Assembly Line Worker Resume Guide

Assembly line workers assemble products on production lines. They ensure that all components are in the right place and working properly, as well as making sure the product is up to quality standards before it moves down the assembly line or out of the factory.

Your speed and efficiency on the assembly line is unrivaled. But if you want to get noticed by hiring managers, you must write a resume that highlights your experience and performance in this field.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

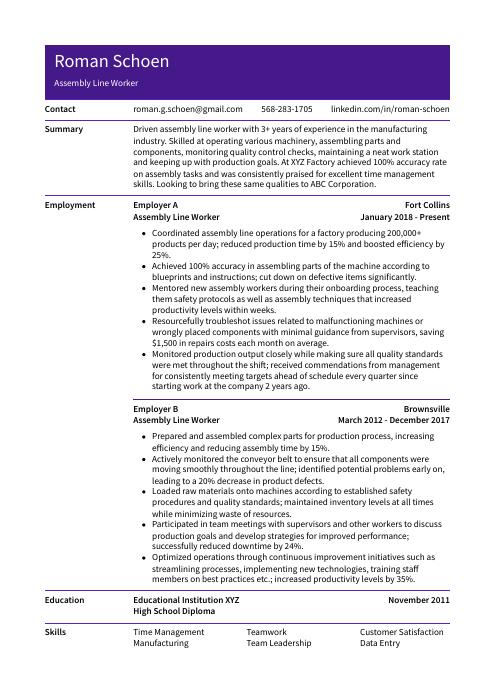

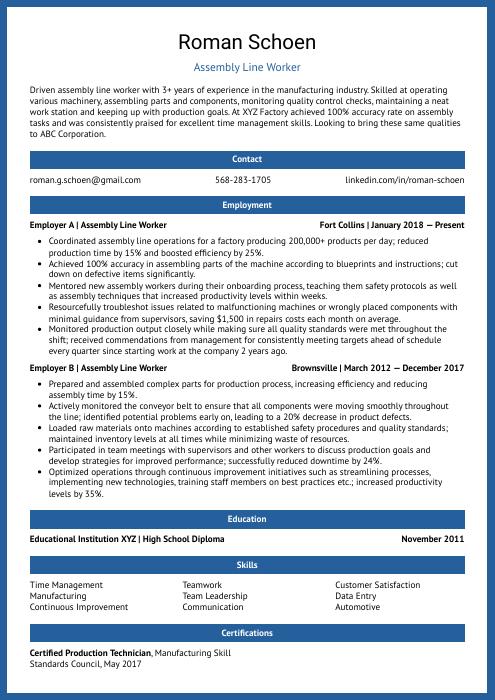

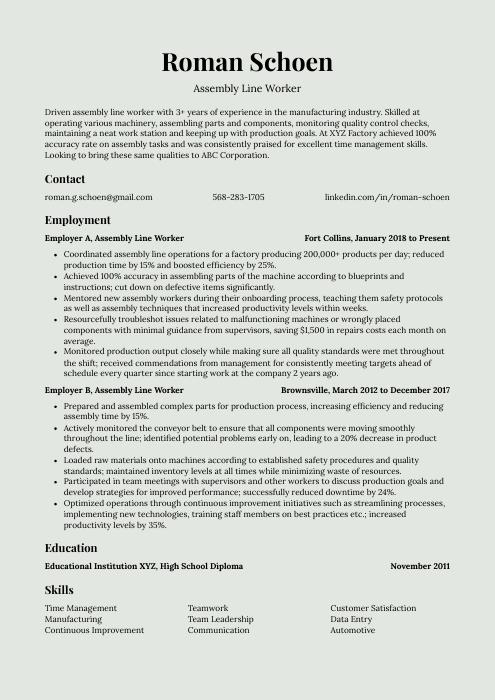

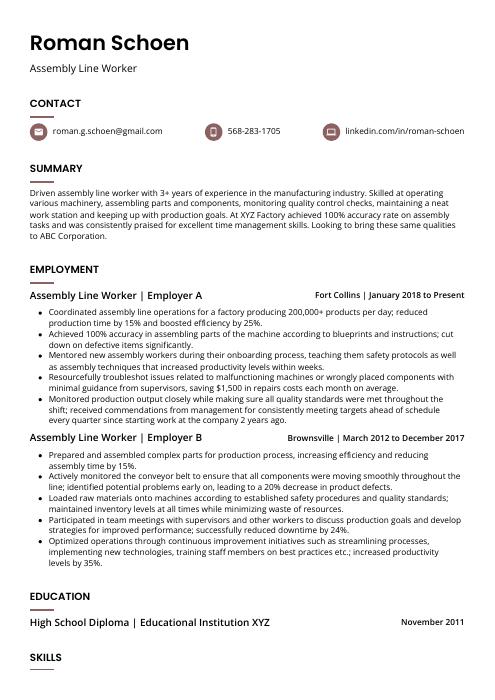

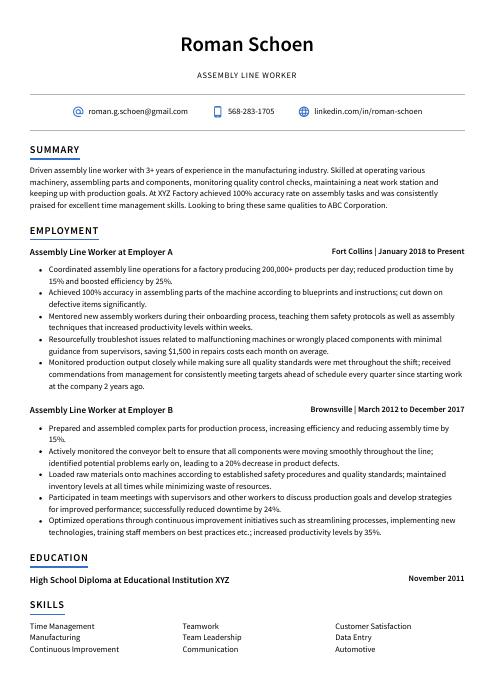

Assembly Line Worker Resume Sample

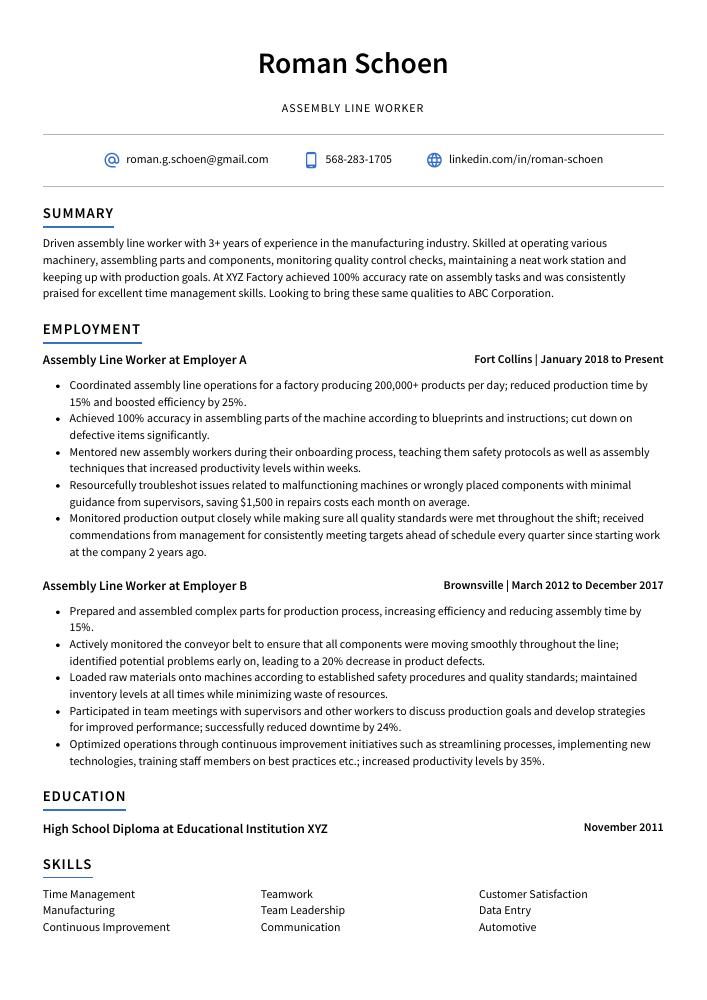

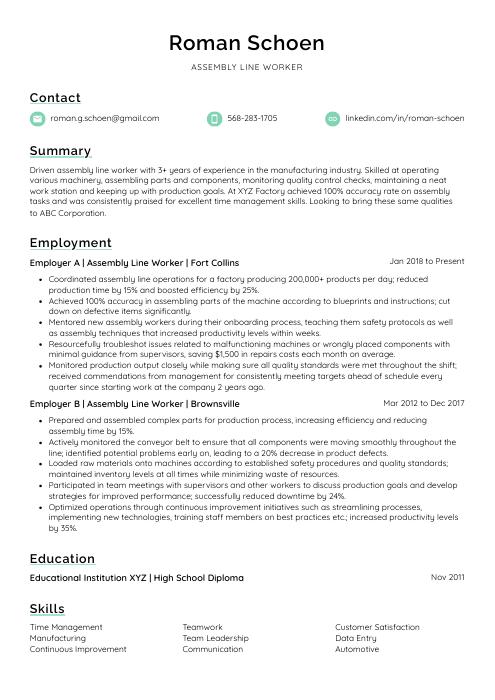

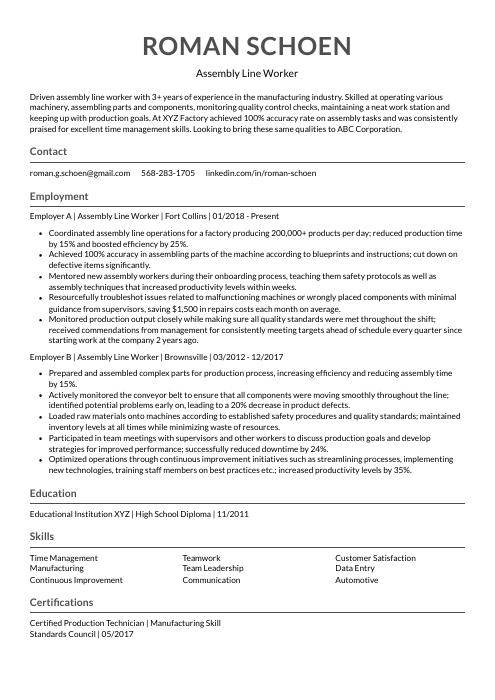

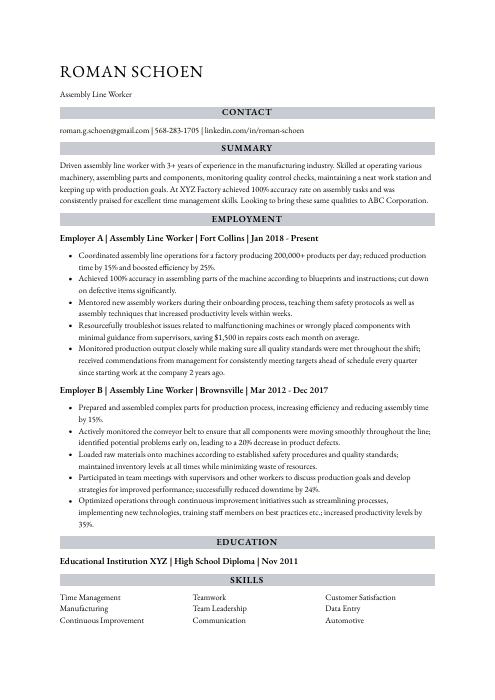

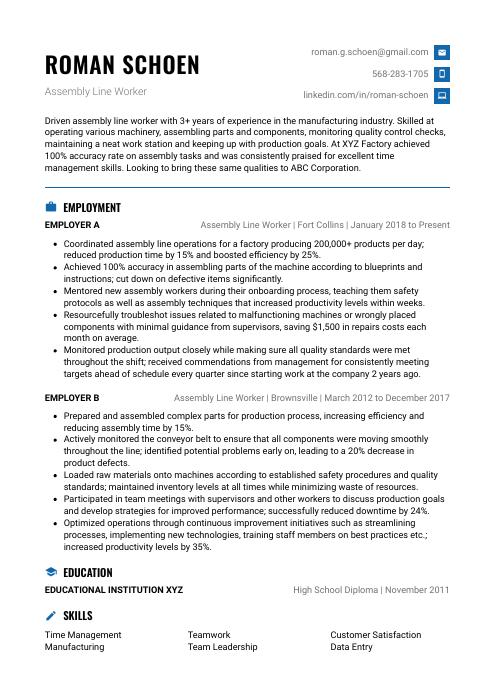

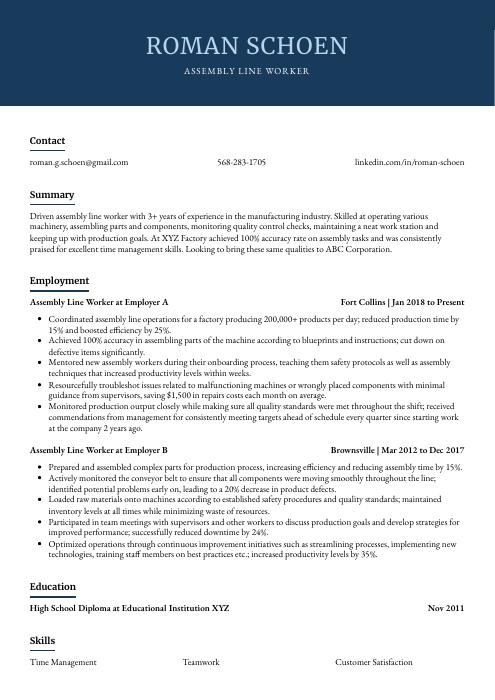

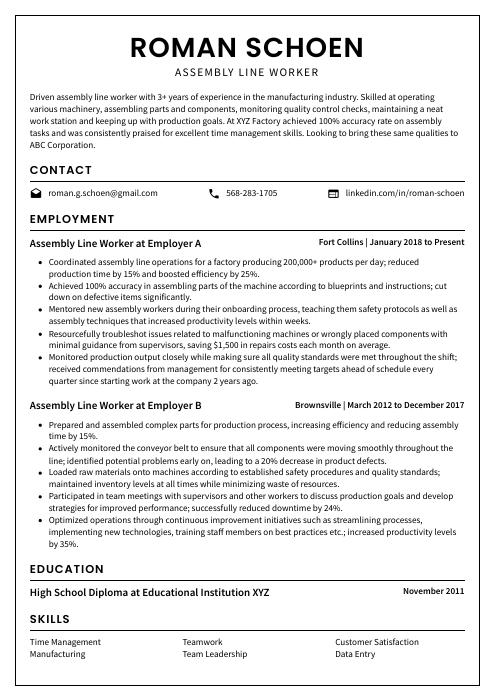

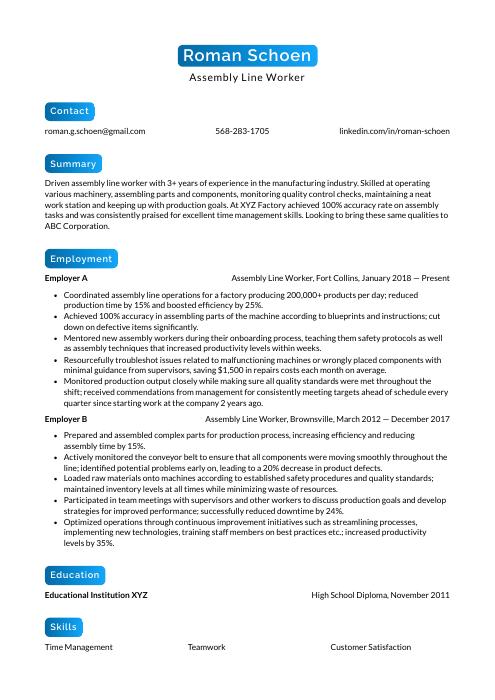

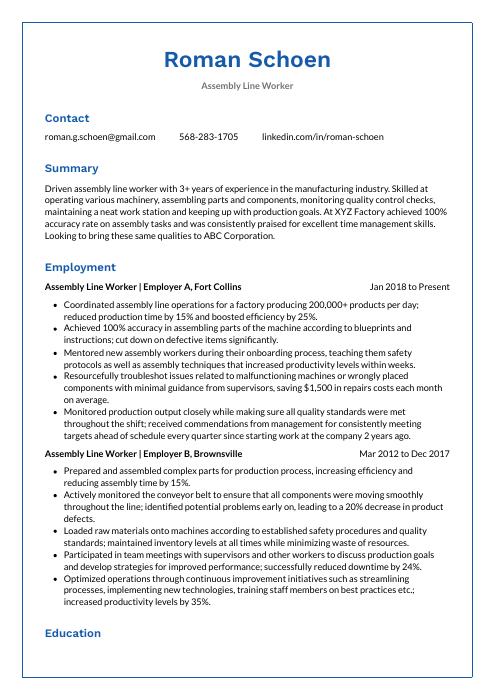

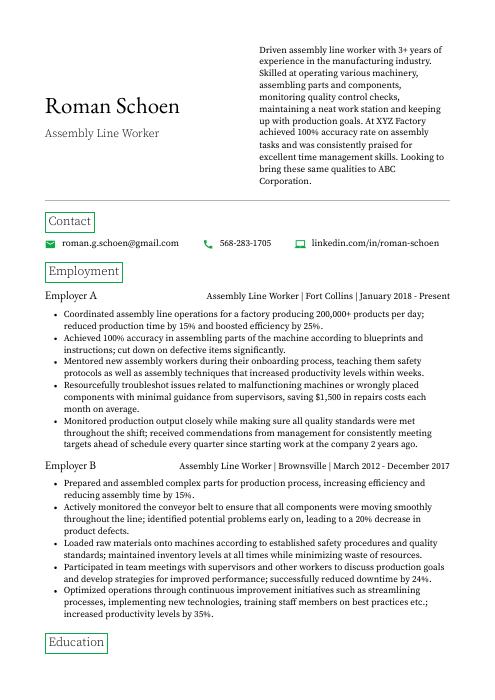

Roman Schoen

Assembly Line Worker

[email protected]

568-283-1705

linkedin.com/in/roman-schoen

Summary

Driven assembly line worker with 3+ years of experience in the manufacturing industry. Skilled at operating various machinery, assembling parts and components, monitoring quality control checks, maintaining a neat work station and keeping up with production goals. At XYZ Factory achieved 100% accuracy rate on assembly tasks and was consistently praised for excellent time management skills. Looking to bring these same qualities to ABC Corporation.

Experience

Assembly Line Worker, Employer A

Fort Collins, Jan 2018 – Present

- Coordinated assembly line operations for a factory producing 200,000+ products per day; reduced production time by 15% and boosted efficiency by 25%.

- Achieved 100% accuracy in assembling parts of the machine according to blueprints and instructions; cut down on defective items significantly.

- Mentored new assembly workers during their onboarding process, teaching them safety protocols as well as assembly techniques that increased productivity levels within weeks.

- Resourcefully troubleshot issues related to malfunctioning machines or wrongly placed components with minimal guidance from supervisors, saving $1,500 in repairs costs each month on average.

- Monitored production output closely while making sure all quality standards were met throughout the shift; received commendations from management for consistently meeting targets ahead of schedule every quarter since starting work at the company 2 years ago.

Assembly Line Worker, Employer B

Brownsville, Mar 2012 – Dec 2017

- Prepared and assembled complex parts for production process, increasing efficiency and reducing assembly time by 15%.

- Actively monitored the conveyor belt to ensure that all components were moving smoothly throughout the line; identified potential problems early on, leading to a 20% decrease in product defects.

- Loaded raw materials onto machines according to established safety procedures and quality standards; maintained inventory levels at all times while minimizing waste of resources.

- Participated in team meetings with supervisors and other workers to discuss production goals and develop strategies for improved performance; successfully reduced downtime by 24%.

- Optimized operations through continuous improvement initiatives such as streamlining processes, implementing new technologies, training staff members on best practices etc.; increased productivity levels by 35%.

Skills

- Time Management

- Teamwork

- Customer Satisfaction

- Manufacturing

- Team Leadership

- Data Entry

- Continuous Improvement

- Communication

- Automotive

Education

High School Diploma

Educational Institution XYZ

Nov 2011

Certifications

Certified Production Technician

Manufacturing Skill Standards Council

May 2017

1. Summary / Objective

A resume summary for an assembly line worker should focus on the candidate’s ability to work quickly and accurately in a fast-paced environment. The summary should also highlight any relevant experience, such as working with complex machinery or managing teams of workers. Additionally, it is important to emphasize your commitment to safety protocols and quality control standards. Finally, mention any awards or certifications that demonstrate your expertise in this field.

Below are some resume summary examples:

Determined assembly line worker with 5+ years of experience in a fast-paced manufacturing environment. Proven track record in streamlining assembly processes to reduce waste and increase production efficiency. Knowledgeable in OSHA regulations and safety protocols, as well as troubleshooting techniques for operating machinery. Excels at working collaboratively with team members while meeting all quality assurance standards.

Seasoned assembly line worker with 10+ years of experience in manufacturing and production. Experienced working on an assembly line, loading/unloading materials, operating machinery, performing quality control checks and troubleshooting mechanical issues. Proven track record for consistently meeting deadlines while ensuring accuracy and efficiency. Committed to providing the highest level of customer service at all times.

Hard-working assembly line worker with 5+ years of experience in high-volume production environments. At XYZ, managed the assembly and disassembly process for over 500 products per day while meeting tight deadlines. Proficient in troubleshooting and maintaining machinery to ensure efficiency on the production floor. Achieved a 15% increase in productivity by introducing new techniques and streamlining existing processes.

Reliable and industrious assembly line worker with 5+ years of experience in manufacturing and production settings. Seeking to leverage expertise in industrial processes, including mechanical/electrical operations, quality control checks, troubleshooting equipment malfunctions and working safely under strict deadlines. Achieved a 20% increase in daily efficiency through improved processes at XYZ Inc.

Proficient assembly line worker with five years of experience in the manufacturing sector, looking to join XYZ Inc. Possess strong mechanical aptitude and exceptional problem-solving abilities; consistently exceed production goals while adhering to safety regulations. At ABC Co., completed up to 2000 pieces per shift without compromising quality standards or efficiency metrics.

Amicable assembly line worker with 3+ years of experience in a fast-paced manufacturing environment. Skilled at operating heavy machinery, adhering to safety protocols, and producing quality products quickly and efficiently. Seeking to join ABC Manufacturing’s team as an assembly line worker to help increase production speed while maintaining a safe work environment.

Enthusiastic and reliable assembly line worker with over 4 years of experience in fast-paced production environments. Proven track record of meeting quotas and deadlines while strictly adhering to safety protocols. Looking to join ABC Manufacturing as an Assembly Line Worker, leveraging strong work ethic and attention to detail to ensure quality product output.

Skilled assembly line worker with 5+ years of experience operating and maintaining production machinery. Experienced in sorting, scanning, packaging, and labeling products while meeting safety regulations. Seeking to join ABC Manufacturing where I can apply my knowledge in a fast-paced environment to ensure timely delivery of high quality goods.

2. Experience / Employment

In the experience/employment/work history section, you should list your previous jobs in reverse chronological order, with the most recent job listed first.

When writing about what you did at each position, stick to bullet points for ease of reading. You want to provide details on what tasks and duties were assigned to you as well as any quantifiable results that may have been achieved due to your work.

For example, instead of saying “Worked on an assembly line,” you could say, “Assembled 200+ pieces per hour while adhering to strict quality control standards.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Operated

- Monitored

- Inspected

- Adjusted

- Troubleshot

- Calibrated

- Tested

- Packaged

- Loaded

- Unloaded

- Measured

- Drilled

- Welded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reorganized the entire assembly line process, resulting in a 20% increase in productivity and 30% reduction of labor costs.

- Streamlined the production cycle to ensure that each unit was assembled with precision within 2 minutes – achieving an average output rate of 300 units/hour for 8-hour shifts.

- Assembled over 1,000 parts per day using hand tools and power drills; consistently met daily quotas without compromising on quality standards or safety protocols.

- Demonstrated excellent time management skills by completing project tasks ahead of schedule while adhering to all safety guidelines at all times during operation hours.

- Effectively troubleshooted any issues arising from machine malfunctions or incorrect fitting of components, minimizing downtime by 75%.

- Assessed the production line for any assembly issues, identified and promptly resolved them to maintain a smooth workflow; improved overall productivity by 10% within 4 weeks.

- Expedited the processing of components along the assembly line in order to meet tight deadlines with an accuracy rate of 98%.

- Spearheaded quality control initiatives to ensure that all products met safety standards before being shipped out; reduced defective items by 25% over 3 months.

- Substantially increased work efficiency through process improvement strategies such as reorganizing parts stocking areas and introducing new tools on the production floor, resulting in labour cost savings of $1,500 per month.

- Formulated daily worker schedules according to customer orders while ensuring proper rest periods were allocated for each shift; effectively managed team operations without sacrificing product quality or delivery timescales (+20%).

- Operated assembly line equipment and machinery with precision, consistently meeting production targets of 800+ units per shift.

- Utilized specialized tools to complete assembly tasks accurately; increased efficiency by 20% through process improvements over the course of 2 years.

- Packaged finished items in accordance with safety and quality standards; reduced product defects rate from 5% to 1%.

- Compiled detailed reports on daily output metrics and submitted them to supervisors for review; saved 10 hours a week in manual data entry time due to automation efforts implemented within team processes.

- Thoroughly inspected products before packing, ensuring that they met all customer specifications while reducing scrap rates by 15%.

- Inspected and tested completed assembly line products for quality assurance and accuracy, leading to a 0.2% defect rate reduction in the last quarter.

- Welded parts together using various tools such as blowtorches, arc welders and soldering irons; successfully completed 250+ pieces of machinery every week with 100% accuracy.

- Proficiently assembled large-scale industrial machines from individual components per technical drawings over a period of 10 hours on average each day, resulting in $4,000 cost savings during the fiscal year end report review process.

- Advised co-workers on proper safety protocols while operating heavy equipment and hand tools throughout their shifts; reduced workplace injuries by 25%.

- Tested all electrical systems within machinery after completion to ensure adherence to industry regulations; identified problems before they could cause damage or harm customers’ investments which saved an estimated $10K annually.

- Introduced 12 new assembly line procedures to improve productivity and quality, resulting in a 10% decrease in production time per item.

- Reliably operated various manual and automated machinery for 8 hours per day on the assembly line; increased output by 25%.

- Unloaded incoming raw materials from trucks within specified deadlines; ensured that all products were accounted for before entering storage areas.

- Reduced scrap rate by 20% through careful inspection of parts during the manufacturing process, ensuring consistency across all items produced.

- Presented monthly reports to supervisors outlining any potential issues or risks with operations, as well as suggesting ways to further enhance efficiency on the assembly line.

- Drilled, bolted and assembled components of various products on the assembly line with precision, increasing production output by 20% in a 4-month period.

- Developed detailed work instructions for new assembly processes to ensure accuracy & safety; trained 10+ employees on proper procedure execution for increased efficiency.

- Calibrated automated machines using advanced tools & techniques, reducing downtime from 30 minutes to 15 minutes per machine cycle.

- Efficiently managed inventory levels at all times; identified defective parts quickly and replaced them without disrupting workflow or impacting productivity targets set by the company management team.

- Improved quality assurance standards through careful inspection of finished items before packaging – resulting in 0 customer complaints over 2 years due to product defects.

- Structured and maintained an efficient assembly line system resulting in a 5% increase of production rate within 2 months.

- Revised work instructions and procedures to streamline operations and reduce defects by 12%.

- Competently operated various machines, tools & equipment for assembling products according to the quality standards; consistently met or exceeded daily quotas with minimal supervision required.

- Represented the company at trade shows, demonstrating product features and providing technical support as needed; gained 20+ new customers from these engagements over 6 months period.

- Adjusted settings on machinery based on customer specifications while ensuring safety protocols were strictly followed; decreased downtime due to machine malfunctions by 45 hours per month on average.

- Measured and cut parts to size, ensuring that all components met manufacturing standards; increased accuracy by 16% when assembling over 200 products daily.

- Facilitated a smooth workflow on the assembly line, coordinating with other workers to optimize production time and reduce machine downtime per shift by 25 minutes on average.

- Accurately followed blueprints and product specifications while operating pneumatic tools such as drills & saws for constructing complex assemblies in compliance with safety protocols.

- Troubleshot issues related to defective or malfunctioning parts; identified potential problems ahead of time resulting in fewer defects and an overall reduction of scrap rate by 11%.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in operating a forklift, while the other may be looking for someone who is adept at using hand tools.

Therefore, you should tailor your skills section to each job that you are applying for. This will help ensure that any applicant tracking systems used by employers can pick up on the relevant keywords and pass your resume along to human recruiters.

In addition to listing them here, it would also be beneficial if you could discuss these abilities further in other parts of your resume – such as the summary or work history sections.

Below is a list of common skills & terms:

- Automotive

- Communication

- Continuous Improvement

- Customer Satisfaction

- Data Entry

- Manufacturing

- Team Leadership

- Teamwork

- Time Management

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, mention the relevant courses and subjects below your resume objective. However, if you have been working as an assembly line worker for years with plenty of responsibilities to showcase, omitting the education section is perfectly fine.

If including an education section is necessary, try to highlight any classes or topics related to the job duties of a typical assembly line worker.

High School Diploma

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise and proficiency in a particular field. They are also an indication that you have taken the time to stay up-to-date with industry trends, as well as having invested in yourself by taking professional development courses.

If you possess any certifications related to the job position for which you are applying, make sure they are included on your resume. This will show potential employers that you have gone above and beyond what is expected of applicants and can be trusted with more responsibility than those without such qualifications.

Certified Production Technician

Manufacturing Skill Standards Council

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Roman Schoen, this would be Roman-Schoen-resume.pdf or Roman-Schoen-resume.docx.

7. Cover Letter

Including a cover letter with your job application is an effective way to make yourself stand out from the competition. It should be composed of 2 to 4 paragraphs and provide additional detail about who you are, why you’re applying for the job and what makes you a strong candidate.

Cover letters can help employers get a better understanding of your skillset and experience as well as give them insight into your personality. Although not all jobs require one, writing a cover letter will show that you have gone the extra mile in expressing interest in the role.

Below is an example cover letter:

Dear Stacey,

I am interested in applying for the assembly line worker position at your company. With more than five years of experience working on an assembly line, I have the skills and knowledge to be a valuable asset to your team.

In my previous job, I was responsible for assembling small parts onto a larger product. I had to pay close attention to detail and follow instructions carefully in order to ensure that the final product met quality standards. My speed and accuracy increased over time, and I was eventually able to assemble up to 500 products per hour without sacrificing quality.

I also have experience training new employees on how to properly use assembly line equipment and follow safety procedures. In this role, I was able to pass on my knowledge and help new hires become productive members of the team quickly.

I am confident that I can be a great asset to your company as an assembly line worker. My attention to detail, abilityto work quickly and accurately, and experience training new employees will contribute significantlyto your bottom line. Please find attached a copy of my resume for your review; you can reach me anytime via phone or email if you would like additional information or would liketo schedule an interview at your earliest convenience.

Sincerely,

Roman

Assembly Line Worker Resume Templates

Lorikeet

Lorikeet Indri

Indri Numbat

Numbat Pika

Pika Ocelot

Ocelot Saola

Saola Fossa

Fossa Axolotl

Axolotl Gharial

Gharial Dugong

Dugong Jerboa

Jerboa Echidna

Echidna Bonobo

Bonobo Rhea

Rhea Hoopoe

Hoopoe Cormorant

Cormorant Kinkajou

Kinkajou Markhor

Markhor Quokka

Quokka Rezjumei

Rezjumei