Assembly Technician Resume Guide

Assembly Technicians assemble and test machinery, equipment and components to ensure they meet industry standards. They use a variety of hand tools, power tools, jigs and fixtures to perform assembly operations with precision. Additionally, they inspect parts for defects or malfunctions before assembling them together into finished products.

You have the precision and expertise to assemble almost anything, but hiring managers don’t know who you are. To make them aware of your talents, you must create a resume that highlights your experience and skills.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

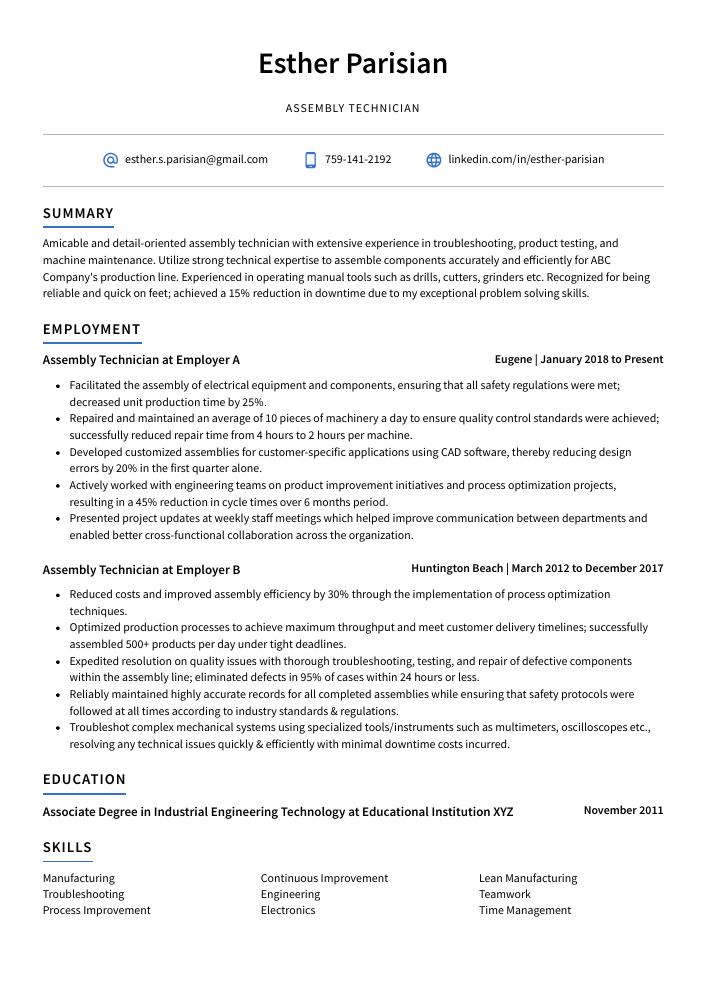

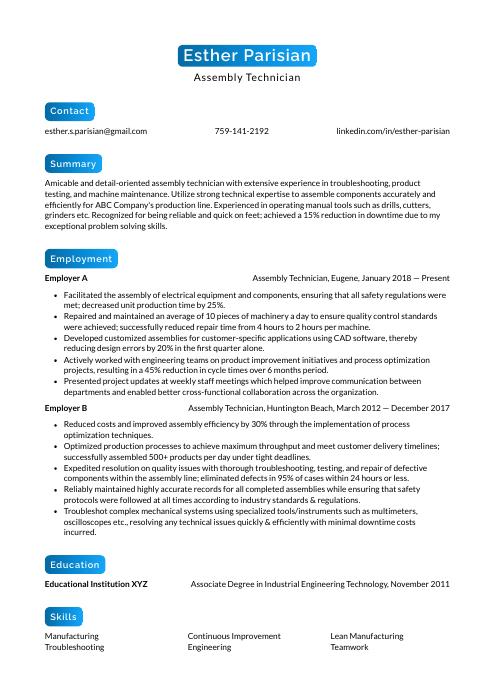

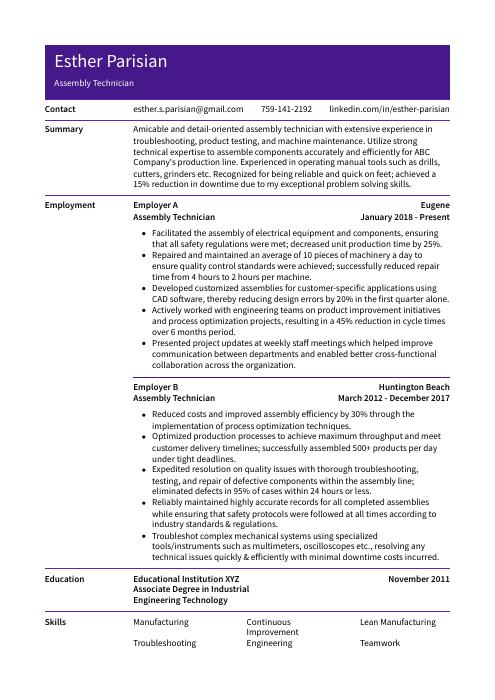

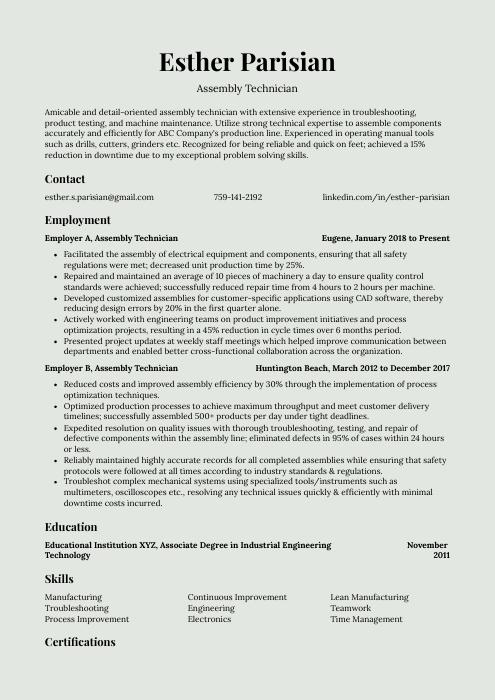

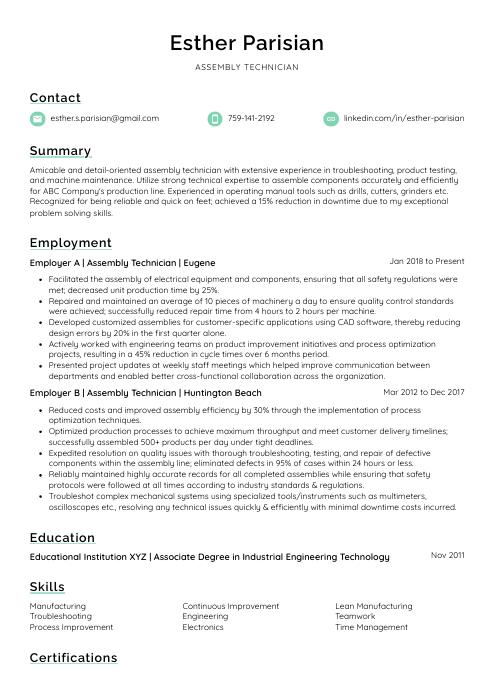

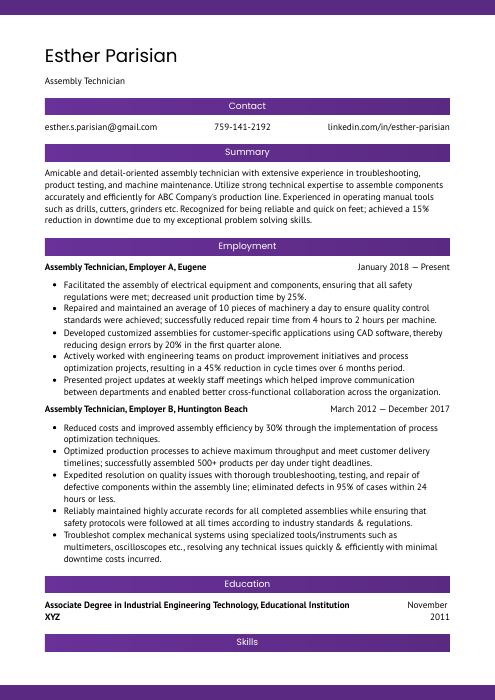

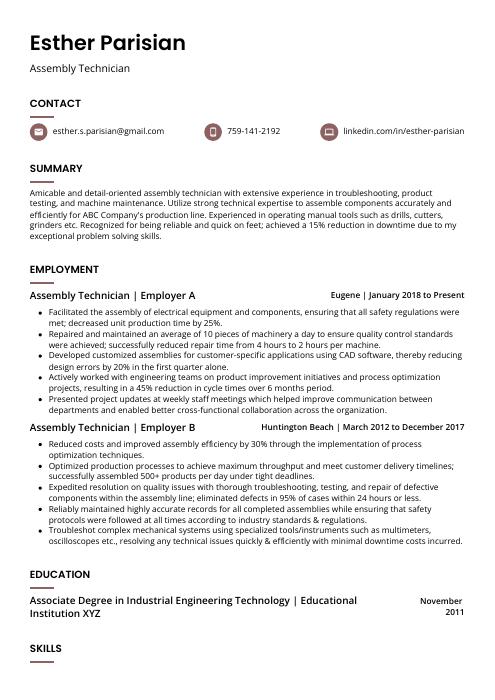

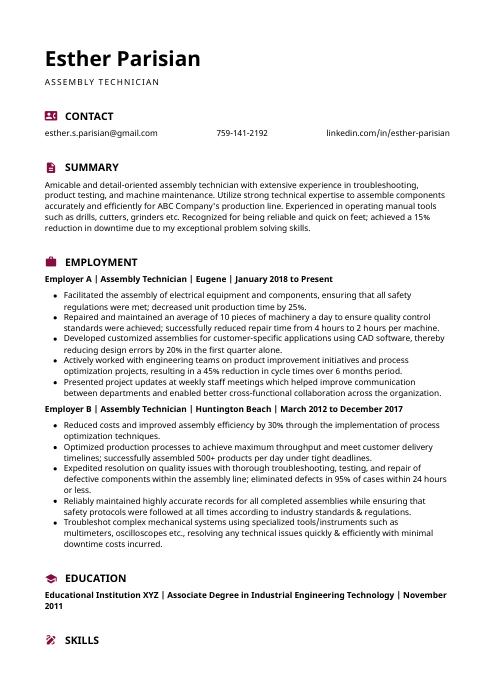

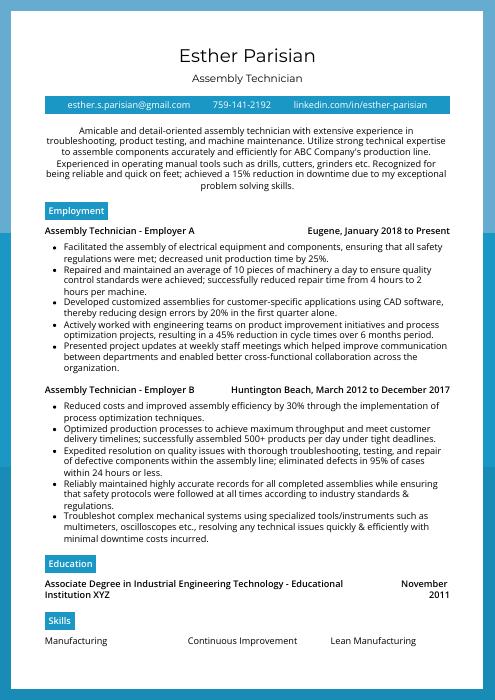

Assembly Technician Resume Sample

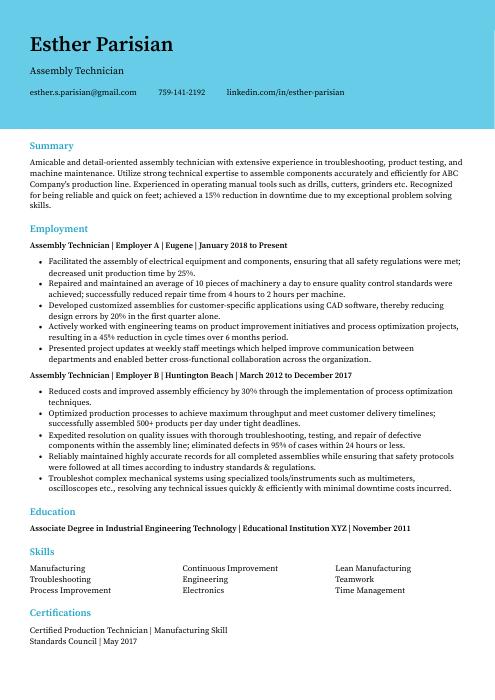

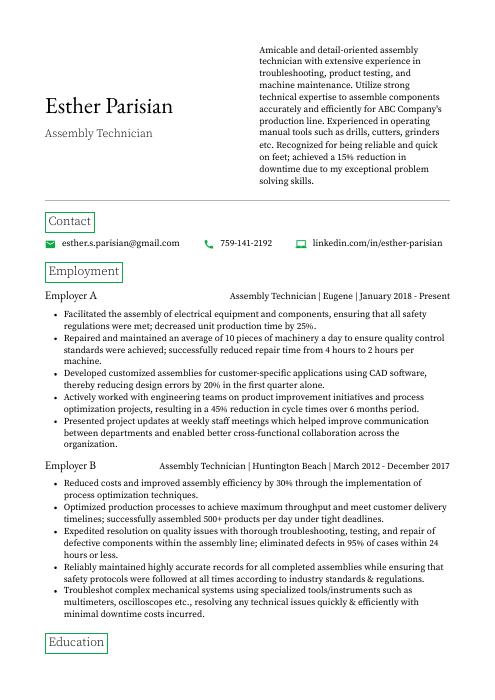

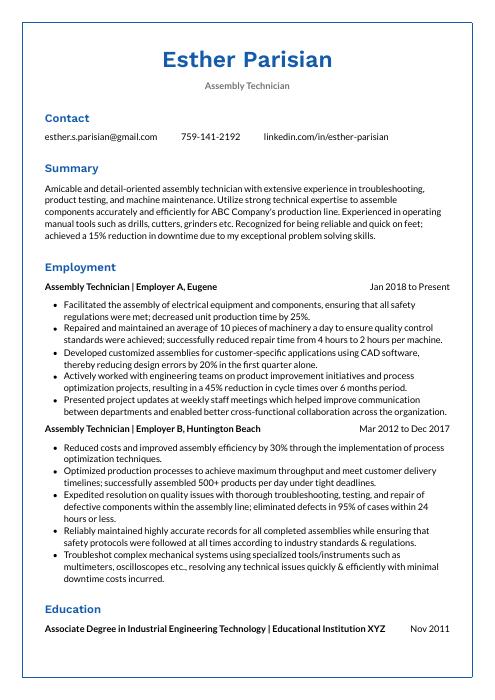

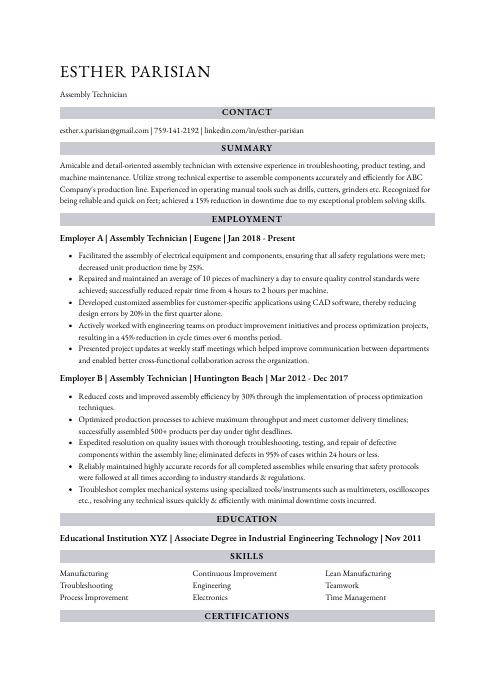

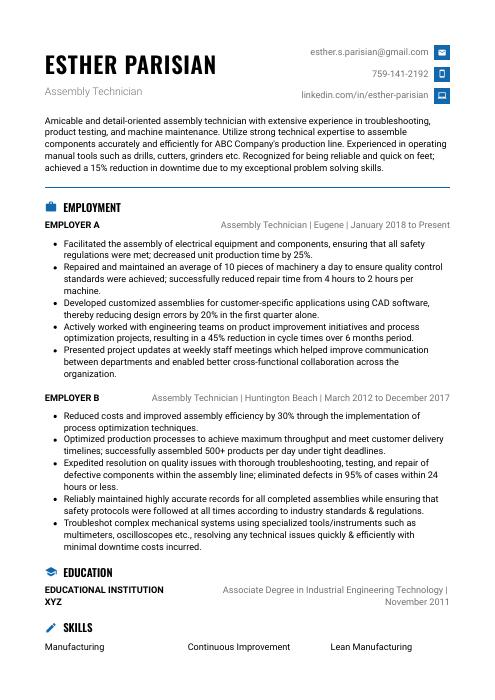

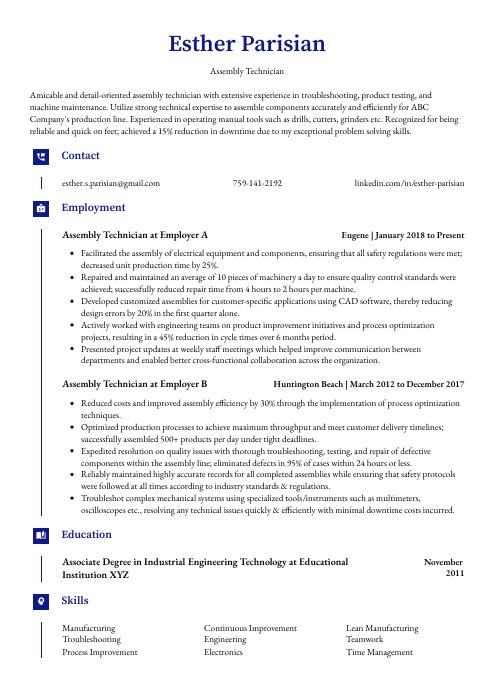

Esther Parisian

Assembly Technician

esther.s.parisian@gmail.com

759-141-2192

linkedin.com/in/esther-parisian

Summary

Amicable and detail-oriented assembly technician with extensive experience in troubleshooting, product testing, and machine maintenance. Utilize strong technical expertise to assemble components accurately and efficiently for ABC Company’s production line. Experienced in operating manual tools such as drills, cutters, grinders etc. Recognized for being reliable and quick on feet; achieved a 15% reduction in downtime due to my exceptional problem solving skills.

Experience

Assembly Technician, Employer A

Eugene, Jan 2018 – Present

- Facilitated the assembly of electrical equipment and components, ensuring that all safety regulations were met; decreased unit production time by 25%.

- Repaired and maintained an average of 10 pieces of machinery a day to ensure quality control standards were achieved; successfully reduced repair time from 4 hours to 2 hours per machine.

- Developed customized assemblies for customer-specific applications using CAD software, thereby reducing design errors by 20% in the first quarter alone.

- Actively worked with engineering teams on product improvement initiatives and process optimization projects, resulting in a 45% reduction in cycle times over 6 months period.

- Presented project updates at weekly staff meetings which helped improve communication between departments and enabled better cross-functional collaboration across the organization.

Assembly Technician, Employer B

Huntington Beach, Mar 2012 – Dec 2017

- Reduced costs and improved assembly efficiency by 30% through the implementation of process optimization techniques.

- Optimized production processes to achieve maximum throughput and meet customer delivery timelines; successfully assembled 500+ products per day under tight deadlines.

- Expedited resolution on quality issues with thorough troubleshooting, testing, and repair of defective components within the assembly line; eliminated defects in 95% of cases within 24 hours or less.

- Reliably maintained highly accurate records for all completed assemblies while ensuring that safety protocols were followed at all times according to industry standards & regulations.

- Troubleshot complex mechanical systems using specialized tools/instruments such as multimeters, oscilloscopes etc., resolving any technical issues quickly & efficiently with minimal downtime costs incurred.

Skills

- Manufacturing

- Continuous Improvement

- Lean Manufacturing

- Troubleshooting

- Engineering

- Teamwork

- Process Improvement

- Electronics

- Time Management

Education

Associate Degree in Industrial Engineering Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Production Technician

Manufacturing Skill Standards Council

May 2017

1. Summary / Objective

A resume summary/objective for an assembly technician should be crafted to highlight your technical skills and experience. Include details such as the types of machinery you have operated, the safety protocols you are familiar with, and any certifications or qualifications that make you stand out from other applicants. You can also mention how many years of experience in this field you possess, as well as any awards or recognition for outstanding performance on past projects.

Below are some resume summary examples:

Well-rounded assembly technician with 7+ years of experience in the manufacturing industry. Skilled at assembling and repairing complex parts, troubleshooting technical issues, and leading teams in assembly line production. At XYZ Company, reduced downtime by 30% through streamlining processes and improving machine maintenance procedures. Efficiently manages time to meet tight deadlines while maintaining high quality standards for all work completed.

Seasoned assembly technician with 7+ years of experience performing intricate assembly operations and troubleshooting equipment failures. At XYZ, became the go-to expert for complex projects due to consistently meeting production deadlines, improving efficiencies by 20%, and training new technicians on proper safety protocols. Looking to join ABC Manufacturing as an Assembly Technician where I can utilize my expertise in a fast-paced environment.

Talented assembly technician with 5+ years of experience in the automotive sector. Skilled in assembling parts, components and sub-assemblies using a variety of hand tools and power equipment. At XYZ Motors, achieved 100% assembly accuracy rate over 2 consecutive quarters which led to 15% reduction in costly defects. Seeking to join ABC Motors where I can utilize my technical expertise and further improve operational efficiency.

Professional assembly technician with over 10 years of experience in the manufacturing industry. Experienced in assembling complex machinery and equipment using hand tools, power tools, and precision measuring instruments. Skilled at troubleshooting mechanical problems to quickly identify solutions that improve machine performance while minimizing downtime. Committed to delivering quality results on time and within budget.

Accomplished assembly technician with 15 years of experience in manufacturing and mechanical assembly. Expertise in troubleshooting, repair and maintenance of a wide range of industrial machinery. Adept at interpreting blueprints to assemble complex components accurately and quickly. Proven record for achieving cost-savings through streamlined processes while maintaining the highest standards quality control.

Enthusiastic assembly technician with 4+ years of experience in fast-paced production environments. Skilled at troubleshooting and repairing complex machinery, including pumps, motors, valves and other industrial equipment. Experienced working on multiple projects simultaneously while meeting tight deadlines. At ABC Company achieved a 95% accuracy rate for assembly work over the course of 3 years.

Driven assembly technician with 7+ years of experience in building, troubleshooting and repairing complex electrical components. Expertise in soldering and wiring circuits as well as testing for functionality. Seeking to join ABC Electronics where I can apply my knowledge to ensure the highest quality parts are produced on time. Accomplishments include reducing assembly line downtime by 33%.

Detail-oriented assembly technician with 5+ years of experience in assembly, testing, and troubleshooting a variety of electronic components. Proven track record of working efficiently both independently and as part of a team to deliver high-quality products on time. Seeking to bring my expertise in efficient problem solving for the benefit ABC Tech’s growing customer base.

2. Experience / Employment

The employment (or experience) section of your resume should be written in reverse chronological order, with the most recent job listed first.

Stick to bullet points when writing this section; doing so makes it easier for the reader to quickly digest what you have said. When describing each role, think about the details of what you did and any results that were achieved as a result of your work.

For example, instead of saying “Assembled products,” you could say, “Successfully assembled 200+ units per day according to precise specifications while adhering strictly to safety protocols.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Installed

- Operated

- Inspected

- Calibrated

- Troubleshot

- Adjusted

- Fabricated

- Programmed

- Measured

- Soldered

- Connected

- Aligned

- Tested

- Repaired

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Fabricated and assembled over 50 mechanical and electrical components for various machines per day, resulting in an increase of assembly efficiency by 25%.

- Formulated preventative maintenance plans to ensure that all parts were functioning correctly; identified issues before they occurred, reducing down time by 15%.

- Spearheaded the implementation of new processes which improved production output by 10% while decreasing errors associated with manual labor tasks.

- Confidently operated a variety of power tools including drills, saws and lathes when assembling product components; reduced assembly times on average by 45 minutes each shift.

- Improved safety protocols within the workplace environment through regular equipment inspections and training sessions for other technicians; lowered accident rates from 8 to 2 incidents every month.

- Introduced innovative assembly techniques to reduce manufacturing errors by 25% and increase production rate by 20%.

- Structured efficient workflows for assembling parts of various products such as vehicles, machines and tools within safety specifications; reduced product defects to 0.4%.

- Resourcefully identified faulty electrical connections in machinery components before installation or shipment, reducing customer complaints from 3 per month to zero over a year’s time period.

- Utilized hand & power tools such as screwdrivers, pliers and wrenches with precision accuracy while connecting the necessary components during assembly processes; increased efficiency level by 30%.

- Assessed completed assemblies for accurate measurements against blueprints/specifications prior to delivery ensuring 100% customer satisfaction on all projects delivered within deadline constraints.

- Represented the assembly team in daily meetings with management, providing feedback on workflow and offering guidance for meeting production goals; increased throughput by 22% over three months.

- Effectively operated various manual and automated machinery to assemble components into finished products, ensuring accuracy of parts placement and quality control of the final product.

- Advised other technicians on best practices during assembly tasks while inspecting completed items for any defects or errors before delivery to customers; reduced customer returns by 10%.

- Measured dimensions of parts using precision tools such as calipers & micrometers, allowing improved calculation of tolerances within a +/- 0.01mm range every time according to design specifications.

- Operated computer-controlled equipment such as robotic arms & CNC machines during complex assembly processes while monitoring their performance throughout shifts; minimized downtime from machine malfunctions by 5%.

- Adjusted and calibrated electronic and mechanical assemblies to ensure accurate performance, resulting in a 15% decrease in faulty production units.

- Thoroughly inspected all components of the assembly line for quality control purposes; identified potential problems before they arose, thus reducing downtime by 20%.

- Aligned parts with accuracy during assembly process according to technical specifications; successfully completed 200+ orders within deadlines without compromise on quality.

- Coordinated the activities of 10 technicians across four shifts per day for effective management of workflow; ensured that all maintenance tasks were conducted efficiently and safely at regular intervals as required.

- Achieved an 85% reduction in customer complaints related to product defects through continuous monitoring and improvement initiatives implemented over 3 months period.

- Prepared and installed over 500 pieces of machinery and equipment, including sensors, motors and circuit boards; shortened assembly time by 10% on average.

- Streamlined production processes to meet high-volume orders within tight deadlines; achieved a 20% improvement in efficiency with minimal errors.

- Independently troubleshooted mechanical problems for all assembled products and revised malfunctioning components accordingly, thus reducing repair costs by $4,000 per quarter.

- Revised existing designs to create more efficient parts capable of handling higher loads; improved product quality control ratings from 75% to 95%.

- Connected essential electrical wiring systems throughout the facility while adhering strictly to safety protocols at all times; reduced electricity consumption by 15%.

- Inspected and maintained production machinery, troubleshooting and repairing any issues to reduce downtime by 25%.

- Participated in assembly line activities for over 200 products a day; heightened efficiency by 12% through process improvement initiatives.

- Tested components of new products for functionality prior to final assembly; identified defective parts ahead of time that saved the company $4,000 in costs last year.

- Demonstrated technical proficiency when operating various tools such as soldering irons, screwdrivers and pneumatic drivers while assembling electronic & mechanical systems with precision accuracy.

- Proficiently read blueprints/schematics & followed detailed instructions to assemble complex machines within specified timelines on a daily basis.

- Reorganized and restocked the assembly floor, reducing material waste by 20% and increasing efficiency of equipment utilization.

- Soldered over 1,500 electronic components for various circuit boards to ensure proper functioning; completed all tasks in 2 hours or less with zero defects reported.

- Calibrated and tested 200+ mechanical assemblies per day according to established protocols; achieved a 98% success rate within tight time constraints on each project assigned.

- Installed 50+ pieces of automated machinery across 3 different production sites while adhering to strict safety guidelines at all times without any accidents occurring during the process.

- Competently operated both manual and computer-controlled machines such as lathes, drills, grinders & milling equipment while consistently meeting daily production targets with minimal errors recorded throughout shift operations.

- Accurately assembled over 500 electronic components per day to build computer systems, printers and other devices; increased output by 8% within 4 months.

- Compiled detailed reports of assembly errors & malfunctions for 10+ different products with a 98% accuracy rate.

- Assembled complex circuit boards utilizing intricate wiring diagrams while maintaining the highest quality standards on all projects.

- Programmed automated robotic systems according to established guidelines and supervised their operations during production runs; successfully lowered downtime occurrences by 15%.

- Mentored new technicians in assembling processes and troubleshooting methods, enabling them to become fully productive members of the team within 2 weeks each time.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization may require the candidate to have knowledge of soldering and another may need experience with 3D printing.

It is important to tailor your skills section accordingly, as many employers now use applicant tracking systems (ATS) that scan resumes for certain keywords before passing them on to a human.

In addition, you should also elaborate on these skills in other sections such as the summary or work experience area; this will give recruiters an insight into how well-versed you are in each skill and why it makes you suitable for the job.

Below is a list of common skills & terms:

- 5S

- Automotive

- Continuous Improvement

- Electronics

- Engineering

- Lean Manufacturing

- Maintenance and Repair

- Manufacturing

- Operations Management

- Process Improvement

- Quality Assurance

- Six Sigma

- Soldering

- Team Leadership

- Teamwork

- Testing

- Time Management

- Troubleshooting

4. Education

Mentioning an education section on your resume will depend on how far you are in your career. If you recently graduated and have no prior work experience, include a brief education section below your resume objective. However, if you have years of assembly technician experience to showcase, it may be best to omit the education section altogether.

If an education section is included, try to mention courses and subjects related to the job description of an assembly technician that you studied or completed during college or university studies.

Associate Degree in Industrial Engineering Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a certain field. They are also an excellent way to show potential employers that you have invested time and effort into keeping up with industry standards, as well as staying current on the latest trends.

Including certifications on your resume can be beneficial if they are relevant to the job or position you’re applying for. It will help hiring managers see that you have taken initiative by investing in yourself professionally, which could give you an edge over other applicants who may not possess such credentials.

Certified Production Technician

Manufacturing Skill Standards Council

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Esther Parisian, this would be Esther-Parisian-resume.pdf or Esther-Parisian-resume.docx.

7. Cover Letter

Writing a cover letter is an important part of the job application process. It is a document that should be treated separately from your resume and allows you to explain why you’re the perfect candidate for the role.

Cover letters are typically made up of 2-4 paragraphs in length, with each one focusing on different aspects related to your skillset and experience. By adding this extra layer, hiring managers can get better insights into who you are as a professional – something they may not have been able to do just by looking at your resume alone.

Below is an example cover letter:

Dear Paxton,

I am writing to apply for the Assembly Technician position at your company. With experience in a wide range of assembly techniques and a strong attention to detail, I am confident that I would be an asset on your team.

In my current role as an Assembly Technician at [company name], I have gained extensive experience in all aspects of assembly work. My responsibilities include reading and interpreting blueprints, assembling parts according to specifications, and testing completed products to ensure they meet quality standards. I have also developed a reputation for being able to troubleshoot problems quickly and efficiently.

In addition to my technical skills, I also have excellent interpersonal skills which allow me to effectively communicate with co-workers and customers alike. My positive attitude and willingness to take on new challenges has allowed me to build good working relationships with everyone I come into contact with.

I believe that my combination of technical skills and personal attributes make me the perfect candidate for this position, and I look forward to putting my skills to work for you. Thank you for your time & consideration; if you have any questions please do not hesitate contact me at [phone number] or [email address].

Sincerely,

Esther

Assembly Technician Resume Templates

Cormorant

Cormorant Ocelot

Ocelot Axolotl

Axolotl Kinkajou

Kinkajou Pika

Pika Saola

Saola Lorikeet

Lorikeet Jerboa

Jerboa Fossa

Fossa Hoopoe

Hoopoe Rhea

Rhea Dugong

Dugong Quokka

Quokka Bonobo

Bonobo Indri

Indri Markhor

Markhor Numbat

Numbat Echidna

Echidna Gharial

Gharial Rezjumei

Rezjumei