Automotive Engineering Technician Resume Guide

Automotive engineering technicians use their technical knowledge and problem-solving skills to maintain, diagnose, and repair vehicles. They may also help design new vehicle models or test existing designs for safety and efficiency. They inspect parts and systems, identify problems, make repairs as needed, document maintenance activities on computers or other records systems.

You have the know-how and experience to be a top automotive engineering technician, but potential employers don’t know you yet. To make them aware of your technical abilities, you need to craft an impressive resume that stands out from the rest.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

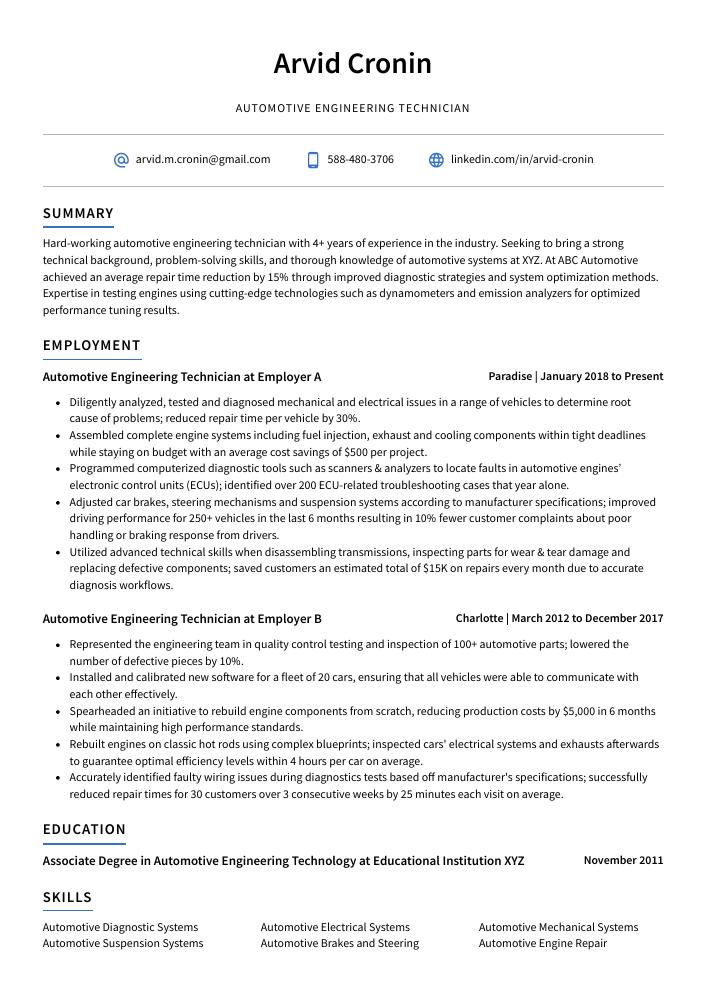

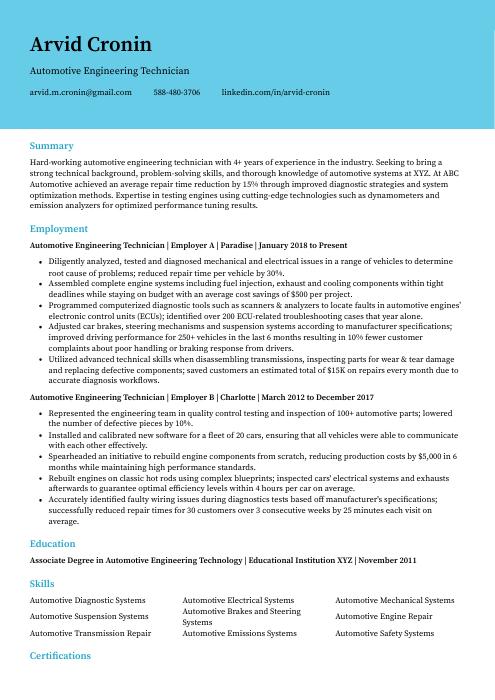

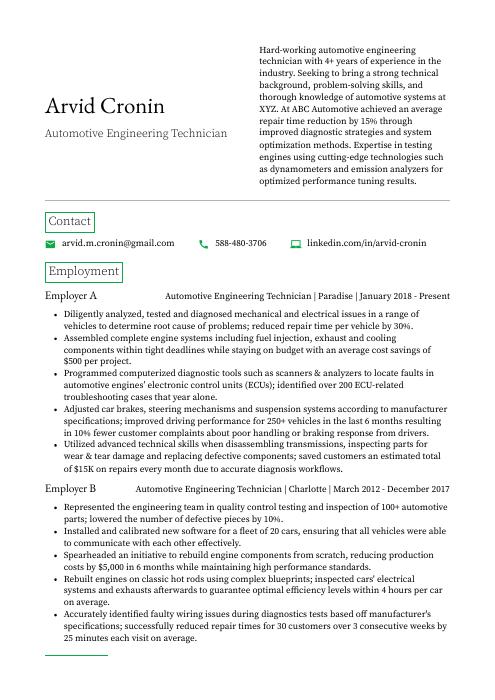

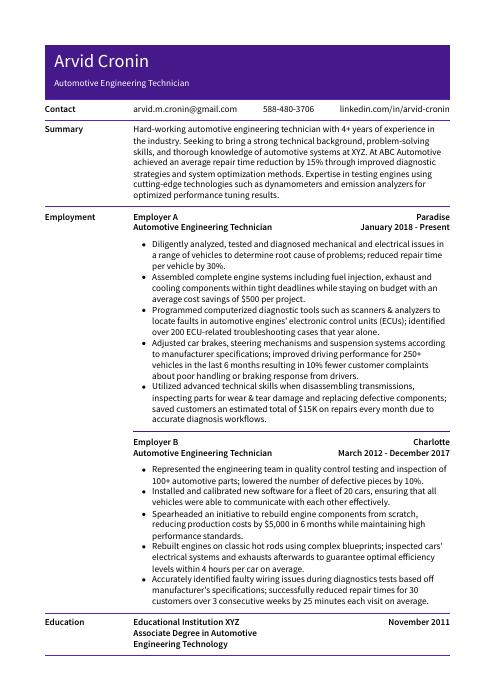

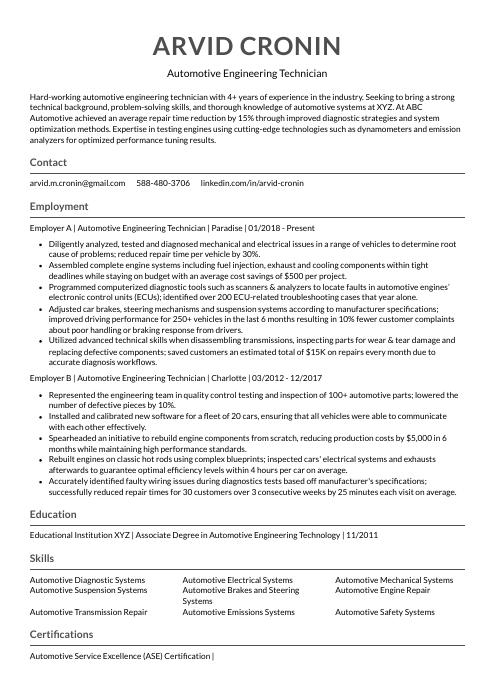

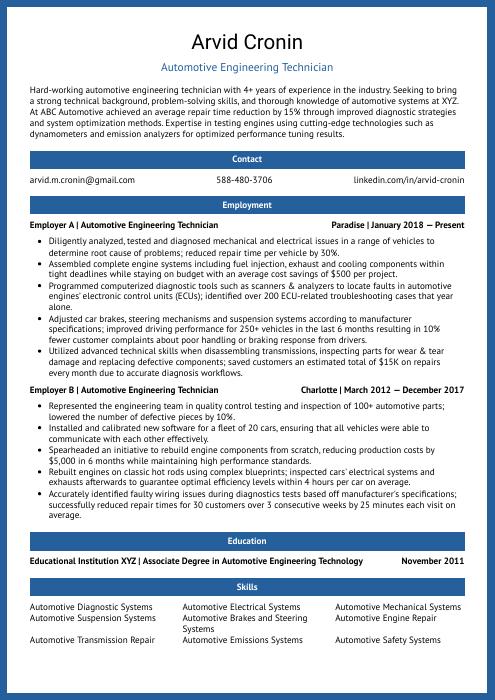

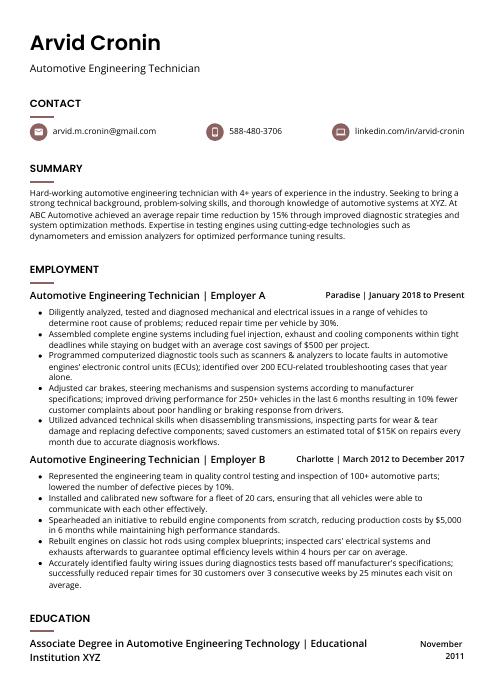

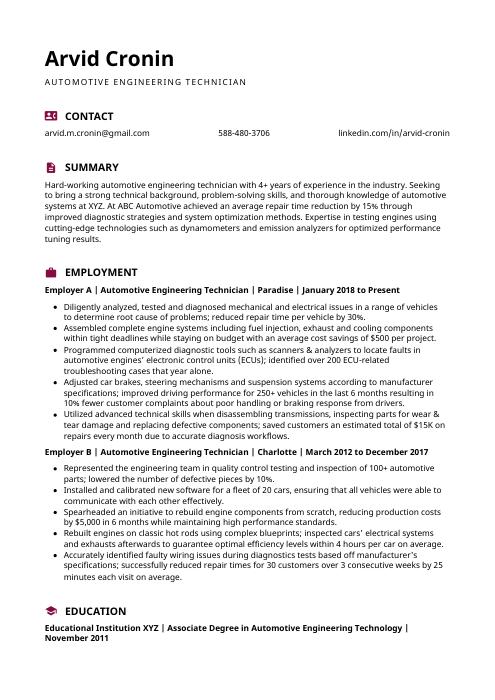

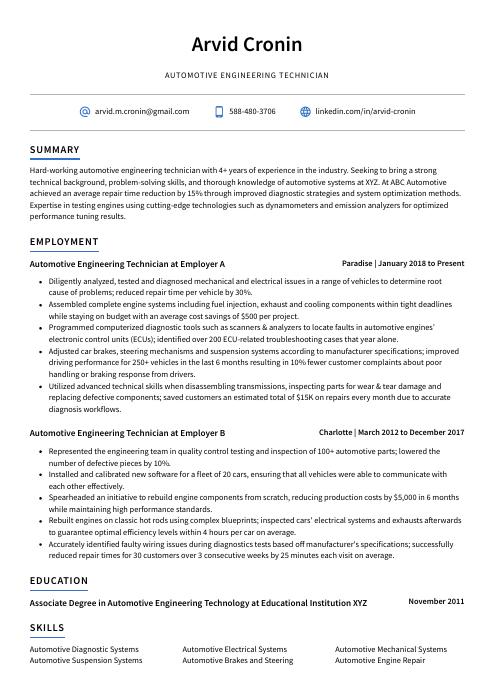

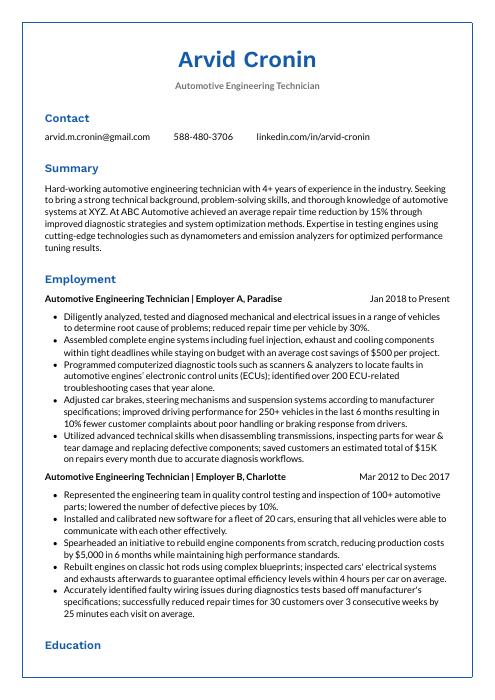

Automotive Engineering Technician Resume Sample

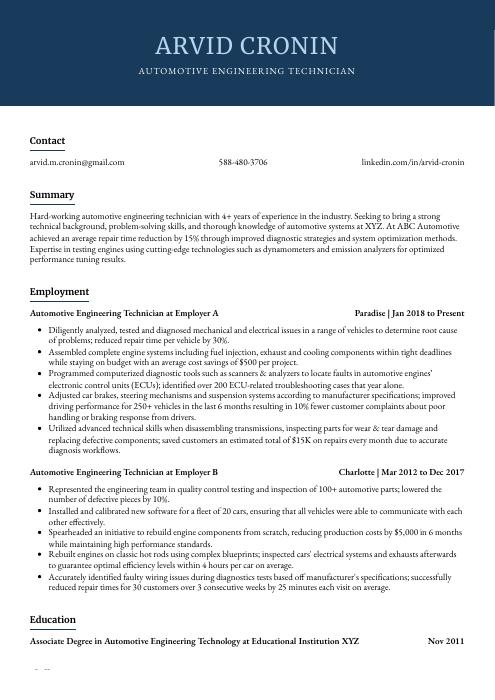

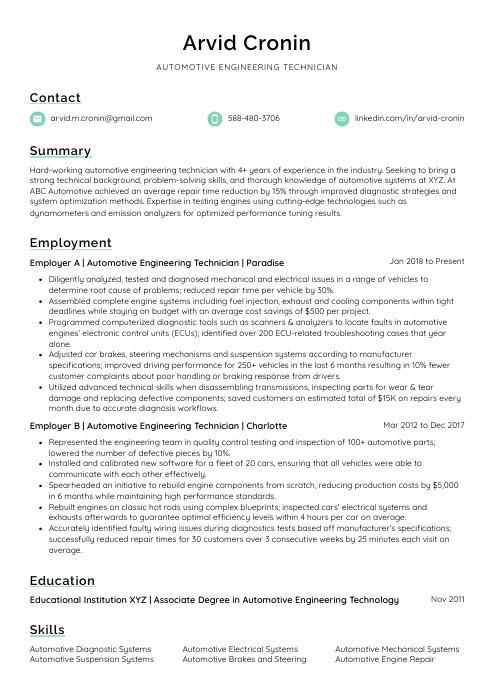

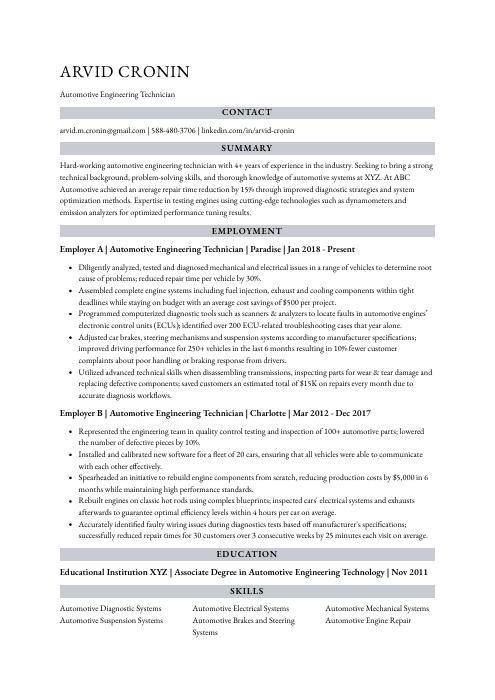

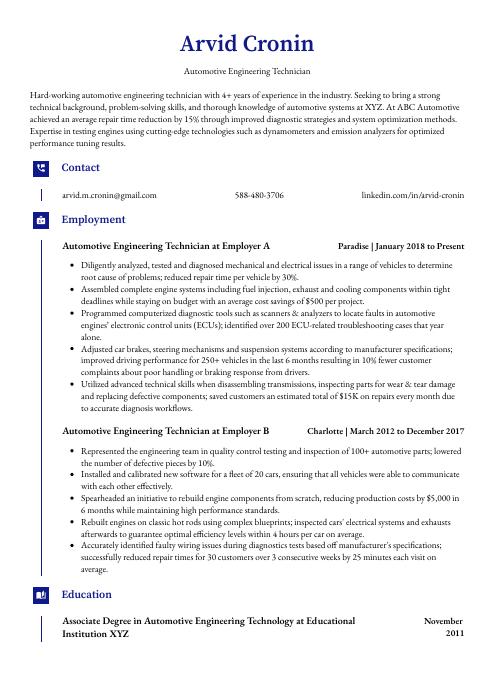

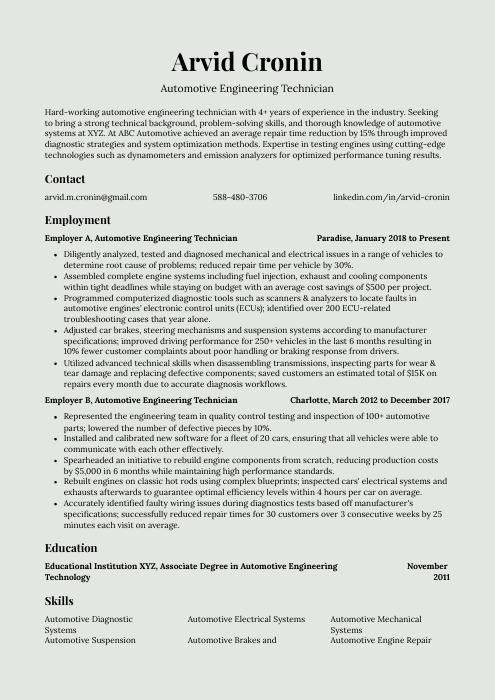

Arvid Cronin

Automotive Engineering Technician

[email protected]

588-480-3706

linkedin.com/in/arvid-cronin

Summary

Hard-working automotive engineering technician with 4+ years of experience in the industry. Seeking to bring a strong technical background, problem-solving skills, and thorough knowledge of automotive systems at XYZ. At ABC Automotive achieved an average repair time reduction by 15% through improved diagnostic strategies and system optimization methods. Expertise in testing engines using cutting-edge technologies such as dynamometers and emission analyzers for optimized performance tuning results.

Experience

Automotive Engineering Technician, Employer A

Paradise, Jan 2018 – Present

- Diligently analyzed, tested and diagnosed mechanical and electrical issues in a range of vehicles to determine root cause of problems; reduced repair time per vehicle by 30%.

- Assembled complete engine systems including fuel injection, exhaust and cooling components within tight deadlines while staying on budget with an average cost savings of $500 per project.

- Programmed computerized diagnostic tools such as scanners & analyzers to locate faults in automotive engines’ electronic control units (ECUs); identified over 200 ECU-related troubleshooting cases that year alone.

- Adjusted car brakes, steering mechanisms and suspension systems according to manufacturer specifications; improved driving performance for 250+ vehicles in the last 6 months resulting in 10% fewer customer complaints about poor handling or braking response from drivers.

- Utilized advanced technical skills when disassembling transmissions, inspecting parts for wear & tear damage and replacing defective components; saved customers an estimated total of $15K on repairs every month due to accurate diagnosis workflows.

Automotive Engineering Technician, Employer B

Charlotte, Mar 2012 – Dec 2017

- Represented the engineering team in quality control testing and inspection of 100+ automotive parts; lowered the number of defective pieces by 10%.

- Installed and calibrated new software for a fleet of 20 cars, ensuring that all vehicles were able to communicate with each other effectively.

- Spearheaded an initiative to rebuild engine components from scratch, reducing production costs by $5,000 in 6 months while maintaining high performance standards.

- Rebuilt engines on classic hot rods using complex blueprints; inspected cars’ electrical systems and exhausts afterwards to guarantee optimal efficiency levels within 4 hours per car on average.

- Accurately identified faulty wiring issues during diagnostics tests based off manufacturer’s specifications; successfully reduced repair times for 30 customers over 3 consecutive weeks by 25 minutes each visit on average.

Skills

- Automotive Diagnostic Systems

- Automotive Electrical Systems

- Automotive Mechanical Systems

- Automotive Suspension Systems

- Automotive Brakes and Steering Systems

- Automotive Engine Repair

- Automotive Transmission Repair

- Automotive Emissions Systems

- Automotive Safety Systems

Education

Associate Degree in Automotive Engineering Technology

Educational Institution XYZ

Nov 2011

Certifications

Automotive Service Excellence (ASE) Certification

National Institute for Automotive

May 2017

1. Summary / Objective

Your resume summary should be a brief but powerful statement that highlights your experience as an automotive engineering technician. This is where you can mention the certifications and qualifications you have obtained, such as ASE certification or advanced training in engine diagnostics. You could also talk about how you successfully troubleshooted complex mechanical issues on cars and trucks at your current job.

Below are some resume summary examples:

Energetic automotive engineering technician with 3+ years of experience in the automotive industry. Experienced in inspecting, testing and diagnosing mechanical components of motor vehicles and other related equipment using a variety of instruments. Passionate about developing innovative solutions to improve vehicle performance while ensuring safety standards are met. Looking for an opportunity to join ABC Automotive as a technical specialist and use my expertise to drive success.

Passionate automotive engineering technician with 6+ years of experience in the automotive industry. Skilled in diagnostics, troubleshooting and repairs for a wide range of vehicles. Awarded “Best Technician” recognition by XYZ Motors for providing exceptional service to customers and resolving complex problems efficiently. Seeking to join ABC Motors as an Automotive Engineering Technician where I can utilize my expertise to deliver quality results on time.

Driven automotive engineering technician with a demonstrated track record of successfully troubleshooting and repairing complex automotive systems. Proven ability to work independently or collaboratively on teams, taking initiative when needed. 5+ years in the industry and experience working for both OEMs and aftermarket companies. Seeking to join ABC Motors as an Automotive Engineering Technician where I can contribute my vast expertise in this field.

Well-rounded automotive engineering technician with a decade of experience in the automotive industry. Experienced at troubleshooting and repairing complex mechanical, electrical, and electronic systems for both cars and trucks. Skilled at diagnosing problems quickly to minimize downtime while offering customer service excellence. Recognized by peers as an effective communicator who can easily explain technical concepts to non-technical people.

Seasoned automotive engineering technician with 8+ years of experience in the automotive industry. Skilled at troubleshooting and repairing a wide range of vehicles, from cars to heavy-duty trucks. Expertise in performing vehicle inspections, identifying faults using diagnostic equipment, and providing comprehensive repairs. Proven track record for delivering exceptional customer service while ensuring safe operation of vehicles on all roads.

Dependable Automotive Engineering Technician with 5+ years of experience in the automotive industry. Experienced in diagnosing and repairing engines, transmissions, and other components on a variety of vehicle models. Skilled at troubleshooting electrical systems, performing preventive maintenance services, and testing repaired parts for proper operation. Committed to delivering quality workmanship with an emphasis on safety standards.

Accomplished Automotive Engineering Technician with 8+ years of hands-on experience in the automotive industry. Seeking to join ABC Auto as a Senior Automotive Engineering Technician, leveraging expertise in troubleshooting and problem-solving complex technical issues while ensuring compliance with all regulatory standards. At XYZ Motors, improved repair process efficiency by 42%, resulting in an estimated savings of $32K annually.

Reliable Automotive Engineering Technician with 8+ years of experience in automotive design and troubleshooting. Expertise in testing, diagnostics, and repairs for a variety of vehicles. Known as an organized problem-solver with excellent communication skills to explain technical solutions to customers. Looking to leverage abilities at ABC Motors by delivering high quality customer service while minimizing repair costs.

2. Experience / Employment

The work history/experience section is where you talk about your past employment. It should be written in reverse chronological order, meaning that the most recent job is listed first.

Stick to bullet points when describing what you did; this makes it easier for the reader to take in all of the information quickly and efficiently. You want to provide detail on each point, explaining what tasks were completed as well as any results or successes achieved from them.

For example, instead of saying “Repaired vehicles,” you could say, “Diagnosed and repaired mechanical issues on a variety of cars and trucks using specialized tools such as diagnostic computers.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Diagnosed

- Inspected

- Assembled

- Repaired

- Calibrated

- Tested

- Troubleshot

- Adjusted

- Installed

- Rebuilt

- Programmed

- Fabricated

- Operated

- Monitored

- Analyzed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Formulated innovative solutions to complex mechanical engineering problems and improved the overall performance of 50+ vehicles, resulting in a 5% increase in customer satisfaction.

- Developed detailed plans for new component designs using SolidWorks 3D CAD software, reducing prototyping costs by $2,500 over the last year.

- Thoroughly tested newly constructed parts under various conditions; identified 6 product deficiencies during pre-delivery inspections which were quickly rectified prior to release into the market.

- Advised clients on best practices when performing vehicle maintenance activities such as oil changes or tire rotations; provided instruction on properly operating 150+ models of cars, trucks and SUVs across multiple makes & brands while ensuring safety standards were met at all times.

- Presented research findings from extensive testing projects to internal committees and external stakeholders; showcased methods for improving fuel efficiency in diesel engines that resulted in an additional 10% reduction in emissions levels compared with traditional gasoline motors.

- Facilitated the design, development and testing of 8+ new automotive engineering products each year; reduced product launch time by 30% through improved efficiency.

- Coordinated with a team of 25 engineers to assemble vehicles from existing components, ensuring that all specifications were met within tight deadlines.

- Utilized specialized tools such as diagnostic equipment and precision measuring instruments for conducting mechanical tests on various parts and components; identified potential issues before they caused costly delays or malfunctions in the assembly line process.

- Revised 10+ manufacturing processes in order to improve overall production output while maintaining quality standards across all vehicle models produced; increased customer satisfaction ratings by 15%.

- Reliably diagnosed problems related to engine systems, brakes & steering mechanisms using advanced technologies like computer-aided diagnosis (CAD) software, resulting in repair costs being lowered by 40%.

- Introduced the use of specialized engineering software in the design and development process, resulting in a 15% improvement in accuracy and efficiency.

- Resourcefully identified issues with vehicle components during pre-manufacturing inspections; enabled cost savings of up to $4,000 by preventing unnecessary production delays.

- Compiled detailed reports on inspection results for various automotive parts such as engines, transmissions and suspensions; improved documentation system reliability by 50%.

- Optimized existing designs using CAD/CAE tools to reduce manufacturing costs without compromising quality; saved over 200 hours of labor every year due to increased automation capabilities.

- Improved safety standards through testing prototype vehicles under a variety of conditions including temperature extremes, vibration analysis & crash simulations tests that resulted in reducing product recalls by 10%.

- Diagnosed mechanical, electrical and fuel system problems on automobiles using advanced diagnostic equipment; identified the root cause of faults in over 300 vehicles while reducing repair time by 20%.

- Reduced labor cost by $5,500 through reorganizing production line processes & procedures to enhance efficiency; increased output and work quality with minimal effort.

- Reorganized automobile parts storage area for improved safety compliance and easy access when searching for components; implemented new inventory tracking techniques to reduce stock levels without compromising customer service standards.

- Proficiently operated specialized tools such as hydraulic jacks, welding torches & torque wrenches during auto repairs or maintenance activities on a daily basis according to company protocols & safety regulations.

- Assessed vehicle performance upon completion of services rendered including brake systems, exhausts and suspension systems; conducted regular inspections on all cars serviced before returning them to customers with 100% satisfaction rate achieved every month since August 2020.

- Participated in the development and testing of 10+ automotive prototypes, troubleshooting any mechanical or electrical issues in a timely manner.

- Fabricated metal components for engines, including crankshafts, camshafts and connecting rods; successfully reduced fabrication time by 25%.

- Operated high-end tools such as CNC lathes/mills to meet design specifications with limited supervision; improved production efficiency by 15% over six months.

- Effectively analyzed vehicle data collected from tests & experiments using advanced software such as MATLAB & LabVIEW, contributing to overall performance improvements of up to 40%.

- Calibrated various aspects of engine systems (fuel injectors/airflow meters) according to manufacturer standards; slashed emissions levels by 7% within 3 weeks on average per project.

- Repaired and performed maintenance on over 100 vehicles per month, troubleshooting and replacing faulty wiring, brakes and other mechanical components; reduced vehicle downtime by 30%.

- Monitored engine performance using diagnostic equipment to identify problems quickly and accurately; saved an average of 3 hours in repair time for each car serviced.

- Mentored junior technicians in the proper use of automotive tools & machines as well as general safety protocols when handling cars; improved quality assurance standards significantly with minimal errors.

- Inspected all newly repaired vehicles prior to customer delivery, ensuring that they met or exceeded manufacturer specifications while adhering to state regulations at all times.

- Confidently operated lifts/jacks in order to change tires or perform oil changes without assistance from others; completed tasks within allotted timeframe every single day with no accidents reported yet.

- Expedited the repair and maintenance of automotive components, reducing turnaround time by 25% while adhering to safety protocols.

- Efficiently tested and diagnosed faults in vehicles using modern diagnostic tools; identified issues in 10+ engines per day with an accuracy rate of 95%.

- Tested vehicle performance on a range of roads, tracked data for analysis and provided recommendations for improved efficiency which saved clients $4,000 annually.

- Streamlined the process for setting up new auto parts inventory systems by 15%, ensuring that all necessary parts were readily available at all times from suppliers.

- Troubleshot complex mechanical problems in over 200 different types of cars each month; reduced downtime caused due to repairs by 20 hours monthly on average.

- Demonstrated advanced knowledge of automotive engineering principles and mechanics by successfully diagnosing and repairing mechanical, electrical and computer-related issues in vehicles.

- Structured diagnostic tests to identify root causes of complex technical problems on a wide range of vehicle models; reduced downtime for repair processes by 15%.

- Prepared detailed written reports documenting the results of all diagnostic evaluations, including necessary repairs or replacements required and estimated costs; generated over 50 such reports per month with 100% accuracy rate.

- Successfully performed tune-ups, oil changes, brake jobs & other preventive maintenance service tasks on 300+ cars each week with an average time reduction per task of 20 minutes compared to industry standard practices.

- Achieved certification as an Automotive Service Excellence (ASE) technician after passing 8 exams related to engine repair & performance; maintained recertification status since 2017 through completion of at least 30 hours every year in continuing education courses designed for professional development.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in engine diagnostics and another for someone with expertise in electrical systems.

Therefore, it is essential to tailor the skills section of your resume to each job you are applying for. This will help ensure that your application does not get filtered out by an applicant tracking system (ATS). ATSs scan resumes for certain keywords; if yours doesn’t contain them, then it won’t be passed on to a human recruiter.

It’s also important to elaborate on the most relevant skillsets within other sections of your resume – such as the summary or work history – so that recruiters can gain a better understanding of what makes you qualified for this role.

Below is a list of common skills & terms:

- Automotive Brakes and Steering Systems

- Automotive Diagnostic Systems

- Automotive Electrical Systems

- Automotive Emissions Systems

- Automotive Engine Repair

- Automotive Mechanical Systems

- Automotive Safety Systems

- Automotive Suspension Systems

- Automotive Transmission Repair

- Automotive Welding and Fabrication

4. Education

Adding an education section to your resume will depend on how much work experience you have. If you are just starting in the automotive engineering technician field and don’t have any prior experience, include an education section below your resume objective to showcase relevant courses or subjects studied. However, if you already have significant work experience under your belt, it might not be necessary to mention your education at all.

If including an education section is appropriate for the job you’re applying for, make sure to list out any coursework or certifications related to automotive engineering that demonstrate a mastery of skills required by this role.

Associate Degree in Automotive Engineering Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the knowledge and skills necessary for a particular job. They also show that you are committed to staying up-to-date with industry trends and developments, as well as continuing your professional development.

Including certifications on your resume is an excellent way of highlighting any specialized qualifications or training you may have received in relation to the position being applied for. This can help demonstrate how qualified and knowledgeable you are about the role, giving hiring managers more confidence in considering your candidacy.

Automotive Service Excellence (ASE) Certification

National Institute for Automotive

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Arvid Cronin, this would be Arvid-Cronin-resume.pdf or Arvid-Cronin-resume.docx.

7. Cover Letter

Including a cover letter with your job application is a great way to demonstrate your enthusiasm and highlight why you are the perfect fit for the role. It’s usually made up of 2 to 4 paragraphs, which should be tailored specifically to the company or position you’re applying for.

Cover letters can help make employers remember you more easily and provide them with additional information about yourself that may not have been included in your resume. Writing one demonstrates professionalism, commitment and dedication – all qualities that recruiters look out for when selecting candidates!

Below is an example cover letter:

Dear Gaston,

I am writing to apply for the Automotive Engineering Technician position at your company. With my experience in designing, testing, and developing automotive systems, I am confident that I will be a valuable asset to your team.

As an engineering technician at ABC Motors, I was responsible for assisting engineers in designing and developing new automotive products. I also assisted in testing prototypes of new products and provided feedback on their performance. In addition, I created technical drawings of new products using CAD software and prepared reports on test results. My experience has given me a strong knowledge of automotive systems and how they work together.

I am also knowledgeable about the latest trends in the automotive industry and have attended several conferences on the topic. My understanding of the latest technologies would be beneficial in developing new products that are compatible with these technologies. In addition, my excellent communication skills would be helpful in communicating with other departments within the company about new product development projects.

I believe that my skills and experience make me well-qualified for this position and I would like to thank you for your consideration. If you have any questions, please do not hesitate to contact me at [email address] or by phone at [phone number]. Thank you for your time!

Sincerely,

Arvid

Automotive Engineering Technician Resume Templates

Dugong

Dugong Quokka

Quokka Pika

Pika Bonobo

Bonobo Lorikeet

Lorikeet Numbat

Numbat Gharial

Gharial Saola

Saola Cormorant

Cormorant Kinkajou

Kinkajou Jerboa

Jerboa Indri

Indri Ocelot

Ocelot Fossa

Fossa Hoopoe

Hoopoe Axolotl

Axolotl Markhor

Markhor Echidna

Echidna Rezjumei

Rezjumei