Chemical Process Engineer Resume Guide

Chemical Process Engineers design, develop, operate and maintain chemical processes for the production of various products. They are responsible for research projects to improve existing process operations or create new ones, as well as ensuring that systems meet safety standards and environmental regulations. Additionally, they may perform laboratory tests on materials and analyze data from experiments in order to optimize process performance.

You have experience and knowledge that would make you an ideal candidate at any chemical engineering firm. But potential employers won’t know who you are unless your resume stands out from the crowd. To show them what makes you unique, write a memorable resume to get their attention.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

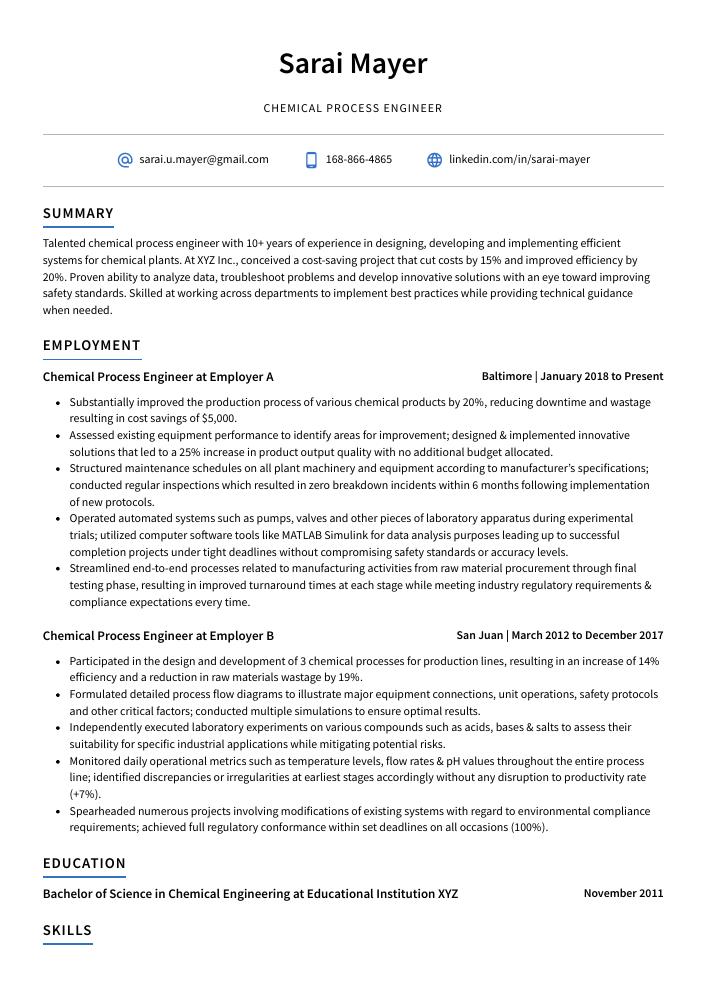

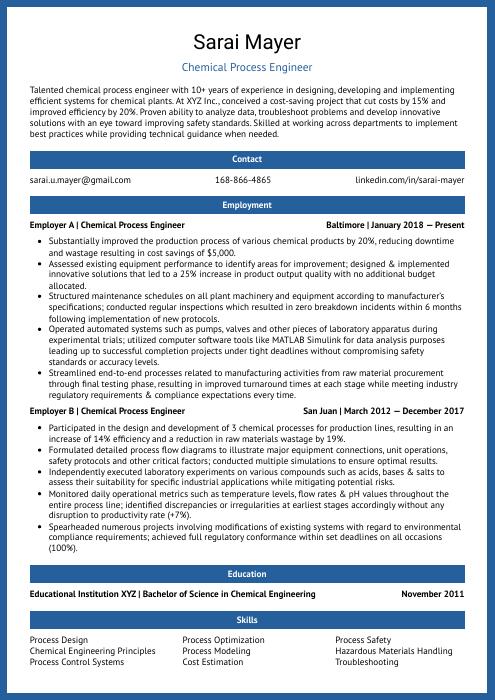

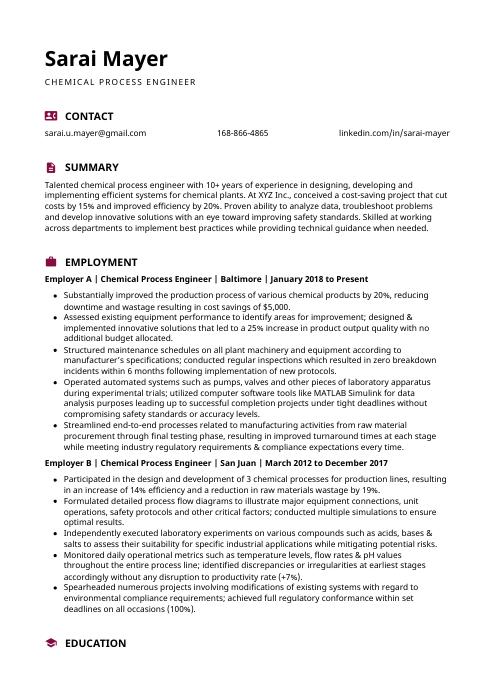

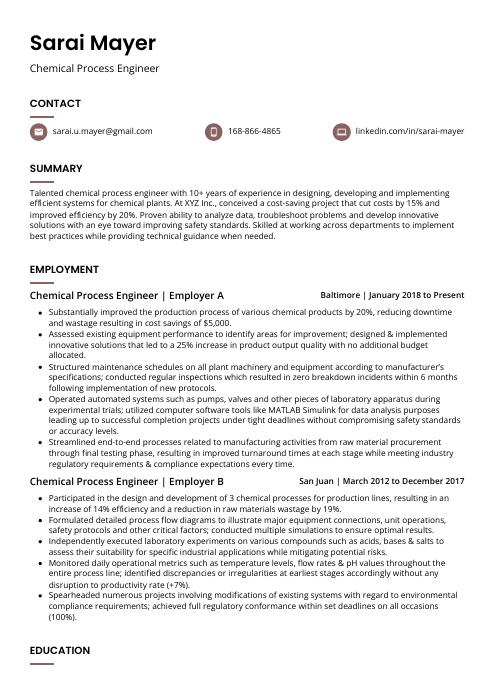

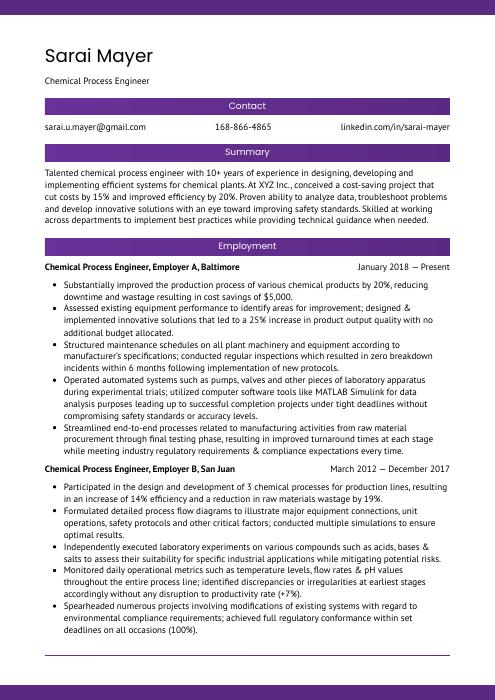

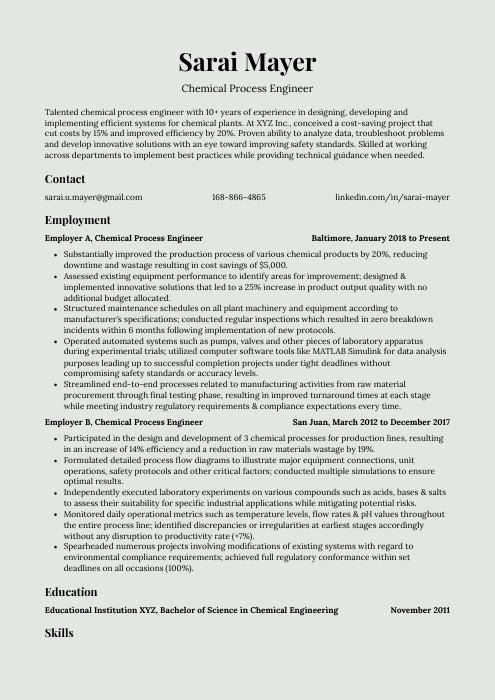

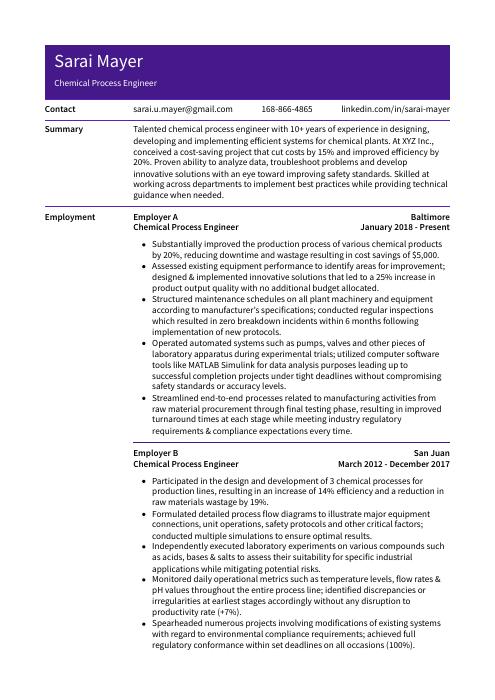

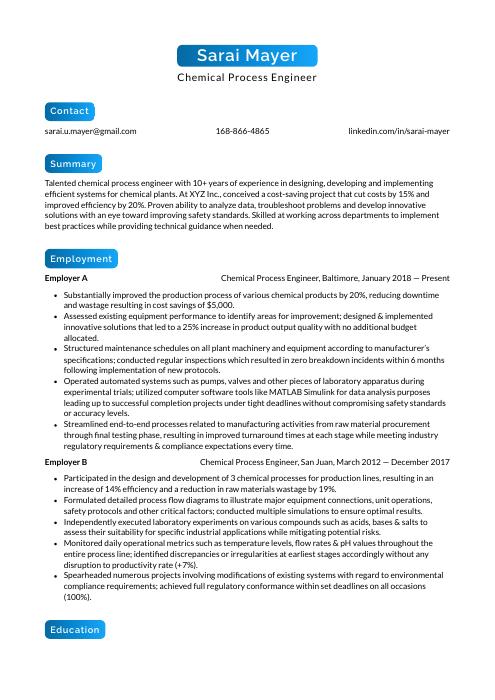

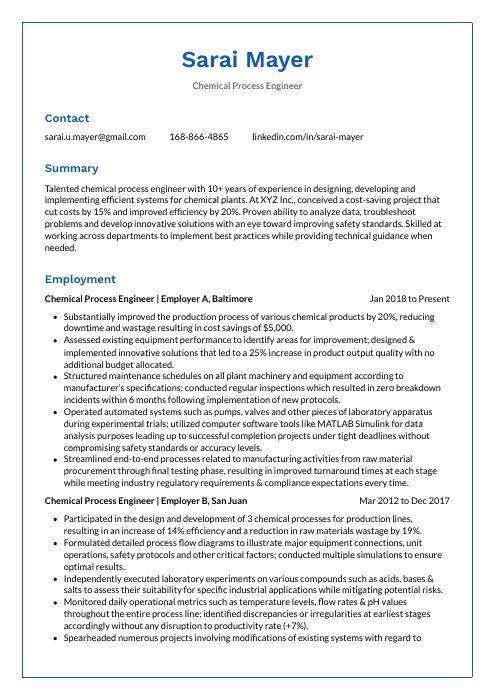

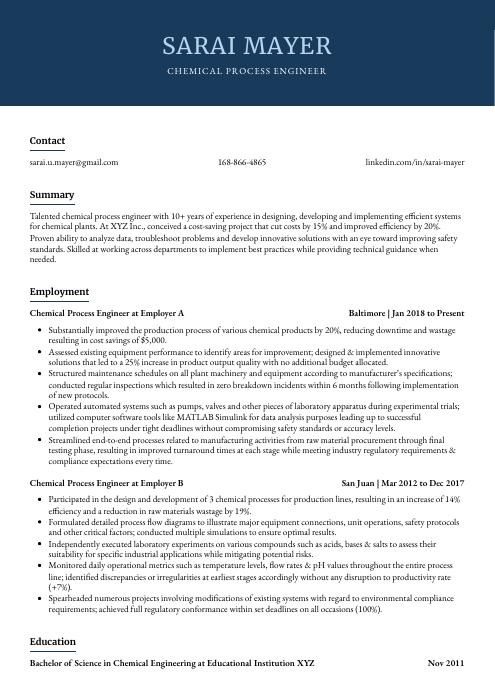

Chemical Process Engineer Resume Sample

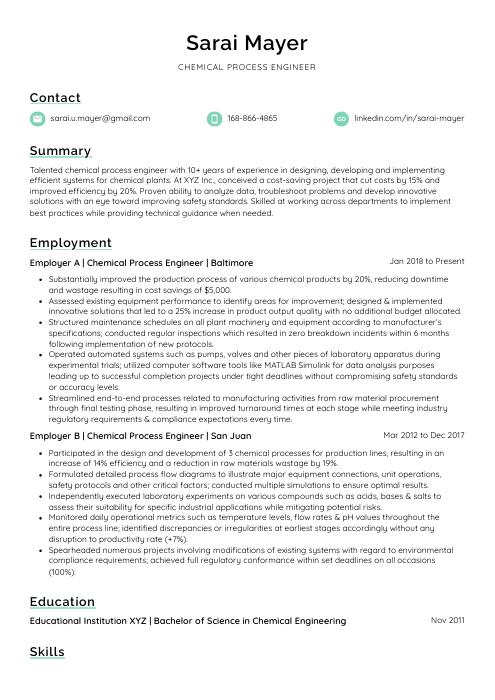

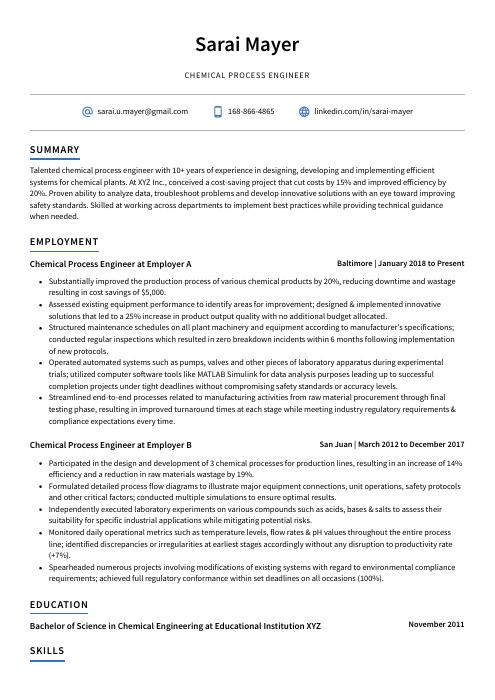

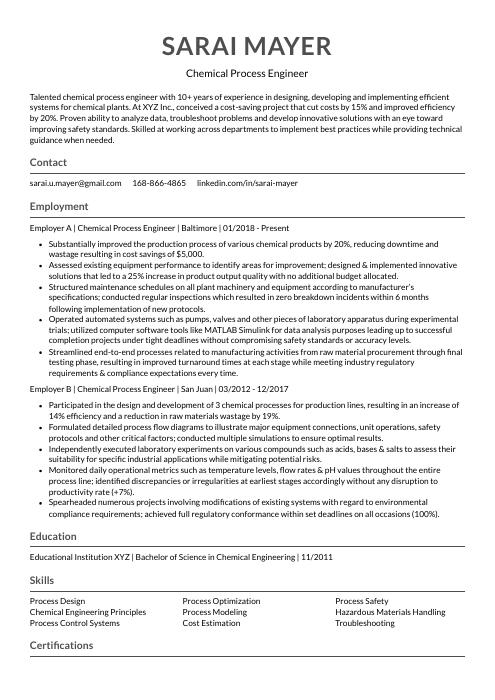

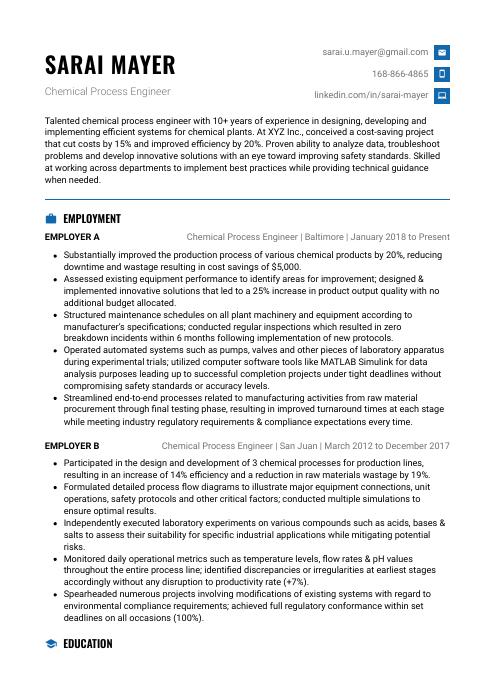

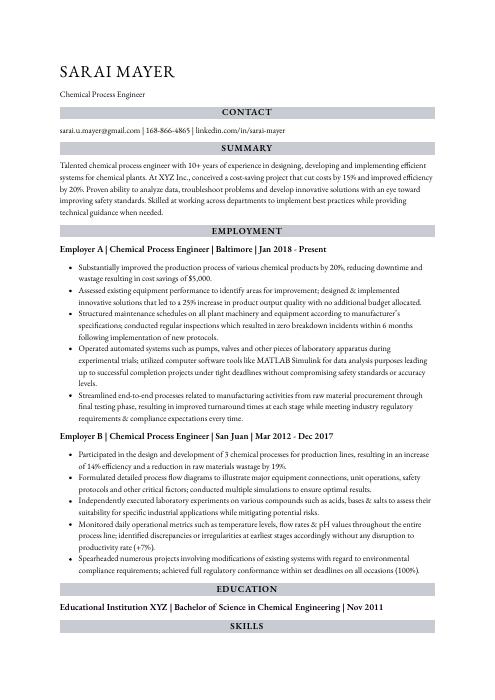

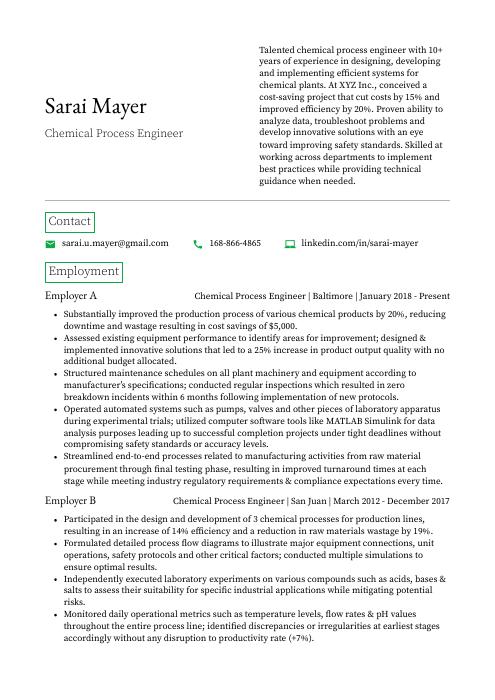

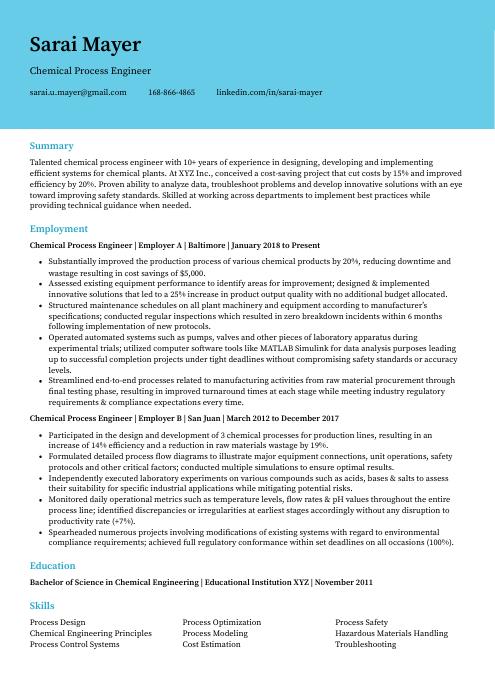

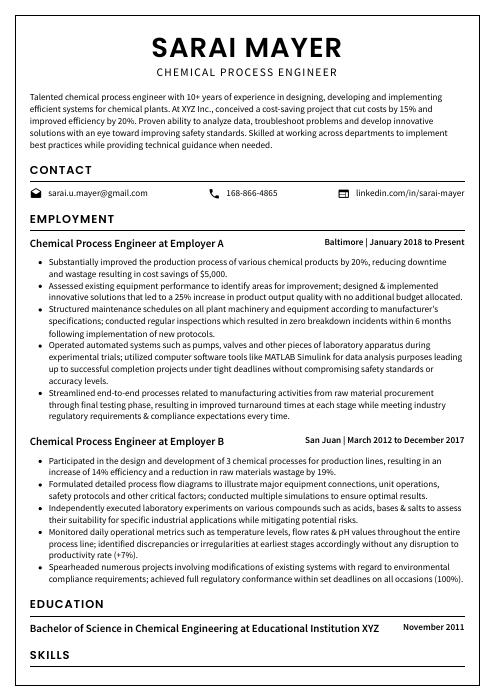

Sarai Mayer

Chemical Process Engineer

[email protected]

168-866-4865

linkedin.com/in/sarai-mayer

Summary

Talented chemical process engineer with 10+ years of experience in designing, developing and implementing efficient systems for chemical plants. At XYZ Inc., conceived a cost-saving project that cut costs by 15% and improved efficiency by 20%. Proven ability to analyze data, troubleshoot problems and develop innovative solutions with an eye toward improving safety standards. Skilled at working across departments to implement best practices while providing technical guidance when needed.

Experience

Chemical Process Engineer, Employer A

Baltimore, Jan 2018 – Present

- Substantially improved the production process of various chemical products by 20%, reducing downtime and wastage resulting in cost savings of $5,000.

- Assessed existing equipment performance to identify areas for improvement; designed & implemented innovative solutions that led to a 25% increase in product output quality with no additional budget allocated.

- Structured maintenance schedules on all plant machinery and equipment according to manufacturer’s specifications; conducted regular inspections which resulted in zero breakdown incidents within 6 months following implementation of new protocols.

- Operated automated systems such as pumps, valves and other pieces of laboratory apparatus during experimental trials; utilized computer software tools like MATLAB Simulink for data analysis purposes leading up to successful completion projects under tight deadlines without compromising safety standards or accuracy levels.

- Streamlined end-to-end processes related to manufacturing activities from raw material procurement through final testing phase, resulting in improved turnaround times at each stage while meeting industry regulatory requirements & compliance expectations every time.

Chemical Process Engineer, Employer B

San Juan, Mar 2012 – Dec 2017

- Participated in the design and development of 3 chemical processes for production lines, resulting in an increase of 14% efficiency and a reduction in raw materials wastage by 19%.

- Formulated detailed process flow diagrams to illustrate major equipment connections, unit operations, safety protocols and other critical factors; conducted multiple simulations to ensure optimal results.

- Independently executed laboratory experiments on various compounds such as acids, bases & salts to assess their suitability for specific industrial applications while mitigating potential risks.

- Monitored daily operational metrics such as temperature levels, flow rates & pH values throughout the entire process line; identified discrepancies or irregularities at earliest stages accordingly without any disruption to productivity rate (+7%).

- Spearheaded numerous projects involving modifications of existing systems with regard to environmental compliance requirements; achieved full regulatory conformance within set deadlines on all occasions (100%).

Skills

- Process Design

- Process Optimization

- Process Safety

- Chemical Engineering Principles

- Process Modeling

- Hazardous Materials Handling

- Process Control Systems

- Cost Estimation

- Troubleshooting

Education

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Chemical Process Operator

American Institute of Chemical Engineers (AICh

May 2017

1. Summary / Objective

A resume summary/objective for a chemical process engineer should highlight your technical knowledge and experience in the field. You could mention the specific processes you have worked on, any certifications or qualifications you possess, as well as how your work has improved safety standards at previous companies. You can also showcase problem-solving skills by mentioning an example of when you identified and resolved a complex issue with one of the systems.

Below are some resume summary examples:

Seasoned chemical process engineer with a track record of successfully managing projects and introducing cost savings. Skilled in developing innovative strategies to reduce waste, optimize resources, and streamline production processes. Experience working on large-scale engineering projects at XYZ Corporation as well as smaller scale operations at ABC Chemicals. Proven ability to apply advanced chemical engineering principles for maximum efficiency across the board.

Energetic chemical process engineer with 5+ years of experience in chemical production and operations. Successfully optimized processes, improved safety protocols, and reduced costs while maintaining consistent quality standards. Skilled at troubleshooting complex problems quickly to ensure minimal downtime and meet critical deadlines. Seeking to join ABC Company as a Chemical Process Engineer to help create innovative solutions for their expanding global market.

Determined and creative chemical process engineer with 7+ years of experience developing and optimizing production processes. At XYZ, designed a cost-effective wastewater treatment system which increased efficiency by 40% while reducing costs by 20%. Proven track record in troubleshooting and resolving complex problems related to chemical engineering operations. Experienced in working with multiple stakeholders for successful project delivery.

Reliable and experienced chemical process engineer with a proven track record of developing and implementing cost-effective strategies to improve production processes. Proficient in troubleshooting systems, optimizing yields, and improving safety protocols. At XYZ Corp., implemented new technologies that resulted in an estimated 20% reduction in energy costs over two years. Seeking to leverage my expertise for ABC Corp’s success.

Skilled chemical process engineer with 5+ years of experience in project development, design, and implementation. At XYZ Corporation, contributed to the successful launch of a new production line within 3 months. Experienced in overseeing all aspects of plant operations from concept to maintenance. Proven track record in developing cost-effective solutions that improve efficiency while ensuring compliance with safety regulations.

Enthusiastic chemical process engineer with 8+ years of experience in the petrochemical industry. Skilled at optimizing and troubleshooting complex processes to drive efficiency, improve safety protocols, and reduce downtime. Successfully led a project that reduced production costs by 20%. Looking to join ABC Corporation as a Chemical Process Engineer where I can use my knowledge and expertise to lead new initiatives.

Diligent and experienced chemical process engineer with 8+ years of experience in the production and optimization of plant processes. Seeking to join ABC Industries, a leading provider of innovative solutions for manufacturing, as a Process Engineer. In previous roles I improved yield rates by 15% and reduced energy costs by 12%. Experienced working with both safety protocols and regulatory standards.

Well-rounded chemical process engineer with 8+ years of experience in the chemical industry. Experienced in developing and implementing cost-effective production processes, improving product quality and yield to meet customer requirements, as well as troubleshooting existing systems. Seeking to join ABC Company’s innovative team to continue developing cutting edge solutions for their clients.

2. Experience / Employment

In the experience section, you should provide details on your previous employment history. This section should be written in reverse chronological order, with the most recent job listed first.

When writing out what you did at each role, use bullet points to make it easier for the reader to digest the information quickly. Take some time to think about what specific tasks and responsibilities you had and any quantifiable results that were achieved from them.

For example, instead of saying “Developed process engineering solutions,” you could say “Designed a new chemical production line which increased throughput by 20% while reducing energy consumption by 15%. ”.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Optimized

- Monitored

- Analyzed

- Implemented

- Troubleshot

- Fabricated

- Commissioned

- Operated

- Calibrated

- Inspected

- Programmed

- Automated

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Implemented process improvements that increased production efficiency by 25% and reduced costs by $20,000.

- Inspected existing chemical processes to identify areas of optimization; successfully identified over 20 potential cost-saving initiatives in the first 3 months.

- Competently operated a variety of process engineering equipment including catalytic reactors, separators, evaporators and distillation columns with an exceptional safety record (no incidents).

- Facilitated communication between operations personnel and management regarding process performance issues; designed new procedures for more effective collaboration within the team.

- Reorganized plant layout to improve material flow resulting in decreased cycle time from 5 days to 2 days per batch on average – saving 80 hours/week companywide.

- Advised senior team on the most efficient chemical processes for producing quality end products, resulting in a 15% reduction of production costs.

- Fabricated process equipment and troubleshot defects to ensure reliable operation of various systems; maintained 95% uptime across all machines during tenure.

- Designed complex blueprints and diagrams outlining workflow, safety protocols and other requirements specific to each project; successfully completed 10 projects within allocated timeline & budget parameters while working with limited resources.

- Mentored junior engineers in best practices related to chemical engineering processes by providing hands-on training sessions; improved overall efficiency rate by 25%.

- Confidently managed hazardous materials according to industry regulations throughout entire work cycle, eliminating any potential risks associated with unsafe handling or storage procedures.

- Demonstrated advanced expertise in the engineering, design and implementation of chemical processes; improved production output by 25% in 3 months.

- Effectively managed a variety of hazardous materials & chemicals throughout processing operations while maintaining safety regulations at all times.

- Improved existing process systems through the development of new technologies and modifications to increase product quality standards by 30%.

- Reduced waste material costs by 15%, allowing for increased profitability within 6 months following changes made to production methods.

- Represented company on various technical committees related to chemical processing initiatives, developing strategies that would improve industrial efficiency and reduce environmental impact across multiple industries.

- Calibrated and maintained critical process equipment to ensure precise operations and safety compliance, resulting in a 10% improvement in production output.

- Analyzed chemical processes using data-driven methods like DOE (Design of Experiments) & SPC (Statistical Process Control); identified root causes for key process issues, enabling timely corrective action that improved overall quality by 15%.

- Optimized existing plant layout with the help of simulation software such as Aspen HYSYS; reduced energy costs by $7,000 per month and minimized personnel exposure to hazardous materials by 22%.

- Consistently monitored all phases of the manufacturing cycle from raw material sourcing through finished product delivery; improved on-time deliveries from 65% to 95%, earning commendations from customers numerous times throughout the year.

- Utilized knowledge of organic chemistry principles along with lab testing techniques such as HPLC/GCMS analysis to develop new products for pharmaceutical industry clients; successfully launched four projects within budget parameters over an 18-month period.

- Reliably maintained and monitored chemical process equipment over a period of 3 years, ensuring production continuity with zero safety incidents.

- Introduced latest machinery technology to automate processes for greater efficiency; achieved 65% reduction in raw material costs within 6 months.

- Documented all test results and analysis according to guidelines set by the company’s Quality Assurance division; consistently maintained quality standards that were 10% higher than industry norms.

- Coordinated with other departments (e.g., research & development) on various projects, ensured completion of tasks as per schedule while controlling budgets within allocated amounts (+$25K).

- Achieved an overall increase in productivity level by 20%, reducing downtime hours from 28/week to 18/week during 6-month period through effective optimization strategies implemented on site.

- Prepared detailed process flow diagrams, mass balance calculations and material balance models to analyze chemical processes in a fast-paced industrial environment; increased operational efficiency by 10%.

- Automated existing manual operations with the use of various control systems and sensors; reduced downtime by 30% while increasing labor productivity by 20%.

- Successfully designed, tested and implemented new production equipment for petrochemical plants, resulting in an additional $4 million in revenue over 6 months.

- Commissioned newly installed instrumentation such as pressure gauges, temperature controllers & safety valves for multiple large-scale projects within strict deadlines; completed tasks 1 week ahead of schedule on average.

- Compiled weekly performance reports outlining key metrics such as throughputs and yields from the plant’s manufacturing units; identified areas for improvement which resulted in a 25% reduction in energy consumption costs annually.

- Presented innovative process engineering solutions to production requirements resulting in a 15% reduction in overall energy costs.

- Programmed and maintained complex chemical process control systems, significantly improving machine efficiency by 25%.

- Expedited the development of new processes for improved product quality; developed 3 successful prototypes within budget and ahead of schedule.

- Actively monitored plant operations to ensure safety compliance with all applicable regulations, reducing risk factors by 40%.

- Revised existing policies/procedures related to hazardous materials management and storage; decreased incident rates due to improper handling by 50%.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for a candidate who is experienced in chemical process engineering and another might want someone with experience in oil refining.

It is important to tailor the skills section of your resume to each job you are applying for, as many employers use applicant tracking systems which scan resumes for certain keywords before passing them on to a human.

In addition, this section should not just list out all of your technical abilities; it’s also beneficial to include soft skills such as communication and problem-solving capabilities that can help set you apart from other candidates. Furthermore, make sure that any relevant qualifications or certifications are included here too.

Below is a list of common skills & terms:

- Chemical Engineering Principles

- Cost Estimation

- Data Analysis

- Hazardous Materials Handling

- Process Control Systems

- Process Design

- Process Modeling

- Process Optimization

- Process Safety

- Troubleshooting

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior work experience, include an education section below your resume objective. However, if you have significant work experience to showcase, it may be best to omit the education section altogether.

If including an education section is necessary, try to mention courses related to chemical engineering or any other topics that could be beneficial for a process engineer role.

Bachelor of Science in Chemical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field. They show potential employers that you have taken the time and effort to become certified in an area of knowledge, which can help make you stand out from other applicants.

When applying for jobs, include any certifications relevant to the position on your resume. This will give hiring managers an indication of how qualified you are for the role and could be what sets you apart from other candidates.

Certified Chemical Process Operator

American Institute of Chemical Engineers (AICh

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Sarai Mayer, this would be Sarai-Mayer-resume.pdf or Sarai-Mayer-resume.docx.

7. Cover Letter

A cover letter is an important document that should be included with any job application. It serves to provide more information about your qualifications and experience, as well as giving you the opportunity to make a personal connection with the hiring manager.

Cover letters are typically made up of 2-4 concise paragraphs and can help highlight why you’re the perfect fit for the role. Although they may not always be requested by employers, writing one is highly recommended in order to stand out from other applicants and showcase your suitability for the position.

Below is an example cover letter:

Dear Jany,

I am writing to apply for the position of Chemical Process Engineer at ABC Corporation. With over five years’ experience in process engineering and a strong interest in chemical processes, I believe I would make a valuable addition to your team.

In my current role as Process Engineer at XYZ Corporation, I am responsible for overseeing the production of chemicals used in a variety of industries. This involves ensuring that all safety regulations are adhered to, optimizing production processes, and troubleshooting any issues that may arise. My experience has given me a detailed understanding of chemical processes and how they can be improved.

I am confident that I could bring this same level of knowledge and expertise to ABC Corporation. In particular, I believe my skills in process optimization would be beneficial in improving your company’s production efficiency. Additionally, my excellent problem-solving skills would enable me to quickly resolve any issues that may occur during the manufacturing process.

Thank you for taking the time to consider my application; I look forward to discussing my qualifications further with you soon.

Sincerely,

Sarai

Chemical Process Engineer Resume Templates

Ocelot

Ocelot Gharial

Gharial Rhea

Rhea Hoopoe

Hoopoe Fossa

Fossa Jerboa

Jerboa Saola

Saola Lorikeet

Lorikeet Axolotl

Axolotl Indri

Indri Echidna

Echidna Pika

Pika Kinkajou

Kinkajou Markhor

Markhor Bonobo

Bonobo Numbat

Numbat Quokka

Quokka Dugong

Dugong Cormorant

Cormorant Rezjumei

Rezjumei