Calibration Engineer Resume Guide

Calibration engineers ensure that all instruments and equipment used in a variety of industries are accurate. They assess, adjust, maintain and repair measuring devices to meet specific standards set by the manufacturer or industry they work in. Additionally, calibration engineers document their findings, process data from measurements taken and provide recommendations for any necessary repairs or adjustments needed to keep equipment running efficiently and accurately.

You have a knack for calibrating instruments and machines, but you need to prove it to potential employers. Crafting an eye-catching resume is key in order to make them aware of your expertise in the field.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Calibration Engineer Resume Sample

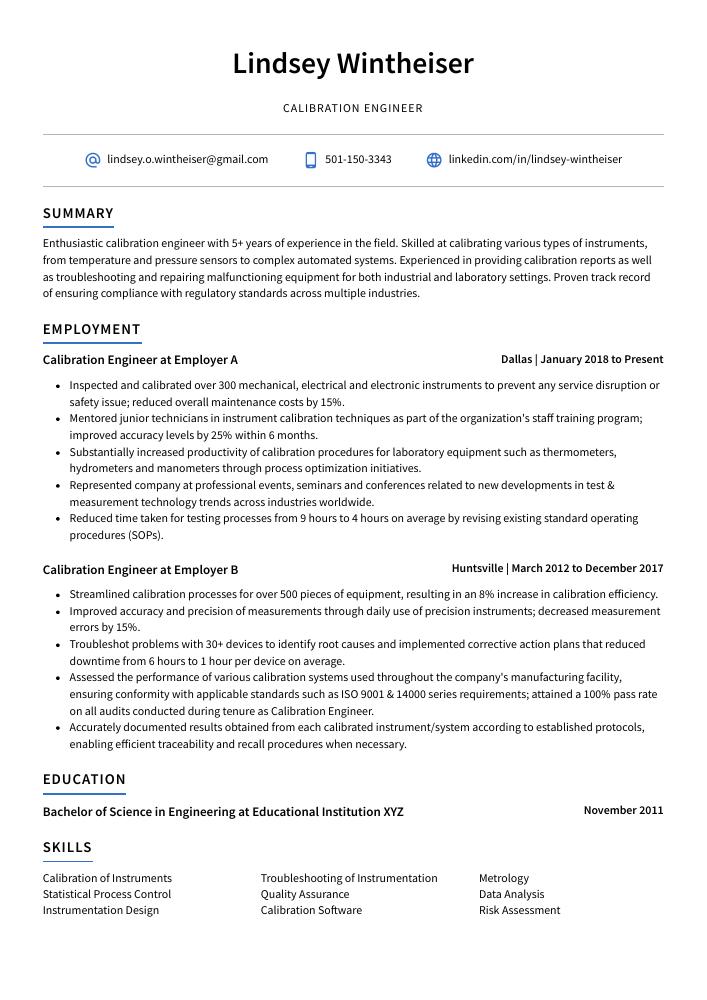

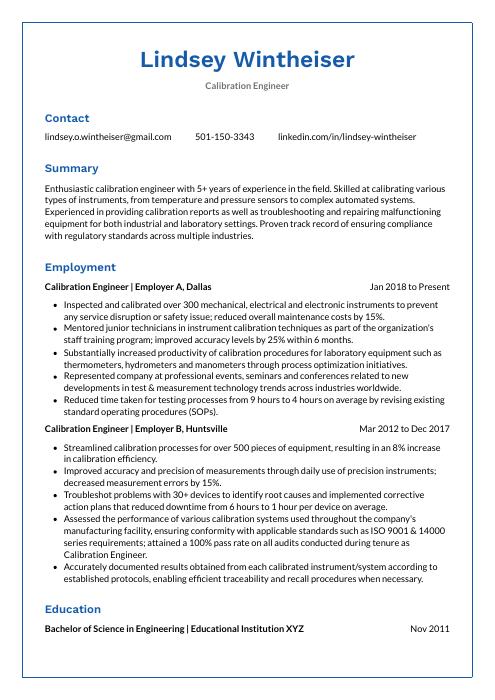

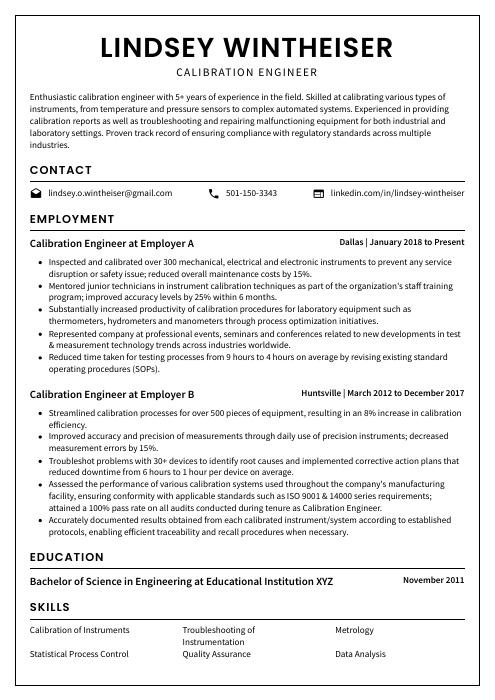

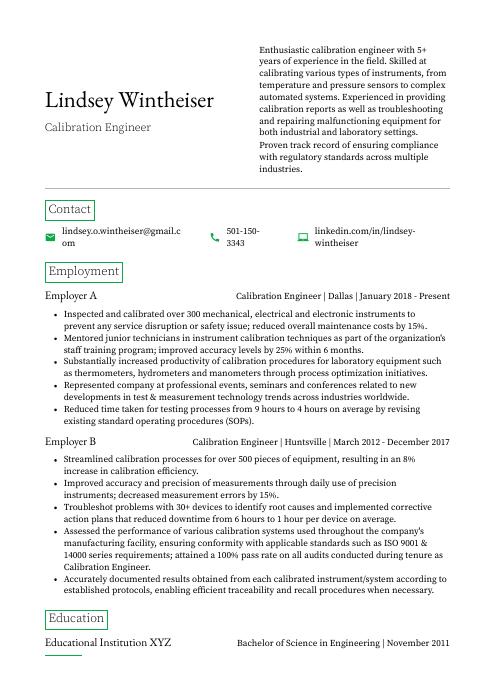

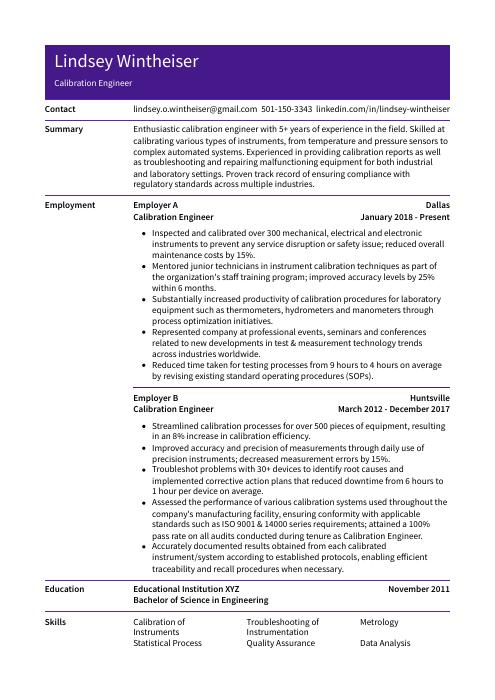

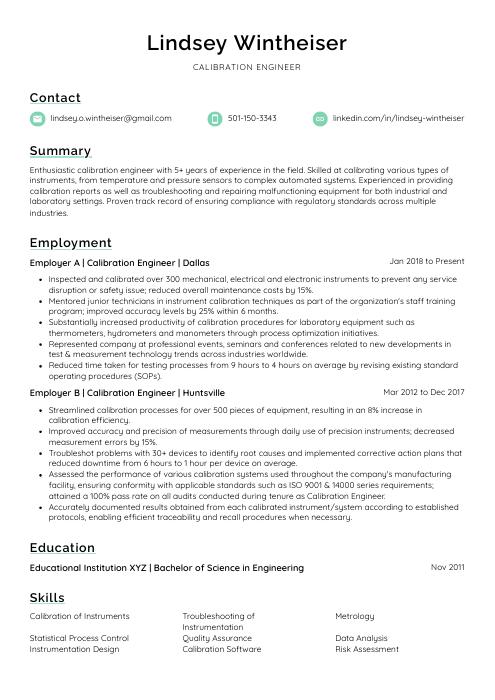

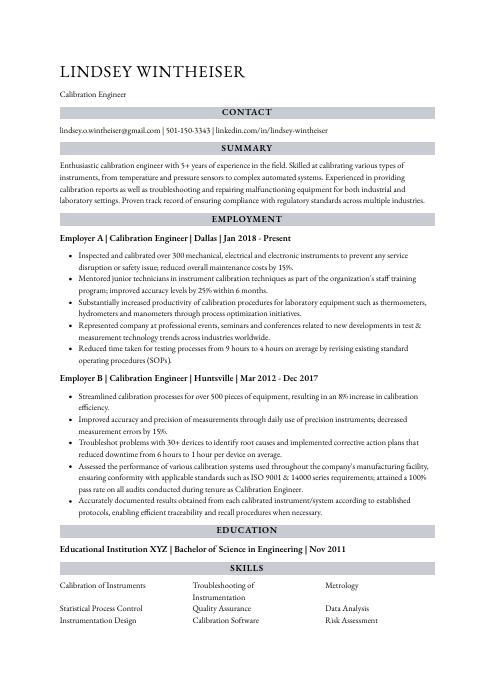

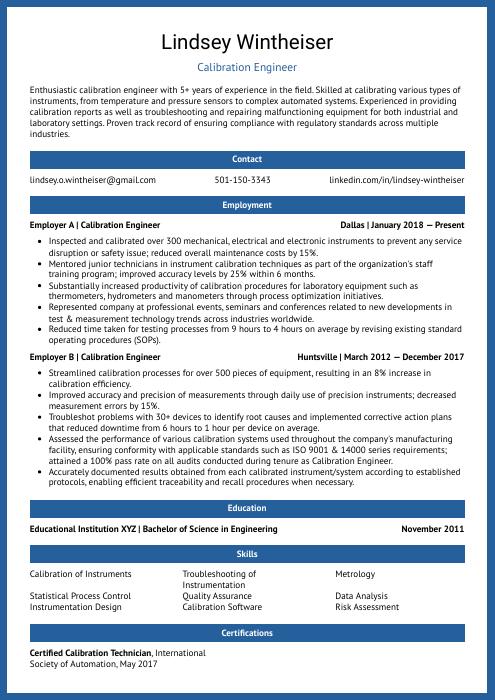

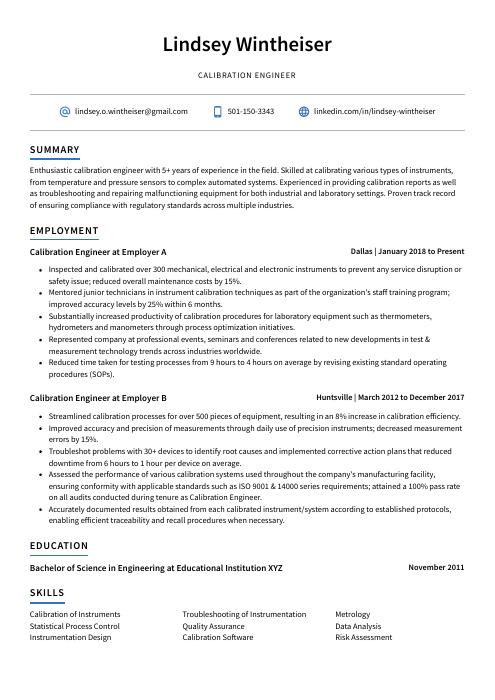

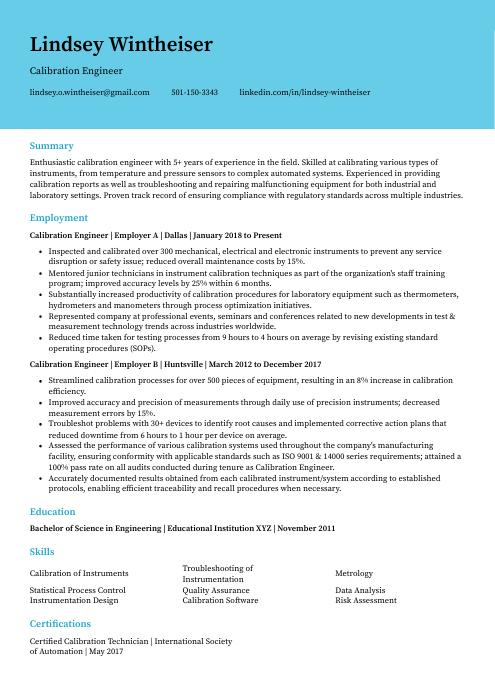

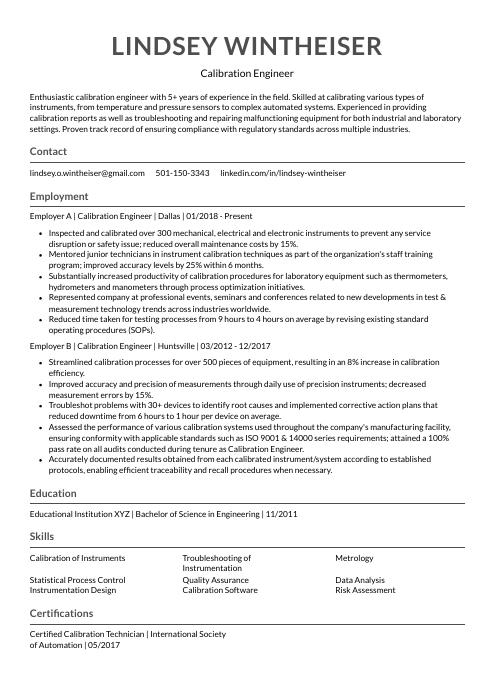

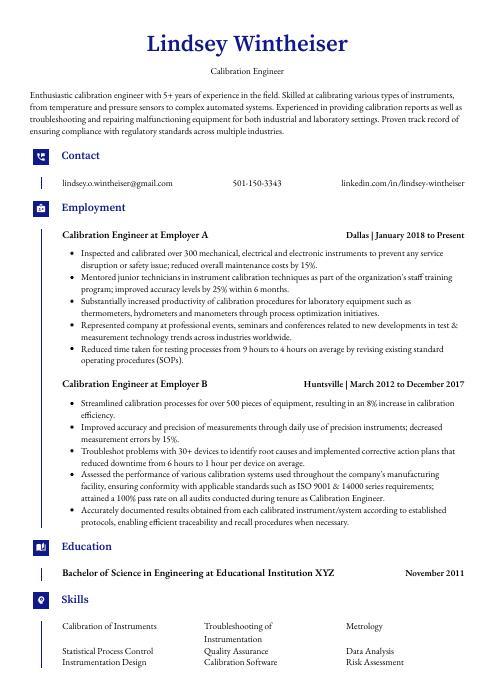

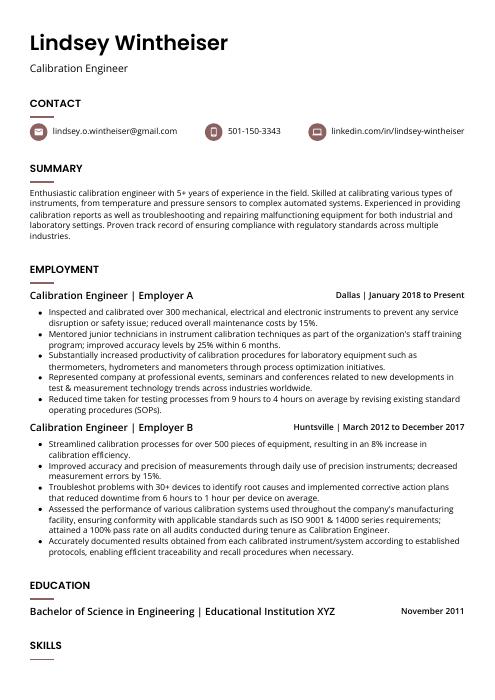

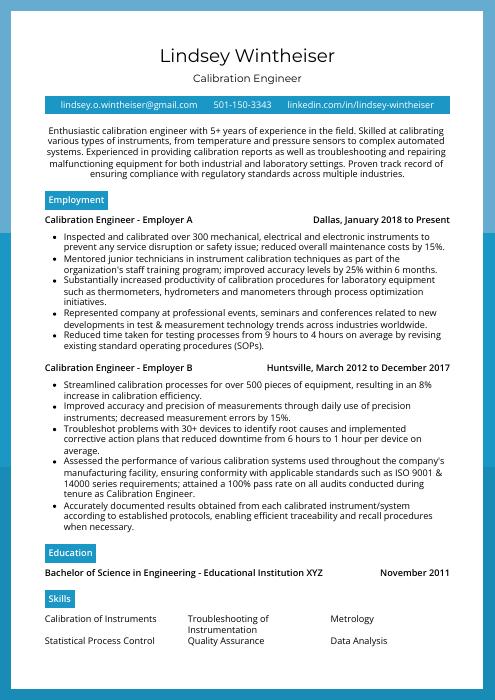

Lindsey Wintheiser

Calibration Engineer

[email protected]

501-150-3343

linkedin.com/in/lindsey-wintheiser

Summary

Enthusiastic calibration engineer with 5+ years of experience in the field. Skilled at calibrating various types of instruments, from temperature and pressure sensors to complex automated systems. Experienced in providing calibration reports as well as troubleshooting and repairing malfunctioning equipment for both industrial and laboratory settings. Proven track record of ensuring compliance with regulatory standards across multiple industries.

Experience

Calibration Engineer, Employer A

Dallas, Jan 2018 – Present

- Inspected and calibrated over 300 mechanical, electrical and electronic instruments to prevent any service disruption or safety issue; reduced overall maintenance costs by 15%.

- Mentored junior technicians in instrument calibration techniques as part of the organization’s staff training program; improved accuracy levels by 25% within 6 months.

- Substantially increased productivity of calibration procedures for laboratory equipment such as thermometers, hydrometers and manometers through process optimization initiatives.

- Represented company at professional events, seminars and conferences related to new developments in test & measurement technology trends across industries worldwide.

- Reduced time taken for testing processes from 9 hours to 4 hours on average by revising existing standard operating procedures (SOPs).

Calibration Engineer, Employer B

Huntsville, Mar 2012 – Dec 2017

- Streamlined calibration processes for over 500 pieces of equipment, resulting in an 8% increase in calibration efficiency.

- Improved accuracy and precision of measurements through daily use of precision instruments; decreased measurement errors by 15%.

- Troubleshot problems with 30+ devices to identify root causes and implemented corrective action plans that reduced downtime from 6 hours to 1 hour per device on average.

- Assessed the performance of various calibration systems used throughout the company’s manufacturing facility, ensuring conformity with applicable standards such as ISO 9001 & 14000 series requirements; attained a 100% pass rate on all audits conducted during tenure as Calibration Engineer.

- Accurately documented results obtained from each calibrated instrument/system according to established protocols, enabling efficient traceability and recall procedures when necessary.

Skills

- Calibration of Instruments

- Troubleshooting of Instrumentation

- Metrology

- Statistical Process Control

- Quality Assurance

- Data Analysis

- Instrumentation Design

- Calibration Software

- Risk Assessment

Education

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Calibration Technician

International Society of Automation

May 2017

1. Summary / Objective

A resume summary for a calibration engineer should be an engaging overview of your skills and experience. It should highlight the technical qualifications that make you stand out from other applicants, such as knowledge of industry-standard software programs, certifications in specific areas like thermodynamics or metrology, and any awards or recognition for outstanding performance. It’s also important to mention how you have used these skills to benefit past employers – for example, by developing new processes that improved accuracy and efficiency in calibrations.

Below are some resume summary examples:

Detail-oriented calibration engineer with 5+ years of experience in the calibration, maintenance and repair of precision measurement equipment. Adept at troubleshooting complex problems with a variety of analytical instruments. Experienced in developing calibration standards for various types of equipment to ensure accuracy and reliability. Successfully reduced downtime by 20% through efficient testing protocols implemented at XYZ Corporation.

Committed Calibration Engineer with 7+ years of experience in the medical industry. Expertise in troubleshooting, calibrating and repairing medical equipment to ensure optimal performance for patient safety. Proven success in reducing calibration time by 25%, increasing productivity at ABC Medical Center through improved process optimization. Highly organized and motivated individual who is committed to providing top-level service excellence.

Proficient Calibration Engineer with 5+ years of experience in the instrumentation industry. Skilled at troubleshooting and calibrating instruments to ensure accuracy, reliability and compliance with regulatory standards. Familiarity with a wide range of lab equipment including pressure gauges, thermometers, balances and other precision measuring tools. At XYZ Inc., developed an automated calibration system that reduced manual effort by 25%.

Seasoned calibration engineer with 10+ years of experience in performing hands-on calibration on various instruments and systems. At XYZ, led the development and implementation of a new system for calibrating temperature sensors that resulted in increased accuracy by 15%. Proven ability to troubleshoot equipment issues quickly while maintaining regulatory compliance. Skilled at working independently or as part of a cross-functional team.

Amicable calibration engineer with 15+ years of experience in calibrating and troubleshooting a wide range of instruments and systems. Skilled at providing technical assistance, training personnel on equipment operation, maintaining records of calibration activities and results, and developing automated processes to improve efficiency. Seeking to join ABC Company as their next Senior Calibration Engineer for the benefit of both parties.

Well-rounded calibration engineer with 5+ years of experience in a variety of industries. Proven track record in delivering accurate and reliable calibrations for both mechanical and electrical instruments, as well as performing routine maintenance on lab equipment. Seeking to apply expertise at ABC Labs to ensure the highest quality standards are met while providing excellent customer service.

Talented calibration engineer with 8+ years of experience in the calibration, repair and maintenance of complex instruments. Seeking to join ABC Company as a Calibration Engineer to utilize expertise in troubleshooting and servicing sophisticated instrumentation. At XYZ Corporation was instrumental in reducing equipment downtime by 35% through regular preventative maintenance checks.

Skilled calibration engineer with 6+ years of experience in designing and developing hardware test systems for a variety of products. Proven track record of delivering quality calibration results on time and under budget. Seeking to join ABC company in order to apply my solid technical skills and knowledge towards calibrating complex electronic components within tight timelines.

2. Experience / Employment

Next comes the work history section, which should be written in reverse chronological order. This means your most recent job is listed first.

Stick to bullet points when writing this section; it makes the content easier for the reader to digest quickly. When describing what you did, include both details and quantifiable results obtained from your actions.

For example, instead of saying “Calibrated equipment,” you could say, “Successfully calibrated over 100 pieces of medical diagnostic equipment per month using a variety of tools, resulting in an average accuracy rate of 95%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Calibrated

- Troubleshot

- Inspected

- Adjusted

- Monitored

- Analyzed

- Programmed

- Documented

- Tested

- Configured

- Operated

- Repaired

- Optimized

- Certified

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Revised and updated calibration and verification protocols for over 100 instruments, ensuring that all systems were operating within agreed-upon accuracy parameters and resulting in improved system performance by 15%.

- Presented technical training sessions to 10+ operators on calibration procedures and best practices; significantly reduced the time required to complete calibrations per instrument by 30 minutes on average.

- Structured a comprehensive timeline of scheduled maintenance activities for 20+ measuring instruments, increasing overall equipment uptime from 75% to 95%.

- Meticulously calibrated 35 test tools according to international standards (IEC 17025), delivering accurate measurements with an error rate as low as 0.5%, while reducing costs associated with rework & scrap material by 25%.

- Calibrated multiple types of electrical test equipment such as multimeters, oscilloscopes and power analyzers using advanced techniques like signal injection methodologies & harmonic analysis techniques.

- Introduced a new system of calibrating and testing over 50 different types of equipment, resulting in a 25% increase in efficiency.

- Operated advanced calibration tools to accurately measure temperature, pressure and other parameters; completed 600+ calibration tests with zero errors each month.

- Reliably verified the accuracy of laboratory instruments by using various comparison methods such as direct comparison, indirect comparison and substitution techniques.

- Programmed automatic data acquisition systems for digital instrumentation used during process analysis to ensure that all results met required standards within acceptable tolerances; reduced manual intervention time by 30%.

- Achieved full certification from ISO 9001:2015 Quality Management System on first attempt after setting up standard operating procedures for laboratory operations and quality control processes.

- Proficiently calibrated, tested and adjusted over 200 pieces of equipment per month according to manufacturer specifications, ensuring all machines were running optimally.

- Certified in National Institute for Standards (NIST) procedures and able to fix difficult calibration issues which reduced downtime by 15%.

- Repaired various instruments including digital multimeters, oscilloscopes, pressure gauges and thermometers; successfully restored 90% of the defective devices within 24 hours.

- Spearheaded a project to install new software on 12 measuring devices that enabled faster data processing times as well as improved accuracy levels by 5%.

- Demonstrated strong technical skills when troubleshooting electrical systems & mechanical components while maintaining precise records of maintenance tasks performed with 100% accuracy rate.

- Configured and calibrated over 500 pieces of laboratory instrumentation, ensuring accuracy and precision in all measurements.

- Advised and trained junior staff on the proper installation/operation of laboratory equipment; reduced calibration time by 25%.

- Formulated comprehensive test plans to assess performance stability for new products, enhancing product quality control processes from start-to-finish.

- Diligently documented results from each calibration process in accordance with internal protocols and government regulations; improved compliance rating by 12%.

- Analyzed customer complaints against existing equipment standards to identify necessary adjustments or repairs, resolving customer issues within a 24 hour timeframe in 95% of cases reported.

- Monitored the performance of up to 50 instruments and tools, ensuring adherence to calibration standards; reduced errors by 15% in the last quarter.

- Documented all calibration results accurately from start-to-finish, including any adjustments or repairs needed for optimal functioning.

- Prepared detailed reports on instrument accuracy and reliability for management review; increased customer satisfaction rate by 8%.

- Competently operated automated systems and diagnostic equipment such as calipers, micrometers, precision gauges & thermometers while calibrating a variety of mechanical devices across multiple industries.

- Optimized existing processes through periodic maintenance checks of machinery parts, which led to improved operational efficiency savings over $5000 annually in repair costs alone.

- Coordinated calibration of over 500 instruments and equipment annually, adhering to quality standards such as ISO 9000 & 17025 while ensuring that all calibrations were completed within the specified time frame.

- Developed a comprehensive calibration system that streamlined processes and enabled tracking of instrument data; improved accuracy by 10% in just two months after implementation.

- Actively participated in customer meetings to discuss their calibration needs, offering suggestions on how they could optimize their systems for better performance; exceeded client expectations which resulted in repeat business worth $50K last year alone.

- Facilitated training sessions for colleagues on proper use of test and measuring instruments, resulting in an increase in overall team productivity by 20%.

- Expedited troubleshooting process for malfunctioning or damaged tools/instruments with timely repair work; reduced down-time from 2 days to 4 hours on average per job request thus saving an estimated 15 personnel hours each month.

- Independently calibrated 500+ pieces of equipment at different sites, ensuring accuracy and adherence to industry-standard protocols; improved calibration speed by 30% while reducing scrap rate by 15%.

- Compiled detailed reports outlining results of each calibration test performed and identified opportunities for improvement in certain processes.

- Participated in the development of new testing methods and techniques that increased efficiency across all departments within the organization.

- Utilized a variety of diagnostic tools including oscilloscopes, multimeters, spectrum analyzers and specialized software programs to troubleshoot issues with machinery as needed during calibrations tests runs.

- Tested calibrated instruments on-site using high precision measuring devices such as micrometers & calipers; maintained records according to ISO/IEC 17025 standards for future reference purposes when necessary.

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may be looking for someone with experience in calibrating complex instruments, while Organization B may be looking for a calibration engineer who is knowledgeable about the National Instruments platform.

It is essential to tailor your skills section of your resume according to each job you are applying for because many employers use applicant tracking systems that scan resumes and filter out those they deem not to be a high-quality match.

In addition to just listing these skills here, it’s also important to discuss them further in other sections such as the summary or experience section.

Below is a list of common skills & terms:

- Calibration Software

- Calibration of Instruments

- Data Analysis

- Instrumentation Design

- Metrology

- Quality Assurance

- Regulatory Compliance

- Risk Assessment

- Statistical Process Control

- Troubleshooting of Instrumentation

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you recently graduated and have no work experience, mention the details of your degree below your resume objective. However, if you have significant work experience that showcases relevant skills for the calibration engineer role, an education section may not be necessary at all.

If including an education section is appropriate for this position, try to list courses and subjects related to engineering or calibration that demonstrate a strong understanding of the job requirements.

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the necessary knowledge and skills for a given job. Having certifications in your field of expertise can be an invaluable asset when applying for jobs, as it shows recruiters that you are serious about your profession and have taken steps to further develop yourself professionally.

Include any relevant certifications on your resume so hiring managers know what qualifications you possess. This will give them confidence in knowing they are selecting someone with the right credentials for their position.

Certified Calibration Technician

International Society of Automation

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Lindsey Wintheiser, this would be Lindsey-Wintheiser-resume.pdf or Lindsey-Wintheiser-resume.docx.

7. Cover Letter

Providing a cover letter when applying for a job can be beneficial in many ways. It is usually made up of 2 to 4 paragraphs and allows you to add personality and detail that cannot always fit in your resume.

Cover letters are not mandatory but they do give recruiters the opportunity to get an insight into who you are as a professional, beyond what’s written on paper. They also allow you to explain why you’re the best candidate for the role, giving yourself an edge over other applicants.

Below is an example cover letter:

Dear Kendra,

I am writing to apply for the position of Calibration Engineer at XYZ Corporation. As a highly skilled and experienced engineer with expertise in calibration, I am confident that I can make a significant contribution to your team.

Throughout my career, I have worked on a variety of calibration projects for different types of equipment. My experience has taught me how to troubleshoot and solve problems quickly and efficiently. In addition, I have excellent communication skills and work well with other engineers and technicians.

Some of the key accomplishments that demonstrate my suitability for this role include:

– Developing a new calibration procedure that reduced testing time by 30%.

– designing a new system for tracking calibrations that improved efficiency by 25%.

– Creating a database of over 1000 calibrated devices which is used by engineers across the company.

Sincerely,

Lindsey

Calibration Engineer Resume Templates

Markhor

Markhor Bonobo

Bonobo Saola

Saola Cormorant

Cormorant Quokka

Quokka Pika

Pika Lorikeet

Lorikeet Numbat

Numbat Ocelot

Ocelot Axolotl

Axolotl Dugong

Dugong Indri

Indri Gharial

Gharial Kinkajou

Kinkajou Jerboa

Jerboa Fossa

Fossa Rhea

Rhea Hoopoe

Hoopoe Echidna

Echidna Rezjumei

Rezjumei