Aviation Support Equipment Technician Resume Guide

Aviation Support Equipment Technicians maintain and repair the machinery used to support aircraft operations. They inspect, service, test and troubleshoot a variety of electrical, hydraulic and mechanical systems such as ground power units, air start units, tow tractors and other specialized equipment required for aircraft maintenance.

Aircraft maintenance requires a special touch and you have it. But potential employers don’t know who you are, so to make yourself stand out from the crowd, you must craft an outstanding resume that highlights your experience in aviation support equipment repair.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

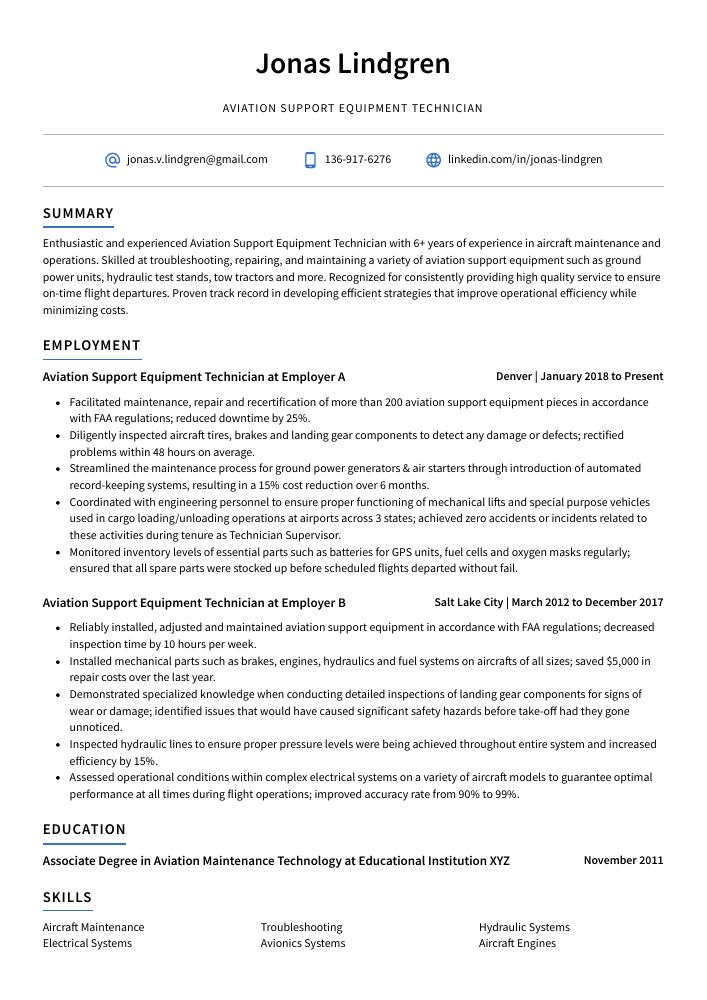

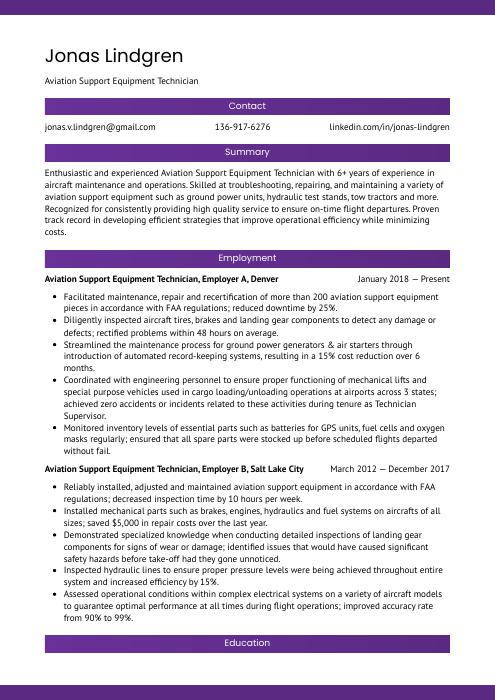

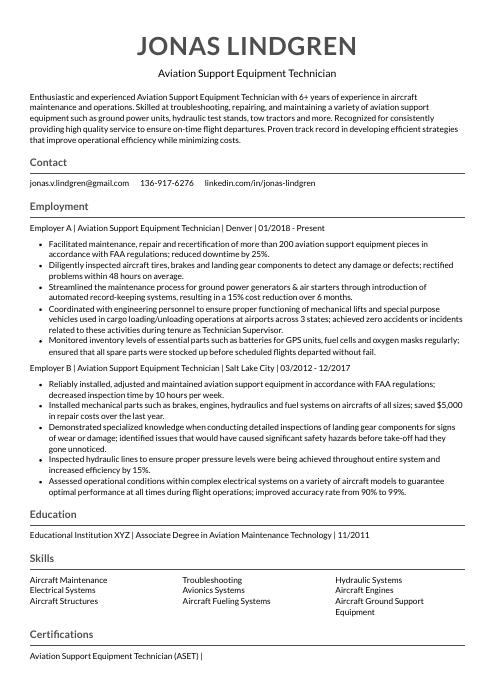

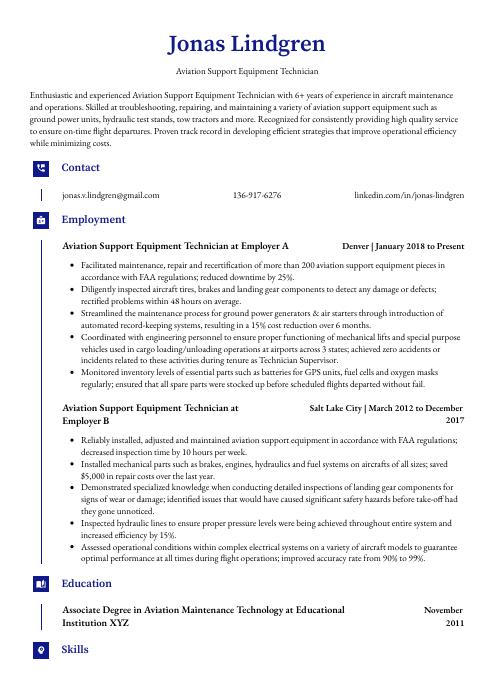

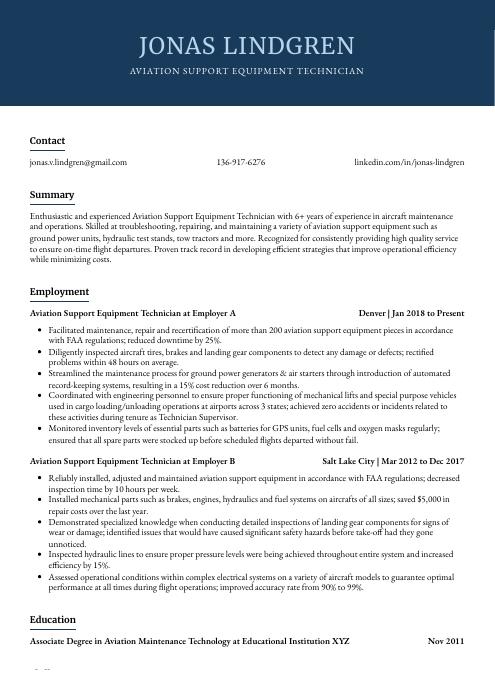

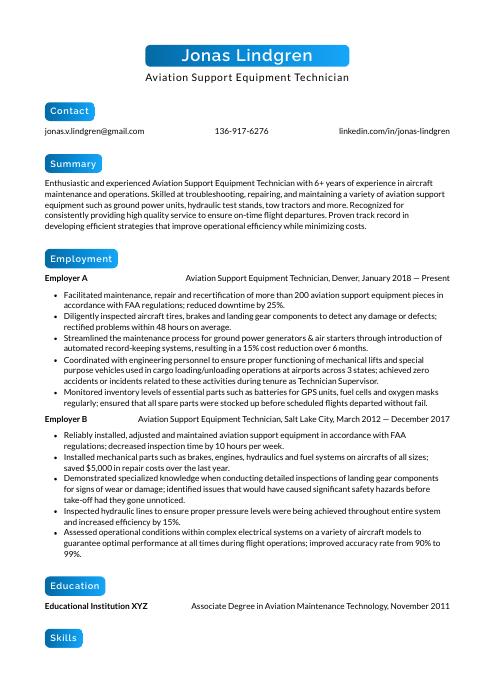

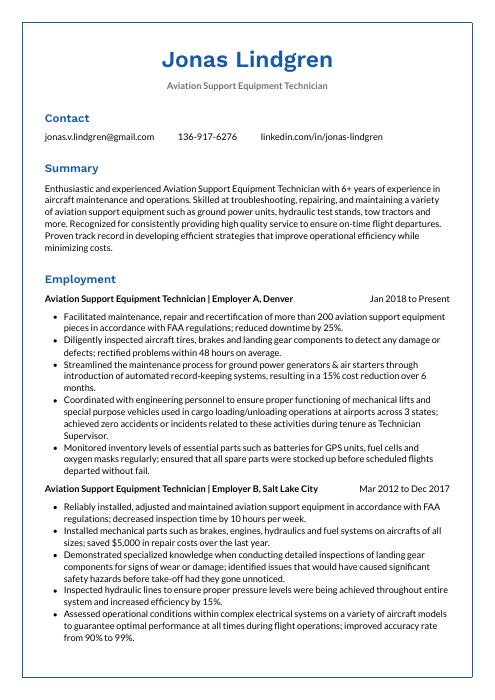

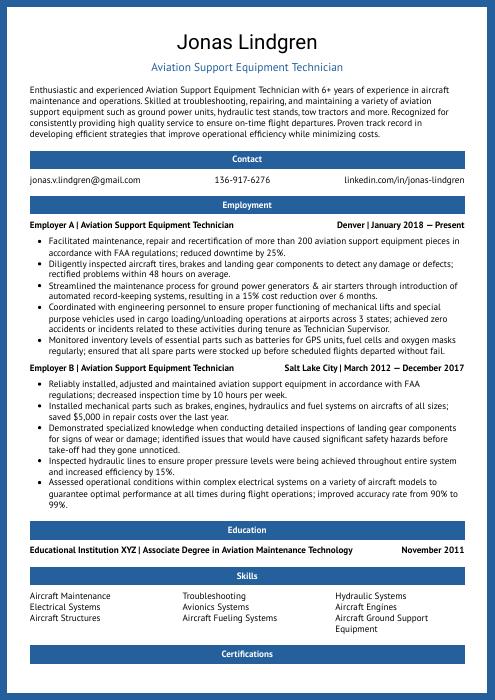

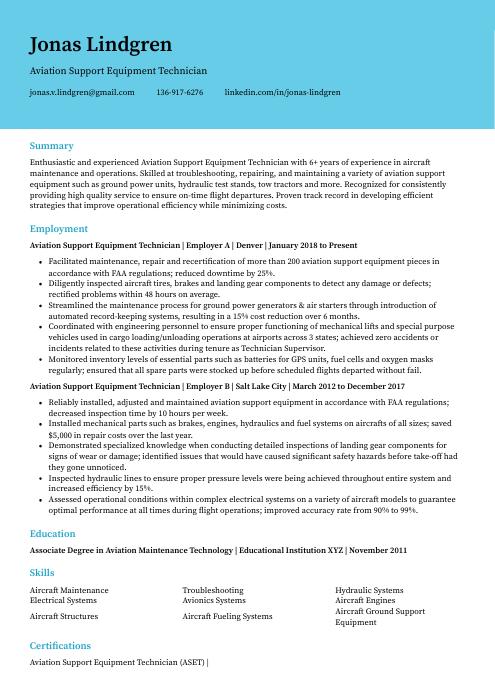

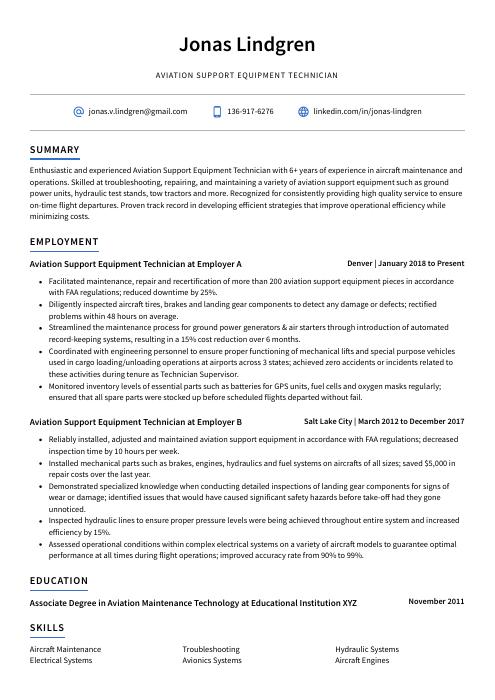

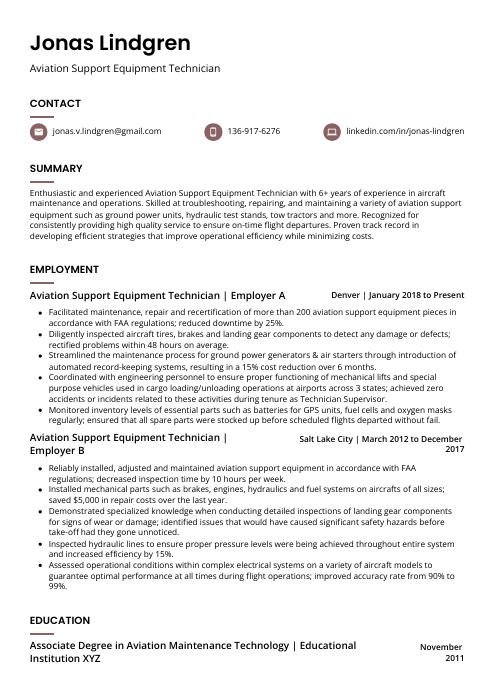

Aviation Support Equipment Technician Resume Sample

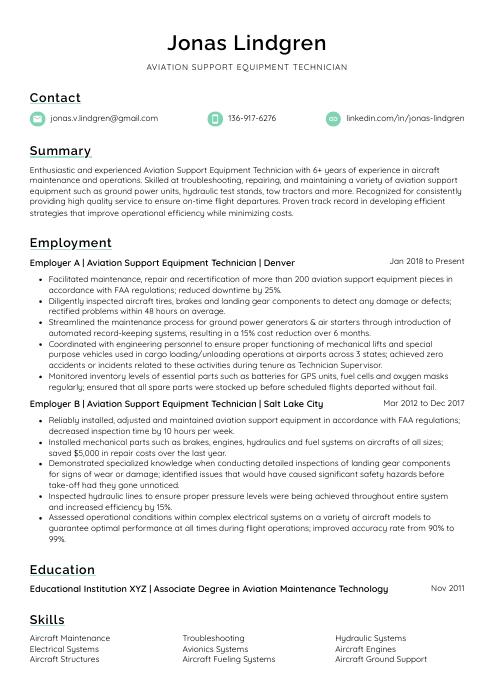

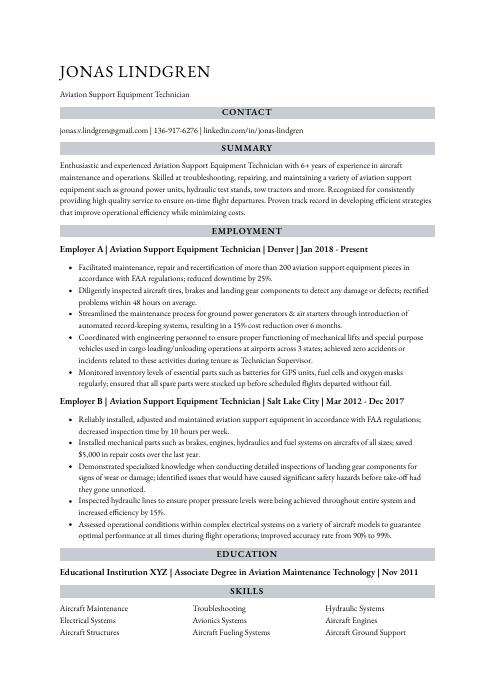

Jonas Lindgren

Aviation Support Equipment Technician

[email protected]

136-917-6276

linkedin.com/in/jonas-lindgren

Summary

Enthusiastic and experienced Aviation Support Equipment Technician with 6+ years of experience in aircraft maintenance and operations. Skilled at troubleshooting, repairing, and maintaining a variety of aviation support equipment such as ground power units, hydraulic test stands, tow tractors and more. Recognized for consistently providing high quality service to ensure on-time flight departures. Proven track record in developing efficient strategies that improve operational efficiency while minimizing costs.

Experience

Aviation Support Equipment Technician, Employer A

Denver, Jan 2018 – Present

- Facilitated maintenance, repair and recertification of more than 200 aviation support equipment pieces in accordance with FAA regulations; reduced downtime by 25%.

- Diligently inspected aircraft tires, brakes and landing gear components to detect any damage or defects; rectified problems within 48 hours on average.

- Streamlined the maintenance process for ground power generators & air starters through introduction of automated record-keeping systems, resulting in a 15% cost reduction over 6 months.

- Coordinated with engineering personnel to ensure proper functioning of mechanical lifts and special purpose vehicles used in cargo loading/unloading operations at airports across 3 states; achieved zero accidents or incidents related to these activities during tenure as Technician Supervisor.

- Monitored inventory levels of essential parts such as batteries for GPS units, fuel cells and oxygen masks regularly; ensured that all spare parts were stocked up before scheduled flights departed without fail.

Aviation Support Equipment Technician, Employer B

Salt Lake City, Mar 2012 – Dec 2017

- Reliably installed, adjusted and maintained aviation support equipment in accordance with FAA regulations; decreased inspection time by 10 hours per week.

- Installed mechanical parts such as brakes, engines, hydraulics and fuel systems on aircrafts of all sizes; saved $5,000 in repair costs over the last year.

- Demonstrated specialized knowledge when conducting detailed inspections of landing gear components for signs of wear or damage; identified issues that would have caused significant safety hazards before take-off had they gone unnoticed.

- Inspected hydraulic lines to ensure proper pressure levels were being achieved throughout entire system and increased efficiency by 15%.

- Assessed operational conditions within complex electrical systems on a variety of aircraft models to guarantee optimal performance at all times during flight operations; improved accuracy rate from 90% to 99%.

Skills

- Aircraft Maintenance

- Troubleshooting

- Hydraulic Systems

- Electrical Systems

- Avionics Systems

- Aircraft Engines

- Aircraft Structures

- Aircraft Fueling Systems

- Aircraft Ground Support Equipment

Education

Associate Degree in Aviation Maintenance Technology

Educational Institution XYZ

Nov 2011

Certifications

Aviation Support Equipment Technician (ASET)

National Center for Aerospace

May 2017

1. Summary / Objective

A resume summary or objective is the first thing a potential employer will read, so it’s important to make sure you grab their attention. As an aviation support equipment technician, your summary should highlight your experience and qualifications in this field. For example, you could mention how many years of experience you have working with aircrafts and other related equipment, any certifications or licenses that are relevant to the job position, as well as any awards or recognition for outstanding performance.

Below are some resume summary examples:

Reliable and dedicated aviation support equipment technician with 10+ years of experience in aircraft maintenance, repair, and inspection. Skilled in troubleshooting complex mechanical problems using sophisticated diagnostic tools and systems. Seeking to leverage expertise and knowledge as the next Aviation Support Equipment Technician at ABC Airline. Key achievements include saving $50K on repairs by identifying an underlying issue that was not previously identified.

Driven aviation support equipment technician with seven years of experience in the industry. Proven track record for successfully troubleshooting, repairing, and maintaining aviation ground support systems. Hands-on knowledge on all aspects of technical operations from hydraulics to pneumatics; electrical engineering to welding/fabrication repair work. Experienced in providing maintenance services as per required regulations such as FAA/EASA 145 & 147 standards.

Detail-oriented aviation support equipment technician with 10+ years of experience troubleshooting, repairing, and maintaining various types of aircraft ground support systems. Proven track record in quickly identifying faults and resolving them to ensure mission-critical operations remain uninterrupted. Dedicated to providing top-notch service as an aviation technician at ABC Airline by leveraging expertise in safety regulations and industry standards.

Amicable aviation support equipment technician with 5+ years of experience in the aviation industry. Seeking to join ABC as an aircraft maintenance specialist and provide dedicated service while using my expertise in troubleshooting, repairing, and maintaining military aircrafts’ ground support systems. Recognized for excellent work ethic throughout my career- track record of successfully completing projects ahead of schedule despite tight deadlines.

Dependable and knowledgeable aviation support equipment technician with 5+ years of experience providing maintenance and repairs to complex aircraft equipment. Skilled at troubleshooting malfunctions, managing inventories, and performing administrative tasks. Excels in both individual work as well as collaborative team projects. Looking to leverage my skillset to become the next Aviation Support Equipment Technician at ABC Company.

Well-rounded Aviation Support Equipment Technician with 9+ years of experience in troubleshooting, repairing, and maintaining aircraft-related systems. Highly skilled at working on complex mechanical equipment and electrical components to ensure peak performance. Experienced in conducting preventive maintenance inspections, as well as testing and calibrating avionics instruments for FAA certification purposes.

Diligent Aviation Support Equipment Technician with 10+ years of experience in the aviation industry. Skilled in troubleshooting and resolving issues related to aircraft ground support equipment, including maintenance and repair. Seeking an opportunity at ABC Aviation Services to use my expertise for keeping up-to-date on all safety protocols while efficiently servicing both commercial and military aircrafts.

Determined and resourceful aviation support equipment technician with 10+ years of experience performing inspections and repairs on a variety of aircraft. Proven ability to identify potential problems, diagnose issues quickly, and take corrective action in a timely manner. Seeking to join ABC Aviation as an experienced technician where I can use my technical know-how to keep aircraft running smoothly.

2. Experience / Employment

In the experience section, you provide details on your employment history. This should be written in reverse chronological order, meaning the most recent job is listed at the top.

When stating what you did and accomplished, stick to bullet points as much as possible. Doing so allows for quick digestion of information by the reader. You also want to include quantifiable results when applicable; this will help demonstrate how effective your work was while making it easier for employers to assess your abilities quickly.

For example, instead of saying “Maintained aircraft support equipment,” you could say, “Performed preventative maintenance checks on a variety of ground support equipment with 100% accuracy within specified timelines.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Troubleshot

- Serviced

- Operated

- Installed

- Repaired

- Tested

- Calibrated

- Adjusted

- Assembled

- Disassembled

- Fabricated

- Replaced

- Monitored

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Disassembled, repaired and reassembled over 40 pieces of aviation support equipment per week, resulting in a 20% decrease in downtime.

- Reduced number of safety issues by inspecting and calibrating all aircraft systems for accuracy; identified minor flaws before they became major problems.

- Adjusted electrical wiring on different types of ground power units to ensure proper operation; successfully returned 12 defective GPUs to service within 4 hours each time.

- Proficiently operated forklifts, tugs, tractors and other heavy machinery when transporting component parts between departments; eliminated manual handling injuries by 30%.

- Compiled detailed maintenance records for all tasks performed following FAA approved standards; maintained up-to-date logs that enabled efficient tracking & troubleshooting activities whenever needed.

- Formulated and implemented preventative maintenance strategies on over 75 pieces of aviation support equipment, resulting in a 20% reduction in repairs and downtime.

- Spearheaded the installation of new aviation parts to ensure optimal performance; successfully installed 25+ new parts with zero errors reported.

- Substantially reduced aircraft inspection times by 50 hours each month through rigorous troubleshooting processes and meticulous adherence to safety protocols and regulations.

- Participated in 10+ team projects related to aircraft servicing, repair works and engine overhauls; completed all tasks according to schedule while maintaining quality standards at all times.

- Replaced defective components within 4 minutes on average upon completion of technical diagnostics & tests; improved overall operational efficiency by 16%.

- Troubleshot aviation support equipment issues and resolved over 200 problems in the last 6 months, resulting in a 15% decrease in downtime.

- Advised colleagues on troubleshooting techniques and safety protocols when servicing aircrafts, leading to 0 reported incidents of injury or accidents since joining the team.

- Consistently followed maintenance schedules for all aviation support equipment; achieved 100% compliance rate to keep operations running smoothly with no delays or disruptions due to technical faults.

- Mentored 3 junior technicians on proper use of diagnostic software systems and safe operating procedures while working around aircrafts; successfully trained 10 new personnel within 12 weeks period each year for 4 years straight.

- Revised existing preventative maintenance plans based on feedback from customers & crew members that increased customer satisfaction by 20%.

- Utilized advanced diagnostic tools to inspect, troubleshoot and repair aviation support equipment in a timely manner; improved aircraft readiness rate by 15% over the past year.

- Improved maintenance quality and efficiency with successful retrofitting of up-to-date avionics systems on 10+ planes last quarter.

- Calibrated navigation receivers, transceivers, communication systems and other electronic devices per FAA guidelines; reduced malfunctions from occurring during flights by 7%.

- Documented service records for all repairs conducted according to safety regulations; completed 20+ scheduled maintenance checkups within specified timelines without compromise on safety standards or quality of workmanship.

- Actively participated in weekly team meetings to discuss new engineering procedures that can be adopted for better performance of aviation support equipment across the fleet; successfully tested 3x new methods resulting in decreased downtime by 22%.

- Presented aviation support equipment maintenance training to a team of 12 technicians, resulting in an overall productivity improvement of 25%.

- Serviced and repaired over 200 aviation ground vehicles such as tractors, transporters & tow bars; successfully returned all units back into service within 24 hours on average.

- Fabricated new components for repairs using specialist tools like lathe machines and millers; completed fabrication projects with zero defects rate in the last 6 months.

- Successfully operated two-way radios, testing systems for accuracy and troubleshooting any operational issues that arose during shift hours; reduced downtime by 50% since taking the lead role on this project 3 years ago.

- Operated heavy machinery including forklift trucks & lifting gantries while observing strict health & safety regulations to ensure workplace compliance at all times.

- Achieved an average of 95% efficiency in the testing, operation and maintenance of over 60 aviation support equipment pieces used on military bases.

- Expedited repair requests to minimize downtime for all aircrafts; reduced wait time from 36 hours to an average of 24 hours with no impact on quality standards.

- Tested functionality and accuracy for more than 100 parts per week using a variety of diagnostic tools; ensured that all components met strict safety guidelines before clearance was granted for service use.

- Resourcefully improvised solutions when spare parts were not available by re-engineering existing components part or building replacements as required; saved up to $1,500 in replacement costs each month due to expertise troubleshooting skillset.

- Represented the organization at two local air shows while providing technical assistance during demonstrations & flight operations activities; showcased exceptional customer service abilities resulting in 15+ new contracts being signed within 6 months following event attendance.

- Optimized aviation support equipment, reducing maintenance time by 30% and increasing overall performance efficiency.

- Prepared periodic reports on the condition of aircrafts and their related systems to ensure compliance with safety regulations; developed maintenance checklists for fleet personnel based off these findings.

- Developed a system for tracking inventory of parts used in repairs and preventive maintenance which saved $4,000 over six months period due to decreased wastage rate.

- Structured regular training sessions for personnel responsible for aviation ground support equipment operation & maintenance; increased knowledge base among team members by 40%.

- Competently performed inspections on all types of motorized ground power units (GPU), hydraulic/pneumatic jacks, wheel chocks & other critical components as per FAA guidelines while ensuring operational continuity at all times.

- Reorganized aviation support equipment and systems for a fleet of 10 aircraft, resulting in faster turnarounds between flights and an increase of 15% efficiency.

- Introduced new maintenance procedures that improved the reliability of parts by 25%, thereby reducing repair costs by $10,000 quarterly.

- Repaired over 200 pieces aviation support equipment components such as wheels & brakes, hydraulic systems and electronic control units with minimal downtime or disruption to flight operations; decreased total number of repairs per month by 10%.

- Assembled airplane engines according to manufacturer specifications within 3 minutes on average; supervised 8 technicians on assembly processes while ensuring quality standards were met at all times.

- Thoroughly inspected all airframes before each takeoff following FAA guidelines; identified potential issues ahead-of-time which allowed timely repairs to be performed without any safety risks or delays due to mechanical problems during flights.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for someone who is highly experienced with aircraft maintenance and another may be seeking an individual proficient in troubleshooting.

Therefore, it’s important to tailor the skills section of your resume to each job that you are applying for. This will make sure that your application stands out from others when employers use applicant tracking systems – computer programs designed to scan resumes for certain keywords before passing them on to a human.

In addition, you can further demonstrate these qualifications by discussing them in other sections such as the summary or experience section.

Below is a list of common skills & terms:

- Aircraft Engines

- Aircraft Fueling Systems

- Aircraft Ground Support Equipment

- Aircraft Inspection and Repair

- Aircraft Maintenance

- Aircraft Structures

- Avionics Systems

- Electrical Systems

- Hydraulic Systems

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the resume objective. However, if you have been working as an aviation support equipment technician for some time now with plenty of experiences to showcase, omitting the education section is perfectly fine.

If including an education section is necessary, try to list courses related to the aviation support equipment technician role that demonstrate a knowledge base relevant to performing job duties successfully.

Associate Degree in Aviation Maintenance Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a given field. They are also an indication that you have taken the time and effort to stay up-to-date with industry knowledge.

When applying for jobs, it is important to include any certifications relevant to the position on your resume. This will show employers that you possess the necessary skills and qualifications needed for success in their organization.

Aviation Support Equipment Technician (ASET)

National Center for Aerospace

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Jonas Lindgren, this would be Jonas-Lindgren-resume.pdf or Jonas-Lindgren-resume.docx.

7. Cover Letter

Including a cover letter with your job application is a great way to make sure you stand out from the competition. It should consist of 2 to 4 paragraphs and provide additional information that isn’t already included in your resume.

Cover letters allow you to explain why you are an ideal fit for the role, as well as providing personal insights into who you are and what drives you professionally. Even though they aren’t always required, writing one can help give recruiters a better idea of who they could be potentially hiring.

Below is an example cover letter:

Dear Jonathon,

I am writing in response to your ad for an Aviation Support Equipment Technician. With over 10 years of experience working on a variety of aircraft, I am confident I can be an asset to your team.

In my current role as an Aviation Support Equipment Technician with the US Navy, I maintain and repair a wide range of aviation support equipment. This includes everything from small hand tools to large pieces of machinery used for moving aircraft. I have a strong understanding of how all this equipment works together and how it is used in relation to the aircraft. In addition, I have experience troubleshooting issues and making repairs as needed.

I believe my skills and experience would make me a valuable asset to your organization. I am eager to put my knowledge and expertise to work in a new capacity and contribute to the success of your team. Thank you for your time and consideration, and I look forward to speaking with you soon about this opportunity.

Sincerely,

Jonas

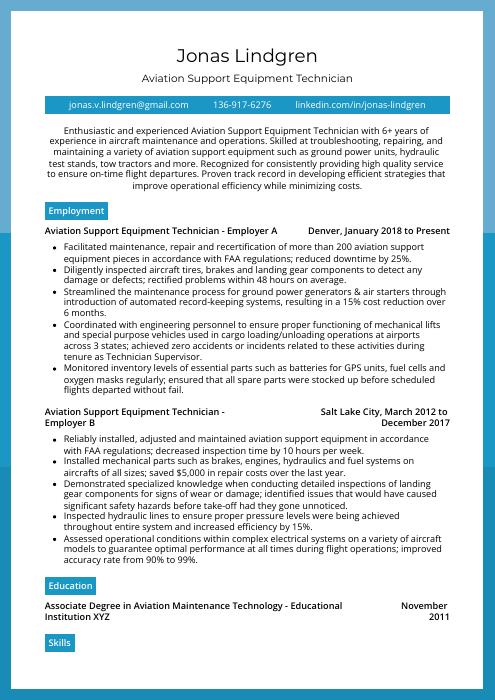

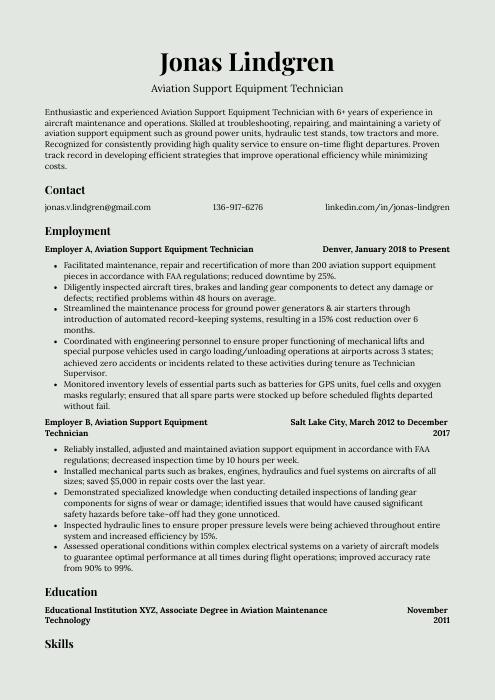

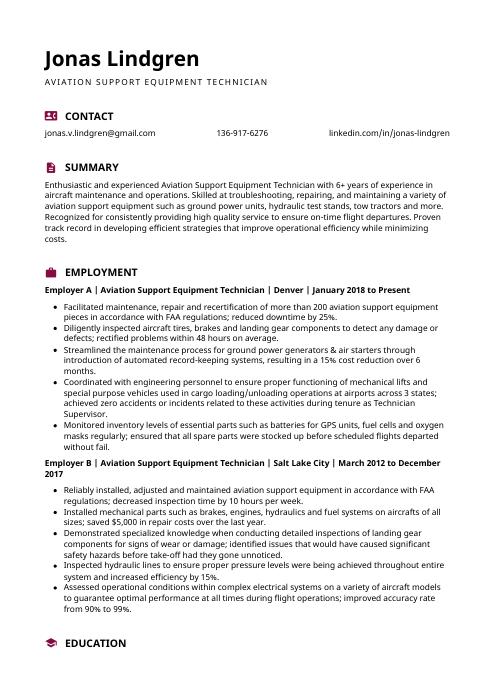

Aviation Support Equipment Technician Resume Templates

Rhea

Rhea Saola

Saola Hoopoe

Hoopoe Lorikeet

Lorikeet Numbat

Numbat Echidna

Echidna Quokka

Quokka Jerboa

Jerboa Indri

Indri Gharial

Gharial Bonobo

Bonobo Kinkajou

Kinkajou Markhor

Markhor Ocelot

Ocelot Dugong

Dugong Axolotl

Axolotl Fossa

Fossa Pika

Pika Cormorant

Cormorant Rezjumei

Rezjumei