintenance and repair logs for all refrigeration systems in the facility, ensuring that equipment was regularly serviced to prevent breakdowns; reduced emergency calls by 46%.

- Independently diagnosed faults and repaired chillers, condensers, evaporators and other components of industrial cooling systems with precision within allotted timeframes.

- Programmed temperature controllers on a range of chilling units according to manufacturer’s instructions; lowered power consumption costs by $500 per month.

- Introduced preventive maintenance techniques to improve reliability of chiller operations across the plant floor; extended equipment life expectancy by 20%.

- Repaired faulty motors & pumps as well as replaced defective parts such as fans blades & compressors over 350 times per year with no safety incidents reported during this period.

- Formulated and implemented preventative maintenance plans for 35 chillers, resulting in a reduction of breakdowns by 15%.

- Reorganized the existing refrigeration system layout to improve energy efficiency levels and save $3,000 per month in power costs.

- Troubleshot electrical and mechanical problems on various types of chiller systems with up to 10 components; repaired over 25 malfunctioning units within specified timelines.

- Installed new cooling equipment including compressors, condensers, evaporators & other parts across 20+ customer sites; completed each job 6 hours ahead of schedule on average.

- Thoroughly tested all newly-installed refrigeration systems before commissioning them, confirming that these were functioning correctly at optimal temperatures every time.

- Developed and implemented preventative maintenance and repair strategies for industrial chillers to ensure maximum operational efficiency; reduced downtime by over 25%.

- Analyzed chiller performance data and identified areas of improvement, resulting in a 20% increase in energy savings within 8 months.

- Spearheaded repairs on refrigeration systems including compressors, condensers, evaporators & expansion valves; completed tasks with minimal disruption to daily operations.

- Utilized computer-controlled diagnostic equipment such as oscilloscopes and clamp meters to troubleshoot mechanical issues promptly; lowered average turnaround time from 5 hours to 2 hours per job order.

- Diligently maintained accurate records of all work performed and parts used for future reference; updated company’s database twice weekly ensuring accuracy of information at all times.

- Assessed and troubleshot a wide range of issues in industrial chillers and refrigeration systems, resulting in an 18% increase in operational efficiency.

- Streamlined the maintenance services for 15+ chillers by scheduling preventive measures such as cleaning compressors, replacing worn out parts and adjusting thermostat settings; reduced total service time by 45 minutes per chiller on average.

- Meticulously followed safety protocols when repairing faulty components or installing new equipment to avoid any potential hazards during operation; ensured that all repair jobs were completed within OSHA standards and regulations.

- Prepared detailed reports on daily inspections outlining any possible problems with various components such as temperature control devices, condensers & evaporators; identified over 40 minor repairs which helped prevent major breakdowns later down the line.

- Replaced worn-out bearings, gaskets & valves using specialized tools while adhering strictly to manufacturer’s instructions; saved $7000 worth of replacement costs year-on-year due to regular maintenance procedures being carried out efficiently.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience working with ammonia-based chillers, while another may be looking for someone proficient in servicing and maintaining water-cooled systems.

It is important to tailor the skills section of your resume to each job you are applying for because many employers use applicant tracking systems (ATS). These programs scan resumes for certain keywords before passing them on to a human recruiter.

In addition to listing relevant skills here, it is also beneficial if you can elaborate on some of these further throughout other sections such as the summary or experience section.

Below is a list of common skills & terms:

- Airflow Balancing

- Compressor Maintenance

- Electrical Wiring

- Gas Charging

- HVAC Systems

- Preventative Maintenance

- Refrigeration Systems

- Temperature Control

- Troubleshooting

- Welding

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the objective statement. However, if you have several years of experience as a chiller technician with plenty to showcase, then omitting an education section is perfectly acceptable.

If including an education section is necessary for this role, try to highlight courses and subjects related to the chiller technician job description that demonstrate relevant knowledge or skillsets such as refrigeration systems or HVAC fundamentals.

Associate Degree in HVAC/R Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and skills in a specific field. They show potential employers that you have taken the time to learn more about an area of expertise, as well as prove that you are proficient in it.

If you have any certifications related to the job for which you are applying, make sure they appear prominently on your resume. This will give hiring managers confidence that you possess the necessary qualifications for success in their organization.

Certified Chiller Technician

Refrigerating Engineers & Technicians Association

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Bianka Greenholt, this would be Bianka-Greenholt-resume.pdf or Bianka-Greenholt-resume.docx.

7. Cover Letter

Providing a cover letter with your job application can make a huge difference in how you’re perceived by recruiters. It enables you to explain why you are an ideal candidate and showcase the skills, qualifications and experience that makes you stand out from the crowd.

A cover letter should be 2 to 4 paragraphs long and provide more detail about who you are professionally. Including details such as previous achievements or successes at work will demonstrate your value as a potential employee.

Below is an example cover letter:

Dear Easter,

I am writing in response to your ad for a Chiller Technician. With my experience in HVAC and refrigeration, as well as my EPA certification, I am confident that I would be a valuable asset to your team.

In my current position, I maintain and repair industrial chillers for a large manufacturing company. I have experience troubleshooting and repairing all types of issues, from electrical problems to leaks in the system. I am also familiar with different types of chiller systems and how they work, which allows me to quickly identify problems and find solutions.

I pride myself on being able to work independently with little supervision, but I also know how to take direction when needed. My positive attitude and willingness to learn new things has allowed me to succeed in every position I’ve held.

Please find attached a copy of my resume for your review. If you have any questions or would like to schedule an interview, please do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration.

Sincerely,

Bianka

Chiller Technician Resume Templates

Gharial

Gharial Dugong

Dugong Hoopoe

Hoopoe Echidna

Echidna Kinkajou

Kinkajou Axolotl

Axolotl Rhea

Rhea Pika

Pika Numbat

Numbat Quokka

Quokka Bonobo

Bonobo Fossa

Fossa Ocelot

Ocelot Saola

Saola Indri

Indri Cormorant

Cormorant Jerboa

Jerboa Markhor

Markhor Lorikeet

Lorikeet Rezjumei

Rezjumei